The Unsung Hero of Modern Packaging: Exploring the Versatility of Transparent PET Film

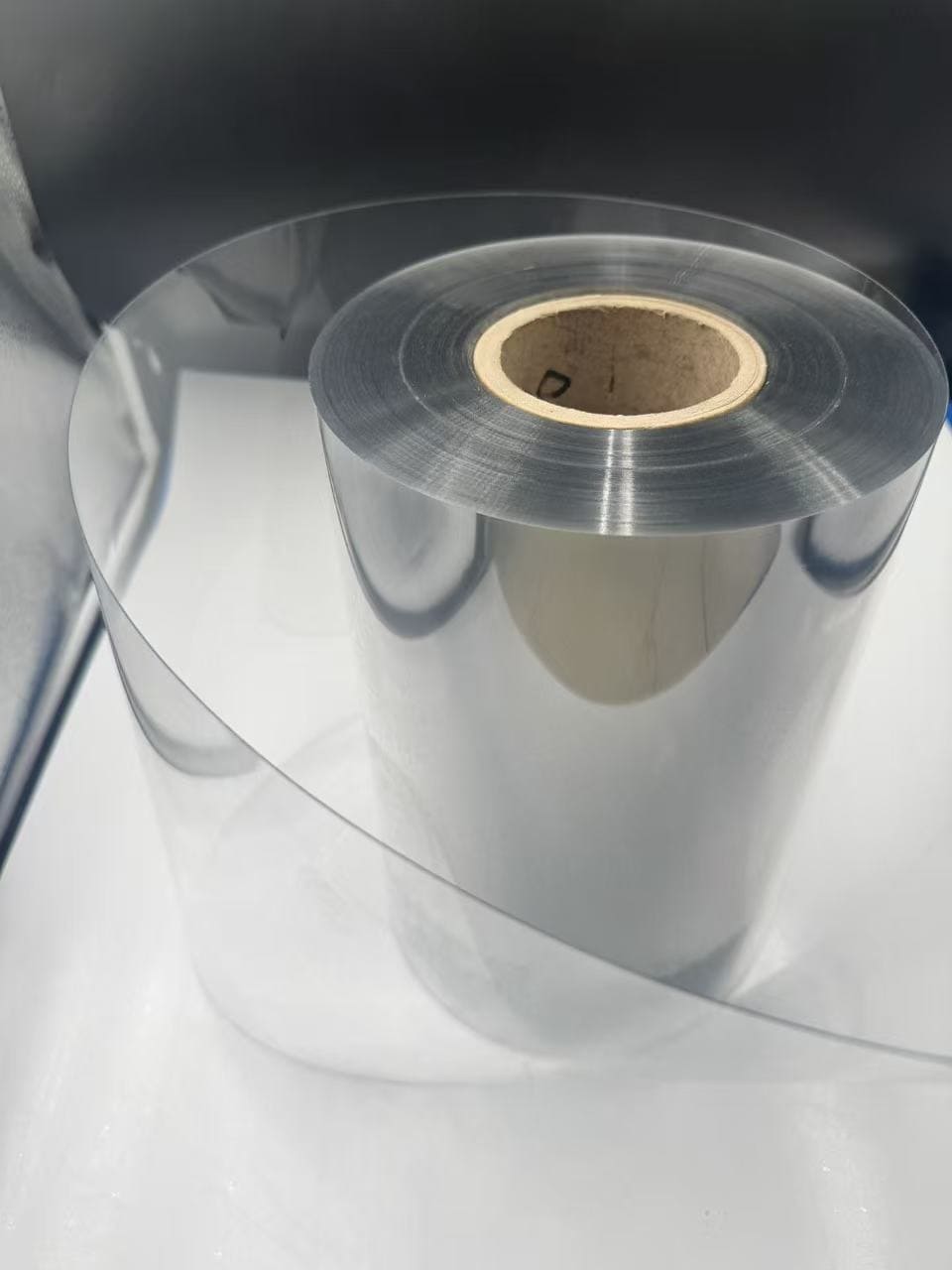

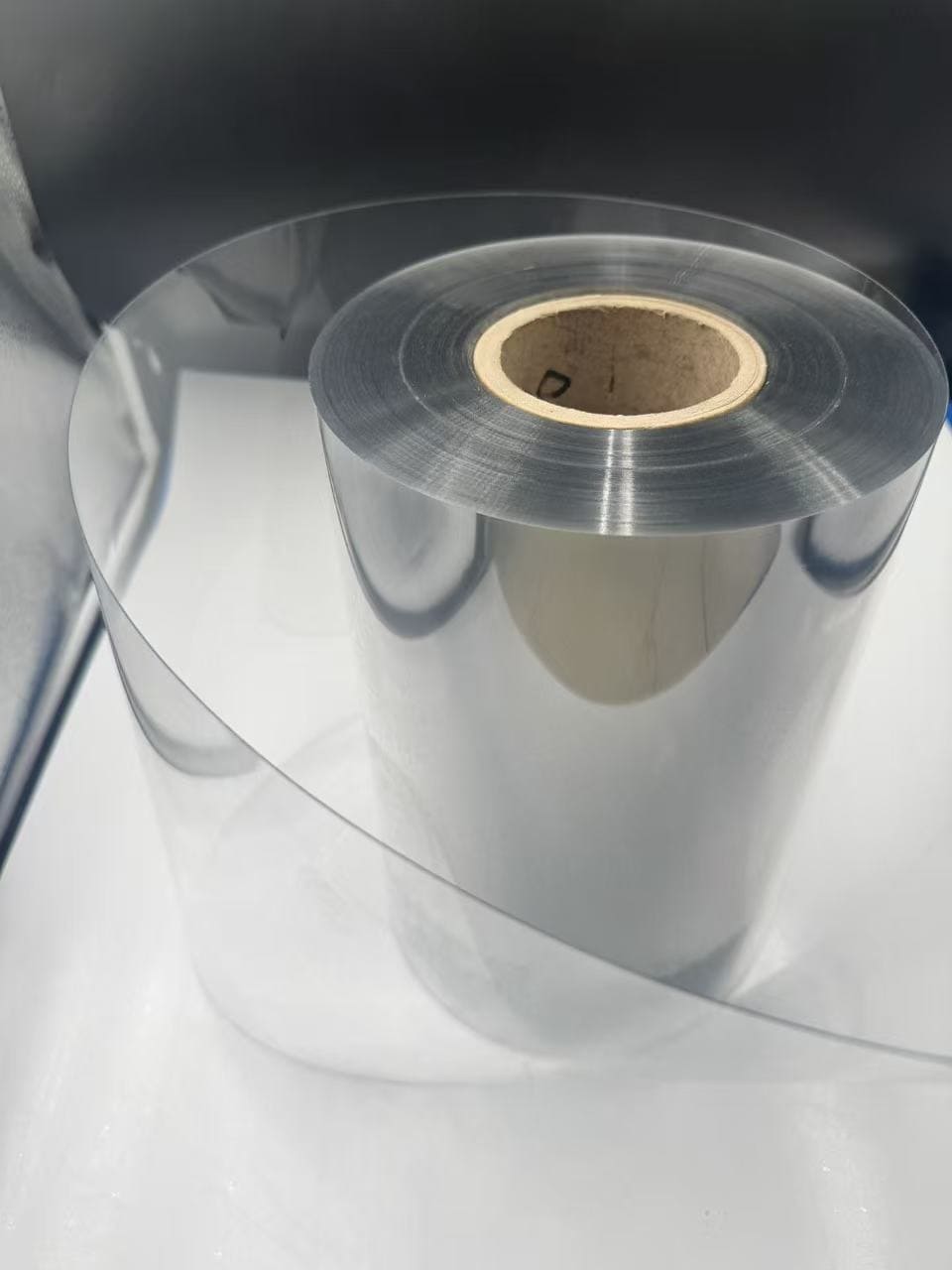

2025-11-26 16:14 The Unsung Hero of Modern Packaging: Exploring the Versatility of Transparent PET Film  Among the countless materials that quietly shape our daily lives, few are as ubiquitous yet underappreciated as transparent PET film. Known chemically as polyethylene terephthalate film, this crystal-clear polyester sheet combines exceptional optical clarity, remarkable mechanical strength, and impressive barrier properties in a single, lightweight package. Walk into any supermarket, pharmacy, or electronics store, and you will encounter it dozens of times — holding fresh fruits in neat clamshells, protecting a new pair of earphones, or keeping disposable cutlery neatly aligned on a retail shelf. Its transparency allows consumers to see exactly what they are buying, while its toughness ensures the product arrives intact. This unique blend of aesthetics and performance has made transparent PET film an indispensable material across industries.Unmatched Optical Clarity and Visual AppealThe first thing anyone notices about PET film is its glass-like transparency. With light transmission often exceeding 90% in the visible spectrum, it rivals the clarity of actual glass but at a fraction of the weight and cost. This optical purity is not just cosmetic; it directly influences consumer behavior. Studies on retail psychology have consistently shown that shoppers are far more likely to purchase products they can see clearly. Transparent PET film turns packaging into a silent salesperson, showcasing the color of ripe strawberries, the shine of a new smartphone screen, or the precise arrangement of disposable spoons inside a blister tray. Unlike opaque or frosted alternatives, PET film invites inspection and builds trust.

Among the countless materials that quietly shape our daily lives, few are as ubiquitous yet underappreciated as transparent PET film. Known chemically as polyethylene terephthalate film, this crystal-clear polyester sheet combines exceptional optical clarity, remarkable mechanical strength, and impressive barrier properties in a single, lightweight package. Walk into any supermarket, pharmacy, or electronics store, and you will encounter it dozens of times — holding fresh fruits in neat clamshells, protecting a new pair of earphones, or keeping disposable cutlery neatly aligned on a retail shelf. Its transparency allows consumers to see exactly what they are buying, while its toughness ensures the product arrives intact. This unique blend of aesthetics and performance has made transparent PET film an indispensable material across industries.Unmatched Optical Clarity and Visual AppealThe first thing anyone notices about PET film is its glass-like transparency. With light transmission often exceeding 90% in the visible spectrum, it rivals the clarity of actual glass but at a fraction of the weight and cost. This optical purity is not just cosmetic; it directly influences consumer behavior. Studies on retail psychology have consistently shown that shoppers are far more likely to purchase products they can see clearly. Transparent PET film turns packaging into a silent salesperson, showcasing the color of ripe strawberries, the shine of a new smartphone screen, or the precise arrangement of disposable spoons inside a blister tray. Unlike opaque or frosted alternatives, PET film invites inspection and builds trust. Mechanical Strength That Defies Its ThinnessDespite being only 0.05–0.50 mm thick in most packaging applications, transparent PET film exhibits extraordinary tensile strength and tear resistance. It can withstand significant stretching and impact without cracking — a property that makes it ideal for thermoformed blister packs and trays. When heated, PET becomes pliable and can be vacuum-formed or pressure-formed into complex three-dimensional shapes that lock products securely in place. Once cooled, the formed tray returns to its original rigidity, creating a tough shell that protects even fragile items during shipping and display.This combination of flexibility during processing and rigidity in the final product is why food manufacturers prefer PET for fresh produce clamshells. Cherry tomatoes, blueberries, and grapes experience constant movement during transportation, yet the PET clamshell rarely splits or deforms. The material’s high modulus also means that stacked trays in a supermarket display do not crush under their own weight, preserving both the packaging and the delicate fruit inside.

Mechanical Strength That Defies Its ThinnessDespite being only 0.05–0.50 mm thick in most packaging applications, transparent PET film exhibits extraordinary tensile strength and tear resistance. It can withstand significant stretching and impact without cracking — a property that makes it ideal for thermoformed blister packs and trays. When heated, PET becomes pliable and can be vacuum-formed or pressure-formed into complex three-dimensional shapes that lock products securely in place. Once cooled, the formed tray returns to its original rigidity, creating a tough shell that protects even fragile items during shipping and display.This combination of flexibility during processing and rigidity in the final product is why food manufacturers prefer PET for fresh produce clamshells. Cherry tomatoes, blueberries, and grapes experience constant movement during transportation, yet the PET clamshell rarely splits or deforms. The material’s high modulus also means that stacked trays in a supermarket display do not crush under their own weight, preserving both the packaging and the delicate fruit inside. Excellent Barrier Properties and Food SafetyContrary to popular belief, PET is not completely impermeable, but its barrier against oxygen, carbon dioxide, and moisture is remarkably good for a plastic film — especially when compared to polyethylene or polypropylene commonly used in flexible packaging. In food blister applications, this moderate gas barrier helps extend shelf life of baked goods, deli meats, and fresh-cut vegetables by slowing oxidation and moisture loss. More importantly, PET is one of the safest plastics in contact with food. It has been approved by regulatory agencies worldwide for direct food contact, does not contain or release bisphenol A (BPA), and exhibits extremely low migration of substances into foodstuffs even at elevated temperatures.For products that require longer shelf life, manufacturers often apply thin functional coatings (such as silicon oxide or aluminum oxide) to the PET film through vacuum deposition, dramatically boosting oxygen and moisture barrier while maintaining high transparency. These coated versions are increasingly seen in premium fresh salad bowls and ready-to-eat meal trays.

Excellent Barrier Properties and Food SafetyContrary to popular belief, PET is not completely impermeable, but its barrier against oxygen, carbon dioxide, and moisture is remarkably good for a plastic film — especially when compared to polyethylene or polypropylene commonly used in flexible packaging. In food blister applications, this moderate gas barrier helps extend shelf life of baked goods, deli meats, and fresh-cut vegetables by slowing oxidation and moisture loss. More importantly, PET is one of the safest plastics in contact with food. It has been approved by regulatory agencies worldwide for direct food contact, does not contain or release bisphenol A (BPA), and exhibits extremely low migration of substances into foodstuffs even at elevated temperatures.For products that require longer shelf life, manufacturers often apply thin functional coatings (such as silicon oxide or aluminum oxide) to the PET film through vacuum deposition, dramatically boosting oxygen and moisture barrier while maintaining high transparency. These coated versions are increasingly seen in premium fresh salad bowls and ready-to-eat meal trays. Dimensional Stability and Heat ResistanceOne technical advantage that packaging engineers love about PET film is its outstanding dimensional stability across a wide temperature range. Unlike many plastics that shrink or warp when exposed to heat, properly crystallized PET film remains flat and stable. This property proves invaluable when products undergo heat-sealing, microwave sterilization, or hot-fill processes. Disposable tableware sets — forks, knives, spoons, and cups — are frequently packaged in transparent PET trays that are heat-sealed with a top film. The sealing temperature can reach 150–180 °C for a brief moment, yet the PET tray beneath does not deform, ensuring a hermetic seal and professional appearance.Antistatic and ESD-Protective VariantsWhile standard transparent PET film already has moderate antistatic properties, many electronic and precision-instrument applications demand far greater control over static electricity. Dust attraction and electrostatic discharge (ESD) can destroy sensitive components like integrated circuits, LCD panels, or medical diagnostic strips. To address this, manufacturers produce specially formulated antistatic PET film and conductive-coated PET film that dissipate static charges almost instantly.These antistatic grades typically achieve surface resistivity in the range of 10⁶–10⁹ ohms/square, preventing dust buildup and eliminating the risk of spark discharge. In cleanroom environments, reels of antistatic PET film are used as carrier tapes, interlayer sheets, and protective covers. The transparency remains nearly identical to standard PET, allowing optical inspection and automated vision systems to function without interference. Major semiconductor and electronics assembly lines rely on these films daily, yet consumers never see the critical role they play behind the scenes.

Dimensional Stability and Heat ResistanceOne technical advantage that packaging engineers love about PET film is its outstanding dimensional stability across a wide temperature range. Unlike many plastics that shrink or warp when exposed to heat, properly crystallized PET film remains flat and stable. This property proves invaluable when products undergo heat-sealing, microwave sterilization, or hot-fill processes. Disposable tableware sets — forks, knives, spoons, and cups — are frequently packaged in transparent PET trays that are heat-sealed with a top film. The sealing temperature can reach 150–180 °C for a brief moment, yet the PET tray beneath does not deform, ensuring a hermetic seal and professional appearance.Antistatic and ESD-Protective VariantsWhile standard transparent PET film already has moderate antistatic properties, many electronic and precision-instrument applications demand far greater control over static electricity. Dust attraction and electrostatic discharge (ESD) can destroy sensitive components like integrated circuits, LCD panels, or medical diagnostic strips. To address this, manufacturers produce specially formulated antistatic PET film and conductive-coated PET film that dissipate static charges almost instantly.These antistatic grades typically achieve surface resistivity in the range of 10⁶–10⁹ ohms/square, preventing dust buildup and eliminating the risk of spark discharge. In cleanroom environments, reels of antistatic PET film are used as carrier tapes, interlayer sheets, and protective covers. The transparency remains nearly identical to standard PET, allowing optical inspection and automated vision systems to function without interference. Major semiconductor and electronics assembly lines rely on these films daily, yet consumers never see the critical role they play behind the scenes. Creative and Emerging ApplicationsBeyond traditional uses, designers continually discover new ways to exploit PET film’s clarity and strength. High-end cosmetic brands use thick, crystal-clear PET boxes to create a luxurious “floating” display for lipsticks and perfume bottles. In horticulture, transparent PET seedling trays allow growers to inspect root development without disturbing the plants. Even in architecture and interior design, ultra-clear PET film serves as a lightweight alternative to glass in partitions and protective screens.

Creative and Emerging ApplicationsBeyond traditional uses, designers continually discover new ways to exploit PET film’s clarity and strength. High-end cosmetic brands use thick, crystal-clear PET boxes to create a luxurious “floating” display for lipsticks and perfume bottles. In horticulture, transparent PET seedling trays allow growers to inspect root development without disturbing the plants. Even in architecture and interior design, ultra-clear PET film serves as a lightweight alternative to glass in partitions and protective screens. ConclusionFrom the moment you pick up a punnet of strawberries in the produce aisle to the instant you unbox a new smartphone protected by an antistatic PET carrier, transparent PET film works silently to deliver clarity, protection, and convenience. Its rare combination of glass-like transparency, toughness, food safety, heat resistance, and recyclability has cemented its position as the material of choice for blister packaging, disposable tableware presentation, and ESD-sensitive applications. As consumer demand for visibility, sustainability, and performance continues to grow, transparent PET film is not just keeping pace — it is leading the way, one crystal-clear package at a time.

ConclusionFrom the moment you pick up a punnet of strawberries in the produce aisle to the instant you unbox a new smartphone protected by an antistatic PET carrier, transparent PET film works silently to deliver clarity, protection, and convenience. Its rare combination of glass-like transparency, toughness, food safety, heat resistance, and recyclability has cemented its position as the material of choice for blister packaging, disposable tableware presentation, and ESD-sensitive applications. As consumer demand for visibility, sustainability, and performance continues to grow, transparent PET film is not just keeping pace — it is leading the way, one crystal-clear package at a time.

Among the countless materials that quietly shape our daily lives, few are as ubiquitous yet underappreciated as transparent PET film. Known chemically as polyethylene terephthalate film, this crystal-clear polyester sheet combines exceptional optical clarity, remarkable mechanical strength, and impressive barrier properties in a single, lightweight package. Walk into any supermarket, pharmacy, or electronics store, and you will encounter it dozens of times — holding fresh fruits in neat clamshells, protecting a new pair of earphones, or keeping disposable cutlery neatly aligned on a retail shelf. Its transparency allows consumers to see exactly what they are buying, while its toughness ensures the product arrives intact. This unique blend of aesthetics and performance has made transparent PET film an indispensable material across industries.Unmatched Optical Clarity and Visual AppealThe first thing anyone notices about PET film is its glass-like transparency. With light transmission often exceeding 90% in the visible spectrum, it rivals the clarity of actual glass but at a fraction of the weight and cost. This optical purity is not just cosmetic; it directly influences consumer behavior. Studies on retail psychology have consistently shown that shoppers are far more likely to purchase products they can see clearly. Transparent PET film turns packaging into a silent salesperson, showcasing the color of ripe strawberries, the shine of a new smartphone screen, or the precise arrangement of disposable spoons inside a blister tray. Unlike opaque or frosted alternatives, PET film invites inspection and builds trust.

Among the countless materials that quietly shape our daily lives, few are as ubiquitous yet underappreciated as transparent PET film. Known chemically as polyethylene terephthalate film, this crystal-clear polyester sheet combines exceptional optical clarity, remarkable mechanical strength, and impressive barrier properties in a single, lightweight package. Walk into any supermarket, pharmacy, or electronics store, and you will encounter it dozens of times — holding fresh fruits in neat clamshells, protecting a new pair of earphones, or keeping disposable cutlery neatly aligned on a retail shelf. Its transparency allows consumers to see exactly what they are buying, while its toughness ensures the product arrives intact. This unique blend of aesthetics and performance has made transparent PET film an indispensable material across industries.Unmatched Optical Clarity and Visual AppealThe first thing anyone notices about PET film is its glass-like transparency. With light transmission often exceeding 90% in the visible spectrum, it rivals the clarity of actual glass but at a fraction of the weight and cost. This optical purity is not just cosmetic; it directly influences consumer behavior. Studies on retail psychology have consistently shown that shoppers are far more likely to purchase products they can see clearly. Transparent PET film turns packaging into a silent salesperson, showcasing the color of ripe strawberries, the shine of a new smartphone screen, or the precise arrangement of disposable spoons inside a blister tray. Unlike opaque or frosted alternatives, PET film invites inspection and builds trust. Mechanical Strength That Defies Its ThinnessDespite being only 0.05–0.50 mm thick in most packaging applications, transparent PET film exhibits extraordinary tensile strength and tear resistance. It can withstand significant stretching and impact without cracking — a property that makes it ideal for thermoformed blister packs and trays. When heated, PET becomes pliable and can be vacuum-formed or pressure-formed into complex three-dimensional shapes that lock products securely in place. Once cooled, the formed tray returns to its original rigidity, creating a tough shell that protects even fragile items during shipping and display.This combination of flexibility during processing and rigidity in the final product is why food manufacturers prefer PET for fresh produce clamshells. Cherry tomatoes, blueberries, and grapes experience constant movement during transportation, yet the PET clamshell rarely splits or deforms. The material’s high modulus also means that stacked trays in a supermarket display do not crush under their own weight, preserving both the packaging and the delicate fruit inside.

Mechanical Strength That Defies Its ThinnessDespite being only 0.05–0.50 mm thick in most packaging applications, transparent PET film exhibits extraordinary tensile strength and tear resistance. It can withstand significant stretching and impact without cracking — a property that makes it ideal for thermoformed blister packs and trays. When heated, PET becomes pliable and can be vacuum-formed or pressure-formed into complex three-dimensional shapes that lock products securely in place. Once cooled, the formed tray returns to its original rigidity, creating a tough shell that protects even fragile items during shipping and display.This combination of flexibility during processing and rigidity in the final product is why food manufacturers prefer PET for fresh produce clamshells. Cherry tomatoes, blueberries, and grapes experience constant movement during transportation, yet the PET clamshell rarely splits or deforms. The material’s high modulus also means that stacked trays in a supermarket display do not crush under their own weight, preserving both the packaging and the delicate fruit inside. Excellent Barrier Properties and Food SafetyContrary to popular belief, PET is not completely impermeable, but its barrier against oxygen, carbon dioxide, and moisture is remarkably good for a plastic film — especially when compared to polyethylene or polypropylene commonly used in flexible packaging. In food blister applications, this moderate gas barrier helps extend shelf life of baked goods, deli meats, and fresh-cut vegetables by slowing oxidation and moisture loss. More importantly, PET is one of the safest plastics in contact with food. It has been approved by regulatory agencies worldwide for direct food contact, does not contain or release bisphenol A (BPA), and exhibits extremely low migration of substances into foodstuffs even at elevated temperatures.For products that require longer shelf life, manufacturers often apply thin functional coatings (such as silicon oxide or aluminum oxide) to the PET film through vacuum deposition, dramatically boosting oxygen and moisture barrier while maintaining high transparency. These coated versions are increasingly seen in premium fresh salad bowls and ready-to-eat meal trays.

Excellent Barrier Properties and Food SafetyContrary to popular belief, PET is not completely impermeable, but its barrier against oxygen, carbon dioxide, and moisture is remarkably good for a plastic film — especially when compared to polyethylene or polypropylene commonly used in flexible packaging. In food blister applications, this moderate gas barrier helps extend shelf life of baked goods, deli meats, and fresh-cut vegetables by slowing oxidation and moisture loss. More importantly, PET is one of the safest plastics in contact with food. It has been approved by regulatory agencies worldwide for direct food contact, does not contain or release bisphenol A (BPA), and exhibits extremely low migration of substances into foodstuffs even at elevated temperatures.For products that require longer shelf life, manufacturers often apply thin functional coatings (such as silicon oxide or aluminum oxide) to the PET film through vacuum deposition, dramatically boosting oxygen and moisture barrier while maintaining high transparency. These coated versions are increasingly seen in premium fresh salad bowls and ready-to-eat meal trays. Dimensional Stability and Heat ResistanceOne technical advantage that packaging engineers love about PET film is its outstanding dimensional stability across a wide temperature range. Unlike many plastics that shrink or warp when exposed to heat, properly crystallized PET film remains flat and stable. This property proves invaluable when products undergo heat-sealing, microwave sterilization, or hot-fill processes. Disposable tableware sets — forks, knives, spoons, and cups — are frequently packaged in transparent PET trays that are heat-sealed with a top film. The sealing temperature can reach 150–180 °C for a brief moment, yet the PET tray beneath does not deform, ensuring a hermetic seal and professional appearance.Antistatic and ESD-Protective VariantsWhile standard transparent PET film already has moderate antistatic properties, many electronic and precision-instrument applications demand far greater control over static electricity. Dust attraction and electrostatic discharge (ESD) can destroy sensitive components like integrated circuits, LCD panels, or medical diagnostic strips. To address this, manufacturers produce specially formulated antistatic PET film and conductive-coated PET film that dissipate static charges almost instantly.These antistatic grades typically achieve surface resistivity in the range of 10⁶–10⁹ ohms/square, preventing dust buildup and eliminating the risk of spark discharge. In cleanroom environments, reels of antistatic PET film are used as carrier tapes, interlayer sheets, and protective covers. The transparency remains nearly identical to standard PET, allowing optical inspection and automated vision systems to function without interference. Major semiconductor and electronics assembly lines rely on these films daily, yet consumers never see the critical role they play behind the scenes.

Dimensional Stability and Heat ResistanceOne technical advantage that packaging engineers love about PET film is its outstanding dimensional stability across a wide temperature range. Unlike many plastics that shrink or warp when exposed to heat, properly crystallized PET film remains flat and stable. This property proves invaluable when products undergo heat-sealing, microwave sterilization, or hot-fill processes. Disposable tableware sets — forks, knives, spoons, and cups — are frequently packaged in transparent PET trays that are heat-sealed with a top film. The sealing temperature can reach 150–180 °C for a brief moment, yet the PET tray beneath does not deform, ensuring a hermetic seal and professional appearance.Antistatic and ESD-Protective VariantsWhile standard transparent PET film already has moderate antistatic properties, many electronic and precision-instrument applications demand far greater control over static electricity. Dust attraction and electrostatic discharge (ESD) can destroy sensitive components like integrated circuits, LCD panels, or medical diagnostic strips. To address this, manufacturers produce specially formulated antistatic PET film and conductive-coated PET film that dissipate static charges almost instantly.These antistatic grades typically achieve surface resistivity in the range of 10⁶–10⁹ ohms/square, preventing dust buildup and eliminating the risk of spark discharge. In cleanroom environments, reels of antistatic PET film are used as carrier tapes, interlayer sheets, and protective covers. The transparency remains nearly identical to standard PET, allowing optical inspection and automated vision systems to function without interference. Major semiconductor and electronics assembly lines rely on these films daily, yet consumers never see the critical role they play behind the scenes. Thermoforming Excellence for Blister and Clamshell Packaging

Thermoforming Excellence for Blister and Clamshell Packaging

Creative and Emerging ApplicationsBeyond traditional uses, designers continually discover new ways to exploit PET film’s clarity and strength. High-end cosmetic brands use thick, crystal-clear PET boxes to create a luxurious “floating” display for lipsticks and perfume bottles. In horticulture, transparent PET seedling trays allow growers to inspect root development without disturbing the plants. Even in architecture and interior design, ultra-clear PET film serves as a lightweight alternative to glass in partitions and protective screens.

Creative and Emerging ApplicationsBeyond traditional uses, designers continually discover new ways to exploit PET film’s clarity and strength. High-end cosmetic brands use thick, crystal-clear PET boxes to create a luxurious “floating” display for lipsticks and perfume bottles. In horticulture, transparent PET seedling trays allow growers to inspect root development without disturbing the plants. Even in architecture and interior design, ultra-clear PET film serves as a lightweight alternative to glass in partitions and protective screens. ConclusionFrom the moment you pick up a punnet of strawberries in the produce aisle to the instant you unbox a new smartphone protected by an antistatic PET carrier, transparent PET film works silently to deliver clarity, protection, and convenience. Its rare combination of glass-like transparency, toughness, food safety, heat resistance, and recyclability has cemented its position as the material of choice for blister packaging, disposable tableware presentation, and ESD-sensitive applications. As consumer demand for visibility, sustainability, and performance continues to grow, transparent PET film is not just keeping pace — it is leading the way, one crystal-clear package at a time.

ConclusionFrom the moment you pick up a punnet of strawberries in the produce aisle to the instant you unbox a new smartphone protected by an antistatic PET carrier, transparent PET film works silently to deliver clarity, protection, and convenience. Its rare combination of glass-like transparency, toughness, food safety, heat resistance, and recyclability has cemented its position as the material of choice for blister packaging, disposable tableware presentation, and ESD-sensitive applications. As consumer demand for visibility, sustainability, and performance continues to grow, transparent PET film is not just keeping pace — it is leading the way, one crystal-clear package at a time.

Get the latest price? We'll respond as soon as possible(within 12 hours)