PP/BOPET Composite Films: Revolutionizing Heat-Sealable Packaging

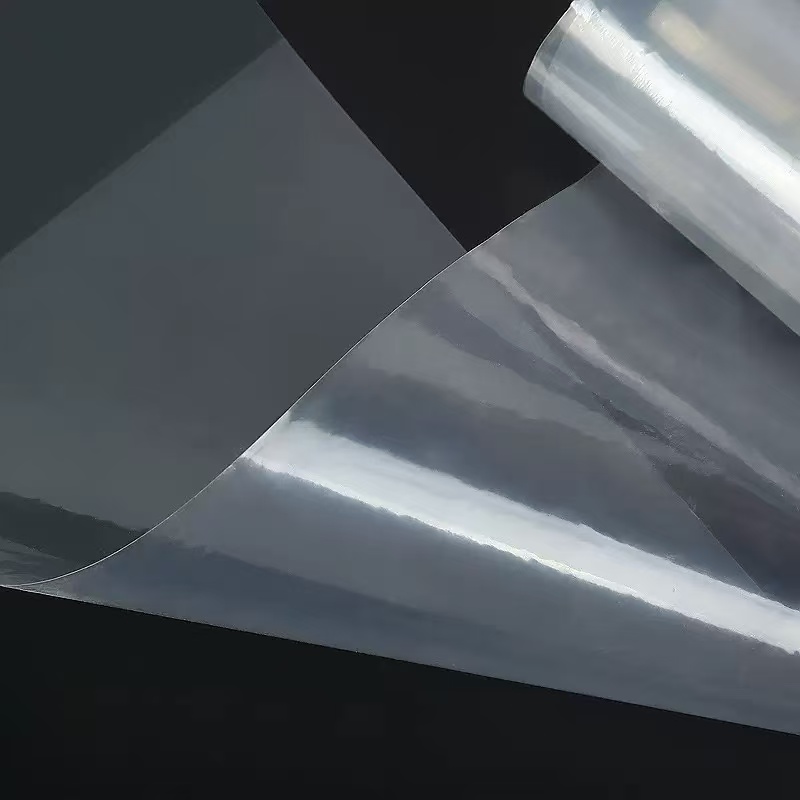

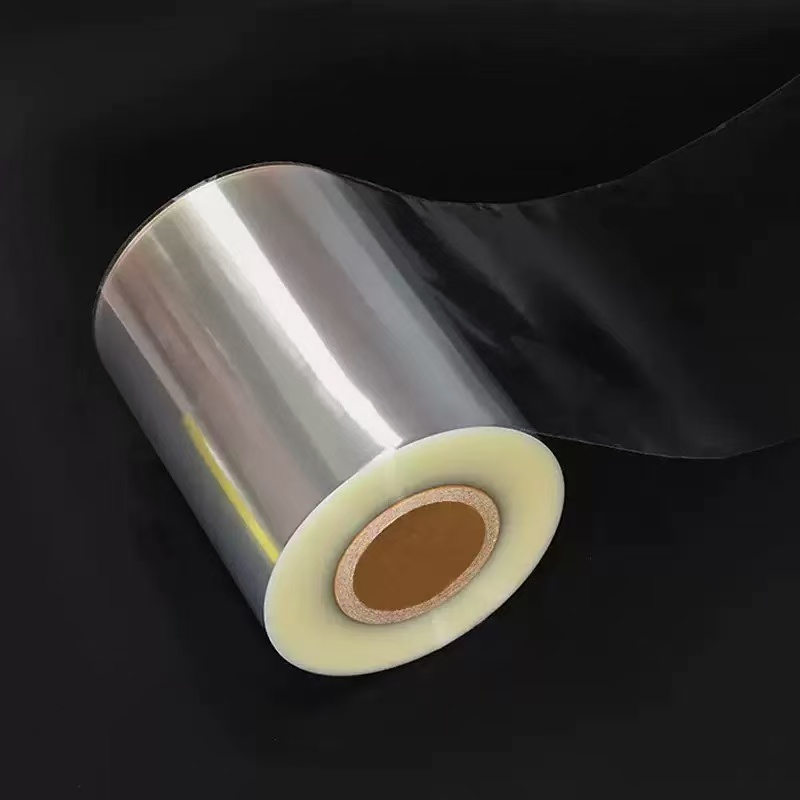

2025-11-19 17:29 The packaging industry has long chased the perfect balance between aesthetics, functionality, and cost for decades. Few materials have come as close to achieving that trifecta as transparent PP/BOPET composite films. By laminating or co-extruding polypropylene (PP) with biaxially oriented polyethylene terephthalate (BOPET), manufacturers have created a hybrid film that combines the outstanding optical clarity and mechanical toughness of BOPET with the excellent heat-sealability and softness of PP. The result is a crystal-clear, strong, and reliably sealable packaging material that dominates modern flexible packaging.Optical Clarity That Sells ProductsConsumers eat with their eyes first. A completely transparent package that lets the product shine through dramatically increases impulse purchases. Transparent PP/BOPET film routinely achieves haze values below 2% and light transmission above 90%, rivaling glass-like clarity. Unlike traditional PP films that can appear slightly milky when thick, or pure BOPET that is brilliantly clear but difficult to heat-seal on standard equipment, the PP/BOPET structure gives brand owners the best of both worlds: shelf-popping transparency plus trouble-free sealing on high-speed vertical form-fill-seal (VFFS) and horizontal form-fill-seal (HFFS) machines.The BOPET layer is biaxially stretched during manufacturing, aligning polymer chains and creating a highly ordered crystalline structure. This orientation is what delivers the trademark sparkle and stiffness. The outer or inner PP layer (usually a heat-sealable copolymer or terpolymer) remains non-oriented or minimally oriented, preserving its low melting point and broad sealing window.

The packaging industry has long chased the perfect balance between aesthetics, functionality, and cost for decades. Few materials have come as close to achieving that trifecta as transparent PP/BOPET composite films. By laminating or co-extruding polypropylene (PP) with biaxially oriented polyethylene terephthalate (BOPET), manufacturers have created a hybrid film that combines the outstanding optical clarity and mechanical toughness of BOPET with the excellent heat-sealability and softness of PP. The result is a crystal-clear, strong, and reliably sealable packaging material that dominates modern flexible packaging.Optical Clarity That Sells ProductsConsumers eat with their eyes first. A completely transparent package that lets the product shine through dramatically increases impulse purchases. Transparent PP/BOPET film routinely achieves haze values below 2% and light transmission above 90%, rivaling glass-like clarity. Unlike traditional PP films that can appear slightly milky when thick, or pure BOPET that is brilliantly clear but difficult to heat-seal on standard equipment, the PP/BOPET structure gives brand owners the best of both worlds: shelf-popping transparency plus trouble-free sealing on high-speed vertical form-fill-seal (VFFS) and horizontal form-fill-seal (HFFS) machines.The BOPET layer is biaxially stretched during manufacturing, aligning polymer chains and creating a highly ordered crystalline structure. This orientation is what delivers the trademark sparkle and stiffness. The outer or inner PP layer (usually a heat-sealable copolymer or terpolymer) remains non-oriented or minimally oriented, preserving its low melting point and broad sealing window. Superior Heat-Seal PerformanceOne of the biggest historical headaches with pure BOPET film has been its high melting point (around 260 °C) and narrow sealing range. Standard packaging lines running at 60–300 packs per minute simply cannot supply enough heat fast enough without burning or distorting the film. By incorporating a 20–50 μm PP heat-seal layer, the composite film seals beautifully between 120–160 °C with dwell times as low as 0.3–0.5 seconds. This wide sealing window reduces leakers, improves line efficiency, and allows the use of lower-cost impulse or hot-bar sealers instead of expensive radio-frequency or ultrasonic equipment.Seal strength typically exceeds 25–40 N/15 mm (depending on PP grade and thickness), strong enough for heavy products yet peelable when intentional easy-open features are engineered in. Anti-fog versions further ensure that even chilled or steamed products remain clearly visible inside the pack without condensation clouding the view.Outstanding Barrier PropertiesWhile pure PP film offers only moderate oxygen and moisture barrier, and pure BOPET is excellent against oxygen but weaker against moisture, the PP/BOPET lamination cleverly complements both materials. Typical structures are:

Superior Heat-Seal PerformanceOne of the biggest historical headaches with pure BOPET film has been its high melting point (around 260 °C) and narrow sealing range. Standard packaging lines running at 60–300 packs per minute simply cannot supply enough heat fast enough without burning or distorting the film. By incorporating a 20–50 μm PP heat-seal layer, the composite film seals beautifully between 120–160 °C with dwell times as low as 0.3–0.5 seconds. This wide sealing window reduces leakers, improves line efficiency, and allows the use of lower-cost impulse or hot-bar sealers instead of expensive radio-frequency or ultrasonic equipment.Seal strength typically exceeds 25–40 N/15 mm (depending on PP grade and thickness), strong enough for heavy products yet peelable when intentional easy-open features are engineered in. Anti-fog versions further ensure that even chilled or steamed products remain clearly visible inside the pack without condensation clouding the view.Outstanding Barrier PropertiesWhile pure PP film offers only moderate oxygen and moisture barrier, and pure BOPET is excellent against oxygen but weaker against moisture, the PP/BOPET lamination cleverly complements both materials. Typical structures are:Outer BOPET (12 μm) / adhesive or extrusion coating / sealant PP (30–80 μm)

Or co-extruded 5-layer BOPET//tie//EVOH or PVDC//tie//PP for ultra-high barrier

Specific Applications Across Industries

Specific Applications Across IndustriesDry Food & Snacks

Transparent PP/BOPET film has become the gold standard for premium nuts, cookies, candies, and dried fruit retail pouches. The combination of high clarity (to show off whole almonds or chocolate pieces), strong aroma barrier, and glossy printable surface drives tremendous on-shelf appeal. Quad-seal or doy-style stand-up pouches with zippers are routinely produced at speeds >120 pouches/min.

Fresh Produce

Anti-fog coated transparent PP/BOPET lidding film on APET or PP trays keeps salads, cut fruit, and vegetables looking garden-fresh even after refrigeration and microwave reheating. Micro-perforated versions provide precise modified atmosphere control, extending shelf life up to 2–3 times versus traditional PVC cling film.Medical & Pharmaceutical Packaging

Sterilizable grades (able to withstand 121 °C retort or gamma irradiation) are widely used for IV bags, wound dressings, and disposable surgical kits. The total inertness of both PET and PP, plus perfect clarity for content inspection, meets the strictest FDA and European Pharmacopoeia requirements.Retort & Hot-Fill Applications

Special high-temperature sealant PP resins allow transparent PP/BOPET pouches to survive 121–130 °C retorting for 30–60 minutes with less than 5% shrinkage and no delamination. Ready meals, soups, baby food, and pet food in see increasing adoption of transparent retort pouches because consumers strongly prefer to see the actual product rather than an opaque aluminum foil version.Industrial & Non-Food

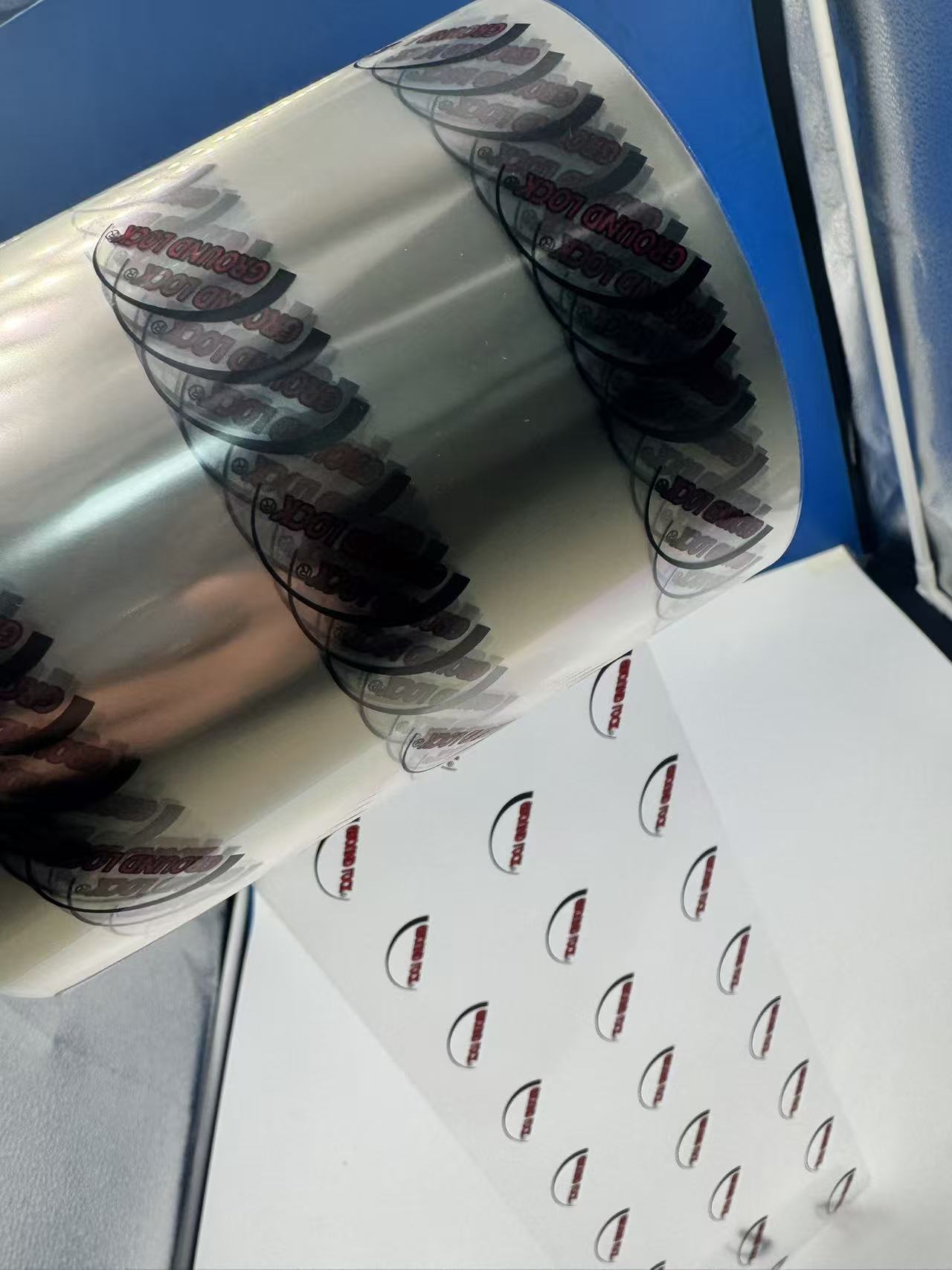

Beyond food, transparent PP/BOPET films wrap electronics components, cosmetics, stationery, and apparel. The anti-static and low-dust grades prevent particle contamination in clean-room environments, while the high surface energy accepts corona or flame treatment for strong ink adhesion in high-quality flexographic or digital printing.

ConclusionTransparent PP/BOPET film is not merely another packaging substrate — it is an enabling technology that allows brands to deliver breathtaking shelf presence while meeting the most demanding functional requirements for barrier, seal integrity, machinability, and consumer convenience. Its unique ability to merge the optical brilliance with robust, low-temperature heat-sealability has made it indispensable across food, medical, and industrial packaging segments. As consumer demand for transparency, sustainability, and premium unboxing experiences continues to rise, expect transparent PP/BOPET composite films to remain at the forefront of flexible packaging innovation for many years to come.

ConclusionTransparent PP/BOPET film is not merely another packaging substrate — it is an enabling technology that allows brands to deliver breathtaking shelf presence while meeting the most demanding functional requirements for barrier, seal integrity, machinability, and consumer convenience. Its unique ability to merge the optical brilliance with robust, low-temperature heat-sealability has made it indispensable across food, medical, and industrial packaging segments. As consumer demand for transparency, sustainability, and premium unboxing experiences continues to rise, expect transparent PP/BOPET composite films to remain at the forefront of flexible packaging innovation for many years to come.