- Home

- >

News

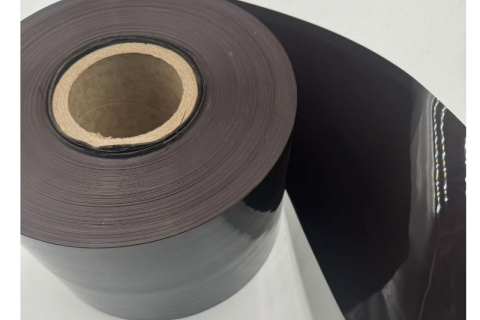

Applications of Brown PVC Film in Pharmaceutical Packaging Brown PVC film is widely used in the packaging of various types of pharmaceuticals, including tablets, capsules, powders, and liquids. It is suitable for both over-the-counter and prescription medications, as well as for generic and branded drugs.

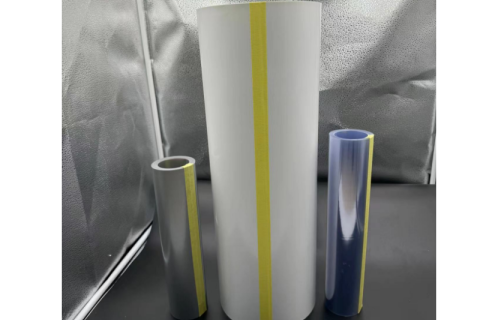

Secondly, white PVC film provides a good barrier against moisture, oxygen, and other contaminants. This helps to extend the shelf life of food products by preventing spoilage and degradation. It keeps the food fresh and flavorful for a longer period, reducing food waste and ensuring consumer satisfaction.

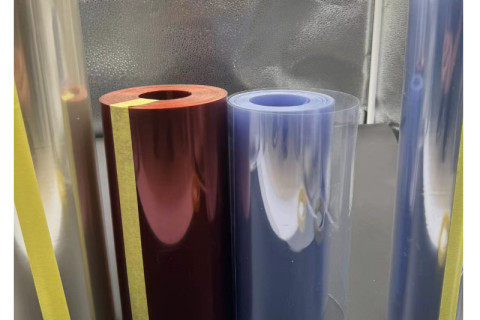

In the medical field, red PVC film also has its applications. It can be used for packaging medical supplies and devices. The material is sterile and can be easily sterilized again if needed. The red color can be used to indicate special instructions or warnings, making it easier for healthcare professionals to identify and handle the packages.

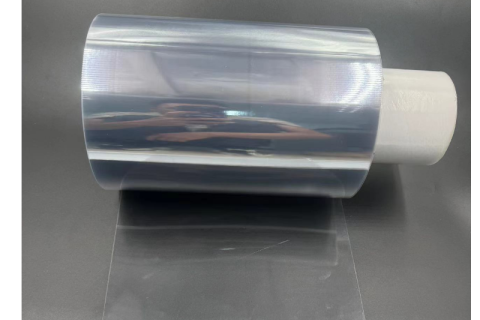

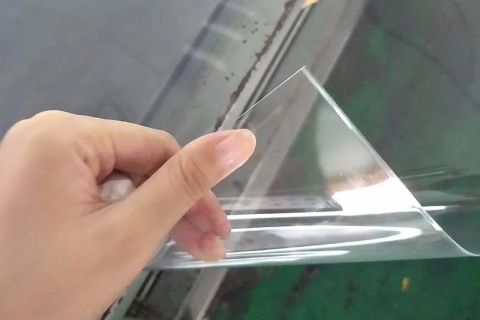

1. Advertising and Signage Printable transparent PVC film is widely used in the advertising and signage industry. Its transparency allows for creative designs that can be applied to windows, glass doors, and other transparent surfaces. Whether it's for promoting a brand, announcing an event, or providing directional signage, PVC film offers a sleek and eye-catching solution. The film can be printed with vibrant colors and high-resolution graphics, ensuring maximum visibility and impact. For example, in retail stores, printable PVC film is used to create window displays that attract customers and showcase products. The transparency of the film allows passersby to see inside the store while still being able to view the promotional messages printed on the film. In addition, PVC film can be used for outdoor signage, such as billboards and banners, as it is weather-resistant and can withstand exposure to sunlight, rain, and wind.

Anti-Static, Thermoformable PVC Film—Emerging Use One fine morning of [date] in the hustling city of [city name], a young entrepreneur, Lily Zhang, demonstrated the amazing versatility of the anti-static, thermoformable PVC film. Since she was a child, Lily was always interested in finding creative solutions for packaging and decoration problems. The first interest in PVC film came when she realized the growing needs for materials that combine functionality and aesthetics. Only the good and careful investigation of this topic, along with the examination, have greatly nurtured this interest, leading to the exploration of the peculiar features of anti-static thermoformable PVC film. At the beginning of this story, Lily visited a local packaging factory. Sensitive electronic parts, being packaged at this factory, would be destroyed by the static electricity. Their acquaintance was made with anti-static PVC film. The ability of the film to dissipate static charge caught immediate attention with the managers of this factory, which decided to give it a try. The PVC film was put on at the packaging stage, and Lily did it with the help of the factory team. The result was that the problem of static electricity disappeared, and the products packed could not be damaged in any way. Improved packaging gave a nicer look to the products, which was more catching for the customers. Not content with this single success, Lily applied her mind to the food packaging industry. She knew the importance of safety and presentation of food. With an anti-static PVC film, she was in a position to offer a solution that would protect the food from static charge, besides offering a clear and hygienic method of packaging. She toured some food processing factories and could demonstrate to them the feasibility of the PVC film. The plant managers could not believe how durable the product was, and how clean it was to use. They bought into the product and were now using the film to package fresh fruits, fresh vegetables, and even processed snack foods. The food can now be transported and stored without going bad and contaminated by any foreign matter. Next was pharmaceutical packaging. The requirements were much tougher: sterile packaging that protected the drugs from moisture and static electricity, yet conformed very strictly with the rules. Lily's anti-static PVC film proved up to the task. She worked in cooperation with pharmaceutical companies for the development of special packaging solutions. Examples of packaging made from this film are pills, tablets, and liquid preparations. Because this material is thermoformable, the form and size of packaging are easily managed to precisely fit a product. Anti-static properties protect medication from static damage, while clarity of the film allows for the possibility of seeing through for quality control. In interior decoration, Lily has found a completely new domain of application for the PVC film. She conceived using it in making those really unique and eye-catching designs in the apartment. She went and started co-operating at first with interior designers, then architects. Together, they were creating such a thing as wall coverings, so-that ceiling paneling, some decorations. Consequently, the PVC film could be let loose with abandon. It could be embossed printed, several patterns and colors could be offered or mixed, thus providing the designer with an ample latitude in working on interiors that are very personalized and chic. It was also easy to install and maintain and for these reasons preferred, not only by households but business establishments as well. Yet, in the field of glass decoration, Lily's PVC film shone once again. She has also created the special adhesive-backed PVC film, which can be directly applied to the surface of glasses to add not only a decorative touch but also privacy and UV protection. The journey of Lily with the anti-static, thermoformable PVC film was not that smooth. She was rejected by convinced clients who would not easily convert to another material. But through her persistence and hard work, she was able to overcome these obstacles and prove the value of the PVC film. With the success of Lily getting announced everywhere, anti-static thermoformable PVC film began to contact more and more industries. For example, automotive interior and aerospace components, the application of it was burgeoning. Actually, Lily's innovation had really made a miracle in many fields. Today, Lily is regarded as one of the authorities in packaging as well as decoration material. And her case is used to inspire others who, in drastic means, seek solutions to their everyday troubles. Because of Lily's vision and insistence, antistatic thermoformable PVC film is now indispensable in many industries. This thermoformable film has found application within the fields of packaging, food packaging, pharmaceutical packaging, decoration, and glass decoration because of its anti-static property. Unique qualities and infinite creativity opened up new paths of innovation and invention. Behind this successful innovation stands Lily Zhang, a young entrepreneur who dared to dream and make a difference.

Revolutionizing Folded Box and Pharmaceutical Thermoforming Packaging—PVC Sheets Date: August 13, 2023 Location: Shanghai, China Key Players: Leading packing manufacturers, pharmaceutical companies, environmental advocates Event Summary: In what could emerge as the most radical paradigm shift in packaging, Shanghai's top manufacturers yesterday announced increased application of polyvinyl chloride sheets for folded box and pharmaceutical thermoforming packaging. This will change the world in terms of product protection, cost efficiency, and manufacturing versatility. Background: Durability, flexibility, and cost represent some of the most preferred characteristics of PVC, and it has thereby found a place in most industries. However, recent developments in manufacturing PVC sheets raise renewed interest in using the material for special applications in pharmaceutical packaging and other consumer products. Cause and Course of Events: The trend of using PVC sheets in folded box and pharmaceutical packaging started this year when a number of packaging specialists, associated with different pharmaceutical companies, launched an all-inclusive study regarding the effectiveness of the material. Their conclusions, published in June 2024, pointed to some main advantages of PVC sheets, first of all related to their better defense against moisture, oxygen, and light—parameters that play a very important role in the preservation of pharmaceutical products. After the research, some leading packaging companies in Shanghai started to apply PVC sheets in their production lines within a very short period of time. It is the possibility of easily cutting, folding, and thermoforming the material into desired shapes that allows these companies to fulfill the tough requirements from pharmaceutical industries while offering beautiful and functional packaging to consumer products. Result: Beginning with the adoption of PVC sheets, fruitful results have already started to show. Pharmaceutical firms are reportedly found to declare that most of the problems related to packaging, such as contamination and damage of the product during transportation, have reduced considerably. Consumers have also welcomed the enhanced protection and longer shelf life of products packaged with PVC. Moreover, this reduces the overall production cost of PVC sheets, thereby enabling the manufacturer to maintain a competitive price and upgrade the quality of packaging. Impact and Future Prospects: Interest in PVC sheets for folded box and pharmaceutical thermoforming packaging has been quite successful, and other markets, like food and electronics, where solid, protective, and cost-efficient packaging is a must, may get attracted to it. Environmentalists still are wary and remind that without recycling programs, harm to the environment from PVC will only continue to grow. As innovations further the development in the packaging industry, PVC sheets can only play an ever-increasing role as a solution providing a reliable performance-cost-consumer safety balance for manufacturers. With Shanghai at the helm of this change, its packaging sector is well on course to lead global efforts towards improving products' packaging through strategic material use, such as PVC.

Polyvinyl chloride (PVC) is one of the most widely used plastics in the world, and its application in the medical packaging industry has become indispensable due to its versatility, durability, and cost-effectiveness. Here, we explore the various applications and benefits of PVC in the medical packaging field.

The material of the heat sealing blister shell is generally PVC, PET