- Home

- >

News

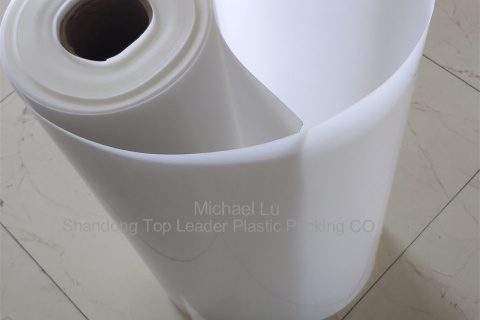

pp It is cold-resistant, freeze-resistant, high-temperature resistant, and can be microwaved. Environmentally friendly materials.

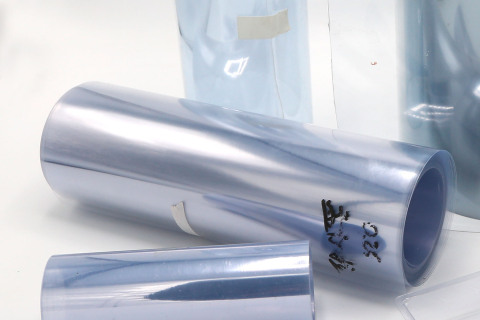

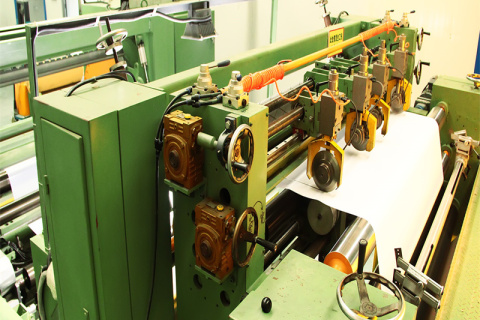

There are many cabinets on the market that use PVC blister film. How to use PVC blister film and its environmental performance? I think most users don’t know that PVC blister film is generally made flat with a cold press or appropriate heat treatment. The curved surface is pressed with a vacuum laminating machine. The principle is to use the pressure difference between the vacuum and the outside world to squeeze. The vacuum laminating machine can be used to laminate flat and curved surfaces.

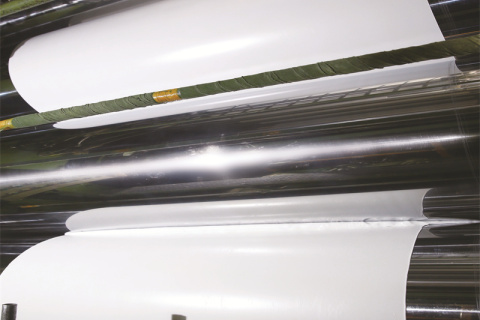

The report provides an in detail study of the BOPP film quickly led to changes in the packaging materials industry, and it began to be widely used in packaging of food, medicine, daily necessities, etc, Current scenario and the development scenario of the market for 2018-2023.

The PP/EVOH/PP film roll offers excellent puncture resistance, high clarity, and good heat resistance. It is commonly used for packaging meat, cheese, seafood, and other perishable food products. The film can also be printed with branding or product information to enhance the visual appeal of the packaging.

Excellent thermoforming properties: PP film can be easily molded into various shapes and sizes using heat, making it ideal for applications such as blister packaging, food trays, and containers.

PLA (Polylactic Acid) film is a type of biodegradable and compostable film made from renewable resources such as corn starch or sugarcane.