- Home

- >

News

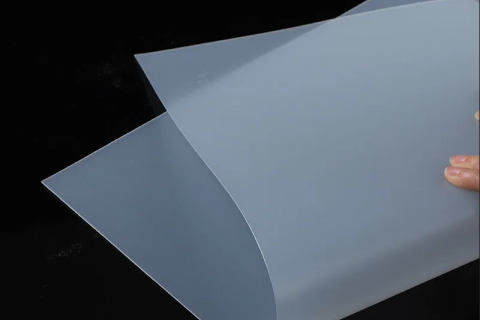

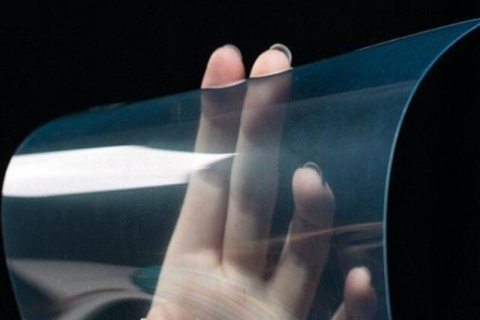

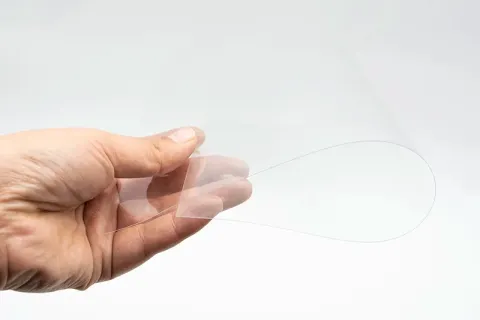

Polycarbonate Sheets Revolutionize Light Diffusion: A Breakthrough in Modern Lighting Solutions Date: August 12, 2024 Location: Shenzhen, China Key Figures: Dr. Li Wei, Senior Researcher at Shenzhen Lighting Technologies; Zhao Ling, Chief Product Officer at BrightLight Innovations Shenzhen, China - In a groundbreaking development for the lighting industry, polycarbonate (PC) sheets have emerged as the leading material for light diffusion applications, thanks to their superior performance and versatility. This breakthrough was announced today at the Shenzhen International Lighting Expo, where Dr. Li Wei, a senior researcher at Shenzhen Lighting Technologies, and Zhao Ling, the Chief Product Officer at BrightLight Innovations, presented the latest research and product developments utilizing PC sheets. The Problem: Seeking the Perfect Light Diffuser The need for efficient and aesthetically pleasing lighting has been a persistent challenge across various industries, from commercial and residential lighting to automotive and architectural applications. Traditional materials used for light diffusion, such as acrylic or glass, have often fallen short in terms of durability, weight, and optical performance. These limitations have driven researchers and manufacturers to explore alternative materials that can deliver consistent, high-quality light diffusion while meeting the rigorous demands of modern applications. The Breakthrough: Why Polycarbonate Sheets? Polycarbonate sheets have long been known for their impact resistance, clarity, and lightweight properties. However, their application as light diffusers has only recently been fully realized, thanks to advancements in material science and processing techniques. During the expo, Dr. Li Wei explained how PC sheets are engineered to achieve optimal light diffusion while maintaining high transparency and strength. "Polycarbonate sheets offer a unique combination of properties that make them ideal for light diffusion," said Dr. Li. "Their inherent ability to scatter light evenly without significant loss of brightness sets them apart from other materials. Additionally, the durability of PC ensures that the diffusers remain effective over time, even in harsh environments." The Process: Development and Testing The journey to this breakthrough began two years ago when Shenzhen Lighting Technologies partnered with BrightLight Innovations to develop a new generation of light diffusers for various lighting applications. The team, led by Dr. Li and Zhao Ling, conducted extensive research and testing to refine the material properties of PC sheets. Through a series of laboratory tests and field trials, the team discovered that PC sheets could be engineered to diffuse light evenly while maintaining a high level of transparency. This was achieved by carefully controlling the thickness and surface texture of the sheets, allowing them to scatter light effectively across a wide area. "We focused on optimizing the material to meet the specific needs of our clients," Zhao Ling explained. "Whether it's for automotive headlights, architectural lighting, or LED panel lights, our PC-based diffusers provide unmatched performance in terms of light quality and durability." The Result: A New Standard in Lighting The introduction of PC sheets as light diffusers has already begun to transform the industry. Several major lighting manufacturers have adopted this technology, citing improved light quality, reduced glare, and increased energy efficiency as key benefits. In addition, the lightweight nature of PC sheets has made them easier to handle and install, further enhancing their appeal in large-scale projects. At the expo, attendees had the opportunity to see the results firsthand, with several demonstrations showcasing the effectiveness of PC sheets in various lighting applications. The response from industry professionals has been overwhelmingly positive, with many expressing interest in integrating PC-based diffusers into their product lines. The Future: Expanding Applications Looking ahead, both Shenzhen Lighting Technologies and BrightLight Innovations plan to continue their collaboration to explore new applications for PC sheets in light diffusion. The companies are already working on the next generation of products that will push the boundaries of what's possible in lighting design. "We believe that this is just the beginning," said Zhao Ling. "The versatility of polycarbonate sheets opens up endless possibilities for innovation in lighting. We're excited to see where this technology will take us next." Conclusion The successful application of polycarbonate sheets in light diffusion represents a significant advancement in the field of lighting. By offering a superior alternative to traditional materials, PC sheets are poised to become the new standard in creating high-quality, durable, and energy-efficient lighting solutions. As this technology continues to evolve, it promises to bring even more innovation to the industry, benefiting both manufacturers and consumers alike.

Innovative Use of Polycarbonate Sheets Transforms Sunrooms in Shanghai Shanghai, China – July 29, 2024 – The latest wave in home renovation has just hit the cosmopolitan city of Shanghai, as more and more people are using polycarbonate (PC) sheets to renovate their sunrooms. Invented to revolutionize the way sunrooms and other house extensions are designed and built, this innovative material gives the best combination of aesthetics, durability, and energy efficiency. Pioneering Project in Xuhui District Recently, another outstanding example of this tendency is the renovation of a sunroom with polycarbonate sheets that Ms. Li Wei from Xuhui District has just completed. The project began in early May and was completed in mid-July, revealing to people the magic of PC sheets in renovating a house. Key Participants and Their Roles Renovation work was led by well-known Shanghai architect Mr. Zhang Jian, who mainly works with sustainable and innovative building materials. Mr. Zhang worked on the design of the sunroom together with Ms. Li, trying to increase both the aesthetic value of her house and natural lighting for improved energy efficiency. Outstanding Results It has newly renovated sunrooms with transparent, high-quality polycarbonate sheets that allow a lot of sunlight into the space while filtering dangerous UV rays to ensure the interior is bright and airy, making it perfect for relaxation and leisure. The PC sheets have improved the thermal insulation drastically, enhancing the sunroom's energy efficiency and thus able to maintain comfortable temperatures throughout the year with very minimal heating or cooling systems. Ms. Li expressed satisfaction with the results and said, "The polycarbonate sheets have renovated my sunroom into a beautiful and practical place. I was impressed by how fast and efficient the renovation was. The room has become the most favorite part of the house; it is full of natural light and very comfortable during summers and winters. Broadening Horizons He added that the application of polycarbonate sheets in renovation projects meant much more than them simply being used. "Indeed, polycarbonate sheets are versatile and solid. Lightweight, easy to install, and well-insulated, they turn out to be the perfect material for any other kinds of works related to sunrooms, greenhouses, patio covers, and interior partitions." Community Impact and Future Prospects The result of the sunroom renovation project for Ms. Li has piqued the interest of all her neighbors and the greater community. Now, more than a few homeowners in the Xuhui District are considering doing similar projects after getting inspired by the beauty and functionality showcased in Ms. Li's home. In the future, Mr. Zhang will continue to promote the use of polycarbonate sheets in building renovations. He actually has been negotiating with several clients regarding the use of PC sheets in their upcoming projects. "I firmly believe that this material will have been installed in most of the buildings in the near future where green construction methods will be implemented," he said. "Its advantages are obvious, and I look forward to more house owners taking advantage of this new solution." Conclusion The use of polycarbonate sheets in sunroom renovations is raising a new bar of excellence in home improvements within Shanghai. With pioneers like Ms. Li and visionary architects such as Mr. Zhang at the helm of this emerging trend, it is only bound to pick up in pace, bringing about a modern, efficient, and visually effective successor to traditional building materials for homeowners.

Building a Sunroom with Polycarbonate Panels: How I Did It. She had always wanted a sunroom where she could make her days basking in the sun with all her favorite plants around her and a corner to snuggle into with a favorite novel. And so, months into the planning, she finally summoned the nerve to take the bold step of carrying out the sunroom project in the backyard. Her friend, an architect, advised her to go for polycarbonate panels since they were offering a lot of advantages for the project work: durability, transparency, and insulation. Eager, Jane started studying the polycarbonate properties until she came up with a material that proved just perfect for her sunroom. The panels were lightweight but incredibly strong to be able to bear the rough weather conditions in her area. Additionally, their resistance to UV would mean her plants thrive without the harmful effects of direct sun and that she doesn't worry about discoloration or damage to the panels over time. First, Jane designed a sunroom layout allowing enough space for plants and a comfortable sitting area. She then hired a contractor and worked on the plan together. Soon enough, after laying the foundation, the frame of the sunroom started taking shape. When the polycarbonate panels had to be fitted in, Jane could hardly believe how easily they could be handled. The contractor cut them to size accurately, and they fitted into the aluminum frame perfectly. As the panels were nailed into place, Jane could already envision the scene: basking in the sun with lush greenery all around. When the construction was all over, she furnished the sunroom with an armchair, a small table, and some pot flowers. The transparent polycarbonate panels permitted inflows of natural light, making it bright and full of attraction. The sunroom had become her favorite place in the house—it was a quiet place to read, rest, and be close to nature regardless of the weather outside. She noticed that the sunroom remained warm during the winter and cool during the summer, thanks to the insulation provided by the polycarbonate panels. Besides, she was greatly surprised at how easily they could be cleaned: just a simple rinse with water and they would look clean and clear. Her friends and family were impressed with the sunroom and visited frequently to see it and enjoy a cup of tea with Jane. Her friends were soon inspired with her successful project, getting down to planning their own sunrooms to enjoy some of the many benefits from the polycarbonate panels. In the end, this was a sunroom of a dream for Jane, and she had always cherished it as part of her home. In fact, using polycarbonate panels was a bright idea in that it provided a fine, strong, and energy-efficient solution to her, which would serve for years to come.

Uses: Side-entry LED and fluorescent lamps, panel lights, as the light source for advertising light boxes, notice boards, outdoor billboards, stage effects, LED electronic display, natural lighting ceiling lights.