- Home

- >

News

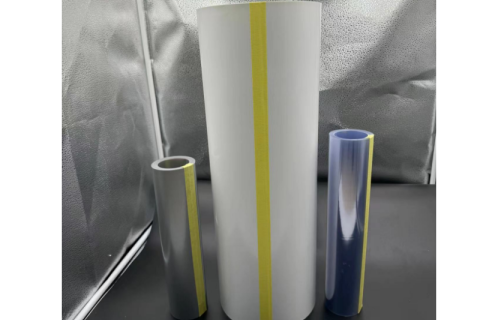

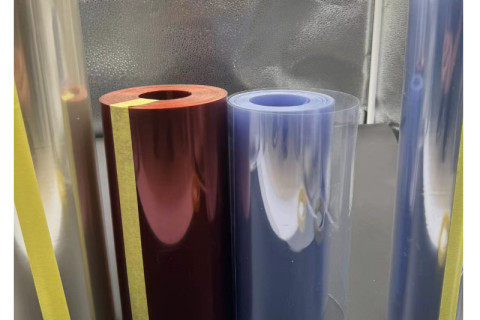

ITEM:TL-PVC-0047 Thickness:0.008-2MM Width:100-1350MM color:white blue red orange black customization Roll core:3-7” feature:Water proof Usage:Color sheet, deco film,cover film capability:5000TON/MONTH Sample:Free less than 10KG

In the world of materials and printing, PVC printable film stands out as a versatile and remarkable product with a wide range of applications. From advertising and signage to personal projects and creative endeavors, this material has proven to be an invaluable asset.

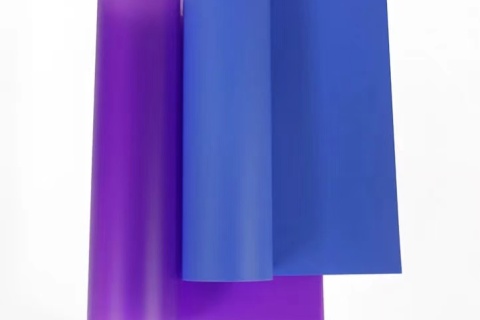

In today's world of design and decoration, colored PVC film has emerged as a highly versatile and innovative material that is transforming the way we think about aesthetics and functionality. From creating stunning colored walls in interior design to enhancing the beauty of lampshades and serving as an essential tool for color selection in the form of color cards, colored PVC film is making its mark in various fields.

Secondly, white PVC film provides a good barrier against moisture, oxygen, and other contaminants. This helps to extend the shelf life of food products by preventing spoilage and degradation. It keeps the food fresh and flavorful for a longer period, reducing food waste and ensuring consumer satisfaction.

In the medical field, red PVC film also has its applications. It can be used for packaging medical supplies and devices. The material is sterile and can be easily sterilized again if needed. The red color can be used to indicate special instructions or warnings, making it easier for healthcare professionals to identify and handle the packages.

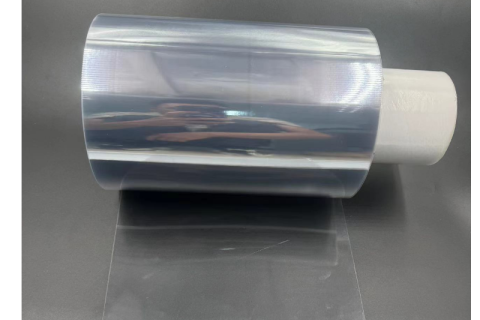

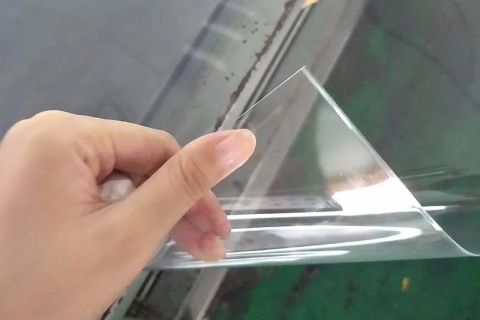

《The Versatility of PVC matte Frosted Film: A Success Story》 In the bustling city of [City Name], there lives a young entrepreneur named Lily. Lily is a visionary and innovative businesswoman who is always on the lookout for new and useful materials that can transform different industries. One day, while attending a trade fair in early 2024, Lily stumbled upon a display of PVC matte frosted film. Intrigued by its unique texture and potential applications, she decided to learn more about this remarkable material. The PVC matte frosted film immediately caught Lily's attention due to its aesthetic appeal and practical features. The frosted surface gave it a soft and elegant look, while the PVC material offered durability and flexibility. As Lily explored further, she discovered that this film had a wide range of uses across various fields. In the packaging industry, PVC matte frosted film proved to be a game-changer. It was ideal for different types of packaging, including (pharmaceutical packaging) and (packaging for spare parts). For pharmaceutical packaging, the film provided a barrier against moisture, light, and contaminants, ensuring the safety and integrity of the medications. The frosted finish also gave the packaging a professional and sophisticated look, enhancing the brand image of the pharmaceutical companies. In the case of spare parts packaging, the film protected the delicate components from scratches and damage during transportation and storage. Its flexibility allowed it to conform to the shape of the parts, providing a snug fit and reducing the risk of movement. Lily also saw great potential for PVC matte frosted film in the field of decoration. Whether it was for glass (glass decoration) or interior design, the film added a touch of elegance and style. For glass decoration, the frosted film created a privacy screen while still allowing light to pass through. It could be used on windows, shower enclosures, and partitions, giving a modern and sleek look to any space. In interior design, the film could be applied to walls, furniture, and accessories, creating unique and personalized designs. Its adhesive backing made it easy to install, and it could be removed without leaving any residue, making it a great option for temporary or rental spaces. Another important feature of PVC matte frosted film is its (thermal insulation) properties. Lily realized that this film could help reduce energy consumption by insulating buildings and vehicles. By applying the film to windows and doors, it could prevent heat transfer, keeping interiors cool in summer and warm in winter. This not only saved on energy costs but also improved the comfort of living and working spaces. In addition to its thermal insulation properties, the PVC matte frosted film also had阻燃 (flame retardant) qualities. This made it a safe choice for various applications, especially in areas where fire safety was a concern. For example, it could be used in hospitals, schools, and public buildings to reduce the risk of fire spread. The film met strict fire safety standards, providing peace of mind to building owners and occupants. Lily was also impressed by the (hygienic packaging) applications of PVC matte frosted film. In the healthcare industry, this film could be used to package medical supplies and equipment, ensuring sterility and hygiene. The frosted finish made it easy to identify the contents of the package, while the PVC material provided a barrier against bacteria and other contaminants. In the food industry, the film could be used for packaging perishable items, keeping them fresh and safe for consumption. Excited by the endless possibilities of PVC matte frosted film, Lily decided to incorporate this material into her own business. She started by using it for packaging her company's products, which immediately received positive feedback from customers. The elegant and professional look of the packaging enhanced the brand image and increased sales. Lily then expanded its use to decoration projects, collaborating with interior designers and architects to create stunning spaces. The thermal insulation and flame retardant properties of the film also appealed to clients who were looking for sustainable and safe solutions. As word spread about Lily's success with PVC matte frosted film, other businesses in the city began to take notice. They started to explore the potential of this material for their own applications, leading to a surge in demand. Lily saw an opportunity to grow her business further and decided to become a distributor of PVC matte frosted film. She established partnerships with manufacturers and suppliers, ensuring a steady supply of high-quality film. She also provided training and support to her customers, helping them understand the benefits and applications of the material. Today, PVC matte frosted film has become a popular choice in [City Name] and beyond. Its versatility and practical features have made it a valuable asset in various industries. Lily's entrepreneurial spirit and vision have played a crucial role in introducing this material to the market and driving its adoption. Thanks to her efforts, businesses and consumers alike are now reaping the benefits of this remarkable film. The story of Lily and PVC matte frosted film is a testament to the power of innovation and perseverance. By being open to new ideas and taking risks, Lily was able to discover a material that has transformed the way we package, decorate, insulate, and protect our products and spaces. As the demand for sustainable and functional materials continues to grow, PVC matte frosted film is sure to play an even more important role in the future.

Anti-Static, Thermoformable PVC Film—Emerging Use One fine morning of [date] in the hustling city of [city name], a young entrepreneur, Lily Zhang, demonstrated the amazing versatility of the anti-static, thermoformable PVC film. Since she was a child, Lily was always interested in finding creative solutions for packaging and decoration problems. The first interest in PVC film came when she realized the growing needs for materials that combine functionality and aesthetics. Only the good and careful investigation of this topic, along with the examination, have greatly nurtured this interest, leading to the exploration of the peculiar features of anti-static thermoformable PVC film. At the beginning of this story, Lily visited a local packaging factory. Sensitive electronic parts, being packaged at this factory, would be destroyed by the static electricity. Their acquaintance was made with anti-static PVC film. The ability of the film to dissipate static charge caught immediate attention with the managers of this factory, which decided to give it a try. The PVC film was put on at the packaging stage, and Lily did it with the help of the factory team. The result was that the problem of static electricity disappeared, and the products packed could not be damaged in any way. Improved packaging gave a nicer look to the products, which was more catching for the customers. Not content with this single success, Lily applied her mind to the food packaging industry. She knew the importance of safety and presentation of food. With an anti-static PVC film, she was in a position to offer a solution that would protect the food from static charge, besides offering a clear and hygienic method of packaging. She toured some food processing factories and could demonstrate to them the feasibility of the PVC film. The plant managers could not believe how durable the product was, and how clean it was to use. They bought into the product and were now using the film to package fresh fruits, fresh vegetables, and even processed snack foods. The food can now be transported and stored without going bad and contaminated by any foreign matter. Next was pharmaceutical packaging. The requirements were much tougher: sterile packaging that protected the drugs from moisture and static electricity, yet conformed very strictly with the rules. Lily's anti-static PVC film proved up to the task. She worked in cooperation with pharmaceutical companies for the development of special packaging solutions. Examples of packaging made from this film are pills, tablets, and liquid preparations. Because this material is thermoformable, the form and size of packaging are easily managed to precisely fit a product. Anti-static properties protect medication from static damage, while clarity of the film allows for the possibility of seeing through for quality control. In interior decoration, Lily has found a completely new domain of application for the PVC film. She conceived using it in making those really unique and eye-catching designs in the apartment. She went and started co-operating at first with interior designers, then architects. Together, they were creating such a thing as wall coverings, so-that ceiling paneling, some decorations. Consequently, the PVC film could be let loose with abandon. It could be embossed printed, several patterns and colors could be offered or mixed, thus providing the designer with an ample latitude in working on interiors that are very personalized and chic. It was also easy to install and maintain and for these reasons preferred, not only by households but business establishments as well. Yet, in the field of glass decoration, Lily's PVC film shone once again. She has also created the special adhesive-backed PVC film, which can be directly applied to the surface of glasses to add not only a decorative touch but also privacy and UV protection. The journey of Lily with the anti-static, thermoformable PVC film was not that smooth. She was rejected by convinced clients who would not easily convert to another material. But through her persistence and hard work, she was able to overcome these obstacles and prove the value of the PVC film. With the success of Lily getting announced everywhere, anti-static thermoformable PVC film began to contact more and more industries. For example, automotive interior and aerospace components, the application of it was burgeoning. Actually, Lily's innovation had really made a miracle in many fields. Today, Lily is regarded as one of the authorities in packaging as well as decoration material. And her case is used to inspire others who, in drastic means, seek solutions to their everyday troubles. Because of Lily's vision and insistence, antistatic thermoformable PVC film is now indispensable in many industries. This thermoformable film has found application within the fields of packaging, food packaging, pharmaceutical packaging, decoration, and glass decoration because of its anti-static property. Unique qualities and infinite creativity opened up new paths of innovation and invention. Behind this successful innovation stands Lily Zhang, a young entrepreneur who dared to dream and make a difference.

"The Versatile World of Colored PVC Film: Transforming Industries and Spaces" In today's fast-paced and ever-evolving world, innovative materials are constantly emerging to meet the diverse needs of various industries. One such material that has been making waves is colored PVC film. With its wide range of applications and remarkable properties, it has become a game-changer in the fields of packaging, pharmaceutical packaging, food packaging, decoration, and glass decoration. Time: Over the past few years. Location: Worldwide. Characters: Manufacturers, designers, consumers, and industry experts. I. Introduction Colored PVC film, with its vibrant hues and durability, has captured the attention of businesses and individuals alike. This versatile material offers a plethora of benefits, from enhancing product visibility to adding a touch of elegance to interiors. Let's explore how it has been making an impact in different sectors. II. Packaging Industry In the packaging industry, the quest for materials that are both functional and visually appealing is ongoing. Colored PVC film emerged as a promising solution due to its ability to protect products while also attracting consumers' attention. Manufacturers began incorporating colored PVC film into their packaging designs. For consumer goods packaging, the film was used to create eye-catching boxes, pouches, and wraps. In the food packaging sector, it was utilized to package snacks, candies, and other perishable items. The film's moisture-resistant and durable properties ensured that the food remained fresh and protected. In pharmaceutical packaging, colored PVC film was employed to distinguish different types of medications and provide a tamper-evident seal. The clear and colorful film allowed for easy identification of the product, while also ensuring its safety. The use of colored PVC film in packaging had several positive outcomes. Firstly, it increased product visibility on store shelves, leading to higher sales. Consumers were drawn to the attractive packaging, which made the products stand out from the competition. Secondly, the film's durability provided excellent protection to the packaged items, reducing the risk of damage during transportation and storage. Additionally, in pharmaceutical packaging, the tamper-evident feature gave consumers confidence in the safety and authenticity of the medications. III. Decoration As people's aesthetic preferences continue to evolve, there is a growing demand for unique and creative decoration solutions. Colored PVC film offered a new way to add color and texture to interiors and exteriors. Interior designers and architects started using colored PVC film to transform spaces. In homes, it was used to create feature walls, backsplashes, and furniture accents. The film's easy application and removal made it a popular choice for those looking to update their living spaces without a major renovation. In commercial spaces such as offices, restaurants, and retail stores, colored PVC film was used to create branded environments and enhance the overall atmosphere. The film could be printed with logos, patterns, and designs, adding a personalized touch to the space. The use of colored PVC film in decoration had a significant impact. It allowed for quick and cost-effective transformations, enabling businesses and homeowners to achieve their desired look. The film's variety of colors and finishes provided endless design possibilities, allowing for unique and personalized creations. Moreover, its durability ensured that the decorations would last for a long time, even in high-traffic areas. IV. Glass Decoration Glass is a popular material for both functional and decorative purposes. However, it can sometimes lack privacy or require an added touch of elegance. Colored PVC film offered a solution to these challenges. Colored PVC film was applied to glass windows, doors, and partitions to add privacy, reduce glare, and enhance the aesthetic appeal. The film could be frosted, tinted, or printed with designs, providing a variety of options to meet different needs. In residential settings, colored PVC film was used to create privacy in bathrooms, bedrooms, and home offices. In commercial spaces, it was used to divide office areas, create conference room partitions, and add branding to storefronts. The application of colored PVC film to glass had several benefits. It provided privacy without sacrificing natural light, creating a comfortable and inviting environment. The film also reduced glare, making it easier to view screens and work in bright areas. Additionally, the decorative options offered by the film added a touch of style and sophistication to the space. V. Conclusion Colored PVC film has truly revolutionized various industries with its versatility and functionality. From packaging to decoration and glass decoration, it has proven to be a valuable material that meets the diverse needs of today's consumers and businesses. As technology continues to advance, we can expect to see even more innovative applications of colored PVC film in the future. Whether it's enhancing product visibility, creating unique interiors, or adding privacy to glass, this remarkable material is sure to continue making an impact.

PVC Film for Blister Packaging: A New Manufacturing Facility to Be Launched in 2023 August 20, 2023 — Houston, Texas: This was the day—the day the packaging industry awaited with bated breath. GlobalPack Industries, one of the largest manufacturers of packaging materials, opened a brand new state-of-the-art facility in Houston, Texas, for the manufacture of PVC film especially intended for use in blister packaging. Among those present at the launch were key figures from the industry, local government authorities, and company bosses. This marked a significant step in production capacity expansion for GlobalPack. Key People Present The event was spearheaded by GlobalPack CEO, Emily Carter, who was flanked by Texas Governor, Jake Martinez, and Houston Mayor, Maria Hernandez. The representatives were from the pharmaceutical, electronics, and consumer goods industries, signaling that this new facility would indeed affect a wide array of sectors. Reasons for Expanding This increase in production was based on a steep rise in demand for PVC film in blister packaging. The COVID-19 pandemic brought higher demands on safe and tamper-evident packaging, notably from the pharmaceutical industry. Substantially relying on the blister packs in medication protection and dispensing, their demands surged. Moreover, consumer electronics adds to pressures on existing capacities with protective packaging. According to Emily Carter, "Our customers need trustworthy, high-quality PVC film for their packaging solutions. This new facility is the direct response to those needs, ensuring that we can answer the growing demand without ever compromising our commitment to sustainability and innovation." The Manufacturing Process The facility in Houston represents a cutting-edge plant capable of producing PVC film of high quality to meet the stringent requirements for blister packaging. It starts polymerizing vinyl chloride monomers into PVC resin and then extrudes and biaxially orients the film. State-of-the-art machines equipped in this facility are able to produce film with well-controlled thickness and surface properties to meet all customer-specific needs. The facility is also designed with sustainability in mind. Energy-efficient processes and recycling of industrial waste are integrated in the facility in order to minimize its impact on the environment. "We invested in technology that would make a better product but would also lower our carbon footprint," said Carter during the launch. Results of the Expansion A new facility in Houston will increase GlobalPack's PVC film production capacity by 40%. This means significantly reduced lead times to any customer located anywhere in North America. This will also mean the creation of more than 200 new jobs within the Houston area, providing a boost to the local economy. This first batch of PVC film from the new facility is due to be shipped to major pharmaceutical and electronics manufacturers by the end of September 2023. Initial tests indicate that the film is well within industry standards in terms of clarity, durability, and resistance to chemicals, and can thus be used in a large variety of blister packaging applications. Industry Effects The opening of GlobalPack's new facility is likely to create a chain reaction within the packaging industry. With more volumes of high-quality PVC film made available, it raises the performance and reliability standards for blister packaging—thereby motivating further innovation in this direction for packaging design, particularly for where safety and tamper evidence come first. The facility will most likely set a new standard within the industry toward sustainability and push other manufacturers to be greener. "This is more than just an expansion; it's a commitment to the future of packaging," said Carter. Conclusion GlobalPack once again leads the way in the packaging industry with the launch of a new PVC film production facility in Houston. With increased capacity in production, attention to sustainability, and the creation of new jobs, it is sure to meet the growing demands of various industries for high-quality blister packaging solutions. As the first shipments come out over the coming weeks, the ripples of this growth will be felt throughout the supply chain, further entrenching GlobalPack's position as a leader in the packaging industry.

Revolutionizing Folded Box and Pharmaceutical Thermoforming Packaging—PVC Sheets Date: August 13, 2023 Location: Shanghai, China Key Players: Leading packing manufacturers, pharmaceutical companies, environmental advocates Event Summary: In what could emerge as the most radical paradigm shift in packaging, Shanghai's top manufacturers yesterday announced increased application of polyvinyl chloride sheets for folded box and pharmaceutical thermoforming packaging. This will change the world in terms of product protection, cost efficiency, and manufacturing versatility. Background: Durability, flexibility, and cost represent some of the most preferred characteristics of PVC, and it has thereby found a place in most industries. However, recent developments in manufacturing PVC sheets raise renewed interest in using the material for special applications in pharmaceutical packaging and other consumer products. Cause and Course of Events: The trend of using PVC sheets in folded box and pharmaceutical packaging started this year when a number of packaging specialists, associated with different pharmaceutical companies, launched an all-inclusive study regarding the effectiveness of the material. Their conclusions, published in June 2024, pointed to some main advantages of PVC sheets, first of all related to their better defense against moisture, oxygen, and light—parameters that play a very important role in the preservation of pharmaceutical products. After the research, some leading packaging companies in Shanghai started to apply PVC sheets in their production lines within a very short period of time. It is the possibility of easily cutting, folding, and thermoforming the material into desired shapes that allows these companies to fulfill the tough requirements from pharmaceutical industries while offering beautiful and functional packaging to consumer products. Result: Beginning with the adoption of PVC sheets, fruitful results have already started to show. Pharmaceutical firms are reportedly found to declare that most of the problems related to packaging, such as contamination and damage of the product during transportation, have reduced considerably. Consumers have also welcomed the enhanced protection and longer shelf life of products packaged with PVC. Moreover, this reduces the overall production cost of PVC sheets, thereby enabling the manufacturer to maintain a competitive price and upgrade the quality of packaging. Impact and Future Prospects: Interest in PVC sheets for folded box and pharmaceutical thermoforming packaging has been quite successful, and other markets, like food and electronics, where solid, protective, and cost-efficient packaging is a must, may get attracted to it. Environmentalists still are wary and remind that without recycling programs, harm to the environment from PVC will only continue to grow. As innovations further the development in the packaging industry, PVC sheets can only play an ever-increasing role as a solution providing a reliable performance-cost-consumer safety balance for manufacturers. With Shanghai at the helm of this change, its packaging sector is well on course to lead global efforts towards improving products' packaging through strategic material use, such as PVC.

PVC Revolutionizes Furniture Stickers and Wallpapers August 5, 2024 – Shenzhen, China Polyvinyl Chloride, commonly known as PVC, has now become the prime choice for manufacturing furniture stickers and wallpapers because of some very outstanding characteristics it possesses. This breakthrough came in front of designers, manufacturers, and consumers this year at the opening day of the annual Home Decoration Expo in Shenzhen. Key Figures: - Mr. Li Wei, Managing Director of Decor Innovations, in his key note address said what were the advantages gained with PVC. - Ms. Zhang Hui, leading Interior decorator displayed her new range of wallpapers, which were made out of PVC. Why: With the increased demand for cost-effective, durable and aesthetically attractive solutions for home decoration, the leaders in the industry were on a quest of new materials. And it is actually PVC, with the rare combination of properties, as mentioned before, won the favor of the leaders. Mr. Li Wei said this enabled them to adopt the PVC material after in-depth research and development. "We have conducted extensive tests so that the PVC material is flame-retardant, wear-resistant, and printable." And, in a way, these properties showed up as very enabling for vibrant designs to translate into long-lasting colors. This has impacted the market a lot, with the introduction of PVC furniture stickers and wallpapers, as everyone has a choice to go for safe, cheap, and durable decoration solutions. Retailers claim that the high quality and beautiful design of PVC products boosted sales. - Cost-Effective: Being cost-effective, it brings the high-quality decor options in the range of more people. - Safe: Since it is flame-retardant, it enhances the safety of homes. - Durability: It easily resists wear and corrosion, ensuring the look stays intact for the longest time in heavily used and damp spaces. - Visual Appeal: Shows fine and lively designs, excelling in printability, meeting people Total incorporation into the home decor industry is a great milestone for PVC. Speaking last, Mr. Li Wei concluded, "PVC is revolutionizing the way we go about interior design, presenting solutions which are not only practical but also beautiful." This discovery is bound to set industry standards that provide grounds for new breakthroughs and further uses of PVC in other areas.

1. Protective Enclosures: Anti-static flame-retardant PVC sheets for the enclosure of electronic devices, offering two-in-one protection. 2. Component Storage: Besides this, it provides storage and conveyance for electronic components without the risk of damage through electrostatic or by any possible fire hazards. 3. Workstations: Anti-static PVC sheets have an extended application at the manufacturing workstations in order to create an atmosphere controlled from the risks of electrostatic discharge. 4. Packaging: Flame-retardant PVC sheets find their usage in the packaging materials and hence add an extra layer of safety during transit and storage.