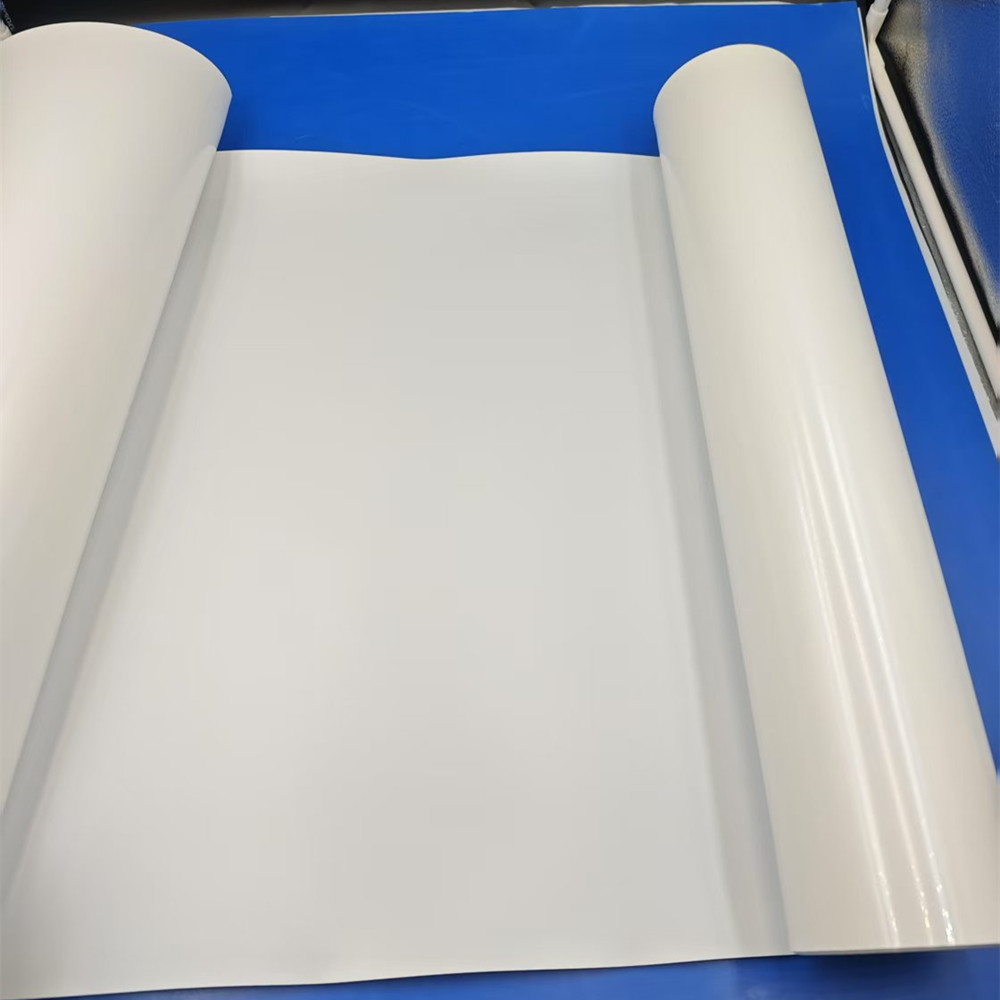

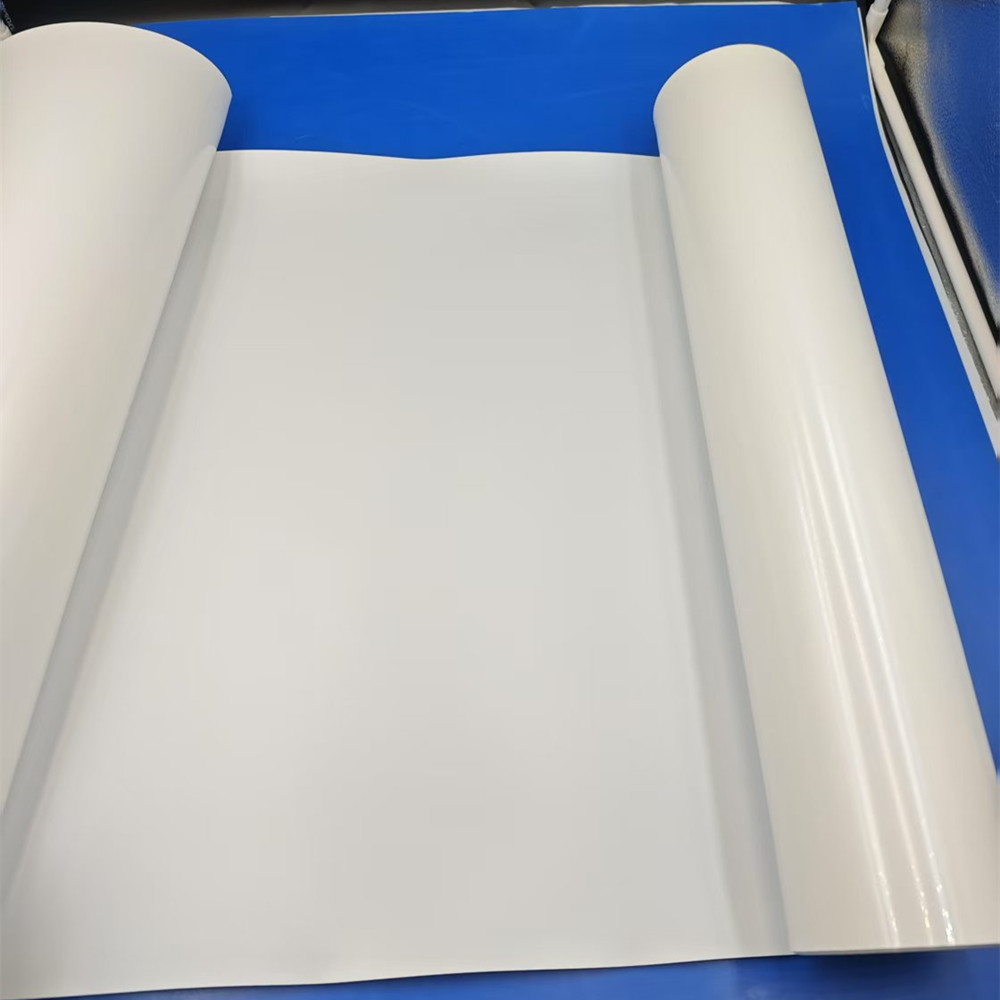

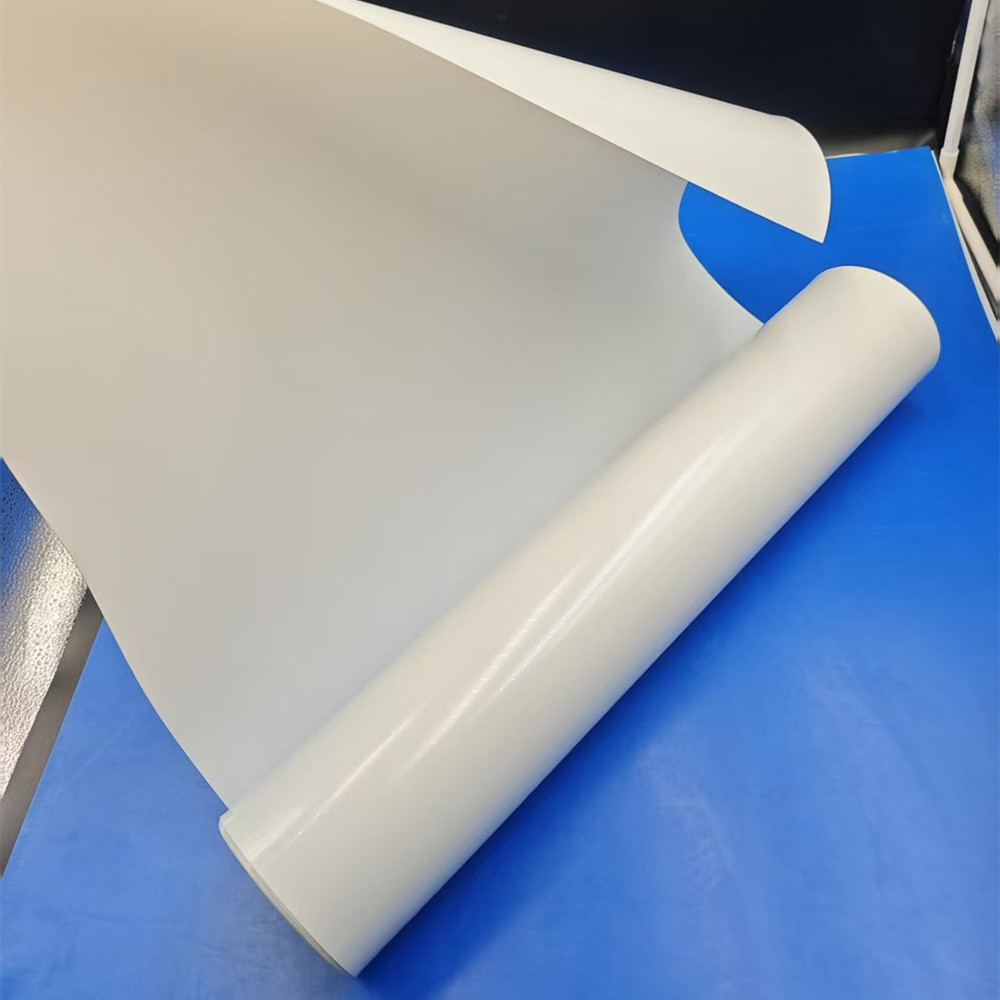

Polystyrene (PS) sheet is a rigid, lightweight thermoplastic sheet made from high-purity polystyrene resin via extrusion molding. It is divided into two main categories: General Purpose Polystyrene (GPPS) sheet and High-Impact Polystyrene (HIPS) sheet, each tailored to diverse application needs in packaging, electronics, and consumer goods industries.

Packaging Industry

GPPS sheet: Clear blister packaging for food (snacks, desserts), toys, stationery, and hardware; transparent display boxes.

HIPS sheet: Inner trays for electronic products, cosmetic packaging components, and disposable food containers (lunch boxes, bowls).

Electronics & Appliances

Advertising & Display

Other Fields

We offer flexible customization to meet your specific requirements:

Size Customization: Thickness, width, and length can be adjusted according to customer orders.

Color Customization: HIPS sheets support custom RAL/Pantone colors; GPPS sheets can be produced with matte or frosted finishes.

Surface Treatment: Anti-static coating, UV-resistant coating, and easy-peel film lamination.

Our PS sheets comply with RoHS, REACH and food contact safety standards (e.g., FDA, LFGB). Strict quality control is implemented throughout the production process, from raw material selection to extrusion, cutting, and packaging, ensuring stable product performance and consistent quality.

Packaging: PE film wrapping + kraft paper protection + wooden pallet reinforcement to prevent scratches and deformation during transportation.

Shipping: Bulk order delivery via sea/air freight; small batch samples available for express delivery.

What's your delivery time?

Within 15-20 days after received payment

...more