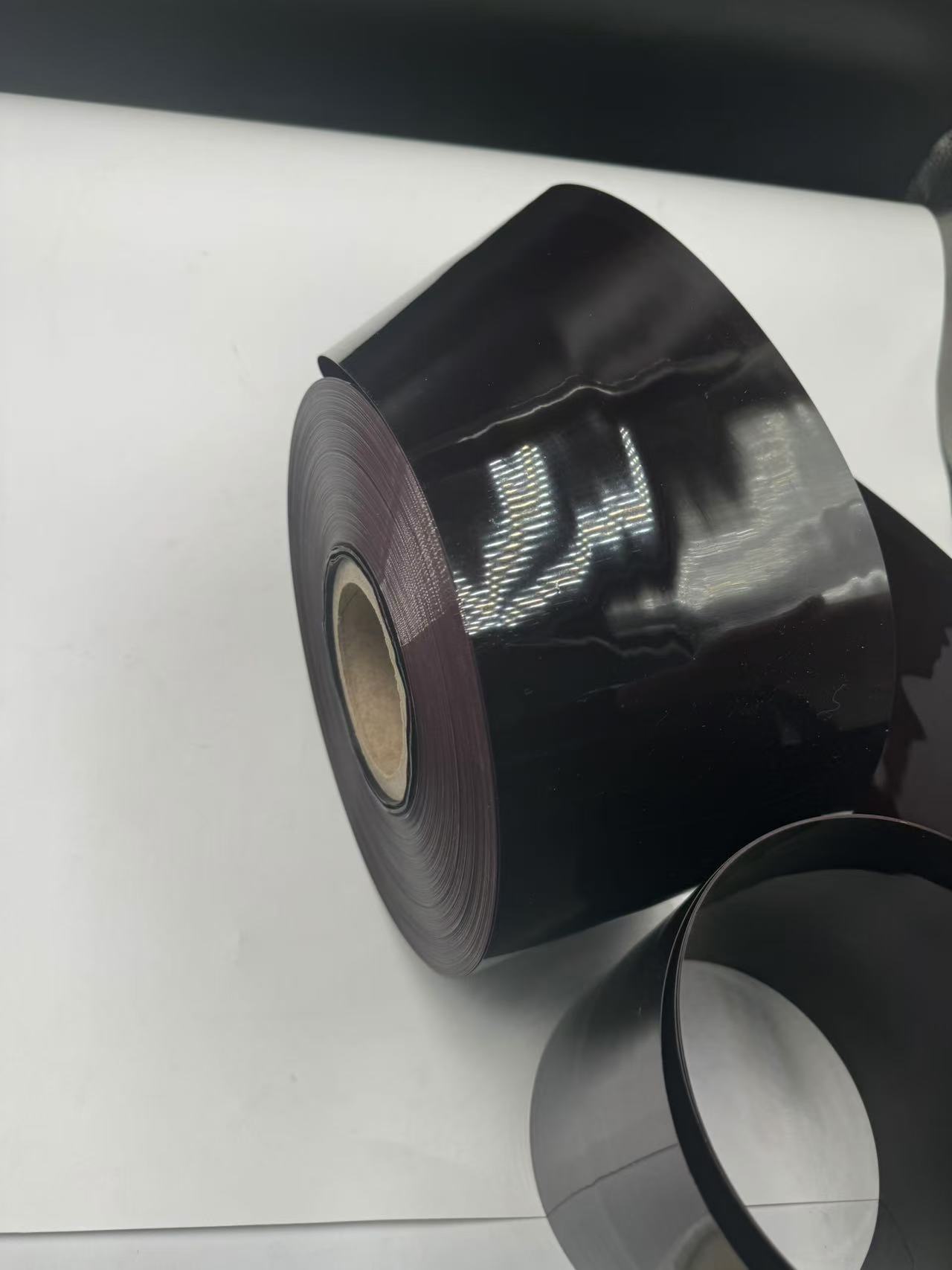

TL-PVC-0052 THE BROWN PVC FILM FOR PACKAGINE

2024-10-14 16:39Brown PVC Film in Blister Pharmaceutical Packaging

Introduction

In the realm of pharmaceutical packaging, the choice of materials plays a crucial role in ensuring the safety, integrity, and effectiveness of medications. One material that has gained significant prominence in recent years is brown PVC film. This versatile and reliable packaging solution offers a host of advantages that make it an ideal choice for blister packaging of pharmaceuticals.

The Significance of Pharmaceutical Packaging

Pharmaceutical packaging is not merely a container for medications; it is a critical component that safeguards the drug from external factors, provides accurate dosing information, and enhances patient compliance. Packaging must meet stringent regulatory requirements to ensure the quality and safety of the product. It also needs to be visually appealing to attract the attention of healthcare providers and patients alike.

Brown PVC Film: An Overview

Brown PVC film is a type of thermoplastic material that is widely used in various industries, including pharmaceuticals. It is known for its durability, flexibility, and resistance to moisture, light, and chemicals. The brown color of the film provides an added layer of protection by blocking out light, which can degrade certain medications. This makes it particularly suitable for packaging light-sensitive drugs.

Properties and Advantages of Brown PVC Film

1. Light Barrier Properties

One of the key advantages of brown PVC film is its excellent light barrier properties. Light can cause degradation of many pharmaceuticals, reducing their potency and effectiveness. By using brown PVC film, manufacturers can ensure that their products are protected from light-induced degradation, thereby extending the shelf life of the medication.

2. Moisture Resistance

Pharmaceuticals need to be protected from moisture to maintain their quality. Brown PVC film is highly resistant to moisture, preventing the ingress of water vapor and ensuring that the drug remains dry and stable. This is especially important for medications that are hygroscopic or prone to degradation in the presence of moisture.

3. Chemical Resistance

The film also offers good chemical resistance, protecting the medication from exposure to chemicals that may be present in the environment or during transportation. This helps to maintain the integrity of the drug and ensures its safety for consumption.

4. Durability and Flexibility

Brown PVC film is durable and flexible, making it easy to form into blister packs. It can withstand the rigors of handling and transportation without cracking or breaking, ensuring that the medication remains protected throughout the supply chain.

5. Customizability

The film can be customized in terms of thickness, size, and shape to meet the specific requirements of different pharmaceutical products. This allows manufacturers to create packaging solutions that are tailored to their needs, enhancing the overall packaging efficiency and effectiveness.

The Blister Packaging Process

Blister packaging is a popular method for packaging pharmaceuticals due to its convenience, safety, and visibility. The process involves forming cavities or pockets in a sheet of material, usually PVC or aluminum foil, and then sealing a backing material over the cavities to enclose the medication. Brown PVC film is commonly used as the blister material due to its properties and advantages as discussed earlier.

The blister packaging process typically involves the following steps:

1. Design and Tooling

The first step is to design the blister pack layout and create the necessary tooling. This includes designing the cavities to hold the medication, determining the size and shape of the blister pack, and creating the molds or dies for forming the blister cavities.

2. Material Selection

Next, the appropriate materials are selected for the blister pack. Brown PVC film is often chosen for its light barrier, moisture resistance, and chemical resistance properties. The backing material, which is usually aluminum foil or paperboard, is also selected based on its compatibility with the medication and the packaging requirements.

3. Forming the Blisters

The brown PVC film is heated and formed into blister cavities using a thermoforming process. The cavities are designed to hold the medication securely and protect it from damage.

4. Filling the Blisters

Once the blisters are formed, the medication is placed into the cavities. This can be done manually or using automated filling machines, depending on the production volume and complexity of the packaging process.

5. Sealing the Blisters

After the medication is filled, the backing material is sealed over the blisters to enclose the medication. This is typically done using heat sealing or adhesive bonding to ensure a tight and secure seal.

6. Inspection and Quality Control

The blister packs are then inspected for quality and integrity. This includes checking for proper sealing, correct filling of the medication, and absence of defects or contaminants. Any defective packs are removed and discarded to ensure that only high-quality products reach the market.

Applications of Brown PVC Film in Pharmaceutical Packaging

Brown PVC film is widely used in the packaging of various types of pharmaceuticals, including tablets, capsules, powders, and liquids. It is suitable for both over-the-counter and prescription medications, as well as for generic and branded drugs.

Some of the common applications of brown PVC film in pharmaceutical packaging include:

1. Packaging of Solid Dosage Forms

Tablets and capsules are the most common solid dosage forms packaged in blister packs. Brown PVC film provides an ideal packaging solution for these products, protecting them from light, moisture, and physical damage. The blister packs can be designed to hold different sizes and shapes of tablets and capsules, making them highly versatile.

2. Packaging of Powders and Granules

Powders and granules can also be packaged in blister packs using brown PVC film. The film can be designed to hold the powder or granules securely and prevent leakage or spillage. This is particularly useful for medications that need to be accurately dosed and protected from moisture.

3. Packaging of Liquids

In some cases, liquids such as syrups and suspensions can also be packaged in blister packs using brown PVC film. Specialized blister designs are used to hold the liquid and prevent leakage. The film provides an effective barrier against light and moisture, ensuring the stability of the liquid medication.

Regulatory Compliance and Quality Assurance

Pharmaceutical packaging is subject to strict regulatory requirements to ensure the safety and quality of the product. Brown PVC film used in pharmaceutical packaging must comply with relevant regulations and standards, such as those set by the Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

Manufacturers of brown PVC film for pharmaceutical packaging are required to implement quality management systems and conduct regular quality control tests to ensure that their products meet the required specifications. These tests may include physical and chemical properties testing, light barrier testing, moisture resistance testing, and compatibility testing with different medications.

Environmental Impact and Sustainability

As the demand for sustainable packaging solutions grows, the environmental impact of brown PVC film is also a concern. PVC is a synthetic material that is derived from petroleum, and its production and disposal can have environmental implications.

However, efforts are being made to develop more sustainable alternatives to PVC film. Some manufacturers are exploring the use of bio-based materials or recyclable plastics to reduce the environmental footprint of pharmaceutical packaging. Additionally, recycling programs are being implemented to collect and recycle used blister packs, reducing waste and conserving resources.

Conclusion

Brown PVC film has emerged as a reliable and effective packaging solution for pharmaceuticals. Its light barrier, moisture resistance, and chemical resistance properties make it an ideal choice for blister packaging of medications, ensuring their safety, integrity, and effectiveness. With its customizability and versatility, brown PVC film can be tailored to meet the specific needs of different pharmaceutical products.

As the pharmaceutical industry continues to evolve, the demand for high-quality packaging solutions will only increase. Brown PVC film is well-positioned to meet this demand, providing manufacturers with a reliable and sustainable packaging option. However, it is important to consider the environmental impact of PVC and explore alternative materials and packaging solutions to ensure a more sustainable future.

In conclusion, brown PVC film plays a crucial role in the packaging of pharmaceuticals, offering protection, convenience, and visibility. Its properties and advantages make it an essential component of the pharmaceutical supply chain, ensuring that medications reach patients in a safe and effective manner.