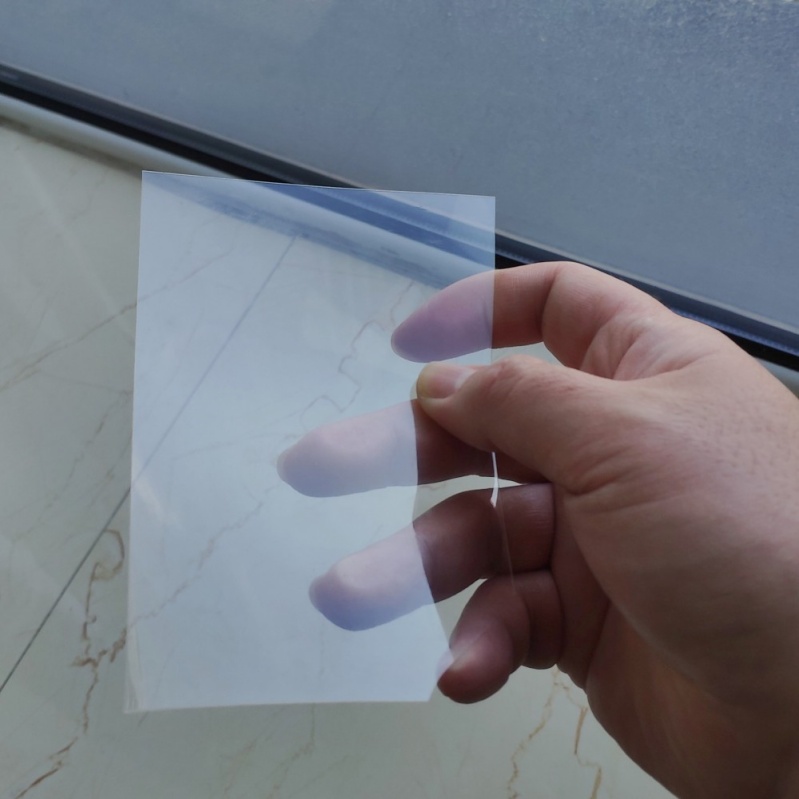

Compostable PLA rigid sheets for thermoforming

Food-grade biodegradable PLA film, white and opaque.

Compostable PLA rigid sheets for thermoforming.

- top leader

- China

- 19 business days

- 200 tons/month

- Information

Food-grade biodegradable PLA film, white and opaque.

Food-grade biodegradable white opaque PLA film and compostable PLA rigid sheets are highly favored in the food packaging industry due to their environmentally friendly properties and adaptability. The following sections detail their material characteristics, processing, applications, and advantages.

Food-Grade Biodegradable White Opaque PLA Film

Core Characteristics

Raw Materials and Safety: Made from polylactic acid (PLA) fermented from plant starches such as corn and cassava, it is a bio-based biodegradable material, free of fluorescent agents, heavy metals, and other harmful substances, meeting the stringent safety standards for food packaging.

Appearance and Performance: Achieves a white opaque effect through blending and modification processes, with a whiteness typically ≥88%. It has good light-blocking properties, effectively extending food shelf life. It also possesses excellent tensile strength, heat sealability, and printability. The heat sealing temperature is generally 120-180℃, and the temperature resistance range is typically -20℃ to 65℃.

Degradation Performance: Under industrial composting conditions, it can decompose into carbon dioxide and water in 3-6 months, with a degradation rate ≥90%, achieving organic recycling.

Typical Applications: Suitable for packaging baked goods, frozen foods, and ready-to-eat foods. It can be made into packaging bags, cling film, and coated paper, ensuring food hygiene while enhancing the environmental image of the packaging.

Compostable PLA Rigid Sheets and Thermoforming Applications

Basic Properties of Rigid Sheets

Specifications and Performance: Common thicknesses are 0.3-2.0mm, and custom cutting is available. Tensile strength is ≥35MPa, and the temperature resistance range is generally -10℃ to 55℃, suitable for cold food packaging. It contains no harmful substances and has passed relevant safety certifications.

Compostability: Degradation rate ≥90% in a composting environment within 180 days, meeting green packaging requirements and helping brands reduce environmental complaints.

Thermoforming Process Key Points

Heating Stage: Heat the PLA rigid sheet to 80-100℃ until it softens. This temperature is lower than traditional plastics, resulting in lower energy consumption. Conventional heaters can be used. Molding and Cooling: Using vacuum and pressure molding methods, the softened sheet is fitted to the mold. The mold temperature is controlled at 20-40℃. After cooling and shaping, products such as food containers, blister trays, and hinged boxes are obtained.

Cutting Treatment: PLA rigid sheets are relatively brittle. It is recommended to cut them at temperatures above 60℃ to avoid cracking and improve the yield rate.

Application Scenarios: Widely used in cold drink cups, fruit trays, food blister packaging, etc. One customer used 0.8mm sheets to make gift box liners, replacing EPS foam and reducing packaging weight by 30%; children's toy packaging boxes used 1.0mm sheets, and passed 20 folding tests without cracking, helping the brand obtain "green product" certification.

Comprehensive Advantages and Development Trends:

Both materials are made from renewable resources, reducing reliance on petroleum and carbon emissions, aligning with the "dual carbon" goals and environmental policies. Currently, by blending with materials such as PBAT, the brittleness and heat resistance of PLA can be further improved, expanding application scenarios and promoting the development of food packaging towards a more environmentally friendly and safe direction.

Compostable PLA rigid sheets for thermoforming.

Within 15-20 days after received payment...more