Unveiling the Crystal Clarity: The Versatile World of Transparent PA/PE Films

2025-10-31 15:49 Introduction: The Invisible Guardian of FreshnessIn the bustling aisles of supermarkets, the quiet hum of food processing plants, and the meticulous craft of artisanal delis, one unsung hero quietly preserves the vibrancy of our daily meals: transparent PA/PE film. This multilayer marvel, blending the robustness of polyamide (PA) with the pliability of polyethylene (PE), forms a thin yet formidable shield that keeps food looking as inviting as the day it was packaged. Imagine slicing open a vacuum-sealed steak that gleams with freshness, or peering through a blister pack to see ripe berries nestled securely—these moments of unmarred visibility and uncompromised quality are courtesy of this film's innate transparency and protective prowess.

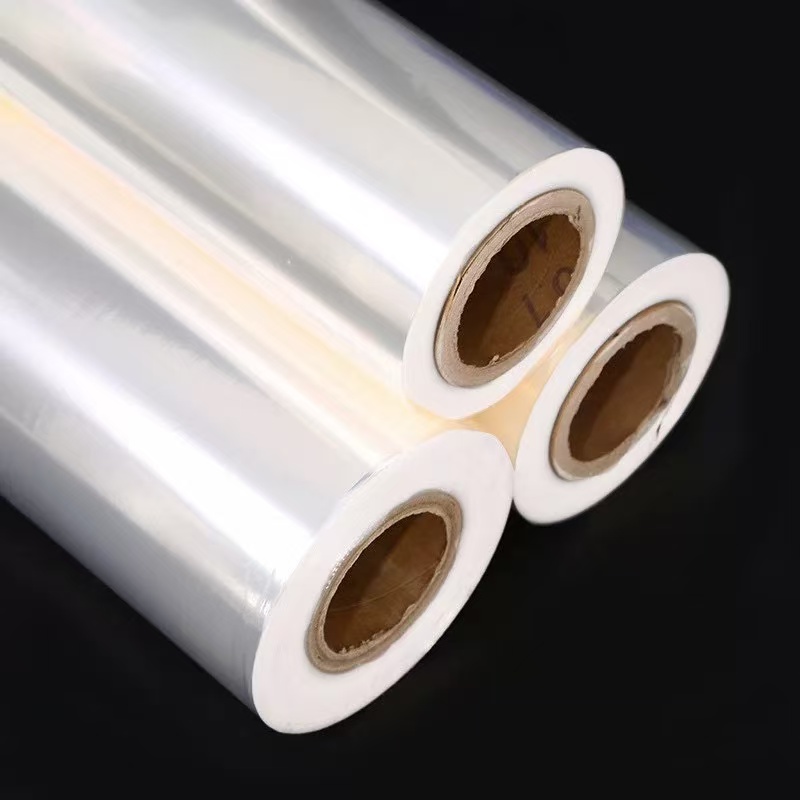

Introduction: The Invisible Guardian of FreshnessIn the bustling aisles of supermarkets, the quiet hum of food processing plants, and the meticulous craft of artisanal delis, one unsung hero quietly preserves the vibrancy of our daily meals: transparent PA/PE film. This multilayer marvel, blending the robustness of polyamide (PA) with the pliability of polyethylene (PE), forms a thin yet formidable shield that keeps food looking as inviting as the day it was packaged. Imagine slicing open a vacuum-sealed steak that gleams with freshness, or peering through a blister pack to see ripe berries nestled securely—these moments of unmarred visibility and uncompromised quality are courtesy of this film's innate transparency and protective prowess. At its core, transparent PA/PE film is a co-extruded laminate where PA layers provide tensile strength and gas barrier properties, while PE layers ensure excellent sealability and moisture resistance. This synergy results in a material that's not just functional but elegantly simple: crystal-clear, lightweight, and adaptable to high-speed production lines. Why does it matter? In an era where consumers demand both convenience and sustainability, this film strikes a perfect balance—extending shelf life without sacrificing aesthetics or the planet's resources. Over the next sections, we'll delve into its standout characteristics, backed by the practical physics of its composition, and explore its transformative roles in food vacuum packaging, blister packaging, high-barrier applications, and sausage wrapping. Through vivid scenarios and logical breakdowns, we'll see how this film doesn't just wrap products; it elevates them.

At its core, transparent PA/PE film is a co-extruded laminate where PA layers provide tensile strength and gas barrier properties, while PE layers ensure excellent sealability and moisture resistance. This synergy results in a material that's not just functional but elegantly simple: crystal-clear, lightweight, and adaptable to high-speed production lines. Why does it matter? In an era where consumers demand both convenience and sustainability, this film strikes a perfect balance—extending shelf life without sacrificing aesthetics or the planet's resources. Over the next sections, we'll delve into its standout characteristics, backed by the practical physics of its composition, and explore its transformative roles in food vacuum packaging, blister packaging, high-barrier applications, and sausage wrapping. Through vivid scenarios and logical breakdowns, we'll see how this film doesn't just wrap products; it elevates them. The Hallmarks of Excellence: Key Characteristics of Transparent PA/PE FilmWhat makes transparent PA/PE film a staple in modern packaging? It's a symphony of properties, each honed by the molecular dance between PA and PE. Let's break it down, starting with its most eye-catching trait: optical clarity.Unrivaled Transparency and Visual Appeal

The Hallmarks of Excellence: Key Characteristics of Transparent PA/PE FilmWhat makes transparent PA/PE film a staple in modern packaging? It's a symphony of properties, each honed by the molecular dance between PA and PE. Let's break it down, starting with its most eye-catching trait: optical clarity.Unrivaled Transparency and Visual AppealPicture a sunlit display case in a high-end grocery store, where packages of gourmet cheeses glow with an almost jewel-like sheen. This isn't luck—it's the film's light transmission rate, often exceeding 90%, allowing nearly all visible light to pass through undistorted. Unlike opaque alternatives that hide contents or tint them yellow, PA/PE film's low haze factor (typically under 5%) ensures colors pop vividly: the crimson of fresh salmon, the golden crust of artisan bread, all preserved in pristine view. This clarity isn't superficial; it's rooted in the amorphous structure of PA, which scatters minimal light, combined with PE's smooth surface. For consumers, this means trust at a glance—no guesswork about spoilage or quality. In production, it enables precise quality checks without unwrapping, slashing waste and boosting efficiency.

Superior Barrier Properties: A Fortress Against Invaders

Superior Barrier Properties: A Fortress Against InvadersFood's greatest enemies—oxygen, moisture, and light—meet their match in PA/PE film's barrier armor. The PA layer acts as a molecular sieve, with oxygen transmission rates as low as 20-50 cm³/m²/day, far below standard PE films' 2000+. This isn't hyperbole; it's chemistry at work. Polyamide's polar groups form tight hydrogen bonds, repelling non-polar oxygen molecules and curbing oxidation that turns fats rancid or fruits brown. Moisture vapor transmission? Capped at 10-20 g/m²/day, thanks to PE's hydrophobic backbone, preventing sogginess in delicate items like pastries. Light barrier? While transparent, the film subtly filters UV rays, extending the life of light-sensitive nutrients like vitamins in juices. In real-world terms, this translates to shelf lives doubled or tripled: a pack of sliced deli meats that stays pink and plump for weeks, rather than wilting in days.

Bend it, twist it, drop it—transparent PA/PE film bounces back. With a tensile strength of 150-250 MPa, it withstands the rigors of automated filling lines, where speeds hit 100 packs per minute. Elongation at break reaches 200-300%, courtesy of PE's ductility, making it puncture-resistant against sharp bones in meat packs or thorns on produce. Yet, it's slim—often 50-100 microns thick—reducing material use by up to 30% compared to single-layer films. This toughness shines in logistics: imagine a pallet of vacuum-packed fish surviving a bumpy truck ride from port to market, arriving taut and intact, not torn and leaking.

Seamless Sealability and Process Compatibility

Seamless Sealability and Process CompatibilityHot enough to fuse, cool enough to handle—PA/PE film's thermal properties are a packager's dream. PE's low melting point (around 110°C) enables quick heat-sealing at 120-150°C, forming hermetic bonds in under a second. No leaks, no weak spots; seals hold up to 20-30 N/15mm peel strength, even under vacuum pressures of 99%. It's thermoformable too, stretching up to 50% without thinning critically, ideal for molded trays. And for eco-conscious brands, it's recyclable—PE layers peel away from PA for streamlined reprocessing, aligning with circular economy goals. These traits aren't abstract; they're the reason a small-batch sausage maker can scale from handmade casings to industrial runs without compromising that homemade snap.Hygiene and Safety: The Silent Sentinel

Inert and non-toxic, this film complies with global food contact standards, leaching zero harmful migrants even after prolonged exposure. Its smooth surface deters bacterial adhesion—studies show microbial growth rates 50% lower than rougher films—making it a boon for HACCP protocols. Add antimicrobial additives if needed, and it becomes a proactive shield. Vividly, think of a family picnic: sandwiches wrapped in this film stay crisp, uncontaminated, turning a simple outing into a worry-free feast.These characteristics interlock like gears in a well-oiled machine, making PA/PE film not just a wrapper, but a strategic asset. Now, let's see it in action across key applications.Revolutionizing Food Vacuum Packaging: Locking in Flavor and FreshnessVacuum packaging is where transparent PA/PE film truly flexes its muscles, transforming perishable goods from fleeting to enduring. Envision a busy seafood market at dawn: crates of shrimp arrive glistening from the ocean, only to be sucked into airless embraces by high-speed vacuum chambers. The film shrinks conformally around contours, its PA layer starving aerobic bacteria of oxygen while PE seals out humidity. Result? A 5-7 day extension in fridge life for raw meats, or up to 3 months frozen without freezer burn—facts borne from the film's oxygen barrier slashing microbial proliferation by 90%.

Elevating Food Blister Packaging: Display Meets DurabilityShift to the vibrant chaos of a grocery store's produce section, where blister packs of strawberries perch like ruby jewels under fluorescent lights. Here, transparent PA/PE film stars in thermoformed blisters—rigid bases topped with lidding films that dome protectively. The PE layer heat-seals to PET trays at precise temperatures, creating tamper-evident bubbles that pop open with a satisfying tear, not a frustrating rip. Mastering High-Barrier Packaging: Shielding the SensitiveFor products where even a whisper of air spells doom, high-barrier PA/PE film rises as the ultimate guardian. Layered configurations—PA/PE/PA/PE—boost oxygen barriers to sub-10 cm³/m²/day, ideal for oxygen-scavenging needs like powdered milks or nutritional supplements. Consider a pharmaceutical-grade yogurt pouch: probiotics demand anaerobic bliss, and this film's EVOH tie-layers (optional enhancements) deliver, preserving live cultures for 6+ months.In high-end confections, it's magic. Delicate truffles, prone to bloom from moisture ingress, stay satin-smooth under the film's vigilant watch. Transmission rates plummet, halting fat migration that dulls chocolate's snap. Retailers stack these in open bins, the transparency teasing bites without exposure risks. Logistically, it endures sterilization—autoclavable up to 121°C— for retorted soups, where flavors meld without metallic taints.

Elevating Food Blister Packaging: Display Meets DurabilityShift to the vibrant chaos of a grocery store's produce section, where blister packs of strawberries perch like ruby jewels under fluorescent lights. Here, transparent PA/PE film stars in thermoformed blisters—rigid bases topped with lidding films that dome protectively. The PE layer heat-seals to PET trays at precise temperatures, creating tamper-evident bubbles that pop open with a satisfying tear, not a frustrating rip. Mastering High-Barrier Packaging: Shielding the SensitiveFor products where even a whisper of air spells doom, high-barrier PA/PE film rises as the ultimate guardian. Layered configurations—PA/PE/PA/PE—boost oxygen barriers to sub-10 cm³/m²/day, ideal for oxygen-scavenging needs like powdered milks or nutritional supplements. Consider a pharmaceutical-grade yogurt pouch: probiotics demand anaerobic bliss, and this film's EVOH tie-layers (optional enhancements) deliver, preserving live cultures for 6+ months.In high-end confections, it's magic. Delicate truffles, prone to bloom from moisture ingress, stay satin-smooth under the film's vigilant watch. Transmission rates plummet, halting fat migration that dulls chocolate's snap. Retailers stack these in open bins, the transparency teasing bites without exposure risks. Logistically, it endures sterilization—autoclavable up to 121°C— for retorted soups, where flavors meld without metallic taints.  The Art of Sausage Packaging: From Farm to Fork PerfectionNo application captures PA/PE film's charisma quite like sausage casing—where tradition meets technology in a savory embrace. Artisanal butchers have long prized natural casings, but transparent PA/PE offers scalability without sacrifice. Extruded as seamless tubes, it mimics collagen's snap while providing clarity to showcase the marbled pink of pepperoni or the herb-flecked coil of Italian sausage. Broader Horizons: Beyond the BasicsWhile our focus hones on food realms, transparent PA/PE film's versatility spills into medical blister packs for pills (sterile, shatterproof), agricultural wraps for silage (UV-stable, rot-proof), and even e-commerce mailers for cosmetics (tamper-evident, lightweight). Each extension leverages its core traits, proving its adaptability.

The Art of Sausage Packaging: From Farm to Fork PerfectionNo application captures PA/PE film's charisma quite like sausage casing—where tradition meets technology in a savory embrace. Artisanal butchers have long prized natural casings, but transparent PA/PE offers scalability without sacrifice. Extruded as seamless tubes, it mimics collagen's snap while providing clarity to showcase the marbled pink of pepperoni or the herb-flecked coil of Italian sausage. Broader Horizons: Beyond the BasicsWhile our focus hones on food realms, transparent PA/PE film's versatility spills into medical blister packs for pills (sterile, shatterproof), agricultural wraps for silage (UV-stable, rot-proof), and even e-commerce mailers for cosmetics (tamper-evident, lightweight). Each extension leverages its core traits, proving its adaptability. Conclusion: A Clear Future Wrapped in InnovationTransparent PA/PE film isn't merely a material; it's a bridge between nature's bounty and modern life's haste—clear, strong, and selfless. From vacuum-sealed steaks whispering of pastures to blister-packed berries singing of summer, it ensures our food arrives not just safe, but seductive. As demands for sustainability and visibility grow, this film's evolution—thinner, greener, smarter—promises to keep wrapping wonders. In every crinkle and seal, it reminds us: the best protectors are the ones we barely notice.(Word count: 1,998)

Conclusion: A Clear Future Wrapped in InnovationTransparent PA/PE film isn't merely a material; it's a bridge between nature's bounty and modern life's haste—clear, strong, and selfless. From vacuum-sealed steaks whispering of pastures to blister-packed berries singing of summer, it ensures our food arrives not just safe, but seductive. As demands for sustainability and visibility grow, this film's evolution—thinner, greener, smarter—promises to keep wrapping wonders. In every crinkle and seal, it reminds us: the best protectors are the ones we barely notice.(Word count: 1,998)