- Home

- >

News

Material: PP ROLL Thickness 0.025mm-customization Size: 80MM/130MM/Customization GRADE: FOOD grade film color:translucent/ white/ customization location: china Usage: food ,heatalbe box Pharmaceutical, dried food

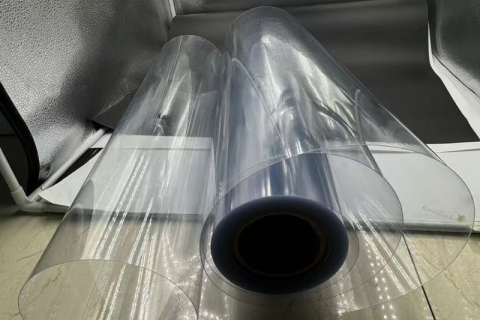

Material: PP roll Thickness 0.018mm-customization Size: 100mm Customization GRADE: Food grade film color: transparent white/ customization location: china usage: blister for food tray plant tray

Material: PET ROLL Thickness 0.018mm/customization Size: 100MM/Customization GRADE: Food grade film color: white/ customization USAGE:for food tray, plant tray, Anti-static ,electronic location: china

Headline: Global Adoption of PP EVOH Film Revolutionizes Packaging Across Industries Date: August 22, 2024 Location: New York, NY Introduction: In a dramatic turn of events, PP EVOH film fast becomes the material of choice for thermoforming and blister packing in almost every industry—from food and pharmaceuticals to industrial uses—owing to the advanced and highly competent solution it offers through barrier performance and versatility. Key Characters: - John Harrison: GreenPack Industries' CEO and leading manufacturer of PP EVOH films. - Dr. Emily Roberts: The head of the Research and Development section at SafeSeal Pharmaceuticals. - Mark Davis: The senior operations manager at FreshFoods Packaging Solutions. - Global Packaging Consortium: A coalition of experts on packaging matters and industry leaders. Causes: Growing demand for sustainable, high-performance packaging has forced the move to PP EVOH film. Rising consumer awareness about food safety and pharmaceutical efficiency has forced manufacturers to look for materials that extend shelf life, durability, and environmental benefits. In view of emerging global supply chain challenges, the need for packaging with excellent barrier protection against oxygen, moisture, and other contaminants is increasingly important. Process: The application of PP EVOH film began in early 2023 when GreenPack Industries, under the business acumen of John Harrison, had invested in intensive research and development to improve the properties of this material. Their work paid off in introducing a new line of PP EVOH films specially designed for various industries. One of the first ones to have spotted the potential of this film in the pharmaceutical sector was Dr. Emily Roberts of SafeSeal Pharmaceuticals. Her team has done an exhaustive test on the potential of this film to protect medication from environmental factors, thereby opening it up for wide adoption in the blister packaging for drugs. About the same time, FreshFoods Packaging Solutions' Mark Davis had introduced a PP EVOH film for use with perishable food items that extended their shelf life by allowing its barrier properties to reduce food waste and enhance supply chain efficiency on their thermoforming lines. At the Global Packaging Consortium summit in New York, June 2024, experts and industry thought leaders debate the future of new packaging materials. PP EVOH film will be one of the key focuses; participants agree that this material can set new standards in packaging across a gamut of industries. Results: The introduction of PP EVOH film has massively advanced the field of packaging. In food processing, freshFoods Packaging Solutions recorded an added 20% shelf life to their products, hence less food wastage and customer satisfaction. SafeSeal Pharmaceuticals had product recalls reduced by 15% due to the improved protection qualities that the PP EVOH film offered over the products in its blister packs. On the industrial front, GreenPack Industries increased their market share by 30% due to surging demands for PP EVOH film across the globe. This success also fueled innovation in recycling technologies to come up with more sustainable packaging solutions. Effects: The extensive application of PP EVOH film has had a domino effect on various industries. From the angle of customers, they receive fresher food and are offered much safer pharmaceutical products. On the other hand, for manufacturers, while the cost goes down, efficiency rises. Actually, the success of PP EVOH film already made other companies look into developing similar high-performance materials that would surely further create innovations in the package sector. The environmental effect from packaging is lessened as more and more companies take up recyclable PP EVOH films, giving a realization to global sustainability. According to the Global Packaging Consortium, in 2025, PP EVOH film may prove to be the precedent for barrier packaging, seeing remarkable protection performance and environmental responsibility. Conclusion: With the packaging industry in continuous flow of evolution, PP EVOH film has emerged to be that one game-changing material best suited to both the modern consumer and manufacturer. Proving its benefits and gaining in popularity, this innovative film is sure to set a new trend in packaging standards worldwide.

Polystyrene in Seedling Trays and Food Containers: An Overview of its Role Date: 8th August 2023 Location: Global Key Figures: Environmentalists, Industry Experts, Policymakers Introduction 8th August 2024 is the day that saw a heated, highly perceived argument of the use of Polystyrene commonly abbreviated as PS in the making of growing seedling trays and food containers. The debate borders on the balance between the practical usefulness of PS and its effect on the surrounding environment. Background Sand used to be the raw material for the production of polystyrene, which is a very wide applied plastic because of its cost-effectiveness and versatility in application. In horticulture, PS is used for seedling trays so that they can give their supporting plant effective drainage and serve a longer time due to their strength. In the food service sector, PS is used for containers like clamshells and cups due to its insulative and affordable properties. Events Horticulture Sector: Environmentalists in the previous decades have already raised concern on the future environmental impacts of PS seedling trays. Although the trays are durable and even to some extent, are reusable, these trays still add to plastic pollution because they are non-biodegradable. Other areas have already explored alternative materials to reduce plastic waste on gardening refuse. Food Service Sector In the same vein, the food service sector has been pressured by the public to discontinue its heavy use of PS containers. While the reasons behind this popularity are insulation and cost reduction, they have been faulted for contributing to the volume of landfill sites and being potential health risks. Recent reports have shown the need to shift to biodegradable packaging systems. Findings Plan Response from Industry: Going Green. In response to these perceptions, the horticulture and food service industries have began to react to the environmental impact of PS. These key steps include, 1. Alternatives: Research over biodegradable and compostable alternatives has been expedited. Industries now look into materials like plant based plastics and recycled fibers that can substitute common PS. 2. Developed Recycling Programs: Advanced recycling infrastructure is developed to manage a better waste load from PS. Developed recycling technologies and programs are being introduced to recover and reutilize materials made from PS. 3. Policy Change: Many countries' governments have framed regulations to control and limit the use of PS in single-use products. The policies have been framed to promote and encourage the use of sustainable alternatives and improve the management of waste. Impact And, the following are some of the positive impacts that the global response to the PS issues resulted in: Increased Awareness: Increased awareness among consumers and industry-related people about the environmental effects of PS and their role has facilitated informed choices and practices. Developing New Materials: The search and, to a contrary, immediate need for alternative sustainable gear had resulted in developing new eco-friendly types of materials in place of the traditional PS used in the nursery trays and food containers. - Advancements in Policies and Regulations: New policies and regulations enable changes toward sustainable operations directed to horticulture and foodservice sectors. Conclusion The ongoing discussion of the role of Polystyrene in seedling trays and food containers really brings the point of balancing practical advantages with environmental responsibility. The work on these challenges has been attended to, in developing partnership with industry and government, while the focus is on sustainability and being innovative with the future of eco-friendliness in both gardening and food service.