- Home

- >

- News

- >

- Product news

- >

News

Transparent Pet film, with its unique properties and versatility, has found extensive applications in various industries. In this article, we will explore the uses of transparent Pet film in different fields at room temperature, including blister jewelry packaging, blister tool packaging, blister pharmaceutical packaging, and insulation boards. Through vivid descriptions and real-life examples, we will showcase the importance and advantages of this remarkable material.

Blister Pharmaceutical Packaging The pharmaceutical industry also relies heavily on transparent PET film for packaging. Similar to food packaging, the transparency of PET film allows for easy inspection of the contents, ensuring the integrity and quality of the medications. PET film provides a barrier against moisture, light, and oxygen, which can degrade the potency of drugs. This is especially important for sensitive medications such as tablets, capsules, and powders.

PLA packaging for cosmetics and skincare products is also in line with the growing trend towards sustainable beauty. Consumers are increasingly looking for products that are packaged in environmentally friendly materials, and PLA film meets this demand. Additionally, PLA can be customized with different colors, prints, and finishes to create unique and eye-catching packaging designs.

Furniture can also be given a new lease on life with colored PVC film. Old pieces can be refurbished to match the latest decor trends, saving money and reducing waste. PVC film is available in a variety of finishes, including glossy, matte, and textured, adding depth and character to any piece of furniture.

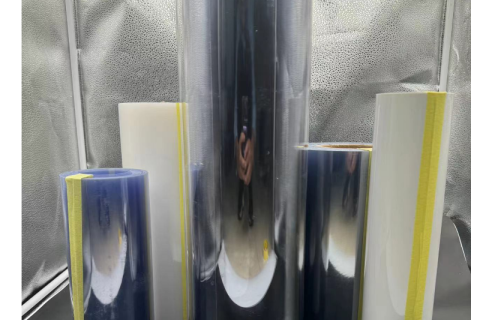

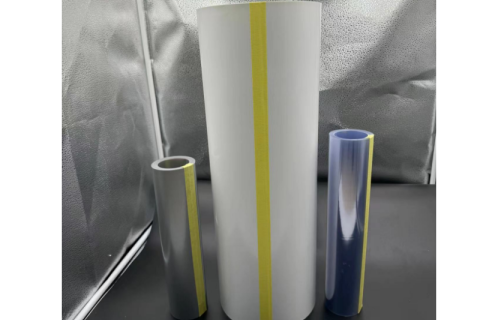

Material Protection Film A. Protecting Surfaces during Transportation and Installation Transparent PVC film is widely used as a material protection film to protect surfaces from scratches, abrasions, and dirt during transportation and installation. Whether it's protecting metal sheets, glass panels, or plastic parts, PVC film provides a temporary yet effective solution. For example, when shipping metal sheets or coils, they are often covered with transparent PVC film to prevent scratches and dents. The film acts as a cushion, absorbing impacts and protecting the surface from damage. Similarly, when installing glass panels or mirrors, PVC film is used to protect the surface from scratches and fingerprints until the installation is complete.

Branding and Marketing High-transparency PETG film can be printed with logos, brand names, and product information, providing an effective way to promote the brand and market the product. For example, a toy manufacturer can use PETG blisters with colorful printing to create an eye-catching packaging that stands out on store shelves. This not only enhances the brand image but also helps to attract the attention of potential customers.

Secondly, white PVC film provides a good barrier against moisture, oxygen, and other contaminants. This helps to extend the shelf life of food products by preventing spoilage and degradation. It keeps the food fresh and flavorful for a longer period, reducing food waste and ensuring consumer satisfaction.

Transparent PET film is a versatile material with a wide range of applications in different fields. Its unique properties, such as transparency, durability, and barrier properties, make it an ideal choice for many applications. Whether it is used for insulation, packaging, decoration, or healthcare, PET film plays an important role in our lives.

1. Advertising and Signage Printable transparent PVC film is widely used in the advertising and signage industry. Its transparency allows for creative designs that can be applied to windows, glass doors, and other transparent surfaces. Whether it's for promoting a brand, announcing an event, or providing directional signage, PVC film offers a sleek and eye-catching solution. The film can be printed with vibrant colors and high-resolution graphics, ensuring maximum visibility and impact. For example, in retail stores, printable PVC film is used to create window displays that attract customers and showcase products. The transparency of the film allows passersby to see inside the store while still being able to view the promotional messages printed on the film. In addition, PVC film can be used for outdoor signage, such as billboards and banners, as it is weather-resistant and can withstand exposure to sunlight, rain, and wind.

Summer 2023Location: A shipping warehouse Warehouse workers, logistics managers Initiating Event: The warehouse was handling a large volume of fragile items that needed to be shipped safely. The logistics managers decided to use transparent PVC soft film as a cushioning material for packaging. The film was wrapped around the fragile items or used as a liner in boxes and crates. Warehouse workers carefully packed each item to ensure maximum protection during transportation. The fragile items arrived at their destinations without any damage. The transparent film allowed for easy inspection of the contents, ensuring that everything was in order. The use of transparent PVC soft film for cushioning packaging helped to reduce the risk of damage during shipping and handling. It also provided a cost-effective packaging solution for the warehouse, saving time and money.

《The Versatility of PVC matte Frosted Film: A Success Story》 In the bustling city of [City Name], there lives a young entrepreneur named Lily. Lily is a visionary and innovative businesswoman who is always on the lookout for new and useful materials that can transform different industries. One day, while attending a trade fair in early 2024, Lily stumbled upon a display of PVC matte frosted film. Intrigued by its unique texture and potential applications, she decided to learn more about this remarkable material. The PVC matte frosted film immediately caught Lily's attention due to its aesthetic appeal and practical features. The frosted surface gave it a soft and elegant look, while the PVC material offered durability and flexibility. As Lily explored further, she discovered that this film had a wide range of uses across various fields. In the packaging industry, PVC matte frosted film proved to be a game-changer. It was ideal for different types of packaging, including (pharmaceutical packaging) and (packaging for spare parts). For pharmaceutical packaging, the film provided a barrier against moisture, light, and contaminants, ensuring the safety and integrity of the medications. The frosted finish also gave the packaging a professional and sophisticated look, enhancing the brand image of the pharmaceutical companies. In the case of spare parts packaging, the film protected the delicate components from scratches and damage during transportation and storage. Its flexibility allowed it to conform to the shape of the parts, providing a snug fit and reducing the risk of movement. Lily also saw great potential for PVC matte frosted film in the field of decoration. Whether it was for glass (glass decoration) or interior design, the film added a touch of elegance and style. For glass decoration, the frosted film created a privacy screen while still allowing light to pass through. It could be used on windows, shower enclosures, and partitions, giving a modern and sleek look to any space. In interior design, the film could be applied to walls, furniture, and accessories, creating unique and personalized designs. Its adhesive backing made it easy to install, and it could be removed without leaving any residue, making it a great option for temporary or rental spaces. Another important feature of PVC matte frosted film is its (thermal insulation) properties. Lily realized that this film could help reduce energy consumption by insulating buildings and vehicles. By applying the film to windows and doors, it could prevent heat transfer, keeping interiors cool in summer and warm in winter. This not only saved on energy costs but also improved the comfort of living and working spaces. In addition to its thermal insulation properties, the PVC matte frosted film also had阻燃 (flame retardant) qualities. This made it a safe choice for various applications, especially in areas where fire safety was a concern. For example, it could be used in hospitals, schools, and public buildings to reduce the risk of fire spread. The film met strict fire safety standards, providing peace of mind to building owners and occupants. Lily was also impressed by the (hygienic packaging) applications of PVC matte frosted film. In the healthcare industry, this film could be used to package medical supplies and equipment, ensuring sterility and hygiene. The frosted finish made it easy to identify the contents of the package, while the PVC material provided a barrier against bacteria and other contaminants. In the food industry, the film could be used for packaging perishable items, keeping them fresh and safe for consumption. Excited by the endless possibilities of PVC matte frosted film, Lily decided to incorporate this material into her own business. She started by using it for packaging her company's products, which immediately received positive feedback from customers. The elegant and professional look of the packaging enhanced the brand image and increased sales. Lily then expanded its use to decoration projects, collaborating with interior designers and architects to create stunning spaces. The thermal insulation and flame retardant properties of the film also appealed to clients who were looking for sustainable and safe solutions. As word spread about Lily's success with PVC matte frosted film, other businesses in the city began to take notice. They started to explore the potential of this material for their own applications, leading to a surge in demand. Lily saw an opportunity to grow her business further and decided to become a distributor of PVC matte frosted film. She established partnerships with manufacturers and suppliers, ensuring a steady supply of high-quality film. She also provided training and support to her customers, helping them understand the benefits and applications of the material. Today, PVC matte frosted film has become a popular choice in [City Name] and beyond. Its versatility and practical features have made it a valuable asset in various industries. Lily's entrepreneurial spirit and vision have played a crucial role in introducing this material to the market and driving its adoption. Thanks to her efforts, businesses and consumers alike are now reaping the benefits of this remarkable film. The story of Lily and PVC matte frosted film is a testament to the power of innovation and perseverance. By being open to new ideas and taking risks, Lily was able to discover a material that has transformed the way we package, decorate, insulate, and protect our products and spaces. As the demand for sustainable and functional materials continues to grow, PVC matte frosted film is sure to play an even more important role in the future.

Antistatic and Thermoformable PET Film: Wonders of Versatility by In the bustling metropolis, one young, innovative entrepreneur named Lily Chang was going to change the world of materials. It was the year 2024, and Lily had just discovered the astonishing properties of antistatic and thermoformable PET film. Little did she know that this would be an exciting journey that would affect many industries and change lives. The finding of sustainable and practical solutions for day-to-day problems had always remained close to her heart. Progressing further in the world of materials, she found anti-static thermoformable PET film. Curious about its capabilities, she started to find ways where it can be used. It was on one such day while sitting in the small office and gazing out at the skyline of the city that she finally thought that with such film, she might print out A4 sheets that are singularly special. She was so thrilled by the very idea that soon she got down to work on it. Lily then called a local printing company and described her idea. To begin with, the printing company was somewhat skeptical, but once they had samples of the PET film, skepticism turned into interest. Together they began experimenting with different ways of printing the film and soon discovered that it could bear excellent bright prints. The news began to circulate about Lily's printable A4 PET film sheets. Their unique features increased the attraction of students and professionals alike towards these sheets. Because of the antistatic property, prints do not possess static electricity and hence are easily handleable and storable. The thermoformable nature of the film opens more ways of creative usage, such as making note cards or bookmarks in an arbitrary form. As the news spread, Lily was invited to present the product at a local trade show. She was happy to expose her innovation to more people, so she accepted the invitation. The booth was flooded with visitors during the trade show. Still, people were further surprised to see the versatility of PET film. One of them was Alex, a graphic designer who was pretty impressed and visualized using these sheets for his design projects. Alex walked up to Lily and started a conversation with her. Soon, both found that they shared an interest in innovation and design. Alex also mentioned to her about the PET film for customized packaging and how she could join on a project to work with it. The idea thrilled Lily, and they did not delay in starting their work. They started researching all types of packaging needs and came up with a few ideas. One of the ideas was to do some innovative packaging for a local cosmetics brand. The cosmetic company was looking for varnish and striking green packaging solutions. Lily and Alex presented their idea of using antistatic and thermoformable PET film. Interested, the company decided to give it a try. Thus, Lily and Alex were putting great effort into designing packaging and then actually making it. They used the thermoformable property of the film to create custom shapes that would fit the cosmetics products perfectly. The antistatic feature would protect them against electrostatic discharges during transport and storage. The result was amazing. The packaging was beautiful, but not only that-it was functional. It called the attention of the consumers and soon became a hit. The cosmetics company loved the result and ordered more of such packaging. Buoyed by the success, Lily and Alex continued to explore other applications of the PET film. They soon turned their attention to food and pharmaceutical industries. Safety and freshness are key factors in the food industry. Lily and Alex realized that the antistatic and thermoformable PET film would assist in maintaining the freshness of the food and containing no contaminants. They had a package designed with the local food manufacturer for his products. This proved ideal for properties such as packaging of food. Antistatic dispensers prohibited the adherence of dust and other particles onto the packagings, while the thermoformable property allowed customized shapes, which fit different food items. In this case, this turned out to be effective yet attractive packaging. The pharmaceutical industry demands sterile and safe packaging. Lily and Alex worked with a pharmaceutical company to develop packaging that would meet these demands. The PET film instantiated an antistatic property of the film which prevented the build-up of the charges capable of damaging some sensitive medications. The thermoformability was adjustable for those custom-designed packaging meant to secure the drugs during transportation and storage. Here, both Lily and Alex had a reason to look forward to further opportunities once their projects were successful in food and pharmaceuticals producing industries. As a matter of fact, they were invited as guest speakers in industry conferences where they shared their experiences with others. As they got more and more popular, one day, Lily and Alex were approached by a local interior designer. The interior designer wanted something very special for his next big decoration project. Lily and Alex recommended the PET film. They worked with designers for the creation of custom walls and decorative panels. The thermoformability of the film allowed for creative designs and figures, along with an antistatic feature of the decorations, which made them without static electric properties, thus giving an amazing look of space. In the field of glass decoration, Lily and Alex also carved their niche. They also developed a method of applying the PET film to glass surfaces to make privacy screens, decorative windows, and other unique glass features. Because of the properties of this film, installation and removal were pretty easy; thus, it found its place in residential and commercial usages. As the year drew to a close, Lily and Alex looked back with pride to see how it had been. They had taken an easily available material and molded it into a multiutility solution making a difference in various industries. From printable A4 sheets to creative packaging, decoration items, up to glass enhancement, the list of applications for thermoformable PET film is endless. Their story of Lily and Alex had emphasized the force of innovation and teamwork. They had proved that with just a little creativity and determination, even one simple material could go a long way into changing the world. They knew that their journey of thermoformable and antistatic PET film was far from over as they looked to the future. Actually, they were pretty excited about the new applications of the material and the new opportunities. Conclusion: This is quite a remarkable story involving discovery and use of antistatic and thermoformable PET film by Lily Chang and Alex. It's reached into printing and packaging, food, pharmaceuticals, decoration, and the decoration of glass. Their traits have proven-you just need to think differently, and you will definitely find something which is suitable and applicable in everyday industrial problems. With ever-growing sustainability concerns and the need for versatile materials, antistatic, and thermoformable PET film possibly holds a bright future for any who would dare to work and venture into it.