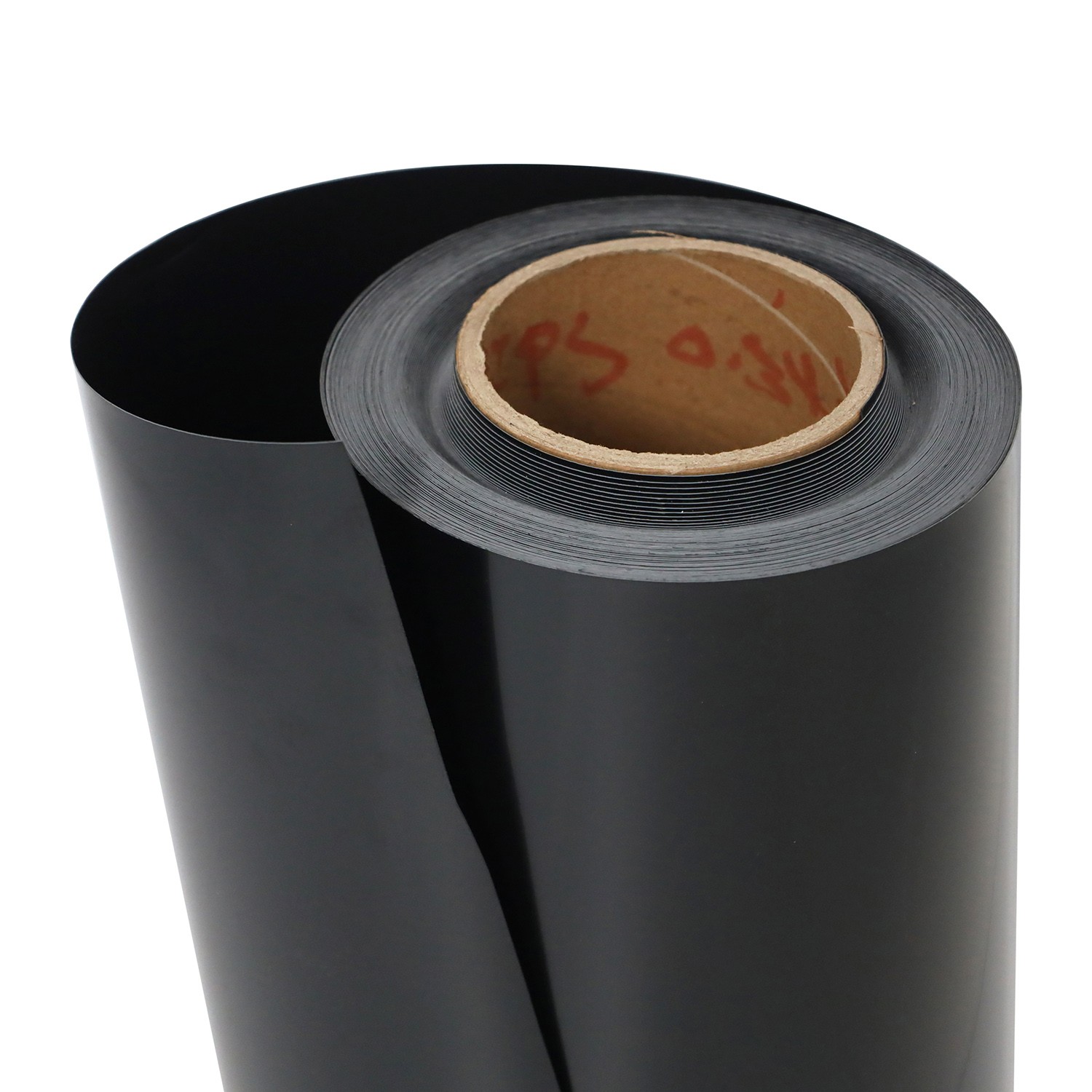

PP thermoforming sheet is a high-performance plastic material made from polypropylene (PP) resin, processed through advanced extrusion technology to meet the requirements of thermoforming processes. It combines excellent physical properties, environmental friendliness, and processing adaptability, becoming a preferred material in packaging, medical, automotive, and other industries.

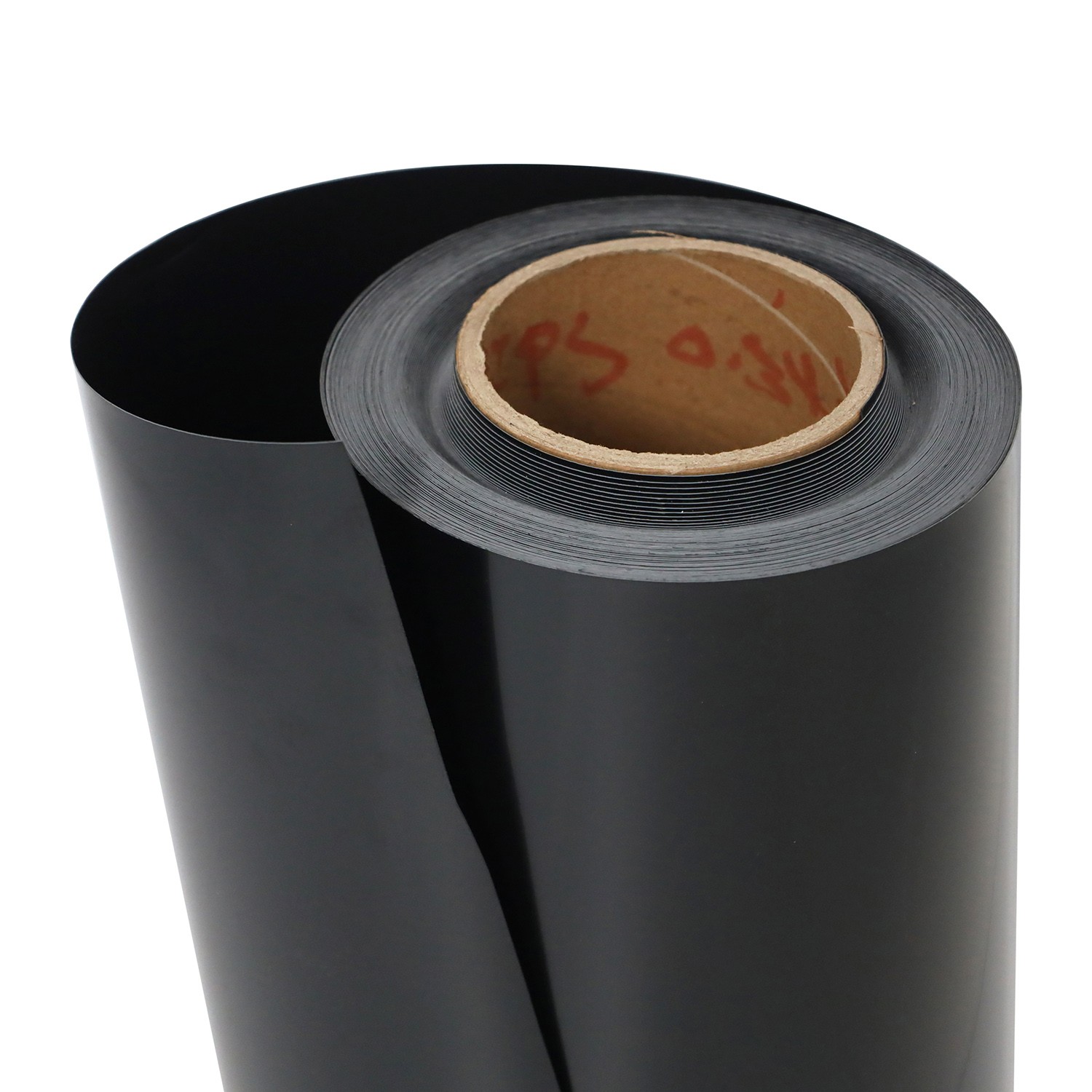

Superior Thermoformability: It softens at a moderate temperature with a broad forming range, easily adapting to vacuum forming, pressure forming, and other processes. It can be shaped into complex structures while maintaining dimensional stability.

Outstanding Physical & Thermal Performance: With a low density of 0.93 g/cm³, it is lightweight yet rigid and impact-resistant. It tolerates short-term temperatures up to 120°C and long-term use at 95°C, suitable for microwave heating scenarios.

Chemical Stability & Hygiene: It is non-toxic, odorless, and resistant to acids, alkalis, organic solvents, and oily foods. It meets food safety and medical hygiene standards without releasing harmful substances.

Environmental Friendliness: As a recyclable mono-material, it has a simple recycling process and low environmental impact during production and combustion.