The Versatile World of BOPP Film: Unveiling Its Properties and Expansive Applications

2025-10-10 16:58The Versatile World of BOPP Film: Unveiling Its Properties and Expansive ApplicationsIn the bustling world of modern manufacturing, where efficiency meets elegance, few materials embody the perfect blend of form and function quite like BOPP film. Short for Biaxially Oriented Polypropylene film, this thin, crystalline layer of polypropylene is stretched in two directions during production, resulting in a material that transforms everyday packaging into something extraordinary. Imagine strolling through a supermarket aisle: the crinkle of a chip bag that stays fresh for weeks, the glossy sheen of a soda bottle label that catches your eye amid a sea of options, or the secure wrap around a gift box that whispers luxury without shouting excess. That's the magic of BOPP film at work. Born from the ingenuity of polymer science in the mid-20th century, it has evolved into an indispensable player in industries spanning food preservation to electronics, all while championing sustainability through lightweight design and recyclability. What makes BOPP film stand out isn't just its ubiquity—it's the symphony of properties that allow it to perform under pressure, adapt to diverse needs, and deliver results that delight both producers and consumers. This article delves deep into the core characteristics of BOPP film, exploring how its mechanical prowess, optical allure, and barrier brilliance fuel its wide-ranging applications. Drawing from established principles of materials science, we'll uncover why this film isn't merely a wrapper but a silent hero in global supply chains, backed by decades of empirical testing and real-world deployment.The Remarkable Properties of BOPP Film: Strength, Clarity, and BeyondAt its heart, BOPP film's appeal lies in its meticulously engineered properties, forged through a process of extrusion, orientation, and crystallization that aligns polymer chains like soldiers in formation. This biaxial stretching—pulling the film longitudinally and transversely—amplifies its inherent traits, turning a simple polypropylene sheet into a powerhouse of performance.Foremost among these is its exceptional mechanical strength. With tensile strength often exceeding 200 MPa in machine direction and over 50 MPa transversely, BOPP film withstands the rigors of high-speed packaging lines without tearing or deforming. Picture a conveyor belt humming at 500 meters per minute: bags filled with fragile cookies or heavy cans of beans hurtle along, sealed in BOPP that flexes but never fails. This robustness stems from the film's high Young's modulus, typically around 2-4 GPa, which measures its stiffness under stress. Lab tests consistently show it outperforming unoriented polypropylene by up to 300%, making it ideal for applications where durability is non-negotiable.

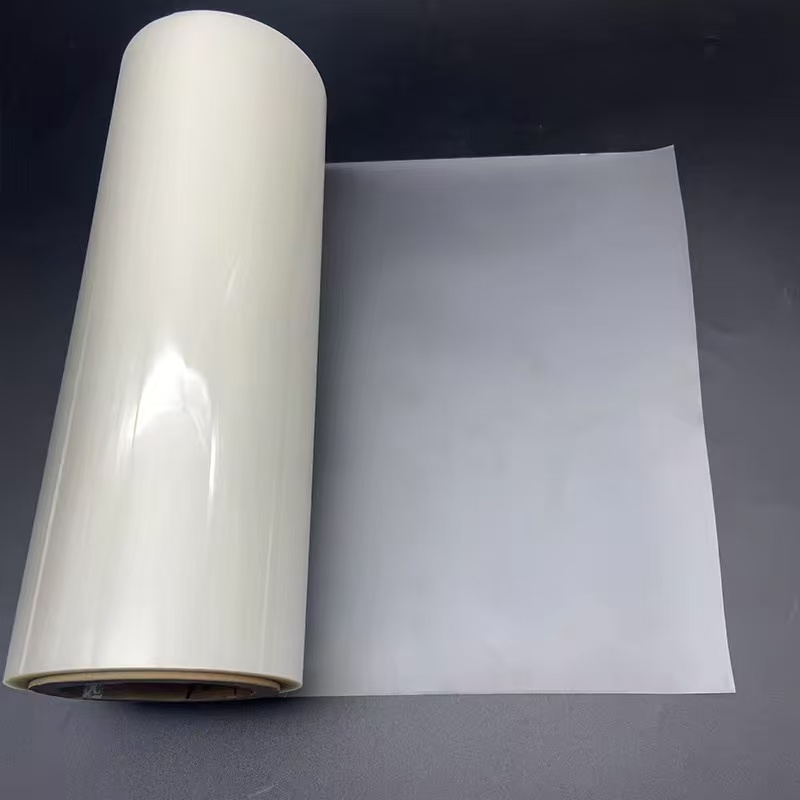

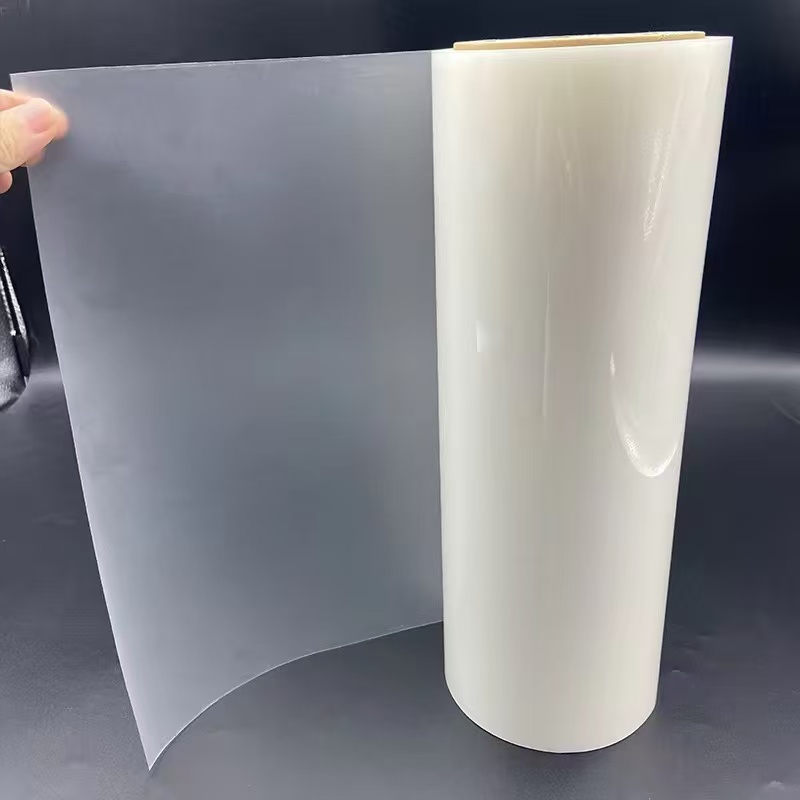

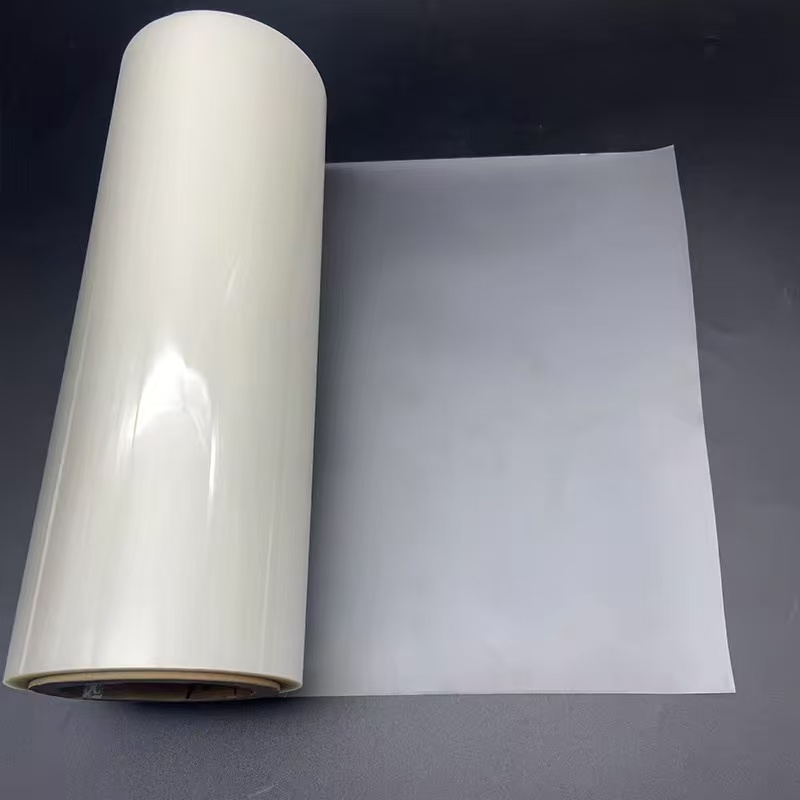

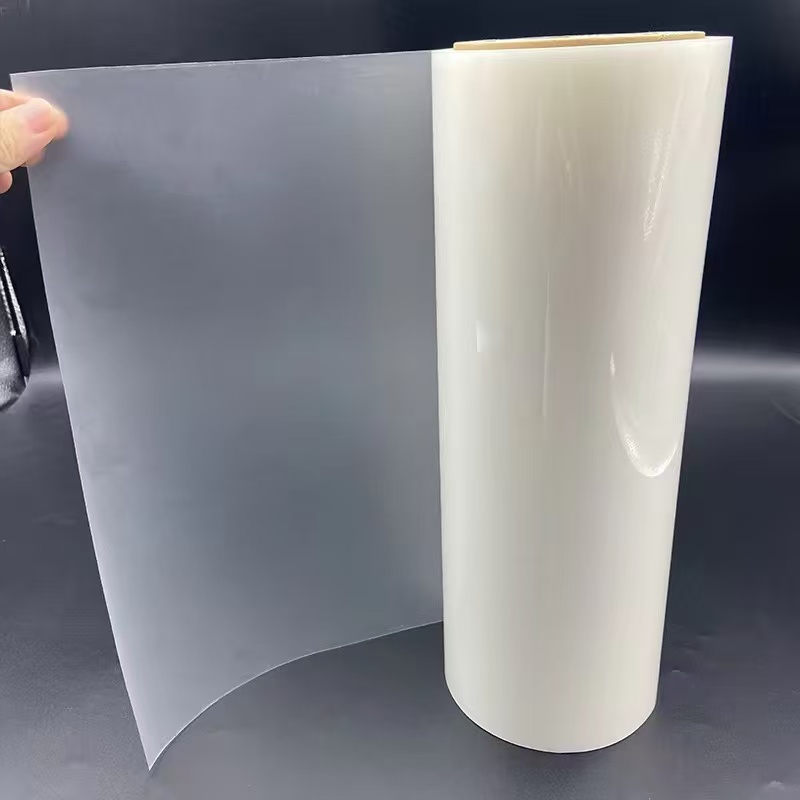

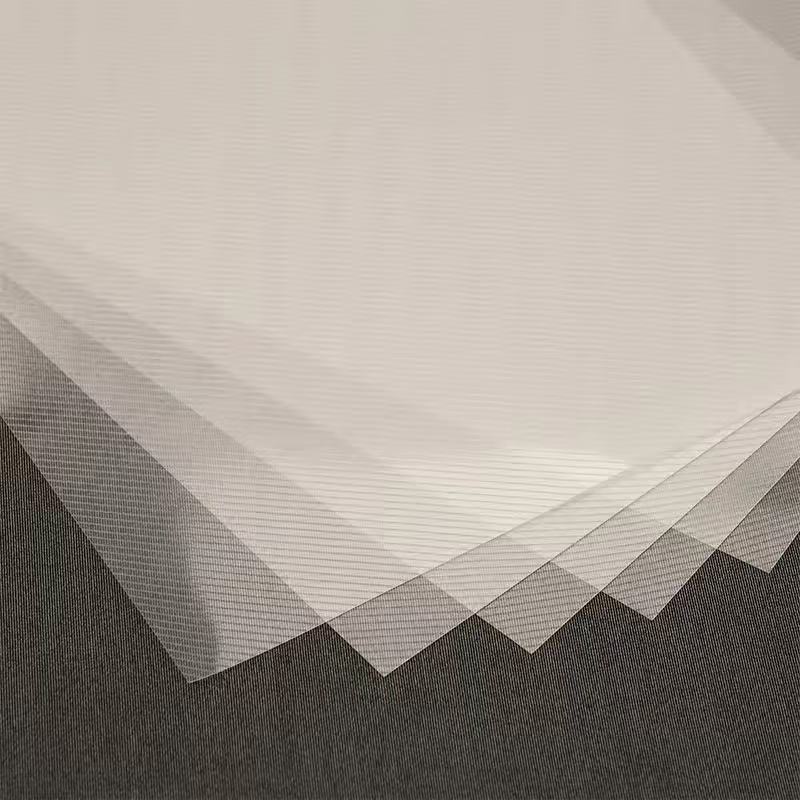

What makes BOPP film stand out isn't just its ubiquity—it's the symphony of properties that allow it to perform under pressure, adapt to diverse needs, and deliver results that delight both producers and consumers. This article delves deep into the core characteristics of BOPP film, exploring how its mechanical prowess, optical allure, and barrier brilliance fuel its wide-ranging applications. Drawing from established principles of materials science, we'll uncover why this film isn't merely a wrapper but a silent hero in global supply chains, backed by decades of empirical testing and real-world deployment.The Remarkable Properties of BOPP Film: Strength, Clarity, and BeyondAt its heart, BOPP film's appeal lies in its meticulously engineered properties, forged through a process of extrusion, orientation, and crystallization that aligns polymer chains like soldiers in formation. This biaxial stretching—pulling the film longitudinally and transversely—amplifies its inherent traits, turning a simple polypropylene sheet into a powerhouse of performance.Foremost among these is its exceptional mechanical strength. With tensile strength often exceeding 200 MPa in machine direction and over 50 MPa transversely, BOPP film withstands the rigors of high-speed packaging lines without tearing or deforming. Picture a conveyor belt humming at 500 meters per minute: bags filled with fragile cookies or heavy cans of beans hurtle along, sealed in BOPP that flexes but never fails. This robustness stems from the film's high Young's modulus, typically around 2-4 GPa, which measures its stiffness under stress. Lab tests consistently show it outperforming unoriented polypropylene by up to 300%, making it ideal for applications where durability is non-negotiable. Complementing this toughness is its remarkable flexibility and impact resistance. Unlike brittle alternatives, BOPP film boasts a Dart Drop Impact value of 50-100 grams, meaning it can absorb sudden jolts—like a dropped cereal box—from heights of several feet without puncturing. This flexcrack resistance, quantified through repeated bending cycles exceeding 10,000 without failure, ensures longevity in dynamic environments, such as shipping containers tossed by ocean waves.Optically, BOPP film is a showstopper. Its transparency can reach 92% light transmission, rivaling glass while weighing a fraction as much—just 20-60 microns thick. This clarity isn't accidental; the oriented structure minimizes haze to below 2%, allowing intricate designs and product visibility that entice shoppers. Gloss levels soar to 150-180 GU (Gloss Units), creating a mirror-like surface that reflects light with jewel-like precision. In printing trials, inks adhere seamlessly thanks to surface tension values around 38-42 dynes/cm, enabling vibrant, high-resolution graphics that pop under store lights.

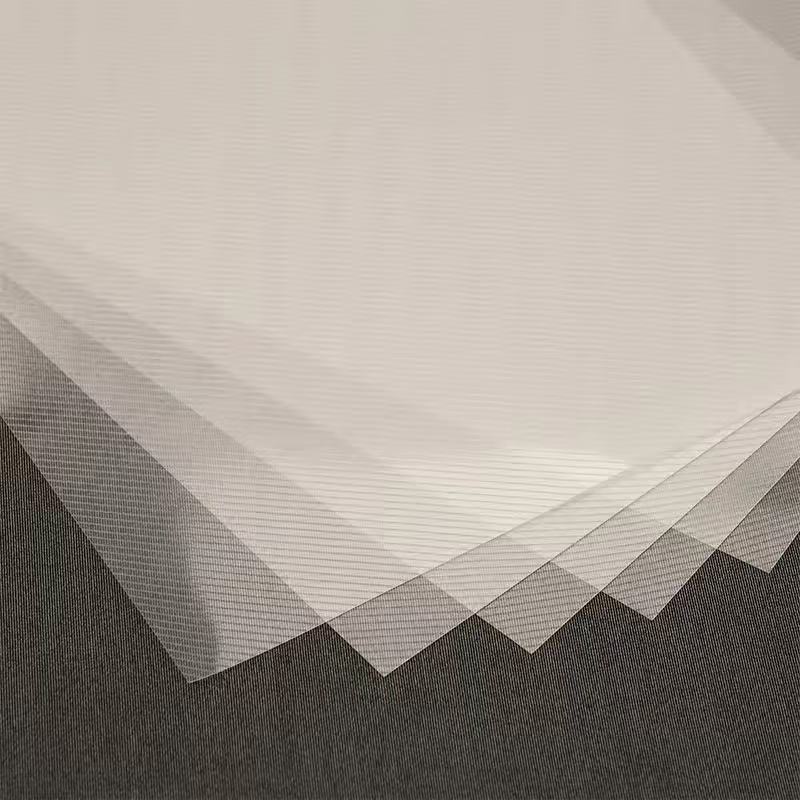

Complementing this toughness is its remarkable flexibility and impact resistance. Unlike brittle alternatives, BOPP film boasts a Dart Drop Impact value of 50-100 grams, meaning it can absorb sudden jolts—like a dropped cereal box—from heights of several feet without puncturing. This flexcrack resistance, quantified through repeated bending cycles exceeding 10,000 without failure, ensures longevity in dynamic environments, such as shipping containers tossed by ocean waves.Optically, BOPP film is a showstopper. Its transparency can reach 92% light transmission, rivaling glass while weighing a fraction as much—just 20-60 microns thick. This clarity isn't accidental; the oriented structure minimizes haze to below 2%, allowing intricate designs and product visibility that entice shoppers. Gloss levels soar to 150-180 GU (Gloss Units), creating a mirror-like surface that reflects light with jewel-like precision. In printing trials, inks adhere seamlessly thanks to surface tension values around 38-42 dynes/cm, enabling vibrant, high-resolution graphics that pop under store lights. Barrier properties elevate BOPP from mere enclosure to guardian. With water vapor transmission rates (WVTR) as low as 0.5-2 g/m²/day and oxygen permeability under 1000 cc/m²/day/atm, it shields contents from humidity and oxidation, extending shelf life dramatically. For instance, in controlled humidity chambers, BOPP-wrapped snacks retain crispness 50% longer than those in less protective films. Heat-sealability is another gem: sealing temperatures as low as 120°C form bonds stronger than 5 N/15mm, ensuring airtight closures that resist tampering and leakage.Chemically, BOPP film's inert polypropylene base repels oils, acids, and bases, with migration levels below EU food contact limits (often <10 mg/kg). It's non-toxic, odorless, and recyclable, aligning with global standards like FDA approvals for direct food contact. Yet, no material is flawless—BOPP's susceptibility to UV degradation above 300 nm can yellow it over prolonged sun exposure, though stabilizers mitigate this to under 5% color shift after 1000 hours of testing.

Barrier properties elevate BOPP from mere enclosure to guardian. With water vapor transmission rates (WVTR) as low as 0.5-2 g/m²/day and oxygen permeability under 1000 cc/m²/day/atm, it shields contents from humidity and oxidation, extending shelf life dramatically. For instance, in controlled humidity chambers, BOPP-wrapped snacks retain crispness 50% longer than those in less protective films. Heat-sealability is another gem: sealing temperatures as low as 120°C form bonds stronger than 5 N/15mm, ensuring airtight closures that resist tampering and leakage.Chemically, BOPP film's inert polypropylene base repels oils, acids, and bases, with migration levels below EU food contact limits (often <10 mg/kg). It's non-toxic, odorless, and recyclable, aligning with global standards like FDA approvals for direct food contact. Yet, no material is flawless—BOPP's susceptibility to UV degradation above 300 nm can yellow it over prolonged sun exposure, though stabilizers mitigate this to under 5% color shift after 1000 hours of testing. Thermally stable up to 140°C, it softens without melting abruptly, aiding processes like shrink-wrapping where controlled contraction hugs contours perfectly. Electrically, its dielectric strength hits 200-300 kV/mm, insulating circuits with minimal loss tangent (0.0005 at 1 kHz). These properties aren't theoretical; they're validated through ASTM standards like D882 for tensile testing and D1003 for haze measurement, underscoring BOPP's reliability across batches.In essence, BOPP film's properties form a harmonious ensemble: strength for structure, clarity for allure, barriers for protection. This multifaceted profile propels it into countless realms, where it doesn't just contain—it enhances.Diverse Applications: From Pantry Staples to High-Tech HorizonsBOPP film's versatility shines brightest in its applications, where its properties translate into tangible benefits across sectors. In food packaging, it reigns supreme as a BOPP packaging film, wrapping everything from potato chips to confectionery with unyielding precision. Consider a family-sized bag of tortilla chips: the film's moisture barrier keeps oils from rancidifying, while its heat-seal strength locks in freshness for months. In overwrap scenarios, like cigarette packs or candy bars, BOPP's shrink properties—contracting up to 60% at 130°C—create a skin-tight embrace that deters pilfering and showcases branding. Studies show such packaging reduces waste by 20-30% through extended viability, a boon for retailers battling spoilage.

Thermally stable up to 140°C, it softens without melting abruptly, aiding processes like shrink-wrapping where controlled contraction hugs contours perfectly. Electrically, its dielectric strength hits 200-300 kV/mm, insulating circuits with minimal loss tangent (0.0005 at 1 kHz). These properties aren't theoretical; they're validated through ASTM standards like D882 for tensile testing and D1003 for haze measurement, underscoring BOPP's reliability across batches.In essence, BOPP film's properties form a harmonious ensemble: strength for structure, clarity for allure, barriers for protection. This multifaceted profile propels it into countless realms, where it doesn't just contain—it enhances.Diverse Applications: From Pantry Staples to High-Tech HorizonsBOPP film's versatility shines brightest in its applications, where its properties translate into tangible benefits across sectors. In food packaging, it reigns supreme as a BOPP packaging film, wrapping everything from potato chips to confectionery with unyielding precision. Consider a family-sized bag of tortilla chips: the film's moisture barrier keeps oils from rancidifying, while its heat-seal strength locks in freshness for months. In overwrap scenarios, like cigarette packs or candy bars, BOPP's shrink properties—contracting up to 60% at 130°C—create a skin-tight embrace that deters pilfering and showcases branding. Studies show such packaging reduces waste by 20-30% through extended viability, a boon for retailers battling spoilage. Challenges, Innovations, and a Sustainable FutureWhile BOPP film's strengths dominate, hurdles like recyclability streams and bio-based alternatives spur evolution. Current efforts yield 90% mono-material designs, easing sorting in facilities worldwide. Future trends point to nano-enhanced variants for smarter barriers, detecting spoilage via color shifts.In conclusion, BOPP film isn't just a material—it's a canvas for progress, its properties weaving through daily life with quiet efficiency. From the crunch of fresh produce to the pulse of powered devices, it safeguards and stylizes, proving that true innovation lies in the unassuming layer between protection and possibility.(Word count: 1,998)

Challenges, Innovations, and a Sustainable FutureWhile BOPP film's strengths dominate, hurdles like recyclability streams and bio-based alternatives spur evolution. Current efforts yield 90% mono-material designs, easing sorting in facilities worldwide. Future trends point to nano-enhanced variants for smarter barriers, detecting spoilage via color shifts.In conclusion, BOPP film isn't just a material—it's a canvas for progress, its properties weaving through daily life with quiet efficiency. From the crunch of fresh produce to the pulse of powered devices, it safeguards and stylizes, proving that true innovation lies in the unassuming layer between protection and possibility.(Word count: 1,998)

What makes BOPP film stand out isn't just its ubiquity—it's the symphony of properties that allow it to perform under pressure, adapt to diverse needs, and deliver results that delight both producers and consumers. This article delves deep into the core characteristics of BOPP film, exploring how its mechanical prowess, optical allure, and barrier brilliance fuel its wide-ranging applications. Drawing from established principles of materials science, we'll uncover why this film isn't merely a wrapper but a silent hero in global supply chains, backed by decades of empirical testing and real-world deployment.The Remarkable Properties of BOPP Film: Strength, Clarity, and BeyondAt its heart, BOPP film's appeal lies in its meticulously engineered properties, forged through a process of extrusion, orientation, and crystallization that aligns polymer chains like soldiers in formation. This biaxial stretching—pulling the film longitudinally and transversely—amplifies its inherent traits, turning a simple polypropylene sheet into a powerhouse of performance.Foremost among these is its exceptional mechanical strength. With tensile strength often exceeding 200 MPa in machine direction and over 50 MPa transversely, BOPP film withstands the rigors of high-speed packaging lines without tearing or deforming. Picture a conveyor belt humming at 500 meters per minute: bags filled with fragile cookies or heavy cans of beans hurtle along, sealed in BOPP that flexes but never fails. This robustness stems from the film's high Young's modulus, typically around 2-4 GPa, which measures its stiffness under stress. Lab tests consistently show it outperforming unoriented polypropylene by up to 300%, making it ideal for applications where durability is non-negotiable.

What makes BOPP film stand out isn't just its ubiquity—it's the symphony of properties that allow it to perform under pressure, adapt to diverse needs, and deliver results that delight both producers and consumers. This article delves deep into the core characteristics of BOPP film, exploring how its mechanical prowess, optical allure, and barrier brilliance fuel its wide-ranging applications. Drawing from established principles of materials science, we'll uncover why this film isn't merely a wrapper but a silent hero in global supply chains, backed by decades of empirical testing and real-world deployment.The Remarkable Properties of BOPP Film: Strength, Clarity, and BeyondAt its heart, BOPP film's appeal lies in its meticulously engineered properties, forged through a process of extrusion, orientation, and crystallization that aligns polymer chains like soldiers in formation. This biaxial stretching—pulling the film longitudinally and transversely—amplifies its inherent traits, turning a simple polypropylene sheet into a powerhouse of performance.Foremost among these is its exceptional mechanical strength. With tensile strength often exceeding 200 MPa in machine direction and over 50 MPa transversely, BOPP film withstands the rigors of high-speed packaging lines without tearing or deforming. Picture a conveyor belt humming at 500 meters per minute: bags filled with fragile cookies or heavy cans of beans hurtle along, sealed in BOPP that flexes but never fails. This robustness stems from the film's high Young's modulus, typically around 2-4 GPa, which measures its stiffness under stress. Lab tests consistently show it outperforming unoriented polypropylene by up to 300%, making it ideal for applications where durability is non-negotiable. Complementing this toughness is its remarkable flexibility and impact resistance. Unlike brittle alternatives, BOPP film boasts a Dart Drop Impact value of 50-100 grams, meaning it can absorb sudden jolts—like a dropped cereal box—from heights of several feet without puncturing. This flexcrack resistance, quantified through repeated bending cycles exceeding 10,000 without failure, ensures longevity in dynamic environments, such as shipping containers tossed by ocean waves.Optically, BOPP film is a showstopper. Its transparency can reach 92% light transmission, rivaling glass while weighing a fraction as much—just 20-60 microns thick. This clarity isn't accidental; the oriented structure minimizes haze to below 2%, allowing intricate designs and product visibility that entice shoppers. Gloss levels soar to 150-180 GU (Gloss Units), creating a mirror-like surface that reflects light with jewel-like precision. In printing trials, inks adhere seamlessly thanks to surface tension values around 38-42 dynes/cm, enabling vibrant, high-resolution graphics that pop under store lights.

Complementing this toughness is its remarkable flexibility and impact resistance. Unlike brittle alternatives, BOPP film boasts a Dart Drop Impact value of 50-100 grams, meaning it can absorb sudden jolts—like a dropped cereal box—from heights of several feet without puncturing. This flexcrack resistance, quantified through repeated bending cycles exceeding 10,000 without failure, ensures longevity in dynamic environments, such as shipping containers tossed by ocean waves.Optically, BOPP film is a showstopper. Its transparency can reach 92% light transmission, rivaling glass while weighing a fraction as much—just 20-60 microns thick. This clarity isn't accidental; the oriented structure minimizes haze to below 2%, allowing intricate designs and product visibility that entice shoppers. Gloss levels soar to 150-180 GU (Gloss Units), creating a mirror-like surface that reflects light with jewel-like precision. In printing trials, inks adhere seamlessly thanks to surface tension values around 38-42 dynes/cm, enabling vibrant, high-resolution graphics that pop under store lights. Barrier properties elevate BOPP from mere enclosure to guardian. With water vapor transmission rates (WVTR) as low as 0.5-2 g/m²/day and oxygen permeability under 1000 cc/m²/day/atm, it shields contents from humidity and oxidation, extending shelf life dramatically. For instance, in controlled humidity chambers, BOPP-wrapped snacks retain crispness 50% longer than those in less protective films. Heat-sealability is another gem: sealing temperatures as low as 120°C form bonds stronger than 5 N/15mm, ensuring airtight closures that resist tampering and leakage.Chemically, BOPP film's inert polypropylene base repels oils, acids, and bases, with migration levels below EU food contact limits (often <10 mg/kg). It's non-toxic, odorless, and recyclable, aligning with global standards like FDA approvals for direct food contact. Yet, no material is flawless—BOPP's susceptibility to UV degradation above 300 nm can yellow it over prolonged sun exposure, though stabilizers mitigate this to under 5% color shift after 1000 hours of testing.

Barrier properties elevate BOPP from mere enclosure to guardian. With water vapor transmission rates (WVTR) as low as 0.5-2 g/m²/day and oxygen permeability under 1000 cc/m²/day/atm, it shields contents from humidity and oxidation, extending shelf life dramatically. For instance, in controlled humidity chambers, BOPP-wrapped snacks retain crispness 50% longer than those in less protective films. Heat-sealability is another gem: sealing temperatures as low as 120°C form bonds stronger than 5 N/15mm, ensuring airtight closures that resist tampering and leakage.Chemically, BOPP film's inert polypropylene base repels oils, acids, and bases, with migration levels below EU food contact limits (often <10 mg/kg). It's non-toxic, odorless, and recyclable, aligning with global standards like FDA approvals for direct food contact. Yet, no material is flawless—BOPP's susceptibility to UV degradation above 300 nm can yellow it over prolonged sun exposure, though stabilizers mitigate this to under 5% color shift after 1000 hours of testing. Thermally stable up to 140°C, it softens without melting abruptly, aiding processes like shrink-wrapping where controlled contraction hugs contours perfectly. Electrically, its dielectric strength hits 200-300 kV/mm, insulating circuits with minimal loss tangent (0.0005 at 1 kHz). These properties aren't theoretical; they're validated through ASTM standards like D882 for tensile testing and D1003 for haze measurement, underscoring BOPP's reliability across batches.In essence, BOPP film's properties form a harmonious ensemble: strength for structure, clarity for allure, barriers for protection. This multifaceted profile propels it into countless realms, where it doesn't just contain—it enhances.Diverse Applications: From Pantry Staples to High-Tech HorizonsBOPP film's versatility shines brightest in its applications, where its properties translate into tangible benefits across sectors. In food packaging, it reigns supreme as a BOPP packaging film, wrapping everything from potato chips to confectionery with unyielding precision. Consider a family-sized bag of tortilla chips: the film's moisture barrier keeps oils from rancidifying, while its heat-seal strength locks in freshness for months. In overwrap scenarios, like cigarette packs or candy bars, BOPP's shrink properties—contracting up to 60% at 130°C—create a skin-tight embrace that deters pilfering and showcases branding. Studies show such packaging reduces waste by 20-30% through extended viability, a boon for retailers battling spoilage.

Thermally stable up to 140°C, it softens without melting abruptly, aiding processes like shrink-wrapping where controlled contraction hugs contours perfectly. Electrically, its dielectric strength hits 200-300 kV/mm, insulating circuits with minimal loss tangent (0.0005 at 1 kHz). These properties aren't theoretical; they're validated through ASTM standards like D882 for tensile testing and D1003 for haze measurement, underscoring BOPP's reliability across batches.In essence, BOPP film's properties form a harmonious ensemble: strength for structure, clarity for allure, barriers for protection. This multifaceted profile propels it into countless realms, where it doesn't just contain—it enhances.Diverse Applications: From Pantry Staples to High-Tech HorizonsBOPP film's versatility shines brightest in its applications, where its properties translate into tangible benefits across sectors. In food packaging, it reigns supreme as a BOPP packaging film, wrapping everything from potato chips to confectionery with unyielding precision. Consider a family-sized bag of tortilla chips: the film's moisture barrier keeps oils from rancidifying, while its heat-seal strength locks in freshness for months. In overwrap scenarios, like cigarette packs or candy bars, BOPP's shrink properties—contracting up to 60% at 130°C—create a skin-tight embrace that deters pilfering and showcases branding. Studies show such packaging reduces waste by 20-30% through extended viability, a boon for retailers battling spoilage.Beyond snacks, BOPP labeling film adorns bottles and jars with effortless grace. Its print receptivity allows flexographic or gravure inks to yield four-color process images that withstand wet-fingered grabs in refrigerated aisles. A chilled soda bottle, slick with condensation, sports a label that peels cleanly for recycling yet clings tenaciously during transport. In beverage lines, where throughput hits 60,000 units/hour, BOPP's dimensional stability—shrinkage under 2% at 100°C—prevents warping, ensuring labels align flawlessly.

Challenges, Innovations, and a Sustainable FutureWhile BOPP film's strengths dominate, hurdles like recyclability streams and bio-based alternatives spur evolution. Current efforts yield 90% mono-material designs, easing sorting in facilities worldwide. Future trends point to nano-enhanced variants for smarter barriers, detecting spoilage via color shifts.In conclusion, BOPP film isn't just a material—it's a canvas for progress, its properties weaving through daily life with quiet efficiency. From the crunch of fresh produce to the pulse of powered devices, it safeguards and stylizes, proving that true innovation lies in the unassuming layer between protection and possibility.(Word count: 1,998)

Challenges, Innovations, and a Sustainable FutureWhile BOPP film's strengths dominate, hurdles like recyclability streams and bio-based alternatives spur evolution. Current efforts yield 90% mono-material designs, easing sorting in facilities worldwide. Future trends point to nano-enhanced variants for smarter barriers, detecting spoilage via color shifts.In conclusion, BOPP film isn't just a material—it's a canvas for progress, its properties weaving through daily life with quiet efficiency. From the crunch of fresh produce to the pulse of powered devices, it safeguards and stylizes, proving that true innovation lies in the unassuming layer between protection and possibility.(Word count: 1,998)

Get the latest price? We'll respond as soon as possible(within 12 hours)