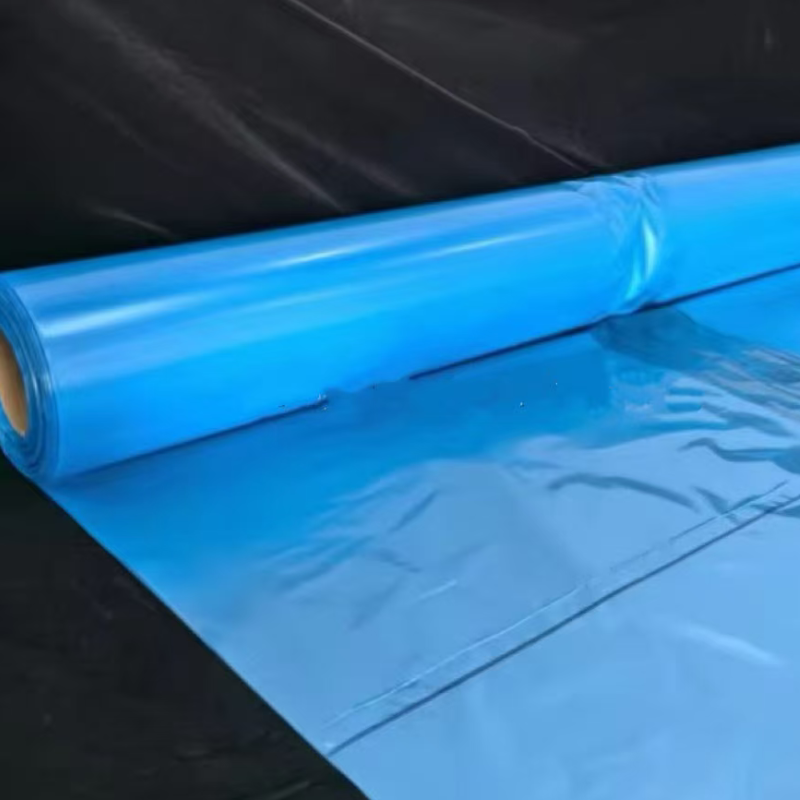

Multilayer co-extruded film, PA/PE FILM

Multilayer co-extruded film, PA/PE medium barrier film, used for food packaging.

The "Freshness-Locking Weapon" in Food Packaging: PA/PE Multilayer Co-extruded Medium Barrier Film – Protecting Food Freshness Through Composite Advantages

- top leader plastic

- China

- 16 business days

- 200 tons/month

- Information

Multilayer co-extruded

The "Freshness-Locking Weapon" in Food Packaging: PA/PE Multilayer Co-extruded Medium Barrier Film – Protecting Food Freshness Through Composite Advantages

In the food packaging industry, "barrier properties" are a core requirement for extending shelf life. PA/PE multilayer co-extruded medium barrier film (including PA/PE base film and stretch film) achieves multiple layers of protection—oxygen barrier, moisture barrier, and leak-proof—through a layered composite of nylon (PA) and polyethylene (PE). It also possesses tensile strength and ease of heat sealing, making it the mainstream packaging choice for meat, cooked food, and snacks, perfectly balancing "freshness-locking function" and "usability compatibility."

PA/PE multilayer co-extruded film is not a single material; rather, it combines PA layers, PE layers, and optional adhesive layers (such as EMA) into a single unit through a co-extrusion process. A typical structure is "PA (outer layer) + adhesive layer + PE (inner layer)," with a thickness typically between 0.08-0.2mm. Each layer complements the other's function, forming a medium barrier capability.

Outer Layer: PA (Nylon) 20%-30% provides core barrier properties – its oxygen barrier rate is 10-15 times that of pure PE film, slowing down food oxidation (such as meat spoilage and snack rancidity); it also improves the film's tensile strength and puncture resistance, preventing punctures by sharp objects during transportation.

Inner Layer: PE (Polyethylene) 60%-75% handles heat sealing and contact functions – PE has a low heat sealing temperature (120-150℃) and a heat sealing strength ≥3.0N/15mm, ensuring a leak-proof seal; food-grade PE material is non-toxic and odorless, conforming to GB 4806.7 standards, and can directly contact food.

In short, this film's logic is "PA layer for oxygen barrier and puncture prevention + PE layer for sealing and safety." The multi-layer co-extrusion process ensures a tight bond between the layers, avoiding the glue residue problems of traditional composite films (such as dry lamination), making it more suitable for the safety requirements of food packaging.

II. Core Advantages: Medium Barrier Strength + Practical Performance, Meeting Essential Food Packaging Needs

The advantages of PA/PE multilayer co-extruded film are concentrated in three dimensions: "barrier properties, processability, and safety." It addresses the pain points of food preservation while adapting to industrial packaging processes.

1. Medium Barrier Strength, Precise Freshness Locking

Dual advantages in oxygen and moisture protection—meeting the needs of meat, cooked foods, and baked goods for "oxygen barrier protection and spoilage prevention" (e.g., extending the shelf life of chilled meat by 3-5 days, and biscuits by 1-3 months), while being more cost-effective than high-barrier films (such as PA/EVOH/PE), making it suitable for the packaging budgets of mass-market foods;

Stable and Undiminished Barrier Strength: The co-extrusion process eliminates glue between layers, ensuring barrier performance is unaffected by temperature and humidity (stable performance within the range of -20℃ to 60℃). Even when used for refrigerated foods (such as yogurt and low-temperature meat products) or room-temperature storage (such as nuts and potato chips), it continues to provide barrier protection, preventing premature spoilage.

2. High tensile strength and toughness, suitable for distribution

Tension resistance + puncture resistance: The tensile strength of the PA layer is ≥50MPa, and the elongation at break of the PE layer is ≥300%. The toughness of the composite film far exceeds that of pure PE film. The stretch film version can be manually or mechanically stretched to wrap food (such as trays for whole boxes of fruit or meat), with a stretch rate of 200%-300%. After wrapping, it fits tightly to prevent loosening during transportation. The bottom film version, when used in bag making, can withstand the pulling of packaging machines and the squeezing of food, and is not easily torn or damaged.

film, PA/PE medium barrier film, used for food packaging.

Within 15-20 days after received payment...more