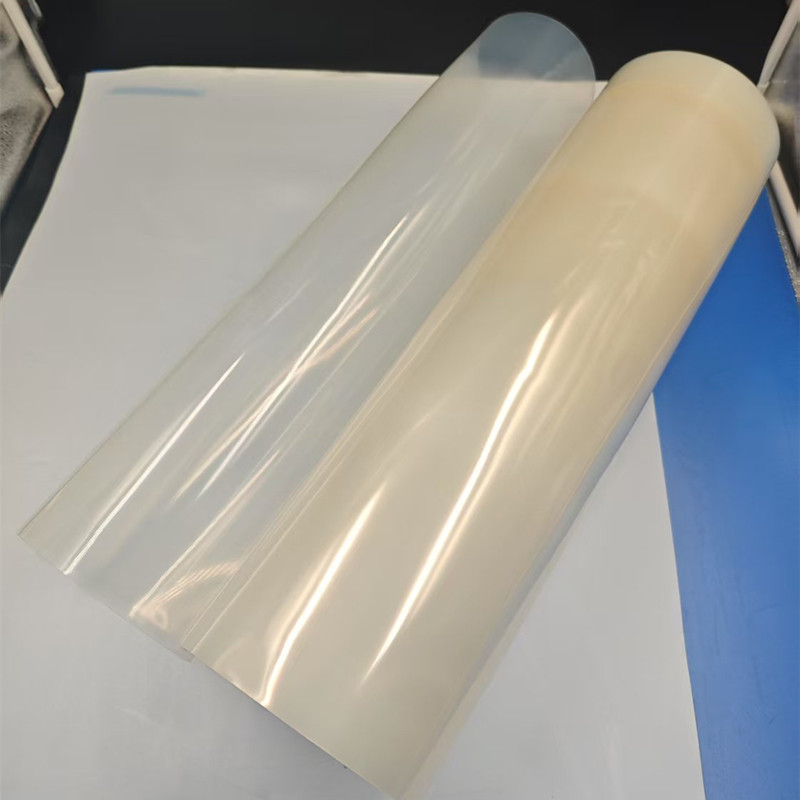

White, translucent PLA film, compostable and biodegradable

White, translucent PLA film, compostable and biodegradable. Environmentally friendly material, food-grade, suitable for thermoforming at room temperature.

- top leader plastic

- China

- 15 business days

- 120 tons/month

- Information

The white translucent, compostable and biodegradable food - grade PLA film suitable for room - temperature thermoforming is a high - quality green packaging material. It is derived from renewable crops and combines environmental protection, safety and processing flexibility. It is widely favored in food packaging and other fields. Here is a detailed introduction to its core advantages, typical application scenarios and supply customization specifications:

Core Performance Advantages

Outstanding environmental protection and food safety: This film is made from renewable raw materials such as corn starch and cassava through microbial fermentation and polymerization. It can be completely degraded into carbon dioxide and water by microorganisms in soil or composting environments within 180 days. After composting, it can even be used to produce organic fertilizers without polluting the environment. As a food - grade material, it is non - toxic and odorless. It will not release harmful substances even when in contact with food for a long time or under certain temperature changes fully meets the safety requirements of food contact materials.

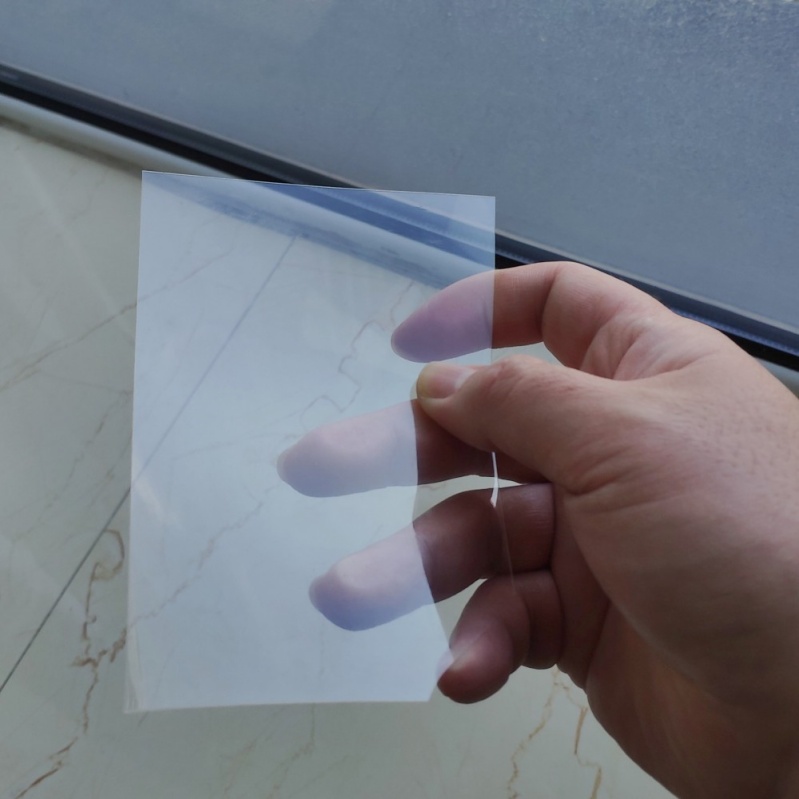

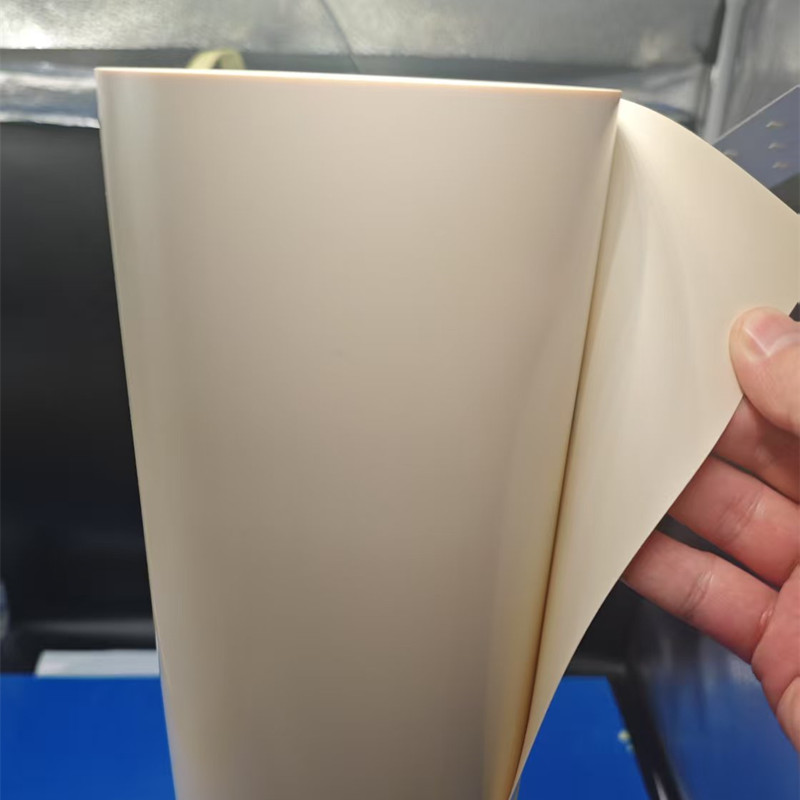

Excellent room - temperature thermoforming and processing adaptability: Different from many materials that require high - temperature heating for forming, this PLA film can complete thermoforming at room temperature, which saves energy consumption in the production process. Its thickness is usually available in the range of 0.2-1mm. It has low shrinkage rate during forming, and the finished products after thermoforming have stable sizes. In addition, it is also suitable for lamination, offset printing, silk screen printing and other processes, which can meet the needs of merchants for printing product information, logos and patterns on the packaging.

Practical physical properties: The white translucent appearance not only can weaken the impact of light on light - sensitive food and slow down the deterioration rate of food, but also can show the rough shape of the packaged products, which is convenient for consumers to observe. It has good mechanical properties, with good tensile strength and elongation at break, which can resist a certain degree of stretching and tearing during use and transportation. Meanwhile, it has certain antibacterial properties and stability to acids, alkalis and salts, which can avoid being corroded by the components of general food.

Typical Application Scenarios

Food packaging field: It is an ideal material for thermoforming of small food packaging. It can be made into thermoformed trays for pastries, sandwiches and sushi to isolate food and prevent contamination; it can also be processed into blister packaging for nuts, candies and other snacks. For fresh fruits and vegetables, it can be made into breathable packaging bags or trays, which can adjust the gas exchange inside the package and reduce water evaporation to extend the fresh - keeping period.

Daily and agricultural fields: It can be made into small daily necessities packaging, such as thermoformed inner trays for biodegradable tableware sets and small household plastic parts, which can play a role of fixation and protection. In agriculture, it can be processed into small - size mulch films or seedling raising films. After use, it can be directly ploughed into the soil for degradation without causing environmental pollution.

Special scenario extensions: In the field of catering that focuses on environmental protection, it can be made into disposable food containers and takeout partition plates through thermoforming. It can also be used for the packaging of some small environmentally friendly toys and biodegradable daily necessities, which is in line with the current consumption concept of pursuing green and environmental protection.

Supply and Customization Specifications

Basic supply parameters: It is usually supplied in rolls, with a maximum roll width of no more than 72cm, and the width can also be customized according to needs. The inner core of the roll is mostly 3 inches (76mm) or 6 inches (152mm). The minimum order quantity is 1000kg, and some industrial compostable specifications have a minimum order quantity of 6000kg.

Customization and delivery: The shade of white and the transparency of the film can be adjusted according to customer needs. We can also provide slitting and cutting services to cut the film into specified sizes to match different thermoforming equipment. The delivery time is generally about 25 - 30 days.

Within 15-20 days after received payment...more