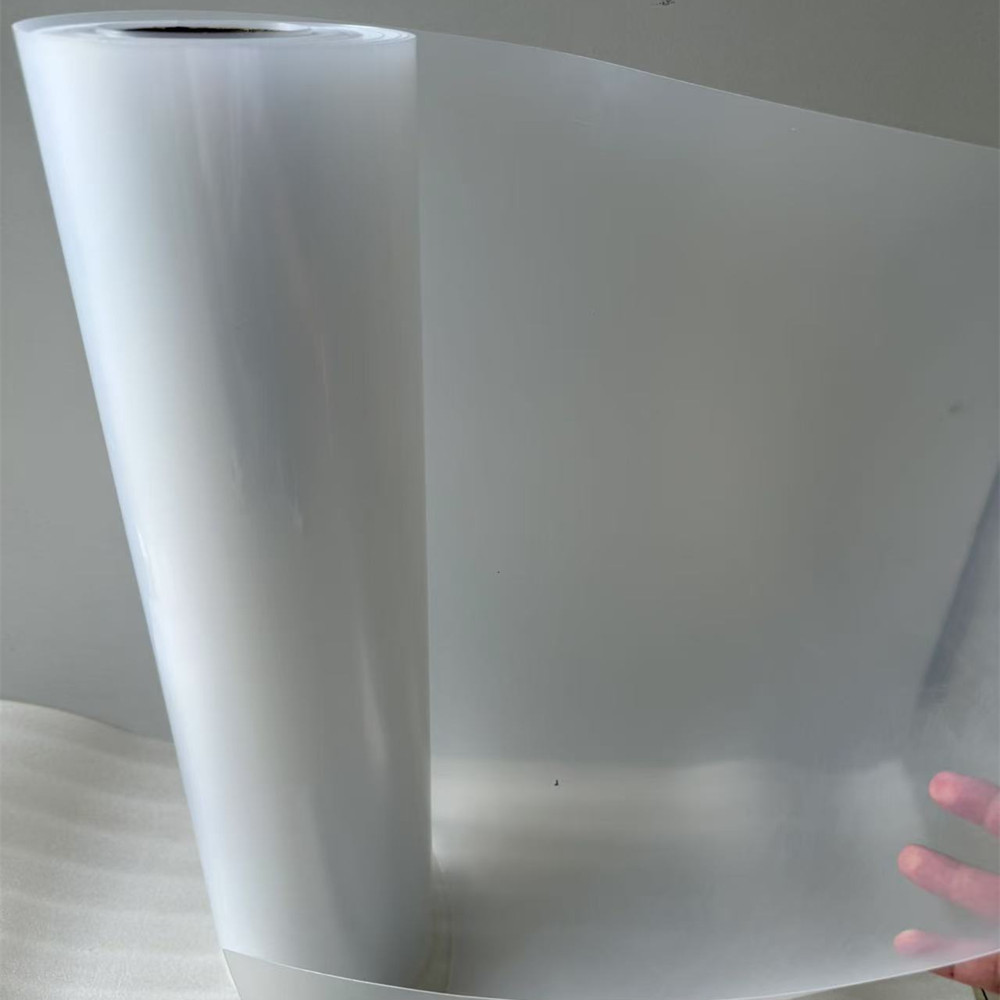

Polypropylene (PP) thermoforming sheets are high-performance thermoplastic materials engineered for the thermoforming process—where sheets are heated to a pliable state and shaped into custom packaging or industrial components. Renowned for their excellent balance of cost-effectiveness, mechanical strength, and chemical resistance, PP thermoforming sheets have become a preferred choice in food packaging, medical supplies, consumer goods, and industrial applications worldwide.

Available in various grades (homo PP, co-PP, reinforced PP) and specifications (thickness: 0.2mm–5.0mm; width: up to 2000mm), the sheets can be customized with features like anti-fog, anti-static, UV resistance, or barrier coatings (EVOH, PVDC) to meet specific application requirements.

Cost-Effective: Lower material cost compared to PET or ABS, ideal for high-volume production.

Eco-Friendly: 100% recyclable (recycling code #5), aligning with global sustainability goals.

Food-Safe: Complies with FDA, EU 10/2011, and other international food contact regulations (BPA-free, non-toxic).

Versatile: Adaptable to various thermoforming processes (vacuum forming, pressure forming, twin-sheet thermoforming).

Moisture Barrier: Natural resistance to moisture, protecting products from humidity damage.