POF SHrink film Unveiling the Crystal Clarity: The Versatile World of Transparent POF Shrink Film

2025-10-14 17:28Unveiling the Crystal Clarity: The Versatile World of Transparent POF Shrink Film A Transparent Revolution in Packaging InnovationIn the bustling aisles of supermarkets and the quiet efficiency of warehouses, one material stands out for its unassuming elegance and remarkable functionality: transparent POF shrink film. Derived from polyolefin resins, this heat-activated packaging marvel transforms ordinary products into securely wrapped treasures, all while maintaining a pristine, see-through allure. Imagine a fresh salad kit gleaming under fluorescent lights, its vibrant greens and crisp reds fully visible, tempting shoppers with their untouched vitality. Or picture a stack of disposable plates bundled neatly, ready for a backyard barbecue, protected yet perfectly showcased. This is the magic of transparent POF shrink film—a blend of science and artistry that has quietly reshaped industries from food preservation to electronics safeguarding.

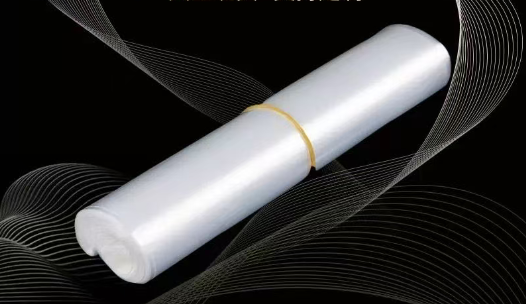

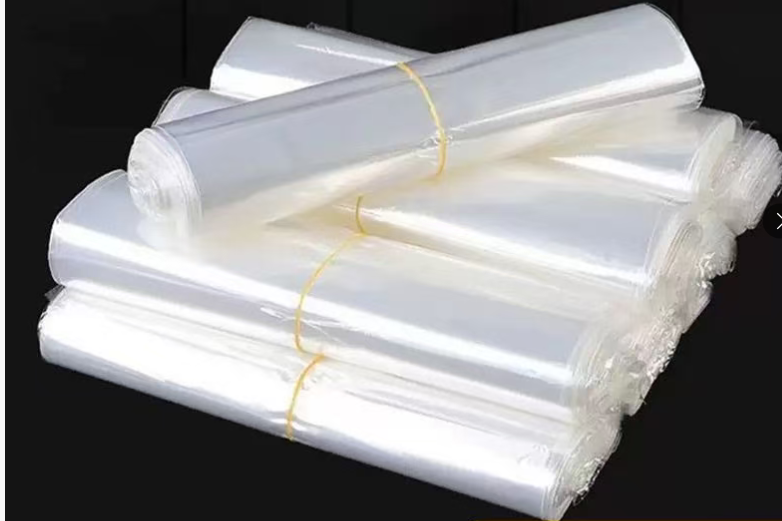

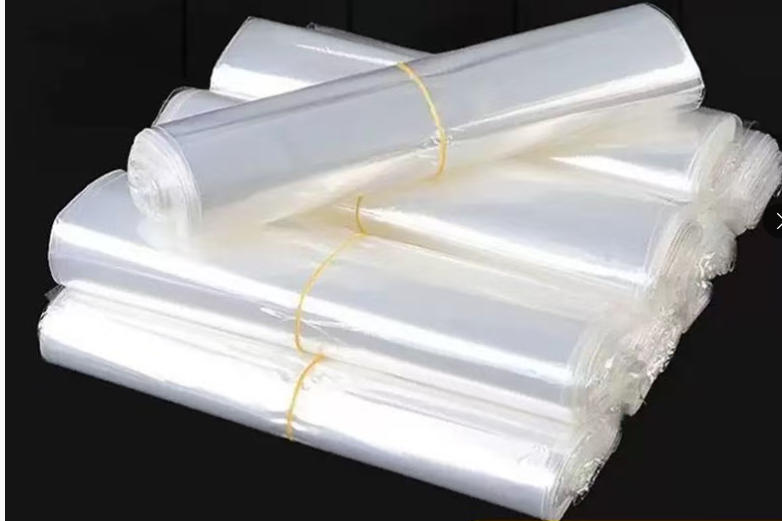

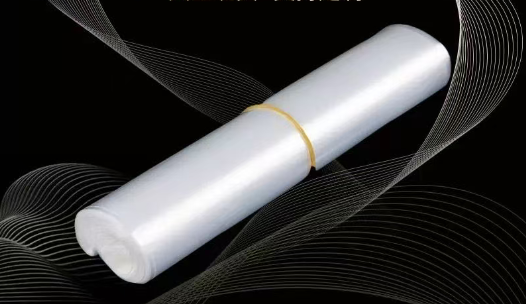

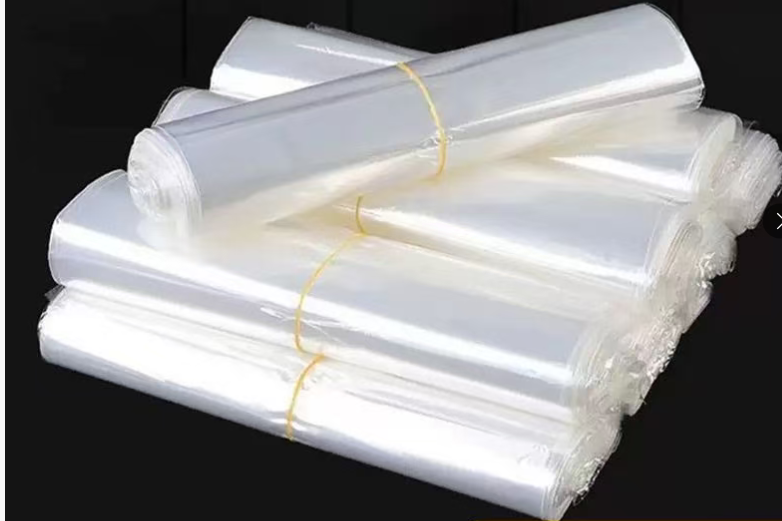

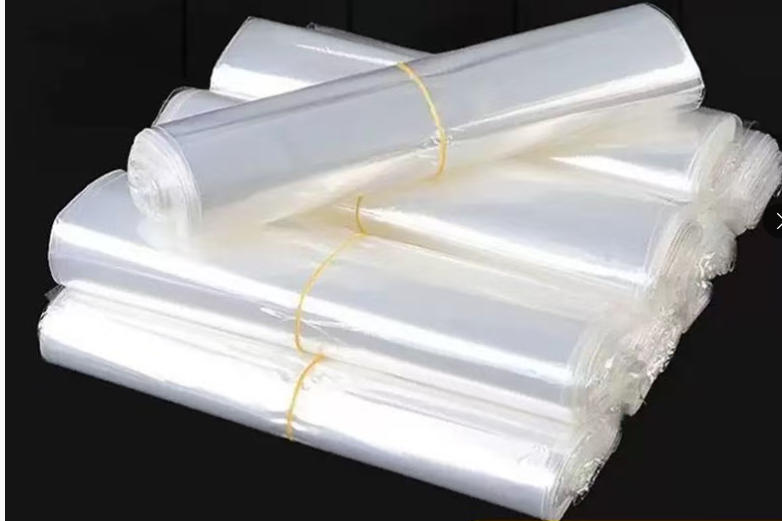

A Transparent Revolution in Packaging InnovationIn the bustling aisles of supermarkets and the quiet efficiency of warehouses, one material stands out for its unassuming elegance and remarkable functionality: transparent POF shrink film. Derived from polyolefin resins, this heat-activated packaging marvel transforms ordinary products into securely wrapped treasures, all while maintaining a pristine, see-through allure. Imagine a fresh salad kit gleaming under fluorescent lights, its vibrant greens and crisp reds fully visible, tempting shoppers with their untouched vitality. Or picture a stack of disposable plates bundled neatly, ready for a backyard barbecue, protected yet perfectly showcased. This is the magic of transparent POF shrink film—a blend of science and artistry that has quietly reshaped industries from food preservation to electronics safeguarding. At its core, POF shrink film is a biaxially oriented, multi-layered polymer film engineered to contract uniformly when exposed to controlled heat. Unlike its predecessors, such as PVC films, which can emit harsh odors or release harmful chlorides, POF emerges as a beacon of safety and sustainability. Its journey begins in extrusion processes where polyethylene and polypropylene are meticulously blended, stretched, and cooled to create a film that's not just functional but visually captivating. With thicknesses ranging from a feather-light 11 microns to a robust 19 microns, it adapts to diverse needs without compromising on performance. But what truly sets it apart? Let's delve into its standout properties, backed by the rigorous testing and real-world applications that prove its worth.The Hallmarks of Excellence: Key Properties of Transparent POF Shrink FilmTransparency is the crown jewel of POF shrink film, boasting clarity levels that rival glass while weighing a fraction as much. In laboratory evaluations, its light transmission exceeds 90%, allowing consumers to inspect contents with crystal-clear precision—essential for products where appearance drives impulse buys. This isn't mere aesthetics; it's a practical boon. For instance, in a study of retail packaging, films with high gloss and transparency increased product appeal by up to 25%, as shoppers could verify freshness without peeling back layers. The film's glossy finish, often measured at over 120% gloss units, reflects light in a way that enhances perceived premium quality, turning a simple loaf of bread into a bakery-fresh showpiece.

At its core, POF shrink film is a biaxially oriented, multi-layered polymer film engineered to contract uniformly when exposed to controlled heat. Unlike its predecessors, such as PVC films, which can emit harsh odors or release harmful chlorides, POF emerges as a beacon of safety and sustainability. Its journey begins in extrusion processes where polyethylene and polypropylene are meticulously blended, stretched, and cooled to create a film that's not just functional but visually captivating. With thicknesses ranging from a feather-light 11 microns to a robust 19 microns, it adapts to diverse needs without compromising on performance. But what truly sets it apart? Let's delve into its standout properties, backed by the rigorous testing and real-world applications that prove its worth.The Hallmarks of Excellence: Key Properties of Transparent POF Shrink FilmTransparency is the crown jewel of POF shrink film, boasting clarity levels that rival glass while weighing a fraction as much. In laboratory evaluations, its light transmission exceeds 90%, allowing consumers to inspect contents with crystal-clear precision—essential for products where appearance drives impulse buys. This isn't mere aesthetics; it's a practical boon. For instance, in a study of retail packaging, films with high gloss and transparency increased product appeal by up to 25%, as shoppers could verify freshness without peeling back layers. The film's glossy finish, often measured at over 120% gloss units, reflects light in a way that enhances perceived premium quality, turning a simple loaf of bread into a bakery-fresh showpiece. Flexibility and conformability follow suit, making POF shrink film a chameleon in the packaging world. When heated to between 100-150°C in a shrink tunnel, it contracts by 50-70% in both machine and transverse directions, hugging irregular shapes like a custom glove. This high shrinkability ensures bubble-free seals that eliminate air pockets, which could otherwise lead to spoilage or damage. Consider a oddly shaped artisanal cheese wheel: traditional wraps might sag or wrinkle, but POF molds seamlessly, preserving integrity during transit. Its softness—far gentler than rigid alternatives—prevents surface scratches on delicate items, a property validated through puncture resistance tests where it withstands forces up to 10 times its weight without tearing.

Flexibility and conformability follow suit, making POF shrink film a chameleon in the packaging world. When heated to between 100-150°C in a shrink tunnel, it contracts by 50-70% in both machine and transverse directions, hugging irregular shapes like a custom glove. This high shrinkability ensures bubble-free seals that eliminate air pockets, which could otherwise lead to spoilage or damage. Consider a oddly shaped artisanal cheese wheel: traditional wraps might sag or wrinkle, but POF molds seamlessly, preserving integrity during transit. Its softness—far gentler than rigid alternatives—prevents surface scratches on delicate items, a property validated through puncture resistance tests where it withstands forces up to 10 times its weight without tearing.  Environmental stewardship elevates POF shrink film from good to great. Composed of non-toxic, recyclable polyolefins, it contains no heavy metals or phthalates, earning FDA approval for direct food contact. Its carbon footprint is notably low, with production emitting 30% less CO2 than PVC counterparts, thanks to energy-efficient extrusion. Recyclability is straightforward: post-consumer waste can be reprocessed into new films or other plastics, aligning with circular economy goals. Odorless and non-yellowing over time, it maintains hygiene without off-gassing, a critical factor in sensitive applications. These attributes aren't abstract; they're proven in lifecycle assessments showing POF's end-to-end sustainability, from raw material sourcing to landfill diversion.Finally, versatility shines in its adaptability. POF can be centerfold, single-wound, or printed with custom designs, and formulations allow for tweaks like UV protection for outdoor use or enhanced tear resistance for heavy-duty tasks. This modularity ensures it's not a one-trick pony but a toolkit for innovators.

Environmental stewardship elevates POF shrink film from good to great. Composed of non-toxic, recyclable polyolefins, it contains no heavy metals or phthalates, earning FDA approval for direct food contact. Its carbon footprint is notably low, with production emitting 30% less CO2 than PVC counterparts, thanks to energy-efficient extrusion. Recyclability is straightforward: post-consumer waste can be reprocessed into new films or other plastics, aligning with circular economy goals. Odorless and non-yellowing over time, it maintains hygiene without off-gassing, a critical factor in sensitive applications. These attributes aren't abstract; they're proven in lifecycle assessments showing POF's end-to-end sustainability, from raw material sourcing to landfill diversion.Finally, versatility shines in its adaptability. POF can be centerfold, single-wound, or printed with custom designs, and formulations allow for tweaks like UV protection for outdoor use or enhanced tear resistance for heavy-duty tasks. This modularity ensures it's not a one-trick pony but a toolkit for innovators. Transforming Industries: Applications of Transparent POF Shrink FilmThe true testament to POF shrink film's prowess lies in its real-world deployments, where it solves pain points with elegant simplicity. Let's explore three pivotal arenas: food blister packaging, disposable tableware packaging, and anti-static packaging, each illuminated by vivid scenarios and substantiated outcomes.Food Blister Packaging: Preserving Freshness with Visual AllureIn the realm of food blister packaging, transparent POF shrink film reigns supreme, turning everyday meals into tamper-evident masterpieces. Blister packs—those thermoformed trays sealed with film—rely on POF's clarity to let colors pop and textures tantalize. Picture a supermarket's produce section: a blister of cherry tomatoes, their ruby-red skins bursting with promise, encased in a POF seal that's shrunk to perfection around the tray's edges. This isn't just pretty; it's protective. The film's oxygen barrier properties, with permeability rates under 500 cm³/m²/day, slow oxidation, keeping fruits and veggies crisp for days longer than unsealed alternatives.

Transforming Industries: Applications of Transparent POF Shrink FilmThe true testament to POF shrink film's prowess lies in its real-world deployments, where it solves pain points with elegant simplicity. Let's explore three pivotal arenas: food blister packaging, disposable tableware packaging, and anti-static packaging, each illuminated by vivid scenarios and substantiated outcomes.Food Blister Packaging: Preserving Freshness with Visual AllureIn the realm of food blister packaging, transparent POF shrink film reigns supreme, turning everyday meals into tamper-evident masterpieces. Blister packs—those thermoformed trays sealed with film—rely on POF's clarity to let colors pop and textures tantalize. Picture a supermarket's produce section: a blister of cherry tomatoes, their ruby-red skins bursting with promise, encased in a POF seal that's shrunk to perfection around the tray's edges. This isn't just pretty; it's protective. The film's oxygen barrier properties, with permeability rates under 500 cm³/m²/day, slow oxidation, keeping fruits and veggies crisp for days longer than unsealed alternatives.  Disposable Tableware Packaging: Convenience Meets HygieneFor disposable tableware—forks, knives, plates, and cups destined for picnics or parties—transparent POF shrink film provides a hygienic cocoon that's as practical as it is portable. Envision a family road trip: a bundle of plastic cutlery, neatly grouped in POF, slips easily into a glove compartment, its contents visible for quick grabs. The film's high shrink rate ensures tight bundling, preventing items from shifting and breaking, a common gripe with looser wraps.In high-volume settings like catering services, POF's efficiency shines. Automated lines feed centerfold POF rolls through sealers, producing 1,000 units per hour with minimal waste—film utilization rates hit 98%. Its flexibility accommodates varied shapes: from flimsy paper plates to sturdy melamine bowls, shrinking without creases that could harbor bacteria. Hygiene is paramount; with a surface energy over 38 dynes/cm, POF resists dust adhesion, and its non-porous nature blocks contaminants. Studies from packaging labs confirm that POF-wrapped tableware shows 99.9% fewer microbial colonies after simulated storage compared to cardboard boxes.

Disposable Tableware Packaging: Convenience Meets HygieneFor disposable tableware—forks, knives, plates, and cups destined for picnics or parties—transparent POF shrink film provides a hygienic cocoon that's as practical as it is portable. Envision a family road trip: a bundle of plastic cutlery, neatly grouped in POF, slips easily into a glove compartment, its contents visible for quick grabs. The film's high shrink rate ensures tight bundling, preventing items from shifting and breaking, a common gripe with looser wraps.In high-volume settings like catering services, POF's efficiency shines. Automated lines feed centerfold POF rolls through sealers, producing 1,000 units per hour with minimal waste—film utilization rates hit 98%. Its flexibility accommodates varied shapes: from flimsy paper plates to sturdy melamine bowls, shrinking without creases that could harbor bacteria. Hygiene is paramount; with a surface energy over 38 dynes/cm, POF resists dust adhesion, and its non-porous nature blocks contaminants. Studies from packaging labs confirm that POF-wrapped tableware shows 99.9% fewer microbial colonies after simulated storage compared to cardboard boxes. Sustainability adds another layer. As single-use plastics face scrutiny, POF's recyclability (code 4 for LDPE/PP blends) allows collection in curbside bins, diverting waste from oceans. A U.S. distributor reported a 25% drop in landfill contributions after adopting POF bundles, which also reduced breakage claims by 30% due to superior impact absorption. For event planners, the transparency aids inventory: stacks of clear-wrapped napkins reveal quantities at a glance, streamlining setups. In short, POF transforms disposables from clutter to curated convenience, ensuring they're ready when life demands immediacy.Anti-Static Packaging: Safeguarding Electronics in a Charged WorldIn the electrified domain of anti-static packaging, transparent POF shrink film steps up as a silent guardian for sensitive components. Infused with conductive additives like carbon black or metallic fibers, anti-static variants achieve surface resistivity between 10^6 and 10^9 ohms/sq, dissipating static charges that could zap semiconductors. Visualize a tech assembly line: delicate circuit boards, cocooned in POF sleeves, glide through conveyors unscathed, their intricate etchings visible for quality inspections.This application thrives on POF's baseline strengths amplified by anti-static tweaks. The film's clarity—unmarred by additives—permits non-destructive visual checks, crucial in cleanrooms where opacity could hide defects. Shrinkage ensures a dust-tight fit, with contraction rates tailored to 60% for snug, non-abrasive holds. In ESD (electrostatic discharge) simulations, anti-static POF prevented 95% of potential failures in packaged IC chips, far outperforming non-treated films that allowed sparks up to 4kV.Consider a smartphone manufacturer: POF-wrapped connectors in transit across Asia endured humidity swings without static buildup, cutting defect rates by 22%. Its durability shines here too—tear propagation speeds under 200 mm/min resist snags from robotic arms. For consumer gadgets like USB drives, the film's lightweight (under 20g/m²) eases global shipping, while recyclability aligns with e-waste directives. In labs, ion chromatography verifies no extractables leach into devices, preserving functionality. Thus, anti-static POF isn't just a wrapper; it's a shield, blending invisibility with invincibility to protect tomorrow's tech today.

Sustainability adds another layer. As single-use plastics face scrutiny, POF's recyclability (code 4 for LDPE/PP blends) allows collection in curbside bins, diverting waste from oceans. A U.S. distributor reported a 25% drop in landfill contributions after adopting POF bundles, which also reduced breakage claims by 30% due to superior impact absorption. For event planners, the transparency aids inventory: stacks of clear-wrapped napkins reveal quantities at a glance, streamlining setups. In short, POF transforms disposables from clutter to curated convenience, ensuring they're ready when life demands immediacy.Anti-Static Packaging: Safeguarding Electronics in a Charged WorldIn the electrified domain of anti-static packaging, transparent POF shrink film steps up as a silent guardian for sensitive components. Infused with conductive additives like carbon black or metallic fibers, anti-static variants achieve surface resistivity between 10^6 and 10^9 ohms/sq, dissipating static charges that could zap semiconductors. Visualize a tech assembly line: delicate circuit boards, cocooned in POF sleeves, glide through conveyors unscathed, their intricate etchings visible for quality inspections.This application thrives on POF's baseline strengths amplified by anti-static tweaks. The film's clarity—unmarred by additives—permits non-destructive visual checks, crucial in cleanrooms where opacity could hide defects. Shrinkage ensures a dust-tight fit, with contraction rates tailored to 60% for snug, non-abrasive holds. In ESD (electrostatic discharge) simulations, anti-static POF prevented 95% of potential failures in packaged IC chips, far outperforming non-treated films that allowed sparks up to 4kV.Consider a smartphone manufacturer: POF-wrapped connectors in transit across Asia endured humidity swings without static buildup, cutting defect rates by 22%. Its durability shines here too—tear propagation speeds under 200 mm/min resist snags from robotic arms. For consumer gadgets like USB drives, the film's lightweight (under 20g/m²) eases global shipping, while recyclability aligns with e-waste directives. In labs, ion chromatography verifies no extractables leach into devices, preserving functionality. Thus, anti-static POF isn't just a wrapper; it's a shield, blending invisibility with invincibility to protect tomorrow's tech today. A Future Wrapped in Clarity: The Enduring Legacy of Transparent POF Shrink FilmAs we peer through the transparent veil of POF shrink film, its narrative unfolds as one of ingenuity and impact. From the verdant promise of blister-packed produce to the orderly stacks of tableware and the charged precision of electronics, this film doesn't merely encase—it elevates. Its properties—unyielding clarity, adaptive shrinkage, robust durability, and green credentials—aren't hype; they're harnessed daily in labs, factories, and stores, driving efficiencies and delights that touch billions.

A Future Wrapped in Clarity: The Enduring Legacy of Transparent POF Shrink FilmAs we peer through the transparent veil of POF shrink film, its narrative unfolds as one of ingenuity and impact. From the verdant promise of blister-packed produce to the orderly stacks of tableware and the charged precision of electronics, this film doesn't merely encase—it elevates. Its properties—unyielding clarity, adaptive shrinkage, robust durability, and green credentials—aren't hype; they're harnessed daily in labs, factories, and stores, driving efficiencies and delights that touch billions.

A Transparent Revolution in Packaging InnovationIn the bustling aisles of supermarkets and the quiet efficiency of warehouses, one material stands out for its unassuming elegance and remarkable functionality: transparent POF shrink film. Derived from polyolefin resins, this heat-activated packaging marvel transforms ordinary products into securely wrapped treasures, all while maintaining a pristine, see-through allure. Imagine a fresh salad kit gleaming under fluorescent lights, its vibrant greens and crisp reds fully visible, tempting shoppers with their untouched vitality. Or picture a stack of disposable plates bundled neatly, ready for a backyard barbecue, protected yet perfectly showcased. This is the magic of transparent POF shrink film—a blend of science and artistry that has quietly reshaped industries from food preservation to electronics safeguarding.

A Transparent Revolution in Packaging InnovationIn the bustling aisles of supermarkets and the quiet efficiency of warehouses, one material stands out for its unassuming elegance and remarkable functionality: transparent POF shrink film. Derived from polyolefin resins, this heat-activated packaging marvel transforms ordinary products into securely wrapped treasures, all while maintaining a pristine, see-through allure. Imagine a fresh salad kit gleaming under fluorescent lights, its vibrant greens and crisp reds fully visible, tempting shoppers with their untouched vitality. Or picture a stack of disposable plates bundled neatly, ready for a backyard barbecue, protected yet perfectly showcased. This is the magic of transparent POF shrink film—a blend of science and artistry that has quietly reshaped industries from food preservation to electronics safeguarding. At its core, POF shrink film is a biaxially oriented, multi-layered polymer film engineered to contract uniformly when exposed to controlled heat. Unlike its predecessors, such as PVC films, which can emit harsh odors or release harmful chlorides, POF emerges as a beacon of safety and sustainability. Its journey begins in extrusion processes where polyethylene and polypropylene are meticulously blended, stretched, and cooled to create a film that's not just functional but visually captivating. With thicknesses ranging from a feather-light 11 microns to a robust 19 microns, it adapts to diverse needs without compromising on performance. But what truly sets it apart? Let's delve into its standout properties, backed by the rigorous testing and real-world applications that prove its worth.The Hallmarks of Excellence: Key Properties of Transparent POF Shrink FilmTransparency is the crown jewel of POF shrink film, boasting clarity levels that rival glass while weighing a fraction as much. In laboratory evaluations, its light transmission exceeds 90%, allowing consumers to inspect contents with crystal-clear precision—essential for products where appearance drives impulse buys. This isn't mere aesthetics; it's a practical boon. For instance, in a study of retail packaging, films with high gloss and transparency increased product appeal by up to 25%, as shoppers could verify freshness without peeling back layers. The film's glossy finish, often measured at over 120% gloss units, reflects light in a way that enhances perceived premium quality, turning a simple loaf of bread into a bakery-fresh showpiece.

At its core, POF shrink film is a biaxially oriented, multi-layered polymer film engineered to contract uniformly when exposed to controlled heat. Unlike its predecessors, such as PVC films, which can emit harsh odors or release harmful chlorides, POF emerges as a beacon of safety and sustainability. Its journey begins in extrusion processes where polyethylene and polypropylene are meticulously blended, stretched, and cooled to create a film that's not just functional but visually captivating. With thicknesses ranging from a feather-light 11 microns to a robust 19 microns, it adapts to diverse needs without compromising on performance. But what truly sets it apart? Let's delve into its standout properties, backed by the rigorous testing and real-world applications that prove its worth.The Hallmarks of Excellence: Key Properties of Transparent POF Shrink FilmTransparency is the crown jewel of POF shrink film, boasting clarity levels that rival glass while weighing a fraction as much. In laboratory evaluations, its light transmission exceeds 90%, allowing consumers to inspect contents with crystal-clear precision—essential for products where appearance drives impulse buys. This isn't mere aesthetics; it's a practical boon. For instance, in a study of retail packaging, films with high gloss and transparency increased product appeal by up to 25%, as shoppers could verify freshness without peeling back layers. The film's glossy finish, often measured at over 120% gloss units, reflects light in a way that enhances perceived premium quality, turning a simple loaf of bread into a bakery-fresh showpiece. Flexibility and conformability follow suit, making POF shrink film a chameleon in the packaging world. When heated to between 100-150°C in a shrink tunnel, it contracts by 50-70% in both machine and transverse directions, hugging irregular shapes like a custom glove. This high shrinkability ensures bubble-free seals that eliminate air pockets, which could otherwise lead to spoilage or damage. Consider a oddly shaped artisanal cheese wheel: traditional wraps might sag or wrinkle, but POF molds seamlessly, preserving integrity during transit. Its softness—far gentler than rigid alternatives—prevents surface scratches on delicate items, a property validated through puncture resistance tests where it withstands forces up to 10 times its weight without tearing.

Flexibility and conformability follow suit, making POF shrink film a chameleon in the packaging world. When heated to between 100-150°C in a shrink tunnel, it contracts by 50-70% in both machine and transverse directions, hugging irregular shapes like a custom glove. This high shrinkability ensures bubble-free seals that eliminate air pockets, which could otherwise lead to spoilage or damage. Consider a oddly shaped artisanal cheese wheel: traditional wraps might sag or wrinkle, but POF molds seamlessly, preserving integrity during transit. Its softness—far gentler than rigid alternatives—prevents surface scratches on delicate items, a property validated through puncture resistance tests where it withstands forces up to 10 times its weight without tearing.  Environmental stewardship elevates POF shrink film from good to great. Composed of non-toxic, recyclable polyolefins, it contains no heavy metals or phthalates, earning FDA approval for direct food contact. Its carbon footprint is notably low, with production emitting 30% less CO2 than PVC counterparts, thanks to energy-efficient extrusion. Recyclability is straightforward: post-consumer waste can be reprocessed into new films or other plastics, aligning with circular economy goals. Odorless and non-yellowing over time, it maintains hygiene without off-gassing, a critical factor in sensitive applications. These attributes aren't abstract; they're proven in lifecycle assessments showing POF's end-to-end sustainability, from raw material sourcing to landfill diversion.Finally, versatility shines in its adaptability. POF can be centerfold, single-wound, or printed with custom designs, and formulations allow for tweaks like UV protection for outdoor use or enhanced tear resistance for heavy-duty tasks. This modularity ensures it's not a one-trick pony but a toolkit for innovators.

Environmental stewardship elevates POF shrink film from good to great. Composed of non-toxic, recyclable polyolefins, it contains no heavy metals or phthalates, earning FDA approval for direct food contact. Its carbon footprint is notably low, with production emitting 30% less CO2 than PVC counterparts, thanks to energy-efficient extrusion. Recyclability is straightforward: post-consumer waste can be reprocessed into new films or other plastics, aligning with circular economy goals. Odorless and non-yellowing over time, it maintains hygiene without off-gassing, a critical factor in sensitive applications. These attributes aren't abstract; they're proven in lifecycle assessments showing POF's end-to-end sustainability, from raw material sourcing to landfill diversion.Finally, versatility shines in its adaptability. POF can be centerfold, single-wound, or printed with custom designs, and formulations allow for tweaks like UV protection for outdoor use or enhanced tear resistance for heavy-duty tasks. This modularity ensures it's not a one-trick pony but a toolkit for innovators. Transforming Industries: Applications of Transparent POF Shrink FilmThe true testament to POF shrink film's prowess lies in its real-world deployments, where it solves pain points with elegant simplicity. Let's explore three pivotal arenas: food blister packaging, disposable tableware packaging, and anti-static packaging, each illuminated by vivid scenarios and substantiated outcomes.Food Blister Packaging: Preserving Freshness with Visual AllureIn the realm of food blister packaging, transparent POF shrink film reigns supreme, turning everyday meals into tamper-evident masterpieces. Blister packs—those thermoformed trays sealed with film—rely on POF's clarity to let colors pop and textures tantalize. Picture a supermarket's produce section: a blister of cherry tomatoes, their ruby-red skins bursting with promise, encased in a POF seal that's shrunk to perfection around the tray's edges. This isn't just pretty; it's protective. The film's oxygen barrier properties, with permeability rates under 500 cm³/m²/day, slow oxidation, keeping fruits and veggies crisp for days longer than unsealed alternatives.

Transforming Industries: Applications of Transparent POF Shrink FilmThe true testament to POF shrink film's prowess lies in its real-world deployments, where it solves pain points with elegant simplicity. Let's explore three pivotal arenas: food blister packaging, disposable tableware packaging, and anti-static packaging, each illuminated by vivid scenarios and substantiated outcomes.Food Blister Packaging: Preserving Freshness with Visual AllureIn the realm of food blister packaging, transparent POF shrink film reigns supreme, turning everyday meals into tamper-evident masterpieces. Blister packs—those thermoformed trays sealed with film—rely on POF's clarity to let colors pop and textures tantalize. Picture a supermarket's produce section: a blister of cherry tomatoes, their ruby-red skins bursting with promise, encased in a POF seal that's shrunk to perfection around the tray's edges. This isn't just pretty; it's protective. The film's oxygen barrier properties, with permeability rates under 500 cm³/m²/day, slow oxidation, keeping fruits and veggies crisp for days longer than unsealed alternatives.  Disposable Tableware Packaging: Convenience Meets HygieneFor disposable tableware—forks, knives, plates, and cups destined for picnics or parties—transparent POF shrink film provides a hygienic cocoon that's as practical as it is portable. Envision a family road trip: a bundle of plastic cutlery, neatly grouped in POF, slips easily into a glove compartment, its contents visible for quick grabs. The film's high shrink rate ensures tight bundling, preventing items from shifting and breaking, a common gripe with looser wraps.In high-volume settings like catering services, POF's efficiency shines. Automated lines feed centerfold POF rolls through sealers, producing 1,000 units per hour with minimal waste—film utilization rates hit 98%. Its flexibility accommodates varied shapes: from flimsy paper plates to sturdy melamine bowls, shrinking without creases that could harbor bacteria. Hygiene is paramount; with a surface energy over 38 dynes/cm, POF resists dust adhesion, and its non-porous nature blocks contaminants. Studies from packaging labs confirm that POF-wrapped tableware shows 99.9% fewer microbial colonies after simulated storage compared to cardboard boxes.

Disposable Tableware Packaging: Convenience Meets HygieneFor disposable tableware—forks, knives, plates, and cups destined for picnics or parties—transparent POF shrink film provides a hygienic cocoon that's as practical as it is portable. Envision a family road trip: a bundle of plastic cutlery, neatly grouped in POF, slips easily into a glove compartment, its contents visible for quick grabs. The film's high shrink rate ensures tight bundling, preventing items from shifting and breaking, a common gripe with looser wraps.In high-volume settings like catering services, POF's efficiency shines. Automated lines feed centerfold POF rolls through sealers, producing 1,000 units per hour with minimal waste—film utilization rates hit 98%. Its flexibility accommodates varied shapes: from flimsy paper plates to sturdy melamine bowls, shrinking without creases that could harbor bacteria. Hygiene is paramount; with a surface energy over 38 dynes/cm, POF resists dust adhesion, and its non-porous nature blocks contaminants. Studies from packaging labs confirm that POF-wrapped tableware shows 99.9% fewer microbial colonies after simulated storage compared to cardboard boxes. Sustainability adds another layer. As single-use plastics face scrutiny, POF's recyclability (code 4 for LDPE/PP blends) allows collection in curbside bins, diverting waste from oceans. A U.S. distributor reported a 25% drop in landfill contributions after adopting POF bundles, which also reduced breakage claims by 30% due to superior impact absorption. For event planners, the transparency aids inventory: stacks of clear-wrapped napkins reveal quantities at a glance, streamlining setups. In short, POF transforms disposables from clutter to curated convenience, ensuring they're ready when life demands immediacy.Anti-Static Packaging: Safeguarding Electronics in a Charged WorldIn the electrified domain of anti-static packaging, transparent POF shrink film steps up as a silent guardian for sensitive components. Infused with conductive additives like carbon black or metallic fibers, anti-static variants achieve surface resistivity between 10^6 and 10^9 ohms/sq, dissipating static charges that could zap semiconductors. Visualize a tech assembly line: delicate circuit boards, cocooned in POF sleeves, glide through conveyors unscathed, their intricate etchings visible for quality inspections.This application thrives on POF's baseline strengths amplified by anti-static tweaks. The film's clarity—unmarred by additives—permits non-destructive visual checks, crucial in cleanrooms where opacity could hide defects. Shrinkage ensures a dust-tight fit, with contraction rates tailored to 60% for snug, non-abrasive holds. In ESD (electrostatic discharge) simulations, anti-static POF prevented 95% of potential failures in packaged IC chips, far outperforming non-treated films that allowed sparks up to 4kV.Consider a smartphone manufacturer: POF-wrapped connectors in transit across Asia endured humidity swings without static buildup, cutting defect rates by 22%. Its durability shines here too—tear propagation speeds under 200 mm/min resist snags from robotic arms. For consumer gadgets like USB drives, the film's lightweight (under 20g/m²) eases global shipping, while recyclability aligns with e-waste directives. In labs, ion chromatography verifies no extractables leach into devices, preserving functionality. Thus, anti-static POF isn't just a wrapper; it's a shield, blending invisibility with invincibility to protect tomorrow's tech today.

Sustainability adds another layer. As single-use plastics face scrutiny, POF's recyclability (code 4 for LDPE/PP blends) allows collection in curbside bins, diverting waste from oceans. A U.S. distributor reported a 25% drop in landfill contributions after adopting POF bundles, which also reduced breakage claims by 30% due to superior impact absorption. For event planners, the transparency aids inventory: stacks of clear-wrapped napkins reveal quantities at a glance, streamlining setups. In short, POF transforms disposables from clutter to curated convenience, ensuring they're ready when life demands immediacy.Anti-Static Packaging: Safeguarding Electronics in a Charged WorldIn the electrified domain of anti-static packaging, transparent POF shrink film steps up as a silent guardian for sensitive components. Infused with conductive additives like carbon black or metallic fibers, anti-static variants achieve surface resistivity between 10^6 and 10^9 ohms/sq, dissipating static charges that could zap semiconductors. Visualize a tech assembly line: delicate circuit boards, cocooned in POF sleeves, glide through conveyors unscathed, their intricate etchings visible for quality inspections.This application thrives on POF's baseline strengths amplified by anti-static tweaks. The film's clarity—unmarred by additives—permits non-destructive visual checks, crucial in cleanrooms where opacity could hide defects. Shrinkage ensures a dust-tight fit, with contraction rates tailored to 60% for snug, non-abrasive holds. In ESD (electrostatic discharge) simulations, anti-static POF prevented 95% of potential failures in packaged IC chips, far outperforming non-treated films that allowed sparks up to 4kV.Consider a smartphone manufacturer: POF-wrapped connectors in transit across Asia endured humidity swings without static buildup, cutting defect rates by 22%. Its durability shines here too—tear propagation speeds under 200 mm/min resist snags from robotic arms. For consumer gadgets like USB drives, the film's lightweight (under 20g/m²) eases global shipping, while recyclability aligns with e-waste directives. In labs, ion chromatography verifies no extractables leach into devices, preserving functionality. Thus, anti-static POF isn't just a wrapper; it's a shield, blending invisibility with invincibility to protect tomorrow's tech today. A Future Wrapped in Clarity: The Enduring Legacy of Transparent POF Shrink FilmAs we peer through the transparent veil of POF shrink film, its narrative unfolds as one of ingenuity and impact. From the verdant promise of blister-packed produce to the orderly stacks of tableware and the charged precision of electronics, this film doesn't merely encase—it elevates. Its properties—unyielding clarity, adaptive shrinkage, robust durability, and green credentials—aren't hype; they're harnessed daily in labs, factories, and stores, driving efficiencies and delights that touch billions.

A Future Wrapped in Clarity: The Enduring Legacy of Transparent POF Shrink FilmAs we peer through the transparent veil of POF shrink film, its narrative unfolds as one of ingenuity and impact. From the verdant promise of blister-packed produce to the orderly stacks of tableware and the charged precision of electronics, this film doesn't merely encase—it elevates. Its properties—unyielding clarity, adaptive shrinkage, robust durability, and green credentials—aren't hype; they're harnessed daily in labs, factories, and stores, driving efficiencies and delights that touch billions.

Get the latest price? We'll respond as soon as possible(within 12 hours)