Crystal Clear Protection: Unveiling the Wonders of Transparent PET Film

2025-11-17 15:47Crystal Clear Protection: Unveiling the Wonders of Transparent PET Film  Introduction: The Unsung Hero of Modern LifePicture this: you're weaving through a crowded farmers' market on a sunny afternoon, your eyes drawn to a vibrant display of plump berries cradled in shimmering, see-through domes that seem to capture the sunlight itself. Or perhaps you're unpacking a sleek new gadget from its protective cocoon, marveling at how the thin layer safeguarding the delicate internals remains pristine despite the journey from factory to your doorstep. In these moments, and countless others, transparent polyethylene terephthalate (PET) film works its quiet magic. This remarkable material, a staple of the packaging world, combines razor-sharp clarity with unyielding toughness, turning ordinary products into eye-catching, secure packages.

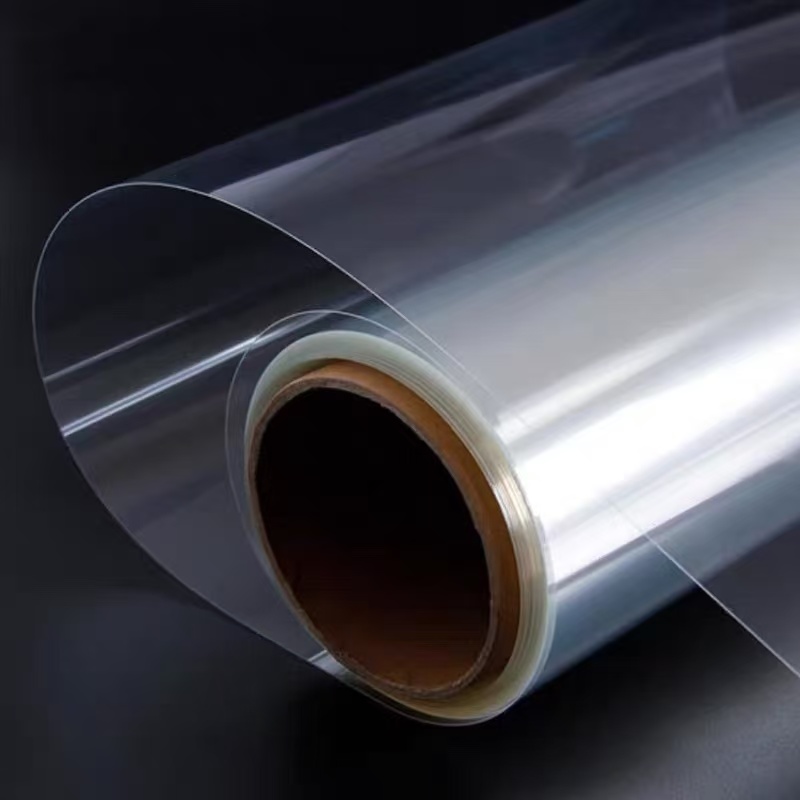

Introduction: The Unsung Hero of Modern LifePicture this: you're weaving through a crowded farmers' market on a sunny afternoon, your eyes drawn to a vibrant display of plump berries cradled in shimmering, see-through domes that seem to capture the sunlight itself. Or perhaps you're unpacking a sleek new gadget from its protective cocoon, marveling at how the thin layer safeguarding the delicate internals remains pristine despite the journey from factory to your doorstep. In these moments, and countless others, transparent polyethylene terephthalate (PET) film works its quiet magic. This remarkable material, a staple of the packaging world, combines razor-sharp clarity with unyielding toughness, turning ordinary products into eye-catching, secure packages. Born from the ingenuity of polymer science in the post-World War II era, transparent PET film has grown into a global powerhouse, used in everything from grocery aisles to electronics labs. Its appeal lies in a perfect storm of attributes: optical purity that lets products breathe visually, mechanical resilience that defies daily abuse, and adaptability that spans industries. In a world obsessed with sustainability, convenience, and aesthetics, this film delivers on all fronts—lightweight to cut shipping costs, recyclable to ease environmental burdens, and versatile enough to mold into forms that hug irregular shapes like a second skin.This article peels back the layers (pun intended) on transparent PET film's core properties, then spotlights its starring roles in food blister packaging, disposable cutlery wraps, and anti-static enclosures. Drawing on established material science principles and real-world performance data, we'll paint a vivid picture of how this film doesn't just contain— it elevates, protects, and inspires. By the end, you'll see it not as mere plastic, but as a transformative force shaping how we interact with the goods that define our lives.

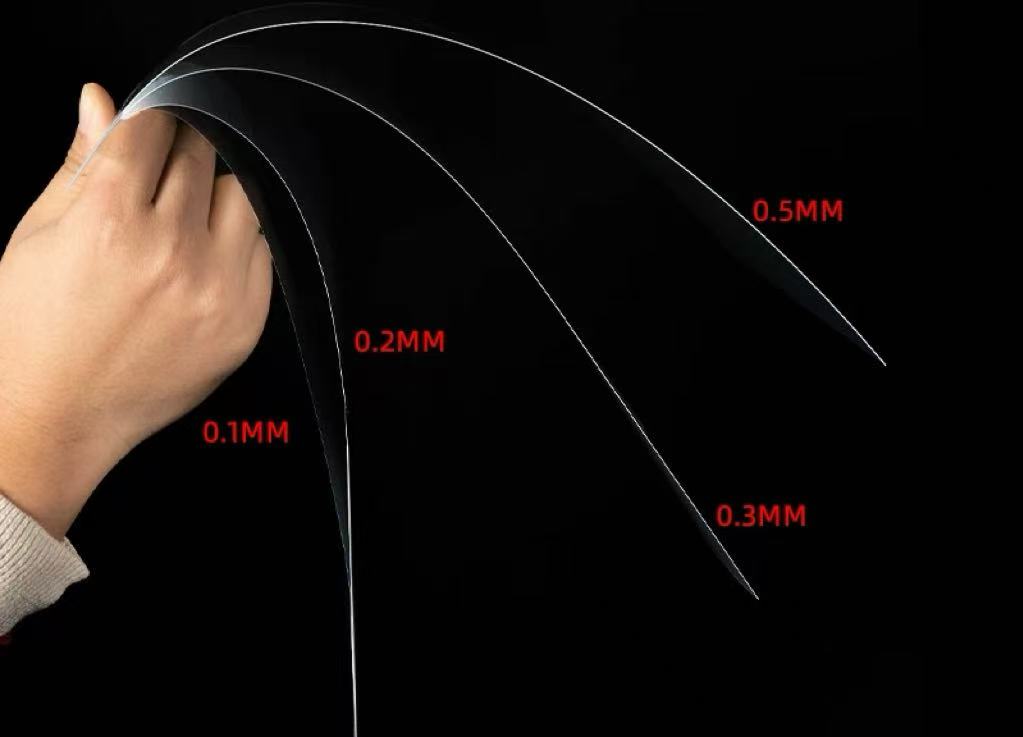

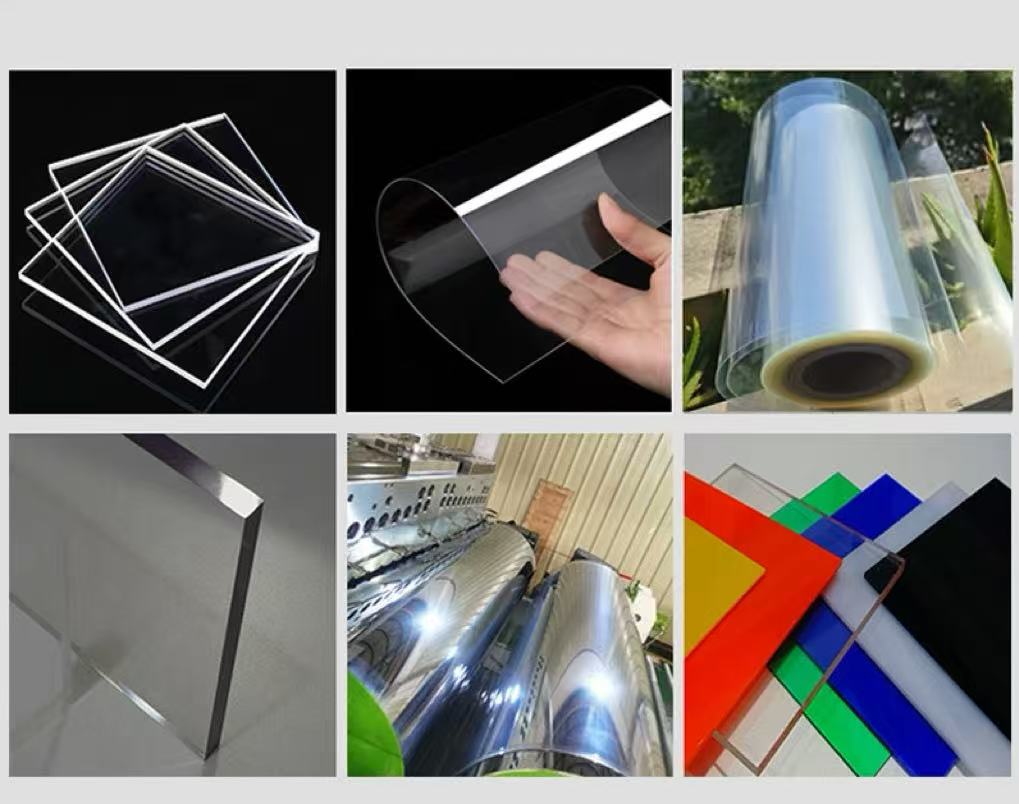

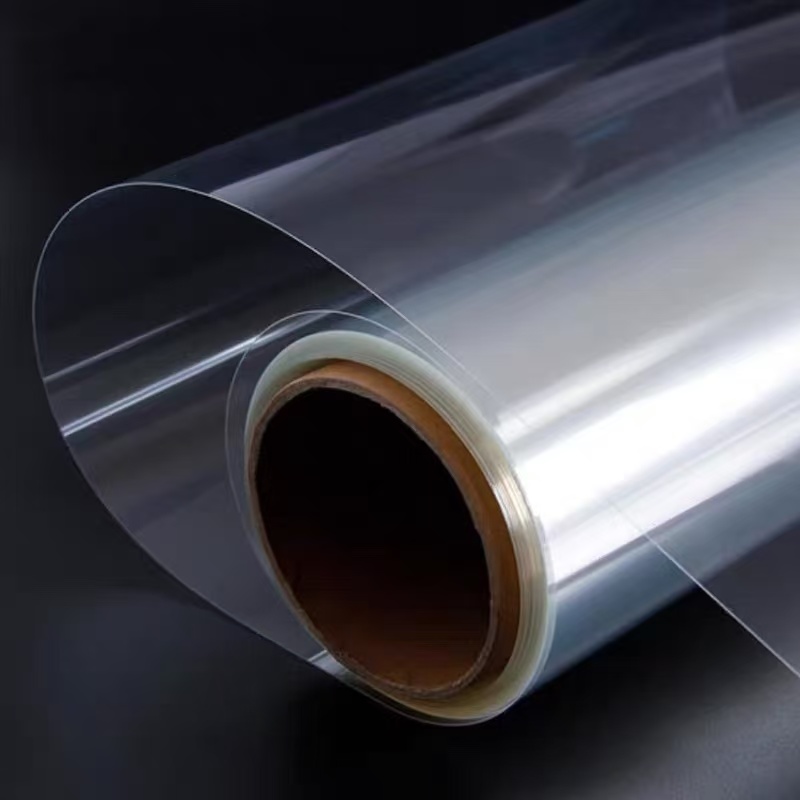

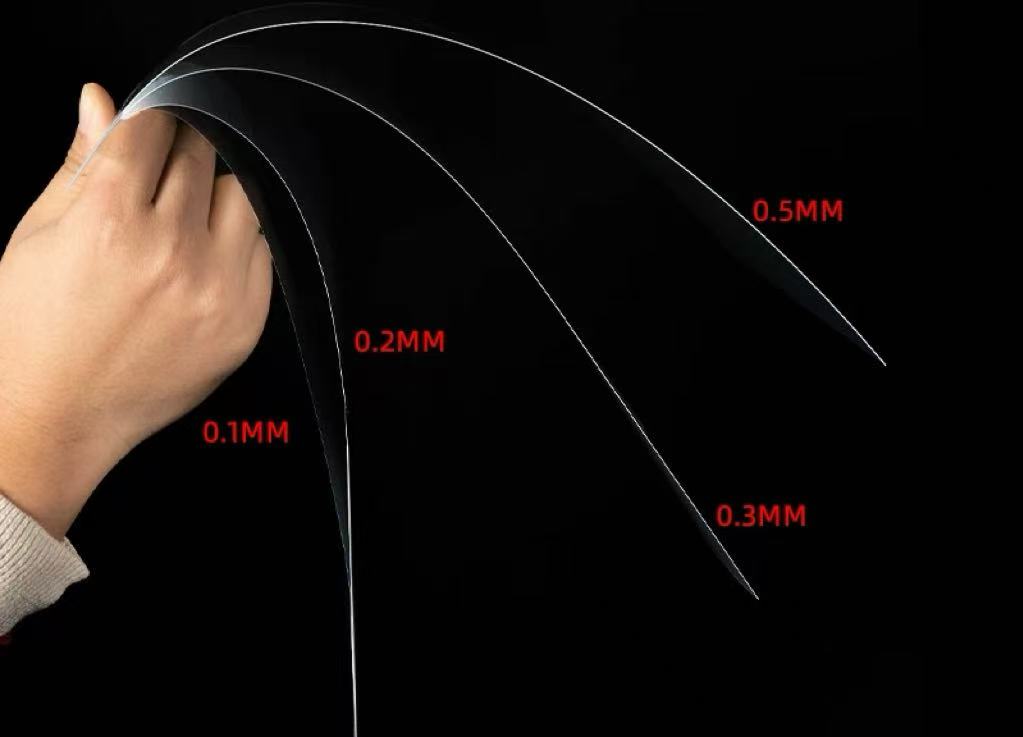

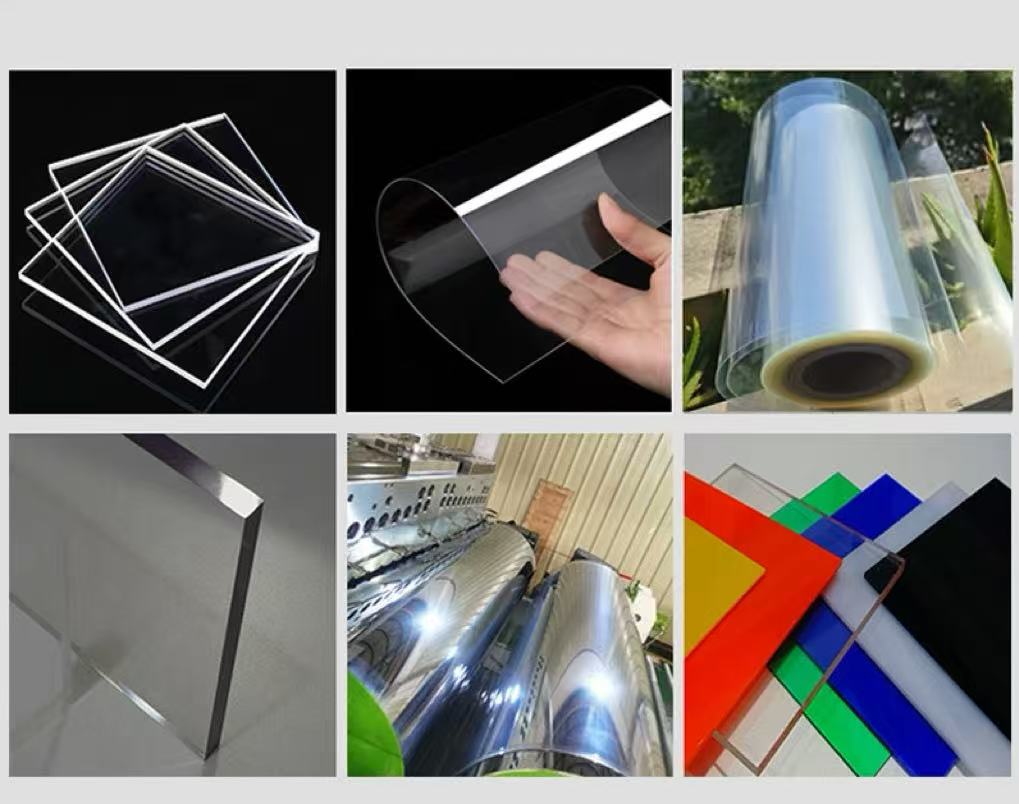

Born from the ingenuity of polymer science in the post-World War II era, transparent PET film has grown into a global powerhouse, used in everything from grocery aisles to electronics labs. Its appeal lies in a perfect storm of attributes: optical purity that lets products breathe visually, mechanical resilience that defies daily abuse, and adaptability that spans industries. In a world obsessed with sustainability, convenience, and aesthetics, this film delivers on all fronts—lightweight to cut shipping costs, recyclable to ease environmental burdens, and versatile enough to mold into forms that hug irregular shapes like a second skin.This article peels back the layers (pun intended) on transparent PET film's core properties, then spotlights its starring roles in food blister packaging, disposable cutlery wraps, and anti-static enclosures. Drawing on established material science principles and real-world performance data, we'll paint a vivid picture of how this film doesn't just contain— it elevates, protects, and inspires. By the end, you'll see it not as mere plastic, but as a transformative force shaping how we interact with the goods that define our lives. The Building Blocks: Key Properties That Define ExcellenceTransparent PET film isn't your average sheet of plastic; it's a meticulously engineered product of biaxial orientation, where the raw polymer is stretched in two directions to align its molecular chains like soldiers in formation. This process yields a film that's as clear as window glass but far more forgiving—typically 12 to 50 microns thick, yet capable of withstanding forces that would shatter brittle alternatives.Start with its optical brilliance: boasting light transmittance rates above 90% across the visible spectrum, it scatters less than 1% of light, creating a haze-free view that's ideal for showcasing products. Imagine a jewelry box where each gem sparkles undimmed; that's the level of clarity PET film provides, enhancing perceived value and driving sales in retail settings where first impressions count.Mechanically, it's a beast in lightweight armor. Tensile strength clocks in at over 200 megapascals in both lengthwise and crosswise directions, allowing it to resist elongation under stress without tearing. Drop tests reveal it can endure falls from heights up to 2 meters without puncturing, a boon for e-commerce shipments prone to rough handling. Its modulus of elasticity—around 4 gigapascals—ensures it snaps back to shape after deformation, preventing the warping that plagues lesser films during storage or transport.

The Building Blocks: Key Properties That Define ExcellenceTransparent PET film isn't your average sheet of plastic; it's a meticulously engineered product of biaxial orientation, where the raw polymer is stretched in two directions to align its molecular chains like soldiers in formation. This process yields a film that's as clear as window glass but far more forgiving—typically 12 to 50 microns thick, yet capable of withstanding forces that would shatter brittle alternatives.Start with its optical brilliance: boasting light transmittance rates above 90% across the visible spectrum, it scatters less than 1% of light, creating a haze-free view that's ideal for showcasing products. Imagine a jewelry box where each gem sparkles undimmed; that's the level of clarity PET film provides, enhancing perceived value and driving sales in retail settings where first impressions count.Mechanically, it's a beast in lightweight armor. Tensile strength clocks in at over 200 megapascals in both lengthwise and crosswise directions, allowing it to resist elongation under stress without tearing. Drop tests reveal it can endure falls from heights up to 2 meters without puncturing, a boon for e-commerce shipments prone to rough handling. Its modulus of elasticity—around 4 gigapascals—ensures it snaps back to shape after deformation, preventing the warping that plagues lesser films during storage or transport. Thermal stability adds another layer of reliability. With a glass transition temperature of about 70°C, it remains rigid up to 150°C for short bursts, making it oven-safe for reheating packaged meals, while flexing without cracking down to -40°C. Shrinkage is minimal, under 1% even after prolonged heat exposure, which means labels or seals stay taut and professional-looking over time.Chemically, PET film stands guard like an impermeable moat. Water vapor transmission rates hover below 2 grams per square meter per day, keeping moisture-sensitive items crisp and dry—think of chocolate bars that stay firm in humid summers. It's equally impervious to most oils, greases, and mild acids, with absorption rates under 0.5%, ensuring no leaching or flavor tainting in food contacts. However, it's worth noting its vulnerability to strong bases, which can hydrolyze the ester bonds, a detail chemists leverage in controlled degradation for recycling.Electrically, plain PET acts as an insulator with dielectric strength exceeding 150 kilovolts per millimeter, but variants tuned for anti-static use incorporate coatings that lower surface resistivity to 10^8 ohms per square, bleeding off static charges in seconds. Environmentally, its density of 1.38 grams per cubic centimeter makes it 70% lighter than glass, slashing transport emissions, and its 100% recyclability supports circular economies—global recovery rates for PET now exceed 30%, with sorted streams yielding high-purity regrind for new film.These traits don't operate solo; they synergize. Low friction coefficients (0.3 to 0.5) enable high-speed machinery runs, reducing jams in automated lines, while excellent print receptivity accepts inks and adhesives for vibrant, durable graphics. In essence, transparent PET film's properties form a robust foundation, blending science-backed performance with practical edge, ready to tackle the demands of diverse applications.

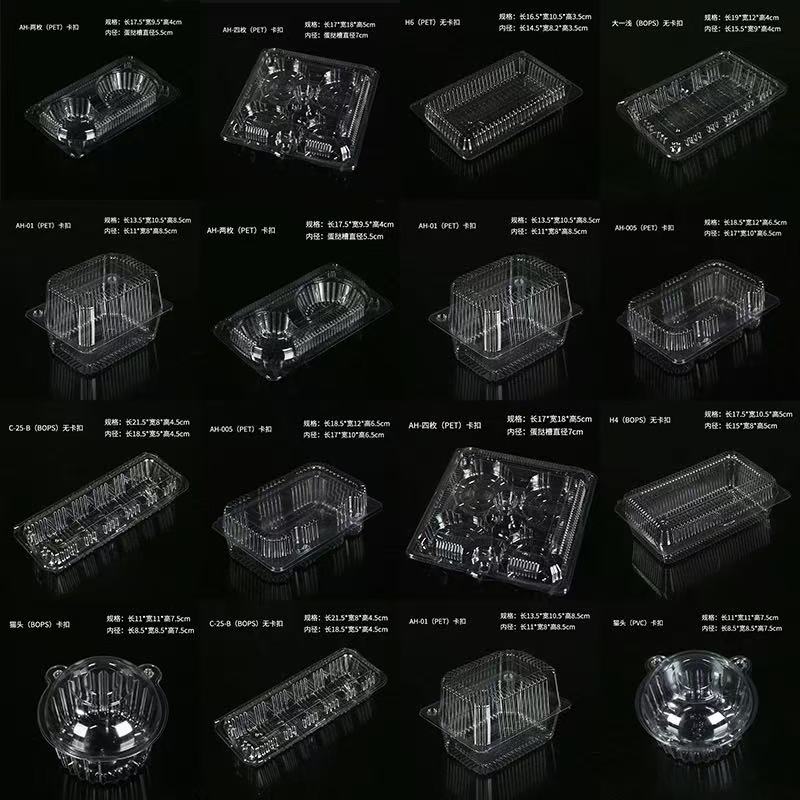

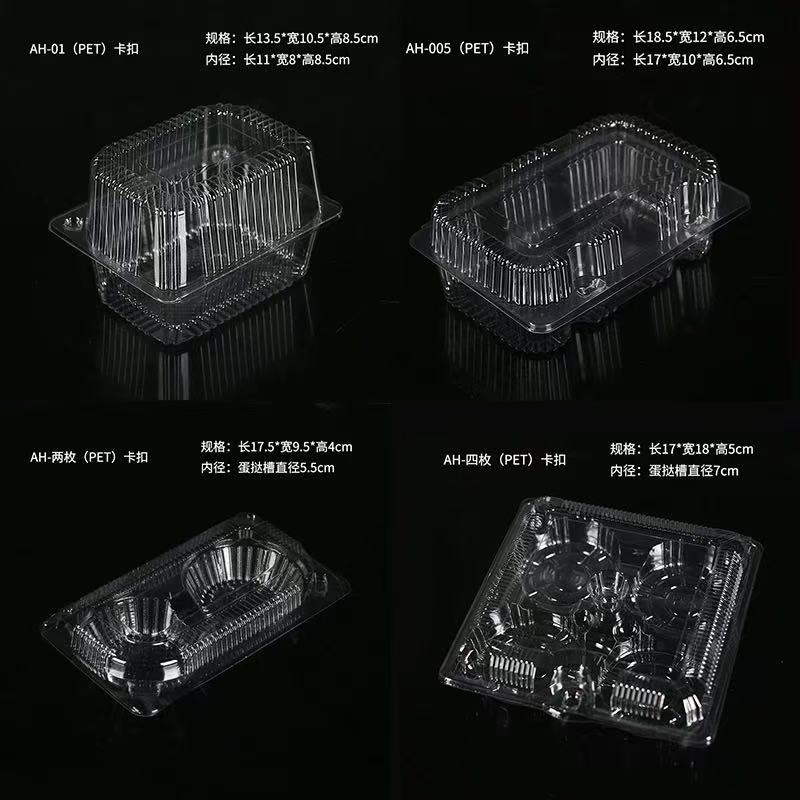

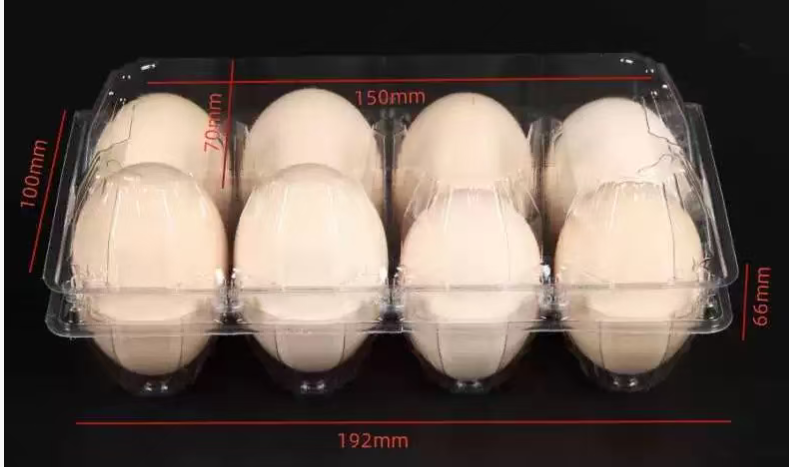

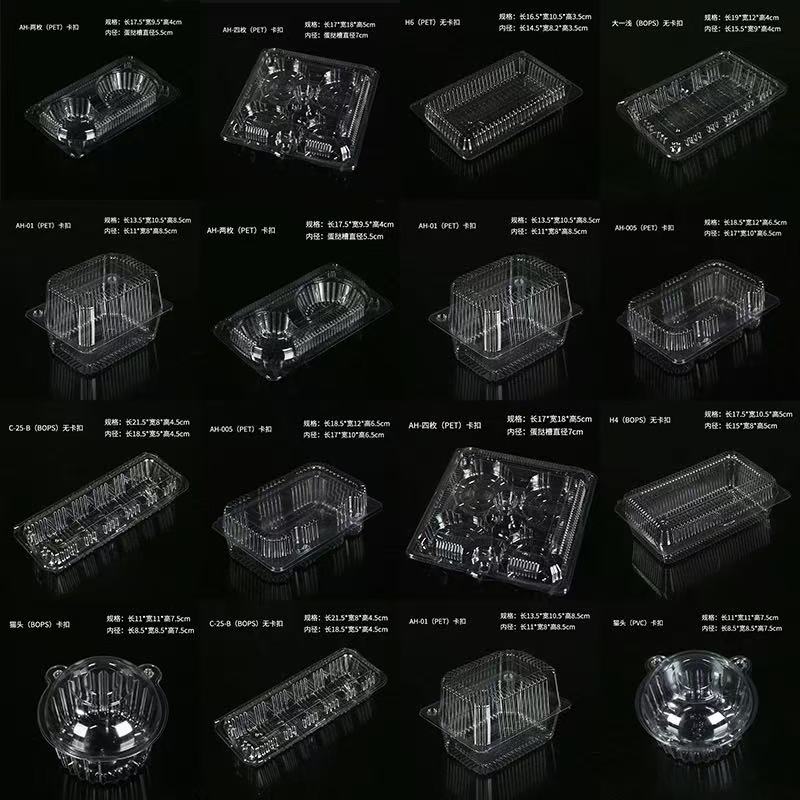

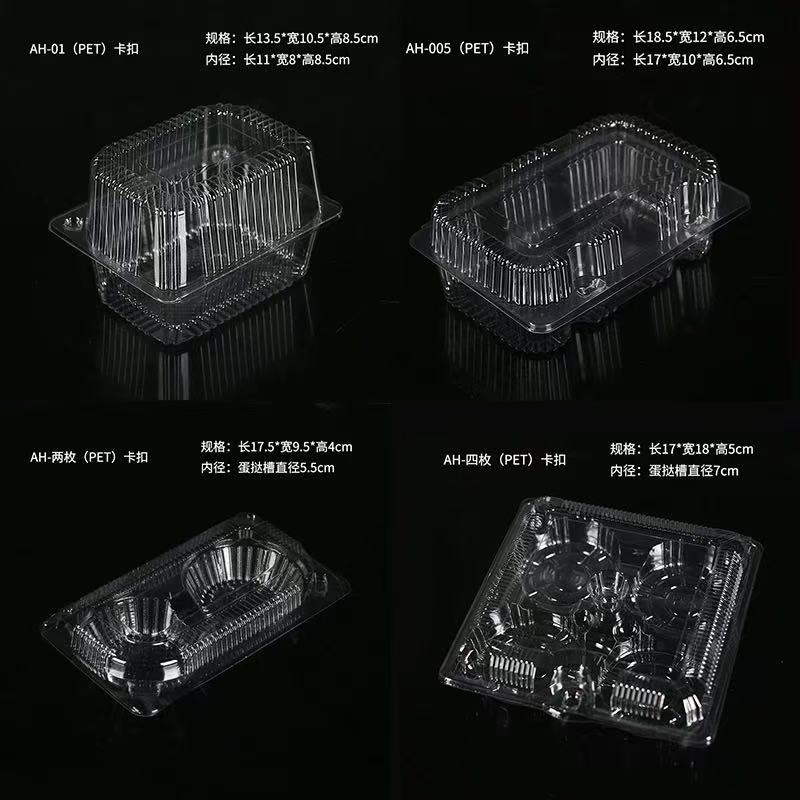

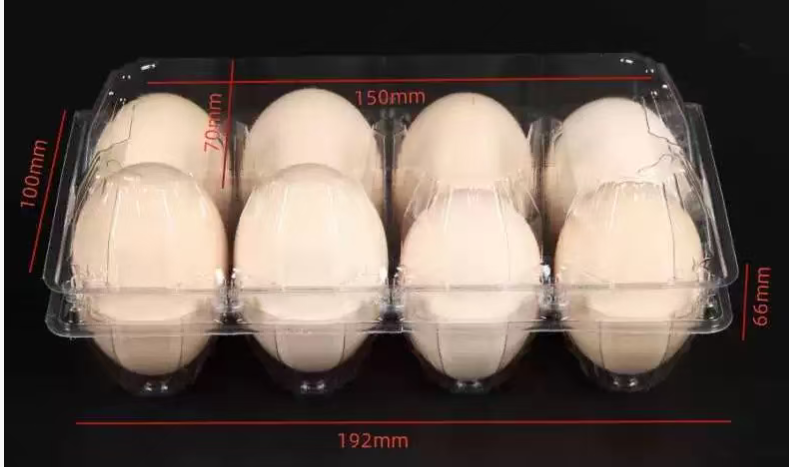

Thermal stability adds another layer of reliability. With a glass transition temperature of about 70°C, it remains rigid up to 150°C for short bursts, making it oven-safe for reheating packaged meals, while flexing without cracking down to -40°C. Shrinkage is minimal, under 1% even after prolonged heat exposure, which means labels or seals stay taut and professional-looking over time.Chemically, PET film stands guard like an impermeable moat. Water vapor transmission rates hover below 2 grams per square meter per day, keeping moisture-sensitive items crisp and dry—think of chocolate bars that stay firm in humid summers. It's equally impervious to most oils, greases, and mild acids, with absorption rates under 0.5%, ensuring no leaching or flavor tainting in food contacts. However, it's worth noting its vulnerability to strong bases, which can hydrolyze the ester bonds, a detail chemists leverage in controlled degradation for recycling.Electrically, plain PET acts as an insulator with dielectric strength exceeding 150 kilovolts per millimeter, but variants tuned for anti-static use incorporate coatings that lower surface resistivity to 10^8 ohms per square, bleeding off static charges in seconds. Environmentally, its density of 1.38 grams per cubic centimeter makes it 70% lighter than glass, slashing transport emissions, and its 100% recyclability supports circular economies—global recovery rates for PET now exceed 30%, with sorted streams yielding high-purity regrind for new film.These traits don't operate solo; they synergize. Low friction coefficients (0.3 to 0.5) enable high-speed machinery runs, reducing jams in automated lines, while excellent print receptivity accepts inks and adhesives for vibrant, durable graphics. In essence, transparent PET film's properties form a robust foundation, blending science-backed performance with practical edge, ready to tackle the demands of diverse applications. Food Blister Packaging: A Window to Freshness and FlavorEnter the realm of food blister packaging, where transparent PET film transforms groceries from bulk bins into premium presentations. Thermoformed into bubble-like cavities and heat-sealed to backing cards or foils, these blisters are everywhere—from pharmacy vitamins to supermarket salads—offering a tamper-proof barrier that lets consumers peek inside without compromise.The film's formability is its superpower here. At processing temperatures around 120°C, it deep-draws up to 60 millimeters without thinning below 80% of original gauge, conforming to the nooks of a strawberry cluster or the ridges of a muffin like a custom glove. This precision minimizes headspace, curbing oxidation that turns fresh produce limp; oxygen permeability under 10 cubic centimeters per square meter per day extends shelf life by 50% compared to uncoated alternatives, as evidenced by studies on packaged berries retaining vitamin C levels 20% higher after a week.Vividly, consider a blister of artisanal cheeses: the film's clarity (haze <0.5%) highlights the creamy marbling and subtle veins, enticing shoppers while its puncture resistance—over 150 Newtons—shields against fork pricks or stack crushes in transit. For baked goods like cookies, the mechanical balance prevents crumbling under 50 kg of overhead pressure, arriving bakery-fresh to doorsteps. And in the war on waste, PET's recyclability shines; lightweight blisters reduce packaging mass by 40% versus rigid trays, aligning with zero-waste initiatives that have cut food industry landfill contributions by 15% in recent years.Hygiene is non-negotiable, and PET delivers with surface energies optimized for sterilization—gamma irradiation at 25 kGy leaves it unscathed, ensuring microbial counts stay below 10 colony-forming units per square centimeter. Seal integrity, achieved at 140°C with peel strengths over 5 Newtons per centimeter, creates child-resistant yet user-friendly openings. Challenges like edge cracking during forming are mitigated by edge-trimming techniques, but the payoff is clear: blister packaging boosts product visibility, lifting conversion rates by 25% in visual merchandising tests. From farm-fresh veggies in urban co-ops to exotic spices in global chains, transparent PET film in food blisters isn't just packaging—it's a portal to purity, blending protection with the poetry of presentation.

Food Blister Packaging: A Window to Freshness and FlavorEnter the realm of food blister packaging, where transparent PET film transforms groceries from bulk bins into premium presentations. Thermoformed into bubble-like cavities and heat-sealed to backing cards or foils, these blisters are everywhere—from pharmacy vitamins to supermarket salads—offering a tamper-proof barrier that lets consumers peek inside without compromise.The film's formability is its superpower here. At processing temperatures around 120°C, it deep-draws up to 60 millimeters without thinning below 80% of original gauge, conforming to the nooks of a strawberry cluster or the ridges of a muffin like a custom glove. This precision minimizes headspace, curbing oxidation that turns fresh produce limp; oxygen permeability under 10 cubic centimeters per square meter per day extends shelf life by 50% compared to uncoated alternatives, as evidenced by studies on packaged berries retaining vitamin C levels 20% higher after a week.Vividly, consider a blister of artisanal cheeses: the film's clarity (haze <0.5%) highlights the creamy marbling and subtle veins, enticing shoppers while its puncture resistance—over 150 Newtons—shields against fork pricks or stack crushes in transit. For baked goods like cookies, the mechanical balance prevents crumbling under 50 kg of overhead pressure, arriving bakery-fresh to doorsteps. And in the war on waste, PET's recyclability shines; lightweight blisters reduce packaging mass by 40% versus rigid trays, aligning with zero-waste initiatives that have cut food industry landfill contributions by 15% in recent years.Hygiene is non-negotiable, and PET delivers with surface energies optimized for sterilization—gamma irradiation at 25 kGy leaves it unscathed, ensuring microbial counts stay below 10 colony-forming units per square centimeter. Seal integrity, achieved at 140°C with peel strengths over 5 Newtons per centimeter, creates child-resistant yet user-friendly openings. Challenges like edge cracking during forming are mitigated by edge-trimming techniques, but the payoff is clear: blister packaging boosts product visibility, lifting conversion rates by 25% in visual merchandising tests. From farm-fresh veggies in urban co-ops to exotic spices in global chains, transparent PET film in food blisters isn't just packaging—it's a portal to purity, blending protection with the poetry of presentation. Disposable Cutlery Packaging: Convenience Wrapped in ClarityFast-forward to the hustle of a food truck festival or the calm of a corporate cafeteria, where streams of disposable forks, knives, and spoons demand packaging that's quick to deploy, sanitary, and stackable. Transparent PET film rises to the occasion, often as shrink sleeves or flat pouches that encase sets in a crystal-clear embrace, revealing the utensils' gleam to assure cleanliness at a glance. fingers.

Disposable Cutlery Packaging: Convenience Wrapped in ClarityFast-forward to the hustle of a food truck festival or the calm of a corporate cafeteria, where streams of disposable forks, knives, and spoons demand packaging that's quick to deploy, sanitary, and stackable. Transparent PET film rises to the occasion, often as shrink sleeves or flat pouches that encase sets in a crystal-clear embrace, revealing the utensils' gleam to assure cleanliness at a glance. fingers. Sustainability weaves through every fold: at half the weight of foil laminates, PET wraps trim shipping volumes by 30%, lowering carbon footprints for distributors serving remote islands or high-altitude resorts. Recycled content integration—up to 50% post-consumer resin—doesn't dull its sheen, supporting brands chasing B Corp certifications. In high-traffic spots like airports, where 1,000 units might cycle hourly, the film's thermal endurance prevents softening in summer heatwaves, ensuring consistent performance. Yet, for single-serve ethos, innovations like perforations for easy-tear reduce plastic use by 10%. Transparent PET film in disposable cutlery packaging thus embodies efficiency: a fleeting wrap that delivers lasting convenience, turning mealtime mundanities into seamless rituals.

Sustainability weaves through every fold: at half the weight of foil laminates, PET wraps trim shipping volumes by 30%, lowering carbon footprints for distributors serving remote islands or high-altitude resorts. Recycled content integration—up to 50% post-consumer resin—doesn't dull its sheen, supporting brands chasing B Corp certifications. In high-traffic spots like airports, where 1,000 units might cycle hourly, the film's thermal endurance prevents softening in summer heatwaves, ensuring consistent performance. Yet, for single-serve ethos, innovations like perforations for easy-tear reduce plastic use by 10%. Transparent PET film in disposable cutlery packaging thus embodies efficiency: a fleeting wrap that delivers lasting convenience, turning mealtime mundanities into seamless rituals.  Broader Impacts and Forward GlancesBeyond these triptych applications, transparent PET film's tentacles reach into medical device trays, where its sterilizability supports autoclaving at 134°C, and graphic arts, leveraging its dimensional stability for durable decals on curved surfaces. Automotive interiors benefit from its UV opacity, fading resistance over 1,000 hours of xenon arc exposure.Peering ahead, bio-derived PET from plant sugars could neutralize its fossil fuel roots by 2030, while multilayer extrusions promise oxygen barriers 10 times tighter. Microplastics mitigation via enzymatic breakdowns offers hope against ocean woes. Yet, the film's true legacy? Empowering a sustainable, sightly world—one transparent layer at a time.

Broader Impacts and Forward GlancesBeyond these triptych applications, transparent PET film's tentacles reach into medical device trays, where its sterilizability supports autoclaving at 134°C, and graphic arts, leveraging its dimensional stability for durable decals on curved surfaces. Automotive interiors benefit from its UV opacity, fading resistance over 1,000 hours of xenon arc exposure.Peering ahead, bio-derived PET from plant sugars could neutralize its fossil fuel roots by 2030, while multilayer extrusions promise oxygen barriers 10 times tighter. Microplastics mitigation via enzymatic breakdowns offers hope against ocean woes. Yet, the film's true legacy? Empowering a sustainable, sightly world—one transparent layer at a time.

Introduction: The Unsung Hero of Modern LifePicture this: you're weaving through a crowded farmers' market on a sunny afternoon, your eyes drawn to a vibrant display of plump berries cradled in shimmering, see-through domes that seem to capture the sunlight itself. Or perhaps you're unpacking a sleek new gadget from its protective cocoon, marveling at how the thin layer safeguarding the delicate internals remains pristine despite the journey from factory to your doorstep. In these moments, and countless others, transparent polyethylene terephthalate (PET) film works its quiet magic. This remarkable material, a staple of the packaging world, combines razor-sharp clarity with unyielding toughness, turning ordinary products into eye-catching, secure packages.

Introduction: The Unsung Hero of Modern LifePicture this: you're weaving through a crowded farmers' market on a sunny afternoon, your eyes drawn to a vibrant display of plump berries cradled in shimmering, see-through domes that seem to capture the sunlight itself. Or perhaps you're unpacking a sleek new gadget from its protective cocoon, marveling at how the thin layer safeguarding the delicate internals remains pristine despite the journey from factory to your doorstep. In these moments, and countless others, transparent polyethylene terephthalate (PET) film works its quiet magic. This remarkable material, a staple of the packaging world, combines razor-sharp clarity with unyielding toughness, turning ordinary products into eye-catching, secure packages. Born from the ingenuity of polymer science in the post-World War II era, transparent PET film has grown into a global powerhouse, used in everything from grocery aisles to electronics labs. Its appeal lies in a perfect storm of attributes: optical purity that lets products breathe visually, mechanical resilience that defies daily abuse, and adaptability that spans industries. In a world obsessed with sustainability, convenience, and aesthetics, this film delivers on all fronts—lightweight to cut shipping costs, recyclable to ease environmental burdens, and versatile enough to mold into forms that hug irregular shapes like a second skin.This article peels back the layers (pun intended) on transparent PET film's core properties, then spotlights its starring roles in food blister packaging, disposable cutlery wraps, and anti-static enclosures. Drawing on established material science principles and real-world performance data, we'll paint a vivid picture of how this film doesn't just contain— it elevates, protects, and inspires. By the end, you'll see it not as mere plastic, but as a transformative force shaping how we interact with the goods that define our lives.

Born from the ingenuity of polymer science in the post-World War II era, transparent PET film has grown into a global powerhouse, used in everything from grocery aisles to electronics labs. Its appeal lies in a perfect storm of attributes: optical purity that lets products breathe visually, mechanical resilience that defies daily abuse, and adaptability that spans industries. In a world obsessed with sustainability, convenience, and aesthetics, this film delivers on all fronts—lightweight to cut shipping costs, recyclable to ease environmental burdens, and versatile enough to mold into forms that hug irregular shapes like a second skin.This article peels back the layers (pun intended) on transparent PET film's core properties, then spotlights its starring roles in food blister packaging, disposable cutlery wraps, and anti-static enclosures. Drawing on established material science principles and real-world performance data, we'll paint a vivid picture of how this film doesn't just contain— it elevates, protects, and inspires. By the end, you'll see it not as mere plastic, but as a transformative force shaping how we interact with the goods that define our lives. The Building Blocks: Key Properties That Define ExcellenceTransparent PET film isn't your average sheet of plastic; it's a meticulously engineered product of biaxial orientation, where the raw polymer is stretched in two directions to align its molecular chains like soldiers in formation. This process yields a film that's as clear as window glass but far more forgiving—typically 12 to 50 microns thick, yet capable of withstanding forces that would shatter brittle alternatives.Start with its optical brilliance: boasting light transmittance rates above 90% across the visible spectrum, it scatters less than 1% of light, creating a haze-free view that's ideal for showcasing products. Imagine a jewelry box where each gem sparkles undimmed; that's the level of clarity PET film provides, enhancing perceived value and driving sales in retail settings where first impressions count.Mechanically, it's a beast in lightweight armor. Tensile strength clocks in at over 200 megapascals in both lengthwise and crosswise directions, allowing it to resist elongation under stress without tearing. Drop tests reveal it can endure falls from heights up to 2 meters without puncturing, a boon for e-commerce shipments prone to rough handling. Its modulus of elasticity—around 4 gigapascals—ensures it snaps back to shape after deformation, preventing the warping that plagues lesser films during storage or transport.

The Building Blocks: Key Properties That Define ExcellenceTransparent PET film isn't your average sheet of plastic; it's a meticulously engineered product of biaxial orientation, where the raw polymer is stretched in two directions to align its molecular chains like soldiers in formation. This process yields a film that's as clear as window glass but far more forgiving—typically 12 to 50 microns thick, yet capable of withstanding forces that would shatter brittle alternatives.Start with its optical brilliance: boasting light transmittance rates above 90% across the visible spectrum, it scatters less than 1% of light, creating a haze-free view that's ideal for showcasing products. Imagine a jewelry box where each gem sparkles undimmed; that's the level of clarity PET film provides, enhancing perceived value and driving sales in retail settings where first impressions count.Mechanically, it's a beast in lightweight armor. Tensile strength clocks in at over 200 megapascals in both lengthwise and crosswise directions, allowing it to resist elongation under stress without tearing. Drop tests reveal it can endure falls from heights up to 2 meters without puncturing, a boon for e-commerce shipments prone to rough handling. Its modulus of elasticity—around 4 gigapascals—ensures it snaps back to shape after deformation, preventing the warping that plagues lesser films during storage or transport. Thermal stability adds another layer of reliability. With a glass transition temperature of about 70°C, it remains rigid up to 150°C for short bursts, making it oven-safe for reheating packaged meals, while flexing without cracking down to -40°C. Shrinkage is minimal, under 1% even after prolonged heat exposure, which means labels or seals stay taut and professional-looking over time.Chemically, PET film stands guard like an impermeable moat. Water vapor transmission rates hover below 2 grams per square meter per day, keeping moisture-sensitive items crisp and dry—think of chocolate bars that stay firm in humid summers. It's equally impervious to most oils, greases, and mild acids, with absorption rates under 0.5%, ensuring no leaching or flavor tainting in food contacts. However, it's worth noting its vulnerability to strong bases, which can hydrolyze the ester bonds, a detail chemists leverage in controlled degradation for recycling.Electrically, plain PET acts as an insulator with dielectric strength exceeding 150 kilovolts per millimeter, but variants tuned for anti-static use incorporate coatings that lower surface resistivity to 10^8 ohms per square, bleeding off static charges in seconds. Environmentally, its density of 1.38 grams per cubic centimeter makes it 70% lighter than glass, slashing transport emissions, and its 100% recyclability supports circular economies—global recovery rates for PET now exceed 30%, with sorted streams yielding high-purity regrind for new film.These traits don't operate solo; they synergize. Low friction coefficients (0.3 to 0.5) enable high-speed machinery runs, reducing jams in automated lines, while excellent print receptivity accepts inks and adhesives for vibrant, durable graphics. In essence, transparent PET film's properties form a robust foundation, blending science-backed performance with practical edge, ready to tackle the demands of diverse applications.

Thermal stability adds another layer of reliability. With a glass transition temperature of about 70°C, it remains rigid up to 150°C for short bursts, making it oven-safe for reheating packaged meals, while flexing without cracking down to -40°C. Shrinkage is minimal, under 1% even after prolonged heat exposure, which means labels or seals stay taut and professional-looking over time.Chemically, PET film stands guard like an impermeable moat. Water vapor transmission rates hover below 2 grams per square meter per day, keeping moisture-sensitive items crisp and dry—think of chocolate bars that stay firm in humid summers. It's equally impervious to most oils, greases, and mild acids, with absorption rates under 0.5%, ensuring no leaching or flavor tainting in food contacts. However, it's worth noting its vulnerability to strong bases, which can hydrolyze the ester bonds, a detail chemists leverage in controlled degradation for recycling.Electrically, plain PET acts as an insulator with dielectric strength exceeding 150 kilovolts per millimeter, but variants tuned for anti-static use incorporate coatings that lower surface resistivity to 10^8 ohms per square, bleeding off static charges in seconds. Environmentally, its density of 1.38 grams per cubic centimeter makes it 70% lighter than glass, slashing transport emissions, and its 100% recyclability supports circular economies—global recovery rates for PET now exceed 30%, with sorted streams yielding high-purity regrind for new film.These traits don't operate solo; they synergize. Low friction coefficients (0.3 to 0.5) enable high-speed machinery runs, reducing jams in automated lines, while excellent print receptivity accepts inks and adhesives for vibrant, durable graphics. In essence, transparent PET film's properties form a robust foundation, blending science-backed performance with practical edge, ready to tackle the demands of diverse applications. Food Blister Packaging: A Window to Freshness and FlavorEnter the realm of food blister packaging, where transparent PET film transforms groceries from bulk bins into premium presentations. Thermoformed into bubble-like cavities and heat-sealed to backing cards or foils, these blisters are everywhere—from pharmacy vitamins to supermarket salads—offering a tamper-proof barrier that lets consumers peek inside without compromise.The film's formability is its superpower here. At processing temperatures around 120°C, it deep-draws up to 60 millimeters without thinning below 80% of original gauge, conforming to the nooks of a strawberry cluster or the ridges of a muffin like a custom glove. This precision minimizes headspace, curbing oxidation that turns fresh produce limp; oxygen permeability under 10 cubic centimeters per square meter per day extends shelf life by 50% compared to uncoated alternatives, as evidenced by studies on packaged berries retaining vitamin C levels 20% higher after a week.Vividly, consider a blister of artisanal cheeses: the film's clarity (haze <0.5%) highlights the creamy marbling and subtle veins, enticing shoppers while its puncture resistance—over 150 Newtons—shields against fork pricks or stack crushes in transit. For baked goods like cookies, the mechanical balance prevents crumbling under 50 kg of overhead pressure, arriving bakery-fresh to doorsteps. And in the war on waste, PET's recyclability shines; lightweight blisters reduce packaging mass by 40% versus rigid trays, aligning with zero-waste initiatives that have cut food industry landfill contributions by 15% in recent years.Hygiene is non-negotiable, and PET delivers with surface energies optimized for sterilization—gamma irradiation at 25 kGy leaves it unscathed, ensuring microbial counts stay below 10 colony-forming units per square centimeter. Seal integrity, achieved at 140°C with peel strengths over 5 Newtons per centimeter, creates child-resistant yet user-friendly openings. Challenges like edge cracking during forming are mitigated by edge-trimming techniques, but the payoff is clear: blister packaging boosts product visibility, lifting conversion rates by 25% in visual merchandising tests. From farm-fresh veggies in urban co-ops to exotic spices in global chains, transparent PET film in food blisters isn't just packaging—it's a portal to purity, blending protection with the poetry of presentation.

Food Blister Packaging: A Window to Freshness and FlavorEnter the realm of food blister packaging, where transparent PET film transforms groceries from bulk bins into premium presentations. Thermoformed into bubble-like cavities and heat-sealed to backing cards or foils, these blisters are everywhere—from pharmacy vitamins to supermarket salads—offering a tamper-proof barrier that lets consumers peek inside without compromise.The film's formability is its superpower here. At processing temperatures around 120°C, it deep-draws up to 60 millimeters without thinning below 80% of original gauge, conforming to the nooks of a strawberry cluster or the ridges of a muffin like a custom glove. This precision minimizes headspace, curbing oxidation that turns fresh produce limp; oxygen permeability under 10 cubic centimeters per square meter per day extends shelf life by 50% compared to uncoated alternatives, as evidenced by studies on packaged berries retaining vitamin C levels 20% higher after a week.Vividly, consider a blister of artisanal cheeses: the film's clarity (haze <0.5%) highlights the creamy marbling and subtle veins, enticing shoppers while its puncture resistance—over 150 Newtons—shields against fork pricks or stack crushes in transit. For baked goods like cookies, the mechanical balance prevents crumbling under 50 kg of overhead pressure, arriving bakery-fresh to doorsteps. And in the war on waste, PET's recyclability shines; lightweight blisters reduce packaging mass by 40% versus rigid trays, aligning with zero-waste initiatives that have cut food industry landfill contributions by 15% in recent years.Hygiene is non-negotiable, and PET delivers with surface energies optimized for sterilization—gamma irradiation at 25 kGy leaves it unscathed, ensuring microbial counts stay below 10 colony-forming units per square centimeter. Seal integrity, achieved at 140°C with peel strengths over 5 Newtons per centimeter, creates child-resistant yet user-friendly openings. Challenges like edge cracking during forming are mitigated by edge-trimming techniques, but the payoff is clear: blister packaging boosts product visibility, lifting conversion rates by 25% in visual merchandising tests. From farm-fresh veggies in urban co-ops to exotic spices in global chains, transparent PET film in food blisters isn't just packaging—it's a portal to purity, blending protection with the poetry of presentation. Disposable Cutlery Packaging: Convenience Wrapped in ClarityFast-forward to the hustle of a food truck festival or the calm of a corporate cafeteria, where streams of disposable forks, knives, and spoons demand packaging that's quick to deploy, sanitary, and stackable. Transparent PET film rises to the occasion, often as shrink sleeves or flat pouches that encase sets in a crystal-clear embrace, revealing the utensils' gleam to assure cleanliness at a glance. fingers.

Disposable Cutlery Packaging: Convenience Wrapped in ClarityFast-forward to the hustle of a food truck festival or the calm of a corporate cafeteria, where streams of disposable forks, knives, and spoons demand packaging that's quick to deploy, sanitary, and stackable. Transparent PET film rises to the occasion, often as shrink sleeves or flat pouches that encase sets in a crystal-clear embrace, revealing the utensils' gleam to assure cleanliness at a glance. fingers. Sustainability weaves through every fold: at half the weight of foil laminates, PET wraps trim shipping volumes by 30%, lowering carbon footprints for distributors serving remote islands or high-altitude resorts. Recycled content integration—up to 50% post-consumer resin—doesn't dull its sheen, supporting brands chasing B Corp certifications. In high-traffic spots like airports, where 1,000 units might cycle hourly, the film's thermal endurance prevents softening in summer heatwaves, ensuring consistent performance. Yet, for single-serve ethos, innovations like perforations for easy-tear reduce plastic use by 10%. Transparent PET film in disposable cutlery packaging thus embodies efficiency: a fleeting wrap that delivers lasting convenience, turning mealtime mundanities into seamless rituals.

Sustainability weaves through every fold: at half the weight of foil laminates, PET wraps trim shipping volumes by 30%, lowering carbon footprints for distributors serving remote islands or high-altitude resorts. Recycled content integration—up to 50% post-consumer resin—doesn't dull its sheen, supporting brands chasing B Corp certifications. In high-traffic spots like airports, where 1,000 units might cycle hourly, the film's thermal endurance prevents softening in summer heatwaves, ensuring consistent performance. Yet, for single-serve ethos, innovations like perforations for easy-tear reduce plastic use by 10%. Transparent PET film in disposable cutlery packaging thus embodies efficiency: a fleeting wrap that delivers lasting convenience, turning mealtime mundanities into seamless rituals.  Broader Impacts and Forward GlancesBeyond these triptych applications, transparent PET film's tentacles reach into medical device trays, where its sterilizability supports autoclaving at 134°C, and graphic arts, leveraging its dimensional stability for durable decals on curved surfaces. Automotive interiors benefit from its UV opacity, fading resistance over 1,000 hours of xenon arc exposure.Peering ahead, bio-derived PET from plant sugars could neutralize its fossil fuel roots by 2030, while multilayer extrusions promise oxygen barriers 10 times tighter. Microplastics mitigation via enzymatic breakdowns offers hope against ocean woes. Yet, the film's true legacy? Empowering a sustainable, sightly world—one transparent layer at a time.

Broader Impacts and Forward GlancesBeyond these triptych applications, transparent PET film's tentacles reach into medical device trays, where its sterilizability supports autoclaving at 134°C, and graphic arts, leveraging its dimensional stability for durable decals on curved surfaces. Automotive interiors benefit from its UV opacity, fading resistance over 1,000 hours of xenon arc exposure.Peering ahead, bio-derived PET from plant sugars could neutralize its fossil fuel roots by 2030, while multilayer extrusions promise oxygen barriers 10 times tighter. Microplastics mitigation via enzymatic breakdowns offers hope against ocean woes. Yet, the film's true legacy? Empowering a sustainable, sightly world—one transparent layer at a time.

Get the latest price? We'll respond as soon as possible(within 12 hours)