PVC Wearing Layer Film: The Invisible Armor That Shapes Modern Surfaces

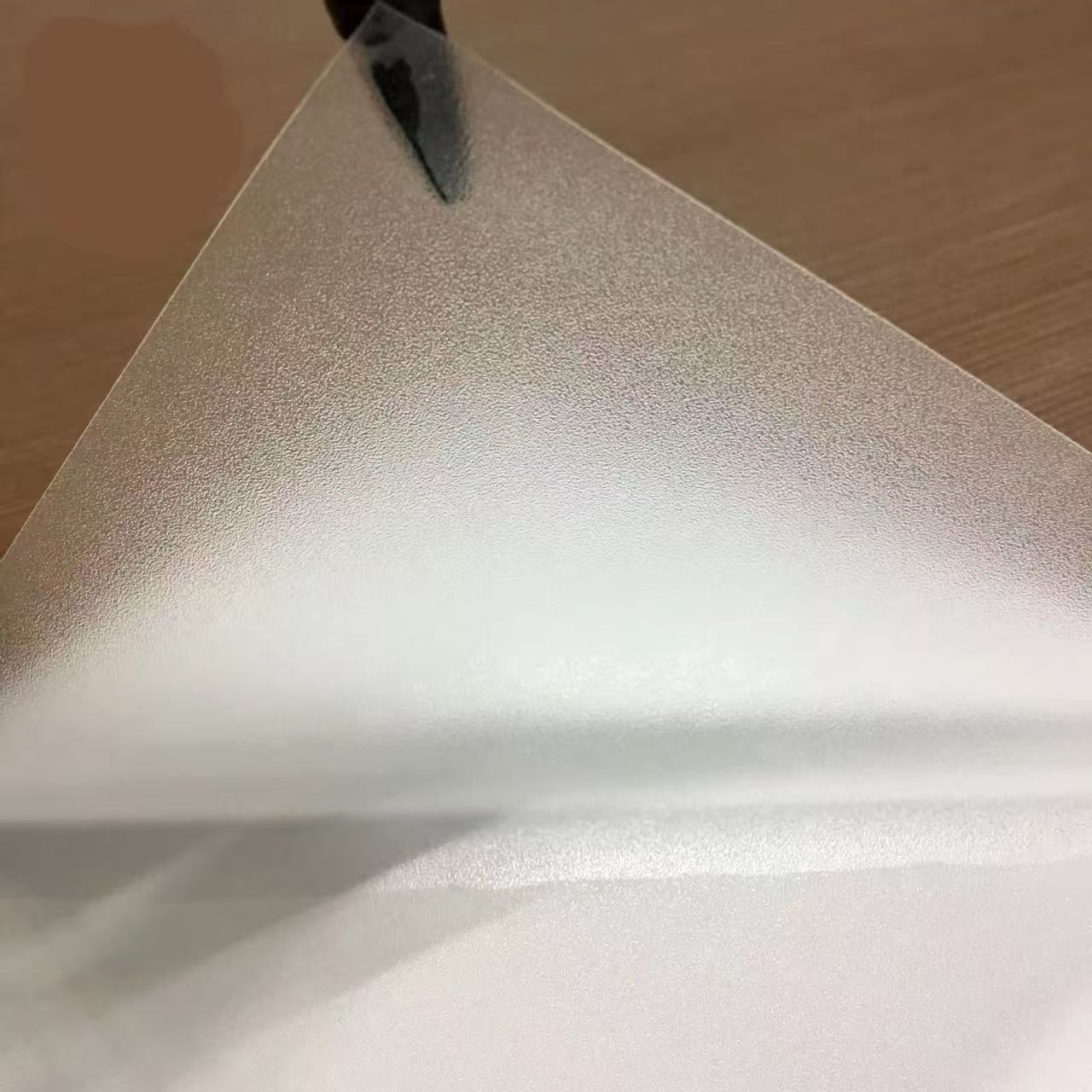

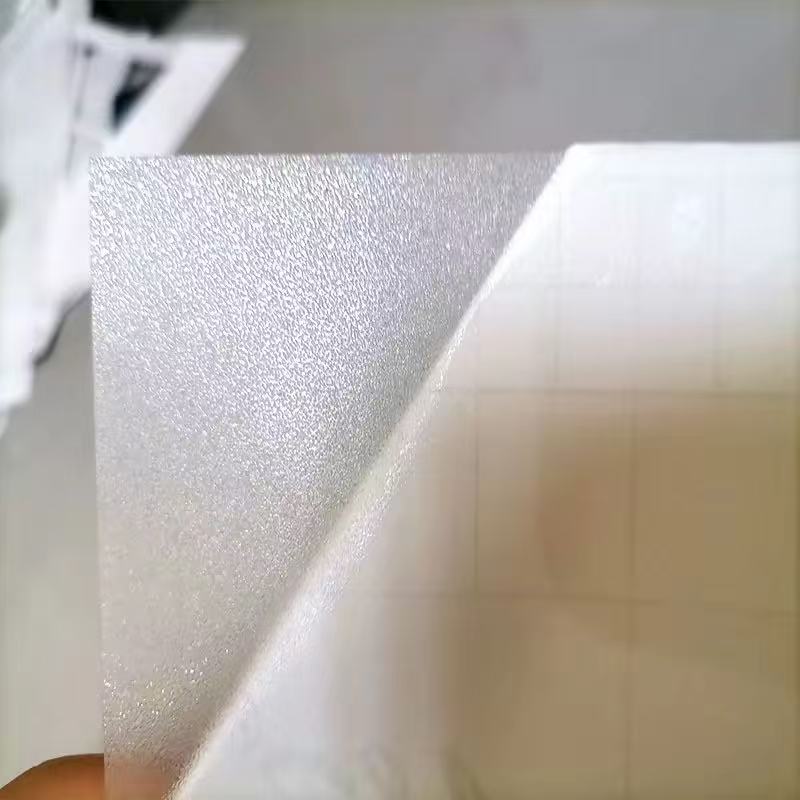

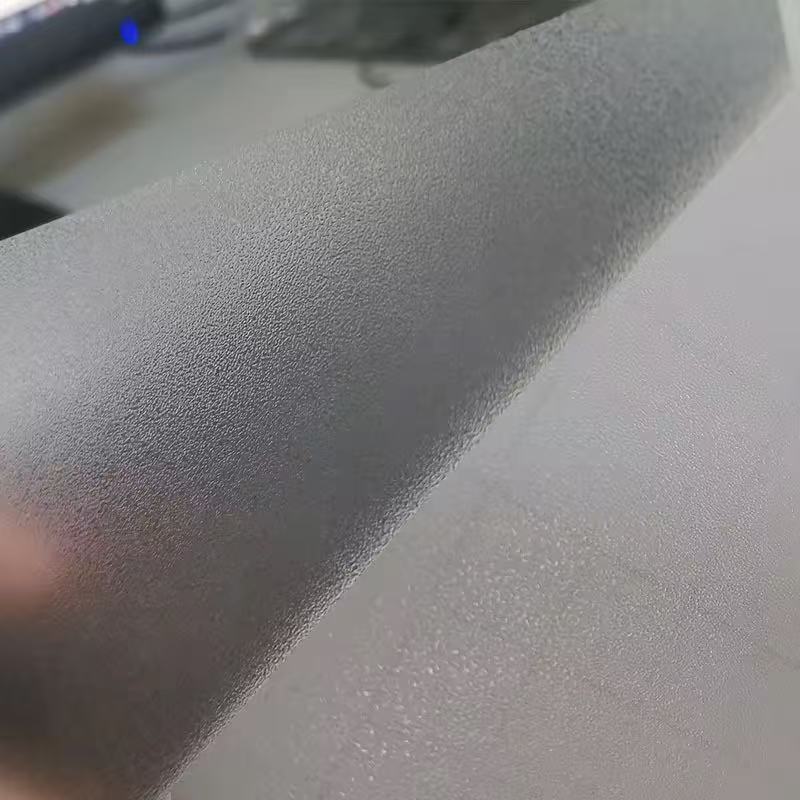

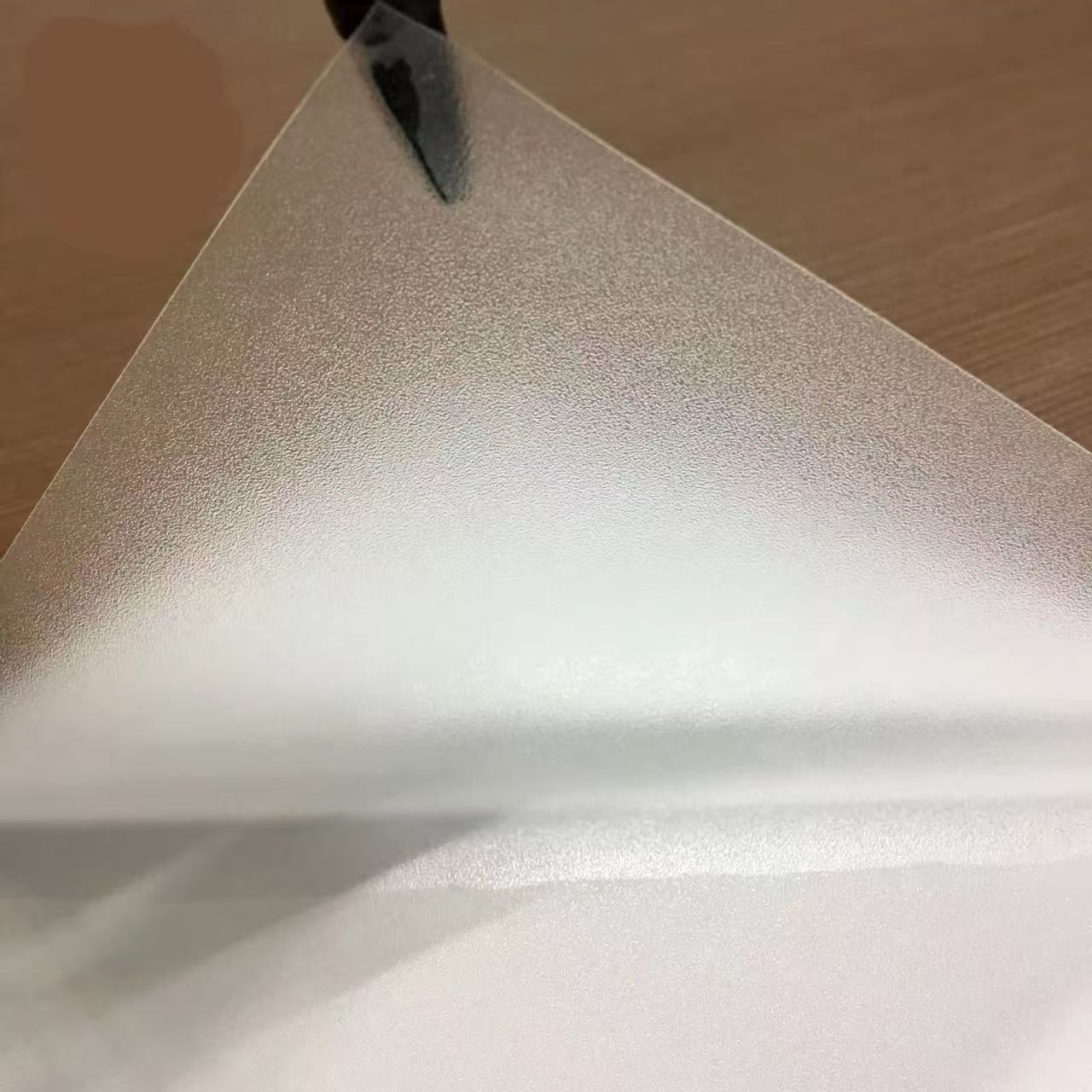

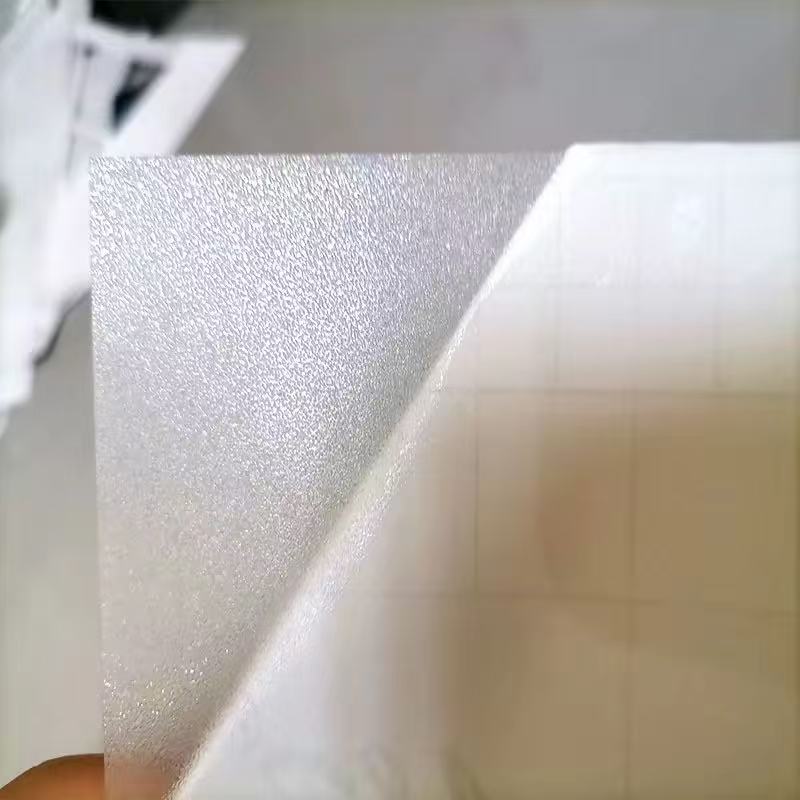

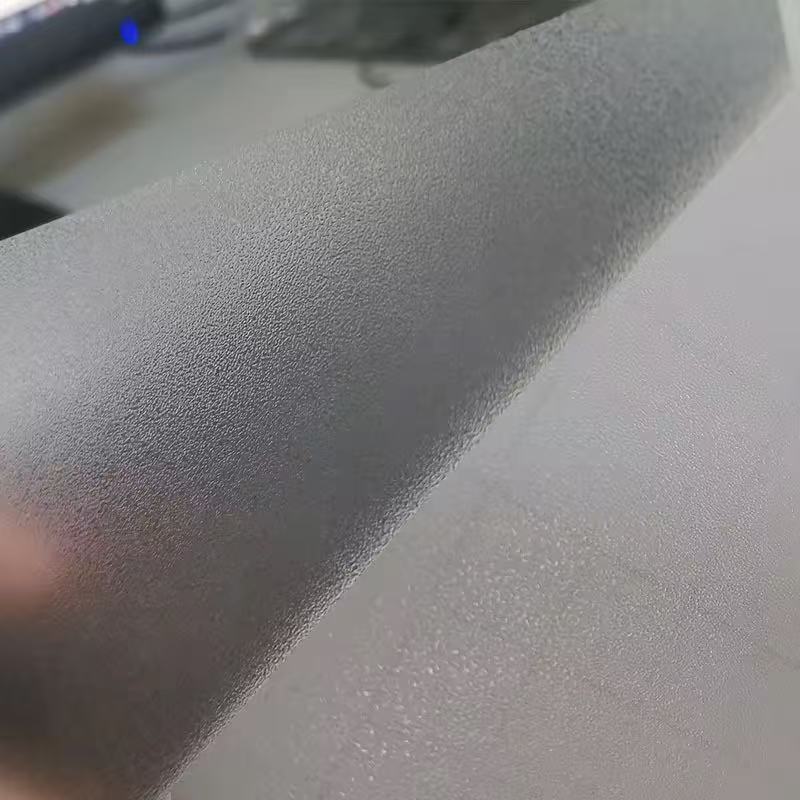

2025-11-18 13:45 PVC Wearing Layer Film: The Invisible Armor That Shapes Modern Surfaces KeywordsPVC wearing layer film, abrasion resistance, UV stabilization, high-definition printability, multi-surface protectionPVC wearing layer film is the unsung hero of modern decorative and protective surfaces. It is a thin, transparent or semi-transparent PVC film, typically 0.07 mm to 0.70 mm thick, that is deliberately engineered to take the punishment so the beautiful layer underneath never has to. Think of it as the sacrificial shield that stands between daily life and the decorative design beneath it. Where ordinary PVC film would scratch, yellow, stain, or wear through, or fade, a properly formulated wearing layer film laughs at the abuse and keeps looking pristine for years. The single most important property of any wearing layer film is, unsurprisingly, abrasion resistance. High-quality wearing layers achieve Taber abrasion values exceeding 20,000–50,000 revolutions (CS-17 wheel, 1000 g load) without visible damage. This is not marketing hype; it is achieved through a combination of highly plasticized but cross-linked PVC resin, ultra-fine aluminum oxide (Al₂O₃) particles distributed throughout the film, and ceramic or nanoceramic bead reinforcement in premium grades. The aluminum oxide particles act like microscopic ball bearings that deflect and distribute impact energy while the hardest ones (Mohs 9) resist cutting and gouging. The result is a surface that can withstand steel-wool scouring, high-heel traffic, shopping-cart wheels, and children dragging toys across it day after day.

The single most important property of any wearing layer film is, unsurprisingly, abrasion resistance. High-quality wearing layers achieve Taber abrasion values exceeding 20,000–50,000 revolutions (CS-17 wheel, 1000 g load) without visible damage. This is not marketing hype; it is achieved through a combination of highly plasticized but cross-linked PVC resin, ultra-fine aluminum oxide (Al₂O₃) particles distributed throughout the film, and ceramic or nanoceramic bead reinforcement in premium grades. The aluminum oxide particles act like microscopic ball bearings that deflect and distribute impact energy while the hardest ones (Mohs 9) resist cutting and gouging. The result is a surface that can withstand steel-wool scouring, high-heel traffic, shopping-cart wheels, and children dragging toys across it day after day. UV stability is equally critical. Cheap PVC yellows and becomes brittle within months of sunlight exposure because of photodegradation of the polymer chains and migration of plasticizers. Modern wearing layer films incorporate hindered amine light stabilizers (HALS), benzotriazole or benzophenone UV absorbers, and titanium dioxide rutile-grade pigments that block 99% of UV-A and UV-B radiation. Independent Xenon arc weathering tests (ISO 4892-2, Method A, 3000–5000 hours) show premium wearing layers retain more than 95% gloss and ΔE < 2 color change after the equivalent of 8–10 years of south-facing vertical exposure in Florida. This is why luxury vinyl flooring installed in sun-drenched atriums still looks brand new a decade later.Chemical and stain resistance is another battlefield where wearing layer films excel. The surface is formulated to be non-porous and slightly hydrophobic. Common household stains—ketchup, red wine, mustard, iodine, shoe polish, permanent marker, and even hair dye—can be wiped away with just a damp cloth if cleaned within 24 hours. In commercial settings, the same film resists disinfectants, quaternary ammonium compounds, and 70% isopropyl alcohol without clouding or softening. Hospitals and schools regularly specify 0.50 mm or 0.70 mm wearing layers precisely because they survive aggressive cleaning protocols that would destroy ordinary vinyl surfaces.

UV stability is equally critical. Cheap PVC yellows and becomes brittle within months of sunlight exposure because of photodegradation of the polymer chains and migration of plasticizers. Modern wearing layer films incorporate hindered amine light stabilizers (HALS), benzotriazole or benzophenone UV absorbers, and titanium dioxide rutile-grade pigments that block 99% of UV-A and UV-B radiation. Independent Xenon arc weathering tests (ISO 4892-2, Method A, 3000–5000 hours) show premium wearing layers retain more than 95% gloss and ΔE < 2 color change after the equivalent of 8–10 years of south-facing vertical exposure in Florida. This is why luxury vinyl flooring installed in sun-drenched atriums still looks brand new a decade later.Chemical and stain resistance is another battlefield where wearing layer films excel. The surface is formulated to be non-porous and slightly hydrophobic. Common household stains—ketchup, red wine, mustard, iodine, shoe polish, permanent marker, and even hair dye—can be wiped away with just a damp cloth if cleaned within 24 hours. In commercial settings, the same film resists disinfectants, quaternary ammonium compounds, and 70% isopropyl alcohol without clouding or softening. Hospitals and schools regularly specify 0.50 mm or 0.70 mm wearing layers precisely because they survive aggressive cleaning protocols that would destroy ordinary vinyl surfaces. Printability has transformed wearing layer film from a mere protective layer into a design enabler. Modern films are corona-treated or coated with a digital-print primer that allows UV, latex, and solvent inks to achieve adhesion values of 5B on cross-hatch tests. The film’s perfectly smooth surface and controlled surface energy (38–44 dynes/cm) produce dot gains comparable to coated paper, delivering photographic realism at 1440 dpi. Wood grains show authentic tick marks and cathedral patterns; stone reproductions display realistic veining and microcracks; abstract designs pop with metallic and pearlescent effects. Because the wearing layer is applied on top of the printed decorative film, the colors never touch the floor—only the tough wearing layer does—ensuring the design remains vibrant for the entire service life of the product.Wallpaper and Wall Panel ApplicationsIn digital wallpaper production, 0.15–0.30 mm wearing layer film is laminated over the printed PVC or non-woven substrate immediately after printing. This over-laminate provides scrubability ratings of Class 4–5 (EN 12956), meaning the wallpaper can be washed repeatedly with mild detergent without fading or delamination. High-end contract wallcoverings in hotels and hospitals now routinely achieve 100,000+ scrub cycles. The wearing layer also adds a subtle texture—matte, satin, gloss, or 3D embossed—that completely changes the tactile experience of the wall. A matte wearing layer makes a bold geometric print feel soft and contemporary; a high-gloss layer turns a simple woodgrain into a luxurious lacquered panel.

Printability has transformed wearing layer film from a mere protective layer into a design enabler. Modern films are corona-treated or coated with a digital-print primer that allows UV, latex, and solvent inks to achieve adhesion values of 5B on cross-hatch tests. The film’s perfectly smooth surface and controlled surface energy (38–44 dynes/cm) produce dot gains comparable to coated paper, delivering photographic realism at 1440 dpi. Wood grains show authentic tick marks and cathedral patterns; stone reproductions display realistic veining and microcracks; abstract designs pop with metallic and pearlescent effects. Because the wearing layer is applied on top of the printed decorative film, the colors never touch the floor—only the tough wearing layer does—ensuring the design remains vibrant for the entire service life of the product.Wallpaper and Wall Panel ApplicationsIn digital wallpaper production, 0.15–0.30 mm wearing layer film is laminated over the printed PVC or non-woven substrate immediately after printing. This over-laminate provides scrubability ratings of Class 4–5 (EN 12956), meaning the wallpaper can be washed repeatedly with mild detergent without fading or delamination. High-end contract wallcoverings in hotels and hospitals now routinely achieve 100,000+ scrub cycles. The wearing layer also adds a subtle texture—matte, satin, gloss, or 3D embossed—that completely changes the tactile experience of the wall. A matte wearing layer makes a bold geometric print feel soft and contemporary; a high-gloss layer turns a simple woodgrain into a luxurious lacquered panel. For PVC wall panels (commonly used in bathrooms, kitchens, and commercial interiors), the wearing layer is hot-roll laminated during the extrusion process. The result is a completely waterproof, impact-resistant panel that can be installed directly in wet zones. Unlike ceramic tiles, these panels have no grout lines to harbor mold, and the wearing layer prevents chipping and scratching during installation and daily use. Many manufacturers now offer 0.50 mm wearing layers on wall panels specifically for healthcare environments where infection control and durability are non-negotiable.

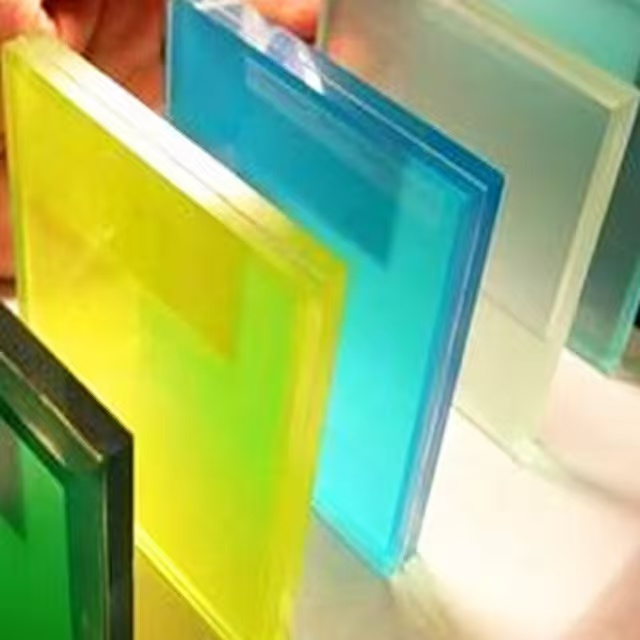

For PVC wall panels (commonly used in bathrooms, kitchens, and commercial interiors), the wearing layer is hot-roll laminated during the extrusion process. The result is a completely waterproof, impact-resistant panel that can be installed directly in wet zones. Unlike ceramic tiles, these panels have no grout lines to harbor mold, and the wearing layer prevents chipping and scratching during installation and daily use. Many manufacturers now offer 0.50 mm wearing layers on wall panels specifically for healthcare environments where infection control and durability are non-negotiable. Luxury Vinyl Flooring (LVT, SPC, WPC)This is where PVC wearing layer film truly shines. In rigid-core flooring (SPC), the typical construction is:

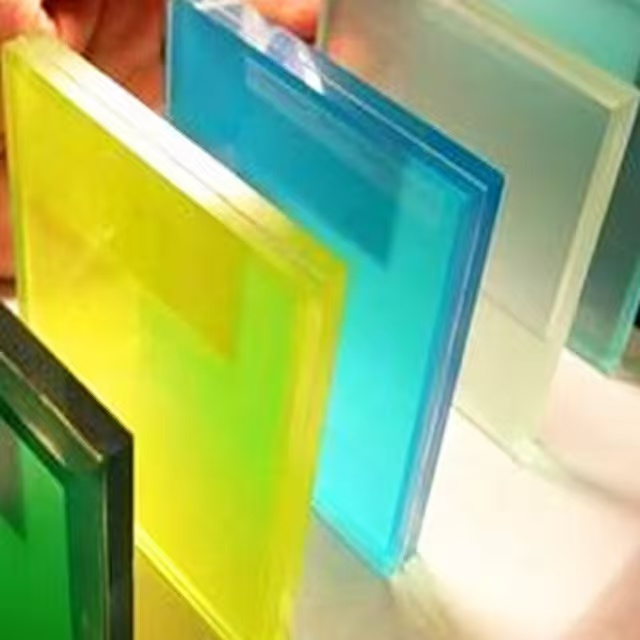

Luxury Vinyl Flooring (LVT, SPC, WPC)This is where PVC wearing layer film truly shines. In rigid-core flooring (SPC), the typical construction is:  Floor Graphics and Wayfinding SignageIn retail stores, museums, and airports, high-tack 0.30–0.50 mm wearing layer films are digitally printed and applied directly to floors as directional graphics, promotional messages, or social-distancing markers. These films conform to textured tiles, withstand floor polishers, and achieve slip ratings of R10–R11 even when wet. The aluminum oxide particles in the wearing layer provide both durability and anti-slip micro-texture. Many major European retailers report that floor graphics with 0.50 mm wearing layers last 3–5 years in high-traffic areas, compared to just 3–6 months for standard vinyl stickers.

Floor Graphics and Wayfinding SignageIn retail stores, museums, and airports, high-tack 0.30–0.50 mm wearing layer films are digitally printed and applied directly to floors as directional graphics, promotional messages, or social-distancing markers. These films conform to textured tiles, withstand floor polishers, and achieve slip ratings of R10–R11 even when wet. The aluminum oxide particles in the wearing layer provide both durability and anti-slip micro-texture. Many major European retailers report that floor graphics with 0.50 mm wearing layers last 3–5 years in high-traffic areas, compared to just 3–6 months for standard vinyl stickers. Automotive and Marine ApplicationsThe same wearing layer technology has migrated into vehicle interiors (dashboard overlays, door panel inserts) and yacht decking, where it resists saltwater, suntan lotion, fish blood, and constant flexing. Some marine-grade wearing layers incorporate antimicrobial silver ions that achieve 99.9% reduction of Staphylococcus aureus and E. coli according to ISO 22196.PVC wearing layer film has evolved from a simple protective overlay into a sophisticated multifunctional material that combines extreme durability with optical clarity and design freedom. It is the reason why today’s vinyl surfaces can look like real oak, marble, or hand-painted murals while surviving conditions that would destroy the genuine materials in weeks. Every time you walk across a hyper-realistic wood-look floor that still looks perfect after ten years later, or wipe red wine off a wallpaper without leaving a mark, you are experiencing the quiet triumph of PVC wearing layer film—the invisible armor that makes modern beauty possible.

Automotive and Marine ApplicationsThe same wearing layer technology has migrated into vehicle interiors (dashboard overlays, door panel inserts) and yacht decking, where it resists saltwater, suntan lotion, fish blood, and constant flexing. Some marine-grade wearing layers incorporate antimicrobial silver ions that achieve 99.9% reduction of Staphylococcus aureus and E. coli according to ISO 22196.PVC wearing layer film has evolved from a simple protective overlay into a sophisticated multifunctional material that combines extreme durability with optical clarity and design freedom. It is the reason why today’s vinyl surfaces can look like real oak, marble, or hand-painted murals while surviving conditions that would destroy the genuine materials in weeks. Every time you walk across a hyper-realistic wood-look floor that still looks perfect after ten years later, or wipe red wine off a wallpaper without leaving a mark, you are experiencing the quiet triumph of PVC wearing layer film—the invisible armor that makes modern beauty possible.

The single most important property of any wearing layer film is, unsurprisingly, abrasion resistance. High-quality wearing layers achieve Taber abrasion values exceeding 20,000–50,000 revolutions (CS-17 wheel, 1000 g load) without visible damage. This is not marketing hype; it is achieved through a combination of highly plasticized but cross-linked PVC resin, ultra-fine aluminum oxide (Al₂O₃) particles distributed throughout the film, and ceramic or nanoceramic bead reinforcement in premium grades. The aluminum oxide particles act like microscopic ball bearings that deflect and distribute impact energy while the hardest ones (Mohs 9) resist cutting and gouging. The result is a surface that can withstand steel-wool scouring, high-heel traffic, shopping-cart wheels, and children dragging toys across it day after day.

The single most important property of any wearing layer film is, unsurprisingly, abrasion resistance. High-quality wearing layers achieve Taber abrasion values exceeding 20,000–50,000 revolutions (CS-17 wheel, 1000 g load) without visible damage. This is not marketing hype; it is achieved through a combination of highly plasticized but cross-linked PVC resin, ultra-fine aluminum oxide (Al₂O₃) particles distributed throughout the film, and ceramic or nanoceramic bead reinforcement in premium grades. The aluminum oxide particles act like microscopic ball bearings that deflect and distribute impact energy while the hardest ones (Mohs 9) resist cutting and gouging. The result is a surface that can withstand steel-wool scouring, high-heel traffic, shopping-cart wheels, and children dragging toys across it day after day. UV stability is equally critical. Cheap PVC yellows and becomes brittle within months of sunlight exposure because of photodegradation of the polymer chains and migration of plasticizers. Modern wearing layer films incorporate hindered amine light stabilizers (HALS), benzotriazole or benzophenone UV absorbers, and titanium dioxide rutile-grade pigments that block 99% of UV-A and UV-B radiation. Independent Xenon arc weathering tests (ISO 4892-2, Method A, 3000–5000 hours) show premium wearing layers retain more than 95% gloss and ΔE < 2 color change after the equivalent of 8–10 years of south-facing vertical exposure in Florida. This is why luxury vinyl flooring installed in sun-drenched atriums still looks brand new a decade later.Chemical and stain resistance is another battlefield where wearing layer films excel. The surface is formulated to be non-porous and slightly hydrophobic. Common household stains—ketchup, red wine, mustard, iodine, shoe polish, permanent marker, and even hair dye—can be wiped away with just a damp cloth if cleaned within 24 hours. In commercial settings, the same film resists disinfectants, quaternary ammonium compounds, and 70% isopropyl alcohol without clouding or softening. Hospitals and schools regularly specify 0.50 mm or 0.70 mm wearing layers precisely because they survive aggressive cleaning protocols that would destroy ordinary vinyl surfaces.

UV stability is equally critical. Cheap PVC yellows and becomes brittle within months of sunlight exposure because of photodegradation of the polymer chains and migration of plasticizers. Modern wearing layer films incorporate hindered amine light stabilizers (HALS), benzotriazole or benzophenone UV absorbers, and titanium dioxide rutile-grade pigments that block 99% of UV-A and UV-B radiation. Independent Xenon arc weathering tests (ISO 4892-2, Method A, 3000–5000 hours) show premium wearing layers retain more than 95% gloss and ΔE < 2 color change after the equivalent of 8–10 years of south-facing vertical exposure in Florida. This is why luxury vinyl flooring installed in sun-drenched atriums still looks brand new a decade later.Chemical and stain resistance is another battlefield where wearing layer films excel. The surface is formulated to be non-porous and slightly hydrophobic. Common household stains—ketchup, red wine, mustard, iodine, shoe polish, permanent marker, and even hair dye—can be wiped away with just a damp cloth if cleaned within 24 hours. In commercial settings, the same film resists disinfectants, quaternary ammonium compounds, and 70% isopropyl alcohol without clouding or softening. Hospitals and schools regularly specify 0.50 mm or 0.70 mm wearing layers precisely because they survive aggressive cleaning protocols that would destroy ordinary vinyl surfaces. Printability has transformed wearing layer film from a mere protective layer into a design enabler. Modern films are corona-treated or coated with a digital-print primer that allows UV, latex, and solvent inks to achieve adhesion values of 5B on cross-hatch tests. The film’s perfectly smooth surface and controlled surface energy (38–44 dynes/cm) produce dot gains comparable to coated paper, delivering photographic realism at 1440 dpi. Wood grains show authentic tick marks and cathedral patterns; stone reproductions display realistic veining and microcracks; abstract designs pop with metallic and pearlescent effects. Because the wearing layer is applied on top of the printed decorative film, the colors never touch the floor—only the tough wearing layer does—ensuring the design remains vibrant for the entire service life of the product.Wallpaper and Wall Panel ApplicationsIn digital wallpaper production, 0.15–0.30 mm wearing layer film is laminated over the printed PVC or non-woven substrate immediately after printing. This over-laminate provides scrubability ratings of Class 4–5 (EN 12956), meaning the wallpaper can be washed repeatedly with mild detergent without fading or delamination. High-end contract wallcoverings in hotels and hospitals now routinely achieve 100,000+ scrub cycles. The wearing layer also adds a subtle texture—matte, satin, gloss, or 3D embossed—that completely changes the tactile experience of the wall. A matte wearing layer makes a bold geometric print feel soft and contemporary; a high-gloss layer turns a simple woodgrain into a luxurious lacquered panel.

Printability has transformed wearing layer film from a mere protective layer into a design enabler. Modern films are corona-treated or coated with a digital-print primer that allows UV, latex, and solvent inks to achieve adhesion values of 5B on cross-hatch tests. The film’s perfectly smooth surface and controlled surface energy (38–44 dynes/cm) produce dot gains comparable to coated paper, delivering photographic realism at 1440 dpi. Wood grains show authentic tick marks and cathedral patterns; stone reproductions display realistic veining and microcracks; abstract designs pop with metallic and pearlescent effects. Because the wearing layer is applied on top of the printed decorative film, the colors never touch the floor—only the tough wearing layer does—ensuring the design remains vibrant for the entire service life of the product.Wallpaper and Wall Panel ApplicationsIn digital wallpaper production, 0.15–0.30 mm wearing layer film is laminated over the printed PVC or non-woven substrate immediately after printing. This over-laminate provides scrubability ratings of Class 4–5 (EN 12956), meaning the wallpaper can be washed repeatedly with mild detergent without fading or delamination. High-end contract wallcoverings in hotels and hospitals now routinely achieve 100,000+ scrub cycles. The wearing layer also adds a subtle texture—matte, satin, gloss, or 3D embossed—that completely changes the tactile experience of the wall. A matte wearing layer makes a bold geometric print feel soft and contemporary; a high-gloss layer turns a simple woodgrain into a luxurious lacquered panel. For PVC wall panels (commonly used in bathrooms, kitchens, and commercial interiors), the wearing layer is hot-roll laminated during the extrusion process. The result is a completely waterproof, impact-resistant panel that can be installed directly in wet zones. Unlike ceramic tiles, these panels have no grout lines to harbor mold, and the wearing layer prevents chipping and scratching during installation and daily use. Many manufacturers now offer 0.50 mm wearing layers on wall panels specifically for healthcare environments where infection control and durability are non-negotiable.

For PVC wall panels (commonly used in bathrooms, kitchens, and commercial interiors), the wearing layer is hot-roll laminated during the extrusion process. The result is a completely waterproof, impact-resistant panel that can be installed directly in wet zones. Unlike ceramic tiles, these panels have no grout lines to harbor mold, and the wearing layer prevents chipping and scratching during installation and daily use. Many manufacturers now offer 0.50 mm wearing layers on wall panels specifically for healthcare environments where infection control and durability are non-negotiable. Luxury Vinyl Flooring (LVT, SPC, WPC)This is where PVC wearing layer film truly shines. In rigid-core flooring (SPC), the typical construction is:

Luxury Vinyl Flooring (LVT, SPC, WPC)This is where PVC wearing layer film truly shines. In rigid-core flooring (SPC), the typical construction is: 0.30 mm–0.70 mm PVC wearing layer

High-resolution printed decorative film

SPC core (stone-plastic composite)

Attached underlayment

0.30 mm → AC3 / Class 32 (heavy residential, moderate commercial)

0.50 mm → AC5 / Class 34 (heavy commercial)

0.70 mm → AC6 / Class 34/43 (very heavy commercial, light industrial)

Floor Graphics and Wayfinding SignageIn retail stores, museums, and airports, high-tack 0.30–0.50 mm wearing layer films are digitally printed and applied directly to floors as directional graphics, promotional messages, or social-distancing markers. These films conform to textured tiles, withstand floor polishers, and achieve slip ratings of R10–R11 even when wet. The aluminum oxide particles in the wearing layer provide both durability and anti-slip micro-texture. Many major European retailers report that floor graphics with 0.50 mm wearing layers last 3–5 years in high-traffic areas, compared to just 3–6 months for standard vinyl stickers.

Floor Graphics and Wayfinding SignageIn retail stores, museums, and airports, high-tack 0.30–0.50 mm wearing layer films are digitally printed and applied directly to floors as directional graphics, promotional messages, or social-distancing markers. These films conform to textured tiles, withstand floor polishers, and achieve slip ratings of R10–R11 even when wet. The aluminum oxide particles in the wearing layer provide both durability and anti-slip micro-texture. Many major European retailers report that floor graphics with 0.50 mm wearing layers last 3–5 years in high-traffic areas, compared to just 3–6 months for standard vinyl stickers. Automotive and Marine ApplicationsThe same wearing layer technology has migrated into vehicle interiors (dashboard overlays, door panel inserts) and yacht decking, where it resists saltwater, suntan lotion, fish blood, and constant flexing. Some marine-grade wearing layers incorporate antimicrobial silver ions that achieve 99.9% reduction of Staphylococcus aureus and E. coli according to ISO 22196.PVC wearing layer film has evolved from a simple protective overlay into a sophisticated multifunctional material that combines extreme durability with optical clarity and design freedom. It is the reason why today’s vinyl surfaces can look like real oak, marble, or hand-painted murals while surviving conditions that would destroy the genuine materials in weeks. Every time you walk across a hyper-realistic wood-look floor that still looks perfect after ten years later, or wipe red wine off a wallpaper without leaving a mark, you are experiencing the quiet triumph of PVC wearing layer film—the invisible armor that makes modern beauty possible.

Automotive and Marine ApplicationsThe same wearing layer technology has migrated into vehicle interiors (dashboard overlays, door panel inserts) and yacht decking, where it resists saltwater, suntan lotion, fish blood, and constant flexing. Some marine-grade wearing layers incorporate antimicrobial silver ions that achieve 99.9% reduction of Staphylococcus aureus and E. coli according to ISO 22196.PVC wearing layer film has evolved from a simple protective overlay into a sophisticated multifunctional material that combines extreme durability with optical clarity and design freedom. It is the reason why today’s vinyl surfaces can look like real oak, marble, or hand-painted murals while surviving conditions that would destroy the genuine materials in weeks. Every time you walk across a hyper-realistic wood-look floor that still looks perfect after ten years later, or wipe red wine off a wallpaper without leaving a mark, you are experiencing the quiet triumph of PVC wearing layer film—the invisible armor that makes modern beauty possible.

Get the latest price? We'll respond as soon as possible(within 12 hours)