Cast Polypropylene (CPP) Film

2026-01-12 16:54Cast Polypropylene (CPP) Film: High-Performance Packaging & Industrial Solution

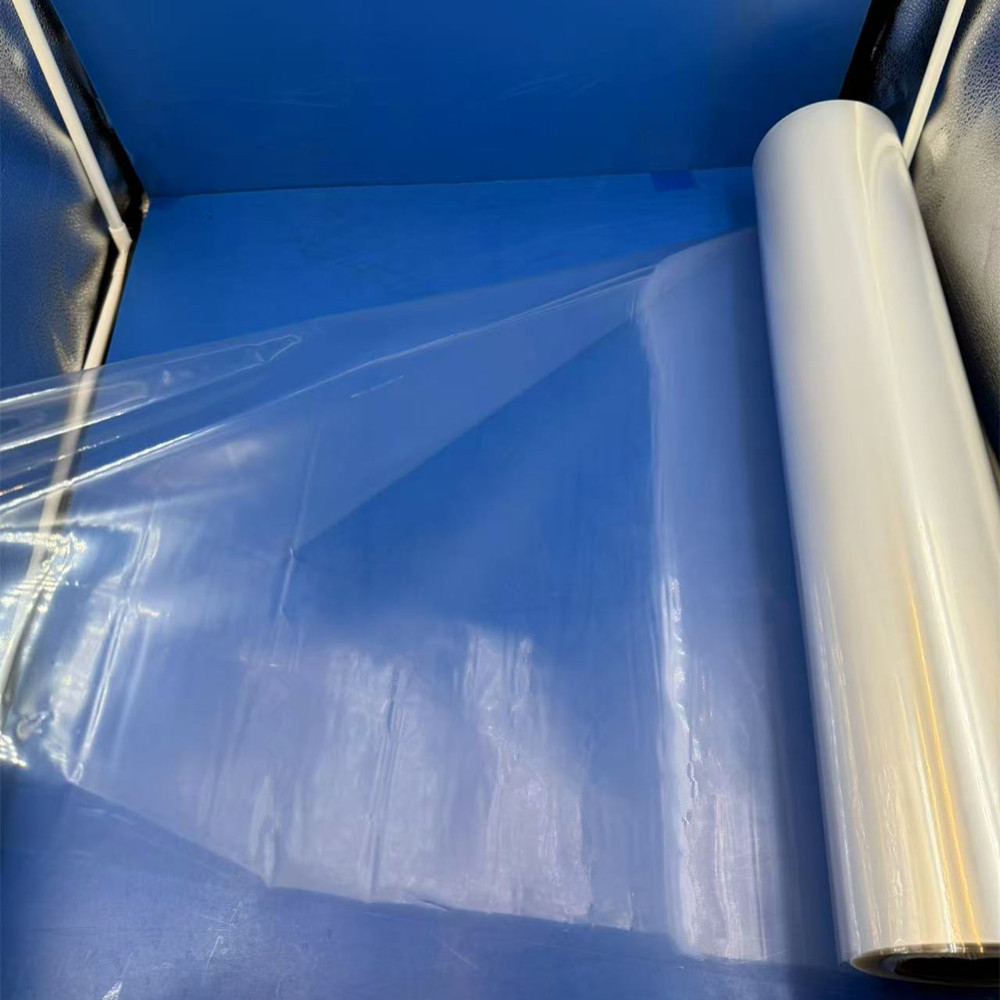

Cast Polypropylene (CPP) film is an innovative non-stretched, cast - extruded polypropylene film, which is a cost - effective and versatile material widely used in packaging, industrial protection, and composite applications. It is made by melting polypropylene resin, extruding it through a T - die, and then rapidly cooling it on a chill roll, resulting in a film with uniform thickness, excellent optical properties, and balanced mechanical performance in both machine and transverse directions.

Core Advantages

Superior Optical & Mechanical Properties: It boasts high transparency (haze as low as 0.5% for optical - grade products), high gloss, and good stiffness that is better than PE film. It has excellent tear resistance and elongation at break (≥400%), enabling it to resist impact during transportation and processing. The density is about 0.90 - 0.91 g/cm³, which helps save material costs.

Excellent Heat - Sealing & Thermal Resistance: It has a low heat - sealing initiation temperature and a wide sealing window, ensuring strong and reliable seals. Retort - grade CPP (RCPP) can withstand high - temperature retorting at 121°C for 30 minutes, and some special grades can even resist 135°C high - temperature processing, making it suitable for packaging high - temperature - sterilized food.

Good Barrier & Chemical Resistance: It has excellent moisture and odor barrier properties, which can effectively protect the contents from moisture and odor contamination. It is resistant to acids, alkalis, and oils, making it ideal for packaging oily foods and products requiring chemical resistance.

Outstanding Processability: Its surface can be easily treated (surface tension 38 - 40 dyn/cm) to meet the requirements of printing, lamination, and metallization. It can be co - extruded into multi - layer structures to enhance barrier performance (such as adding EVOH layer) or functional properties (like anti - fogging and anti - static).

Food - Safe & Eco - Friendly: It is non - toxic, odorless, and compliant with global food contact standards (such as FDA 21 CFR §177.1520, EU 10/2011). It is recyclable and aligns with the trend of sustainable packaging development.

Product Classification & Applications

| Type | Key Features | Typical Applications | Thickness Range |

|---|---|---|---|

| General - Purpose CPP (GCPP) | Good transparency, gloss, and heat - sealing performance | Daily food packaging (bread, confectionery), garment bags, stationery films | 25 - 50μm |

| Metallizable CPP (MCPP) | Optimized surface for vacuum metallization, good adhesion to aluminum | Metallized film for snack packaging, barrier packaging, decorative films | 20 - 40μm |

| Retort - Grade CPP (RCPP) | High heat resistance (121°C/30min), excellent oil and air barrier | High - temperature - sterilized food packaging (meat, seafood, ready - to - eat meals) | 60 - 80μm |

| Special - Function CPP | Customized properties (anti - static, anti - fogging, high - barrier co - extrusion) | Electronic component protection films, fresh - keeping packaging for fruits and vegetables, composite film base layers |