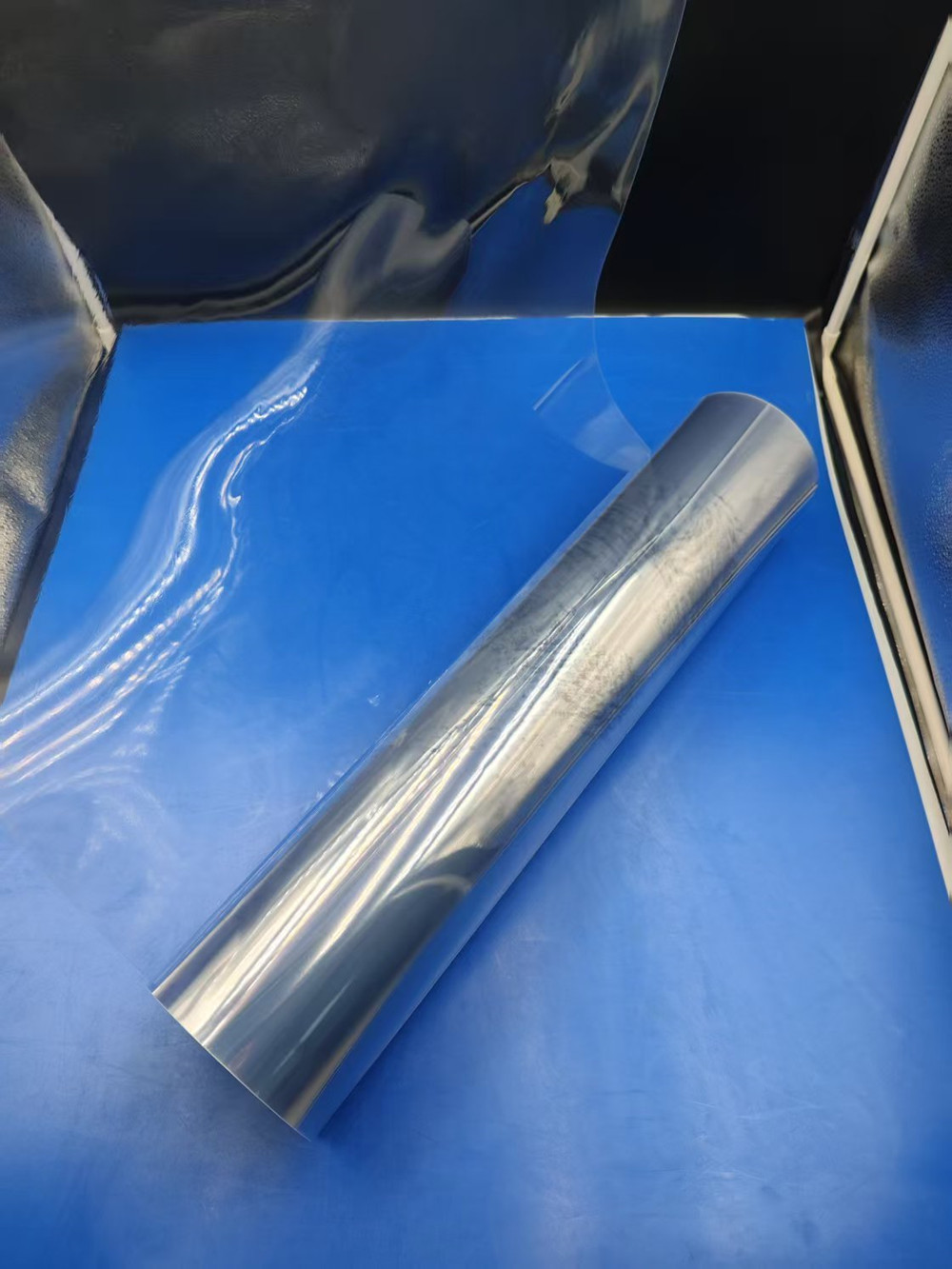

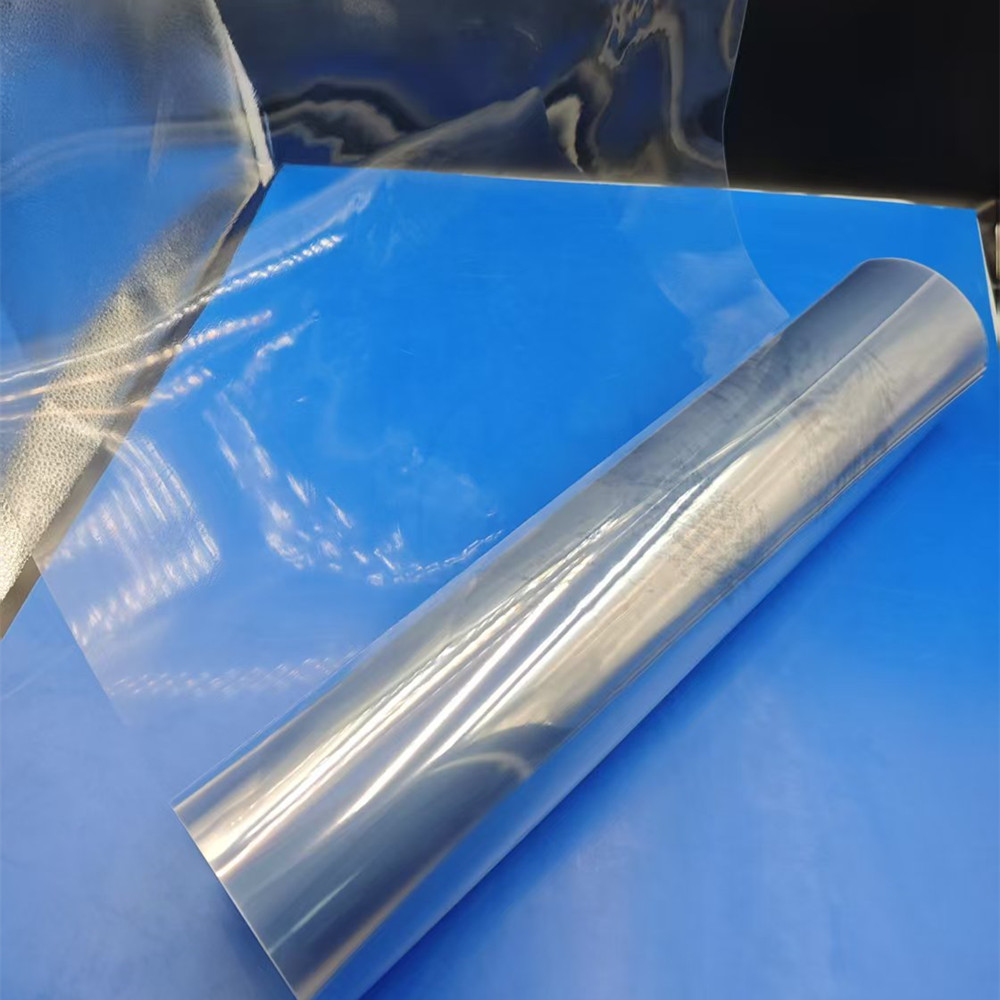

PVC thermoplastic product

2026-01-07 16:50PVC Sheet

Key Features

- Superior Physical PropertiesBoasts high tensile strength and dimensional stability, ensuring minimal deformation under ambient and moderate temperature conditions. Its smooth, uniform surface enables excellent printing, laminating, and bonding effects, ideal for customized surface treatments.

- Strong Chemical ResistanceResists corrosion from most acids, alkalis, and organic solvents (excluding strong oxidants), making it suitable for chemical storage, laboratory equipment, and industrial component manufacturing.

- Versatile ProcessabilityEasy to cut, punch, bend, and thermoform into complex shapes without cracking. Compatible with common processing techniques such as CNC routing, ultrasonic welding, and vacuum forming, meeting diverse production needs.

- Customizable Specifications

Thickness: 0.2–10 mm (customizable for special requirements)

Width: Max 1500 mm (roll or sheet form available)

Color: Transparent, white, black, or customized RAL/Pantone colors

Surface Finish: Glossy, matte, embossed (wood grain, diamond pattern, etc.)

Typical Applications

Packaging Industry: Blister packaging for electronics, toys, and hardware; rigid packaging boxes with high structural strength.

Construction Sector: Wall panels, ceiling tiles, window and door frames, decorative profiles, offering fire retardancy and weather resistance.

Advertising & Signage: UV printing boards, display stands, light boxes, with excellent light transmittance for clear imaging.

Industrial Components: Machine guards, chemical tank liners, insulation panels, electrical enclosures due to its insulating properties.