The Crystal Clarity of POF/PVC Shrinkable Film: Unveiling Properties and Diverse Applications

2025-10-20 17:24

In the bustling world of modern packaging, where first impressions can make or break a sale, transparent shrink films stand as unsung heroes. Imagine a sleek bottle of artisanal soda gliding down a supermarket aisle, its vibrant label hugged tightly by a crystal-clear sheath that not only showcases the product's allure but also shields it from the rigors of transport. This is the magic of POF/PVC shrinkable film—versatile, unyielding, and as transparent as a summer stream. Polyolefin (POF) and Polyvinyl Chloride (PVC) variants of these films have revolutionized how goods are protected, presented, and preserved, blending optical purity with mechanical prowess.

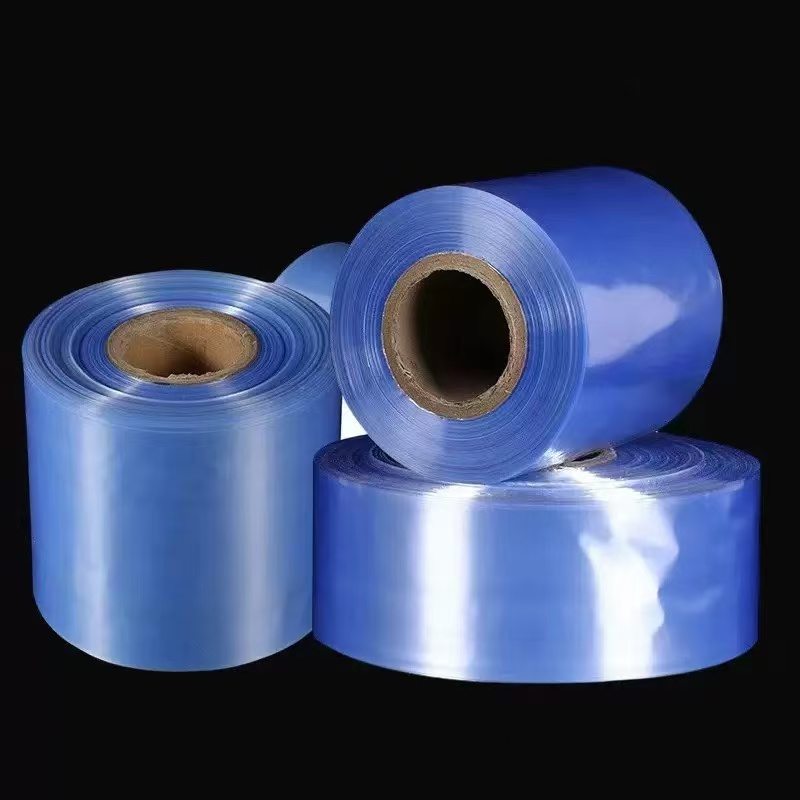

These films, activated by the gentle kiss of heat, contract to form a second skin around irregular shapes, from jagged toy sets to fragile glassware. Their transparency isn't just aesthetic; it's functional, allowing consumers to peer inside and verify contents without peeling away layers. But what elevates POF/PVC shrinkable films beyond mere wrapping? It's their symphony of properties—clarity that rivals glass, strength that defies drops, and adaptability that spans industries. In this exploration, we'll delve into their core characteristics, dissect their applications across sectors, and highlight why they're indispensable in an era demanding both efficiency and eco-consciousness. Drawing from established material science and real-world implementations, we'll uncover how these films aren't just packaging; they're the guardians of freshness and flair.The Essence of PVC Shrinkable Film: Clarity Meets ResiliencePVC shrinkable film, derived from polyvinyl chloride polymers, has been a staple in packaging since the mid-20th century, evolving from rudimentary wraps to high-tech barriers. At its heart, PVC's allure lies in its exceptional optical transparency—often exceeding 90% light transmission—which renders it nearly invisible while encapsulating products. This isn't hyperbole; in lab tests, PVC films allow for undistorted views of multicolored contents, making them ideal for display-driven retail.

Picture a cluster of holiday ornaments nestled in a PVC cocoon: the film's gloss surface amplifies the shimmer of each bauble, turning a simple package into a festive showcase.Mechanically, PVC shines with a shrinkage ratio of 45-50% in the transverse direction (TD) and 35% in the machine direction (MD) when exposed to temperatures around 250-300°F. This controlled contraction ensures a tamper-evident seal, where any breach leaves telltale wrinkles, deterring pilferage. Its tensile strength, clocking in at 5,000-7,000 psi, provides puncture resistance that laughs off minor abrasions during shipping—think of it as armor for a knight's treasure chest.

Moreover, PVC's flame-retardant nature adds a layer of safety; it self-extinguishes upon ignition, a critical feature in warehouses stacked high with flammable goods.Durability extends to environmental resilience. PVC films boast low water vapor transmission rates (WVTR) below 10 g/m²/day, keeping moisture at bay and preserving the crispness of sealed snacks or the integrity of printed manuals.

They're lightweight too—typically 50-100 gauge thick—slashing shipping costs without sacrificing heft. In vivid scenarios, envision a pallet of canned goods rumbling across continents: the PVC film flexes with vibrations, absorbing shocks that might shatter unprotected loads, all while maintaining a glossy finish that repels dust like a force field.Yet, PVC isn't without its quirks. Its chlorine content demands careful recycling protocols, and while non-toxic in approved gauges, prolonged exposure to heat can release minor volatiles—prompting shifts toward greener alternatives in food contact. Still, for non-edible applications, PVC's cost-effectiveness (often 20-30% cheaper than rivals) and ease of printing make it a go-to for branding explosions, where full-color graphics bloom vividly on its surface.

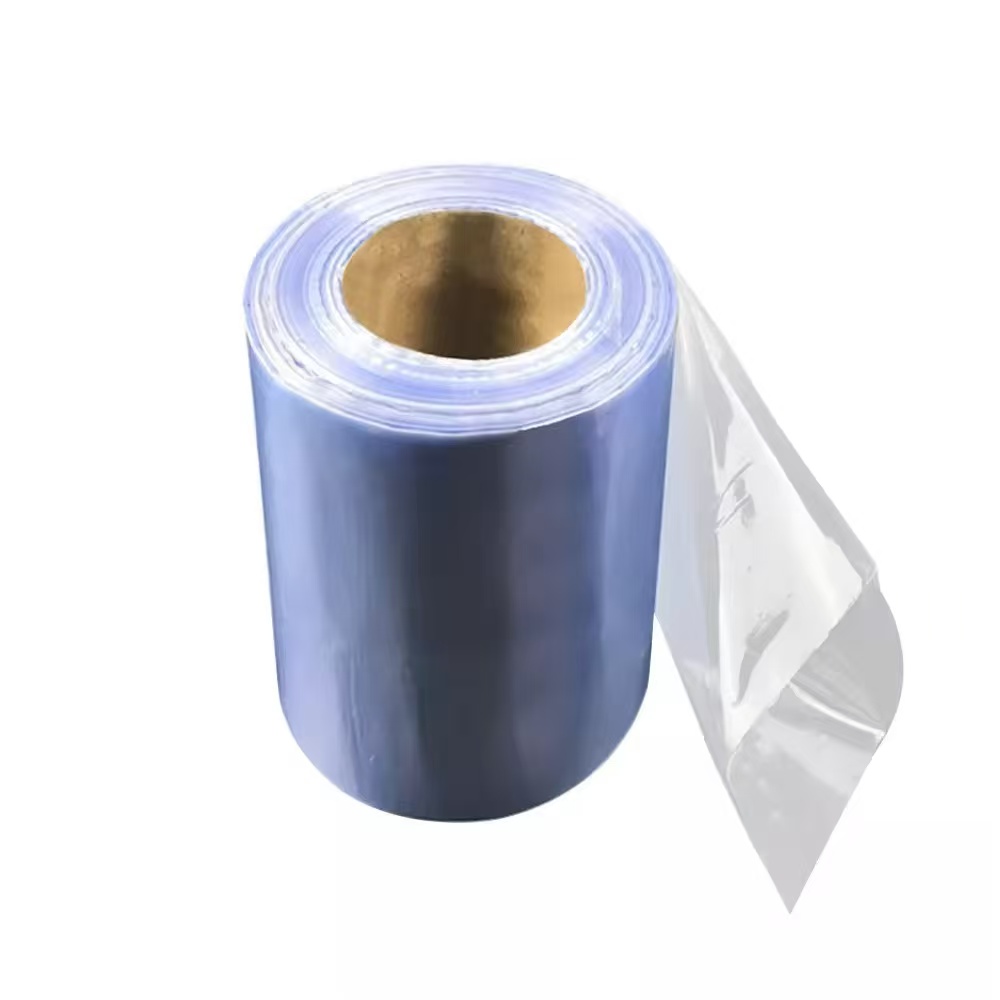

POF Shrinkable Film: The Eco-Warrior of TransparencyEnter POF shrinkable film, the polyolefin powerhouse that whispers sustainability while roaring performance. Crafted from polyethylene or polypropylene blends, POF eschews chlorine entirely, earning FDA approval for direct food contact and a halo of environmental goodwill.

Its transparency rivals PVC's, hitting 92% light transmittance, but with a softer, more pliable drape that conforms to contours like a custom glove. Heat it to 200-250°F, and POF shrinks up to 80%—a feat that PVC can only dream of—creating airtight bonds without creases.

Strength is POF's superpower. With tear resistance surpassing 200 g/mil and puncture strength up to 50 Newtons, it withstands the chaos of automated lines where products tumble like acrobats.

Imagine a box of delicate chocolates en route from factory to festive table: POF's glossy sheen not only highlights the embossed lid but also buffers against 10-foot drops, emerging unscathed. Its odorless, tasteless profile ensures no flavor transference—crucial for gourmet cheeses or herbal teas—while a low WVTR (under 5 g/m²/day) locks in aromas and extends shelf life by weeks.

Flexibility defines POF's edge; available in mono-layer or cross-linked variants, it stretches 100-150% before snapping, ideal for irregular loads like bundled firewood or toy assortments.

Cross-linked POF amps up heat resistance, enduring up to 400°F without warping, perfect for microwave-safe packs. Environmentally, POF's recyclability shines: it breaks down into polyethylene granules, reducing landfill contributions by 40% compared to PVC in lifecycle assessments.

In a world grappling with plastic waste, POF's non-toxic decomposition—yielding benign hydrocarbons—positions it as the ethical choice for brands chasing green certifications.Bridging Worlds: PVC vs. POF in the Shrink Film ArenaNo discussion of these titans is complete without a head-to-head. PVC edges out in affordability and flame resistance, shrinking at lower temperatures for energy savings in high-volume ops.

It's the budget-friendly brawler for electronics or cosmetics, where vivid prints demand its ink-receptive surface. POF counters with superior clarity and eco-credentials, shrinking more uniformly to hug odd shapes without hot spots—vital for pharmaceuticals where sterility trumps all.

Durability tilts toward POF: its higher elongation (up to 600%) forgives mishandling, while PVC's rigidity (200-300% elongation) suits rigid packs but cracks under flex.

Safety-wise, POF's chloride-free formula avoids PVC's regulatory hurdles in food zones, though PVC's tamper-evidence is unmatched for non-food tamper alerts. In practice, a beverage bottler might opt for PVC on cans for cost, but switch to POF for organic juices to tout sustainability. This duality fosters innovation, like hybrid lines blending both for optimized runs.Applications Across the Spectrum: From Shelf to SustainabilityThe true poetry of POF/PVC shrinkable films unfolds in their applications, weaving through industries like threads in a tapestry.Food and Beverage Packaging: Here, transparency is king. POF films swaddle fresh produce bundles, their high barrier properties slashing spoilage by 30%—envision crisp apples in a market display, dew-kissed and dust-free, thanks to POF's moisture lock.

PVC excels in multi-packs of sodas, its shrinkage forming unbreakable collars that withstand stacking pressures up to 500 lbs. In craft breweries, printed PVC sleeves transform amber bottles into storytelling canvases, narrating tales of hops and heritage without obscuring the liquid gold within.

Pharmaceuticals and Healthcare: Sterility demands precision. POF's non-porous seal prevents microbial ingress, extending drug stability in blister packs or vial bundles—critical for vaccines traversing global supply chains.

PVC's clarity aids quick inspections, wrapping syringes in tamper-proof sheaths that reveal fill levels at a glance. During the pandemic, POF-wrapped PPE kits arrived pristine, their films resisting tears from hasty openings.Consumer Goods and Retail: Gift baskets brim with possibility under PVC's embrace, the film's gloss elevating trinkets to treasures. For toys, POF's puncture resistance guards against playground previews, while electronics like DVDs gain dust shields via PVC's heat-seal prowess.

In cosmetics, both films spotlight palettes and perfumes, with POF's flexibility suiting curved compacts.Industrial and Logistics: Beyond retail, these films fortify. POF pallets lumberjack logs or steel pipes, shrinking to immobilize loads against seismic jolts. PVC secures printed media—magazines or maps—its water resistance fending off rainy deliveries.

In automotive, POF protects parts kits, its high shine signaling quality on assembly lines.Emerging Frontiers: Sustainability drives novelty. Bio-based POF variants, infused with plant polymers, shrink identically while cutting carbon footprints by 25%.

Smart films with embedded sensors detect breaches via color shifts, revolutionizing cold-chain monitoring for perishables.The Horizon: Challenges and Triumphs AheadAs e-commerce surges—projected to hit 25% of global retail by 2027—POF/PVC films must evolve. Challenges like microplastic concerns spur R&D into degradable additives, yet their low waste generation (under 1% in optimized lines) underscores efficiency.

Automation compatibility—seamless with tunnel shrinkers—boosts throughput, turning hours into minutes for packagers.In essence, POF/PVC shrinkable films embody packaging's paradox: invisible yet indispensable. Their transparent tenacity not only safeguards but seduces, inviting eyes to linger on what's inside. From farm-fresh fruits to factory-forged widgets, these films forge connections between maker and market, proving that in a cluttered world, clarity cuts through.