- Home

- >

News

In conclusion, white HIPS film's unique combination of properties, including impact resistance and high internal pressure resistance, has led to its widespread use in a diverse range of fields. From health packaging to electronic insulation, decoration to protection, and construction to manufacturing, this versatile film continues to prove its worth. As technology and innovation progress, it is likely that new and exciting applications for white HIPS film will emerge, further expanding its role in our daily lives.

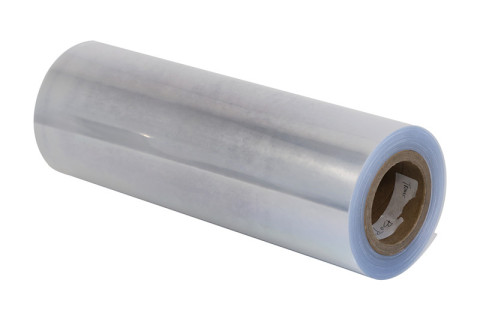

Title: Pharmaceutical Company Launches New Thermoformed PS Film Packaging to Enhance Product Safety Date: August 15, 2023 Location: Basel, Switzerland In a groundbreaking move for the pharmaceutical industry, Swiss-based pharmaceutical giant, MediPharm, has announced the launch of its latest packaging innovation—thermoformed polystyrene (PS) film packaging. The new packaging solution was unveiled at a press conference held at MediPharm's headquarters in Basel, where company executives highlighted the advantages and future implications of this development for the industry. Key People Involved: The announcement was led by MediPharm's CEO, Dr. Andreas Müller, and the Head of Packaging Development, Dr. Elena Weiss. Both have been instrumental in driving the project from concept to implementation. Also in attendance were representatives from the company’s manufacturing partners and key stakeholders in the pharmaceutical supply chain. Causes and Motivations: The initiative to develop thermoformed PS film packaging stemmed from MediPharm's commitment to enhancing the safety and integrity of its pharmaceutical products. In recent years, the company has faced challenges with existing packaging materials that, while effective, did not fully meet the evolving needs of the market, particularly regarding durability, product visibility, and cost efficiency. Additionally, the rising concern for product safety during transportation and storage pushed the company to seek out a more robust packaging solution. Development Process: The development of the new PS film packaging began two years ago, with MediPharm's R&D team conducting extensive research into various materials and packaging technologies. The team focused on identifying a material that could offer superior protection against environmental factors, maintain the integrity of sensitive medications, and be easily customizable for different pharmaceutical products. After rigorous testing and several iterations, the team settled on polystyrene (PS) films due to their clarity, rigidity, and excellent thermoforming capabilities. Collaborating with leading packaging manufacturers, MediPharm developed a production process that utilizes advanced thermoforming techniques to create custom-fit packaging for various pharmaceutical products, including blister packs, trays, and clamshells. Results of the Launch: The introduction of thermoformed PS film packaging has been met with positive responses from industry experts and partners. Dr. Elena Weiss highlighted that the new packaging not only enhances the protection of the products but also significantly improves the efficiency of the packaging process. “We’ve seen a 20% reduction in material costs and a 15% increase in production speed, thanks to the lightweight and easily moldable nature of PS films,” Dr. Weiss reported. Moreover, the clear visibility offered by PS films has been praised for its potential to reduce errors in product identification and enhance quality control. The launch also aligns with MediPharm’s sustainability goals, as the new packaging material is fully recyclable, addressing concerns about environmental impact. Effects and Future Implications: The successful rollout of thermoformed PS film packaging is expected to set a new standard in pharmaceutical packaging. MediPharm plans to extend the use of this packaging across its entire product line within the next year, with the potential for collaboration with other pharmaceutical companies seeking to adopt similar technologies. Dr. Andreas Müller expressed confidence that this innovation would not only improve the safety and efficiency of MediPharm's products but also drive positive change across the pharmaceutical industry. “We believe this new packaging will lead to greater confidence among consumers and healthcare providers in the safety and reliability of our products,” Dr. Müller stated. As the industry continues to prioritize product safety and sustainability, MediPharm’s introduction of thermoformed PS film packaging could mark a significant shift in how pharmaceutical products are packaged and delivered to the market.

Polystyrene in Seedling Trays and Food Containers: An Overview of its Role Date: 8th August 2023 Location: Global Key Figures: Environmentalists, Industry Experts, Policymakers Introduction 8th August 2024 is the day that saw a heated, highly perceived argument of the use of Polystyrene commonly abbreviated as PS in the making of growing seedling trays and food containers. The debate borders on the balance between the practical usefulness of PS and its effect on the surrounding environment. Background Sand used to be the raw material for the production of polystyrene, which is a very wide applied plastic because of its cost-effectiveness and versatility in application. In horticulture, PS is used for seedling trays so that they can give their supporting plant effective drainage and serve a longer time due to their strength. In the food service sector, PS is used for containers like clamshells and cups due to its insulative and affordable properties. Events Horticulture Sector: Environmentalists in the previous decades have already raised concern on the future environmental impacts of PS seedling trays. Although the trays are durable and even to some extent, are reusable, these trays still add to plastic pollution because they are non-biodegradable. Other areas have already explored alternative materials to reduce plastic waste on gardening refuse. Food Service Sector In the same vein, the food service sector has been pressured by the public to discontinue its heavy use of PS containers. While the reasons behind this popularity are insulation and cost reduction, they have been faulted for contributing to the volume of landfill sites and being potential health risks. Recent reports have shown the need to shift to biodegradable packaging systems. Findings Plan Response from Industry: Going Green. In response to these perceptions, the horticulture and food service industries have began to react to the environmental impact of PS. These key steps include, 1. Alternatives: Research over biodegradable and compostable alternatives has been expedited. Industries now look into materials like plant based plastics and recycled fibers that can substitute common PS. 2. Developed Recycling Programs: Advanced recycling infrastructure is developed to manage a better waste load from PS. Developed recycling technologies and programs are being introduced to recover and reutilize materials made from PS. 3. Policy Change: Many countries' governments have framed regulations to control and limit the use of PS in single-use products. The policies have been framed to promote and encourage the use of sustainable alternatives and improve the management of waste. Impact And, the following are some of the positive impacts that the global response to the PS issues resulted in: Increased Awareness: Increased awareness among consumers and industry-related people about the environmental effects of PS and their role has facilitated informed choices and practices. Developing New Materials: The search and, to a contrary, immediate need for alternative sustainable gear had resulted in developing new eco-friendly types of materials in place of the traditional PS used in the nursery trays and food containers. - Advancements in Policies and Regulations: New policies and regulations enable changes toward sustainable operations directed to horticulture and foodservice sectors. Conclusion The ongoing discussion of the role of Polystyrene in seedling trays and food containers really brings the point of balancing practical advantages with environmental responsibility. The work on these challenges has been attended to, in developing partnership with industry and government, while the focus is on sustainability and being innovative with the future of eco-friendliness in both gardening and food service.

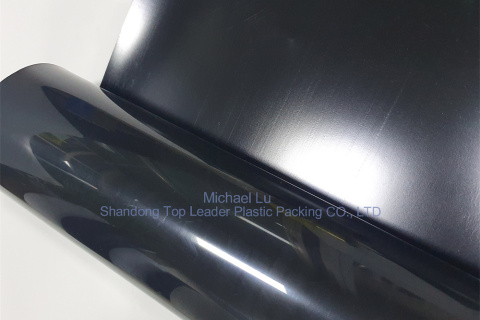

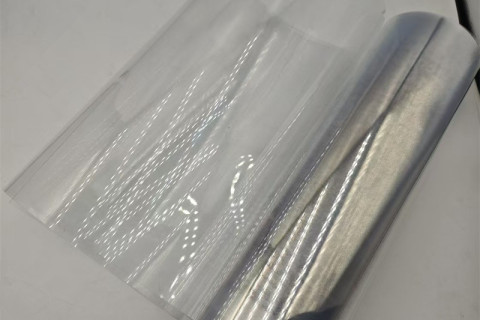

Polystyrene (PS) has a series of advantages such as hard texture, high rigidity, excellent electrical insulation