- Home

- >

News

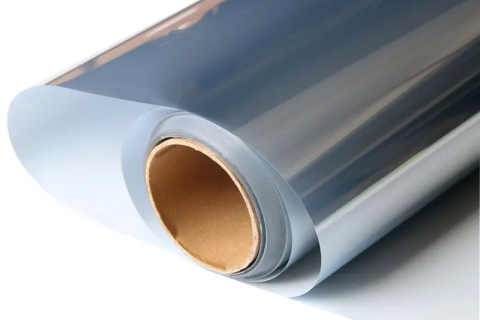

An application of the BPET conductive material boosts the electronics industry. August 2024, Shanghai, Global Electronics Manufacturing Exhibition; Zhang Qiang: technical director of a leading electronics materials R&D company. In August 2024, at the Global Electronics Manufacturing Exhibition held in Shanghai, a new type of conductive material took center stage. The Technical Director, Zhang Qiang, of one of the key Electronics Materials R&D enterprises, has brought along with him a team to introduce very latest BPET (Biaxially Oriented Polyethylene Terephthalate) conductive material. This launch marks the large step forward applying static protection and conductive materials within the electronics industry. Background: Help Needed to Meet Increased Demand for Static Protection With their ever-growing sophistication and complication, electronic products are also requiring more dependable static protection and conductive materials. Having noticed this emerging market demand, Zhang Qiang and his group embarked on a multi-year development program in search of creating a high-performance material to satisfy the demand. "We all noticed that all kinds of conductive materials available in the market had a number of problems, such as low transparency and unstable conductivity, which limited their usage in high-end electronic devices," Zhang Qiang explained during the launch. "It is this that moved us to develop a material that links high transparency, brightness, and stable conductive performance to serve the industry much better." Process: Overcoming Technical Challenges and Enhancing Performance The BPET material is produced with the help of imported production lines to ensure high transparency, brightness, and crystal-free surfaces with excellent flatness. Food grade slip agents were added by the team into the material to give it excellent surface smoothness, good processability, and well-preserved conductive properties. BPET sheets come in various specifications, thereby allowing for high production capacity at superior quality and cost-effectiveness. This is an environment-friendly and non-toxic material that meets QS food safety certification and passes the European Union's SGS environmental certification, hence suitable for industries with strict compliance criteria to safety and the environment. The following are several conductive grades for the materials: - Permanent Conductive Sheet: $10^10$ ohms - Permanent Antistatic Sheet: 10^10 ohms - Permanent Semi-Conductive Sheet: 10^6-10^9 ohms These variations show steady and smooth conductive performance, which ensures the stability and reliability of products for various applications. Besides, BPET can be processed into flat sheets, slit, and laminated; while PET-G and GAG grades are especially suitable for producing high-end electronic products. Result: Good Market Response and Wide Industrial Application In the exhibition, BPET conductive material was very fast.