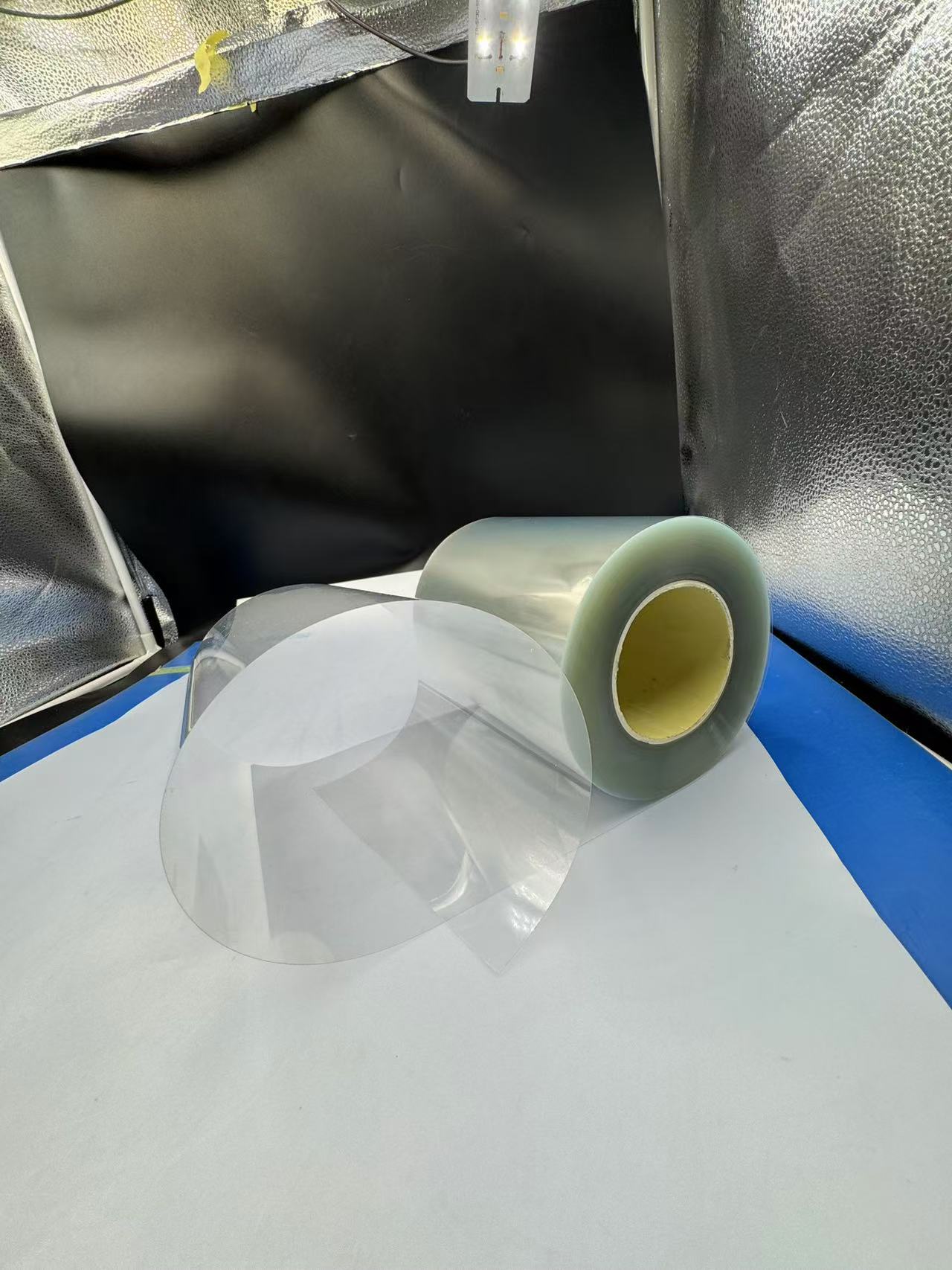

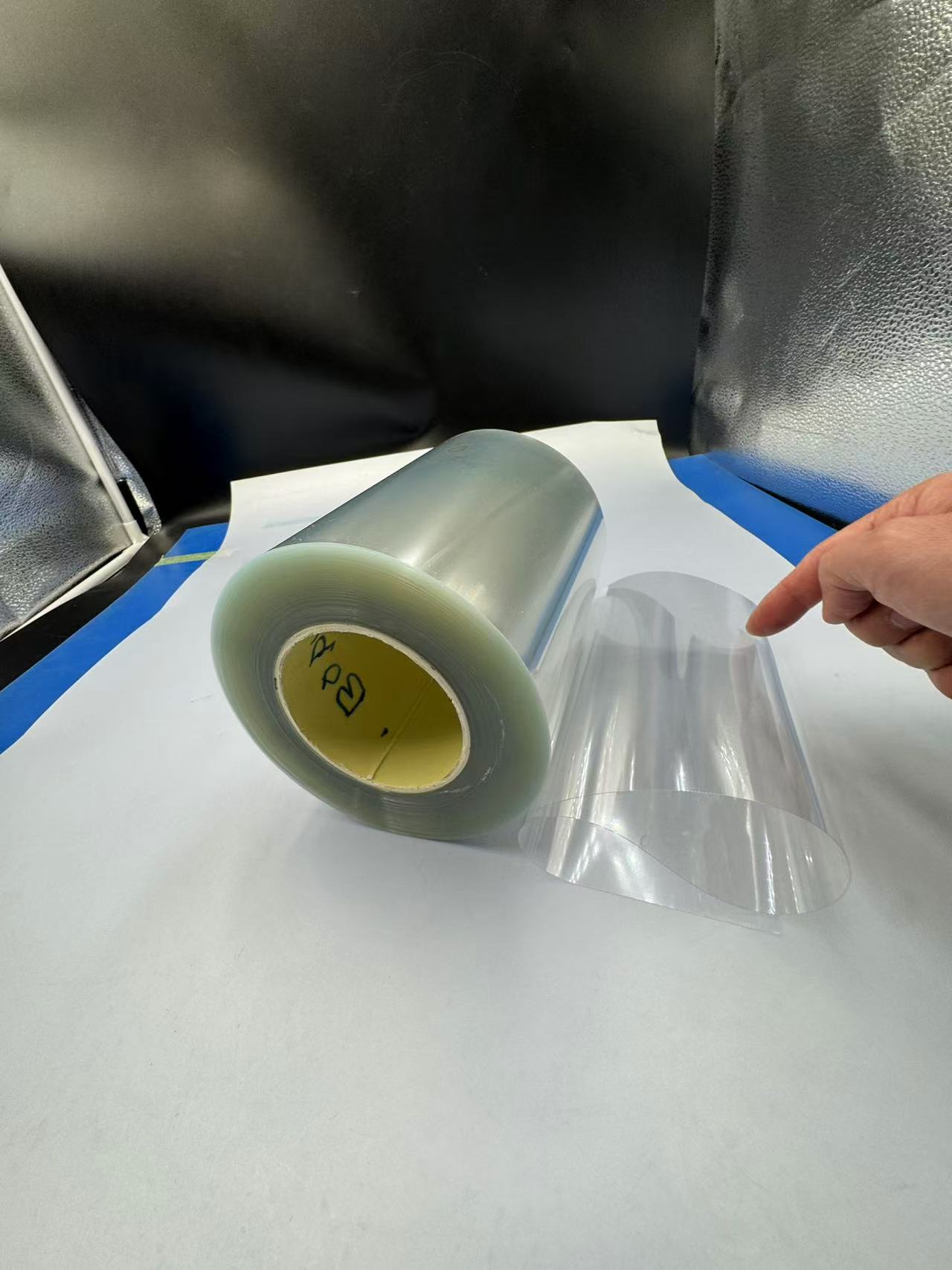

Properties of Transparent PET Heat-Resistant Film: A Multifaceted Marvel

2025-03-24 15:10In the fast-evolving world of electronics, where precision, durability, and protection are paramount, transparent PET (polyethylene terephthalate) heat-resistant film has emerged as a versatile champion. Renowned for its clarity, thermal stability, and adaptability, this material bridges the gap between functionality and innovation. From shielding sensitive components to insulating circuits, PET film plays a critical role in modern technology. This article explores the standout properties of transparent PET heat-resistant film and its applications in antistatic protection, electronic packaging, and electrical insulation. With a mix of scientific insight and real-world examples, we’ll reveal why this film is a cornerstone of the electronic age.

From shielding sensitive components to insulating circuits, PET film plays a critical role in modern technology. This article explores the standout properties of transparent PET heat-resistant film and its applications in antistatic protection, electronic packaging, and electrical insulation. With a mix of scientific insight and real-world examples, we’ll reveal why this film is a cornerstone of the electronic age.

The Core Properties of Transparent PET Heat-Resistant Film

PET film, a thermoplastic polyester derived from ethylene glycol and terephthalic acid, is a staple in industries requiring robust yet clear materials. When engineered for heat resistance, it gains attributes that make it ideal for demanding electronic applications. Let’s unpack its key characteristics:

Heat Resistance

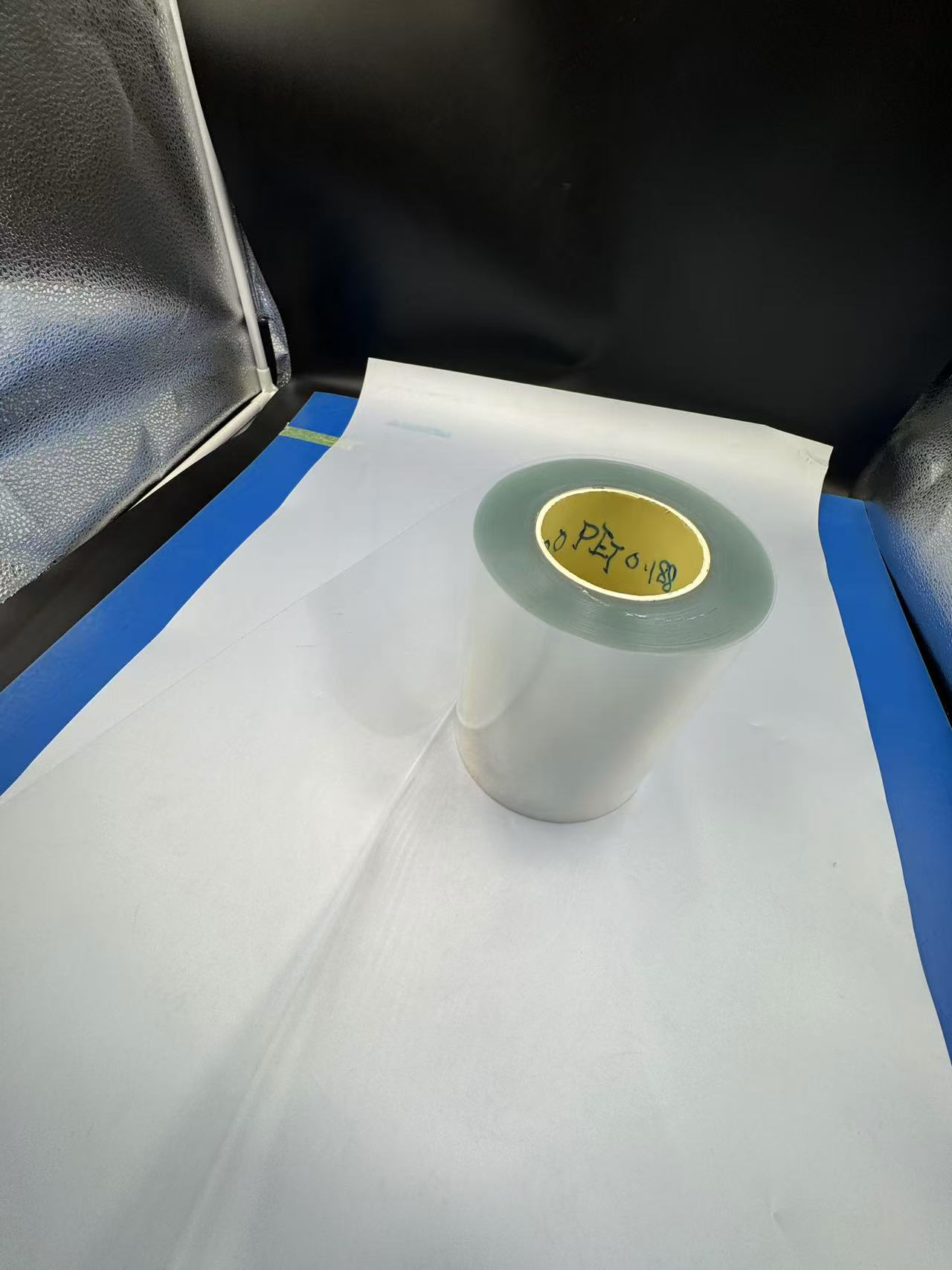

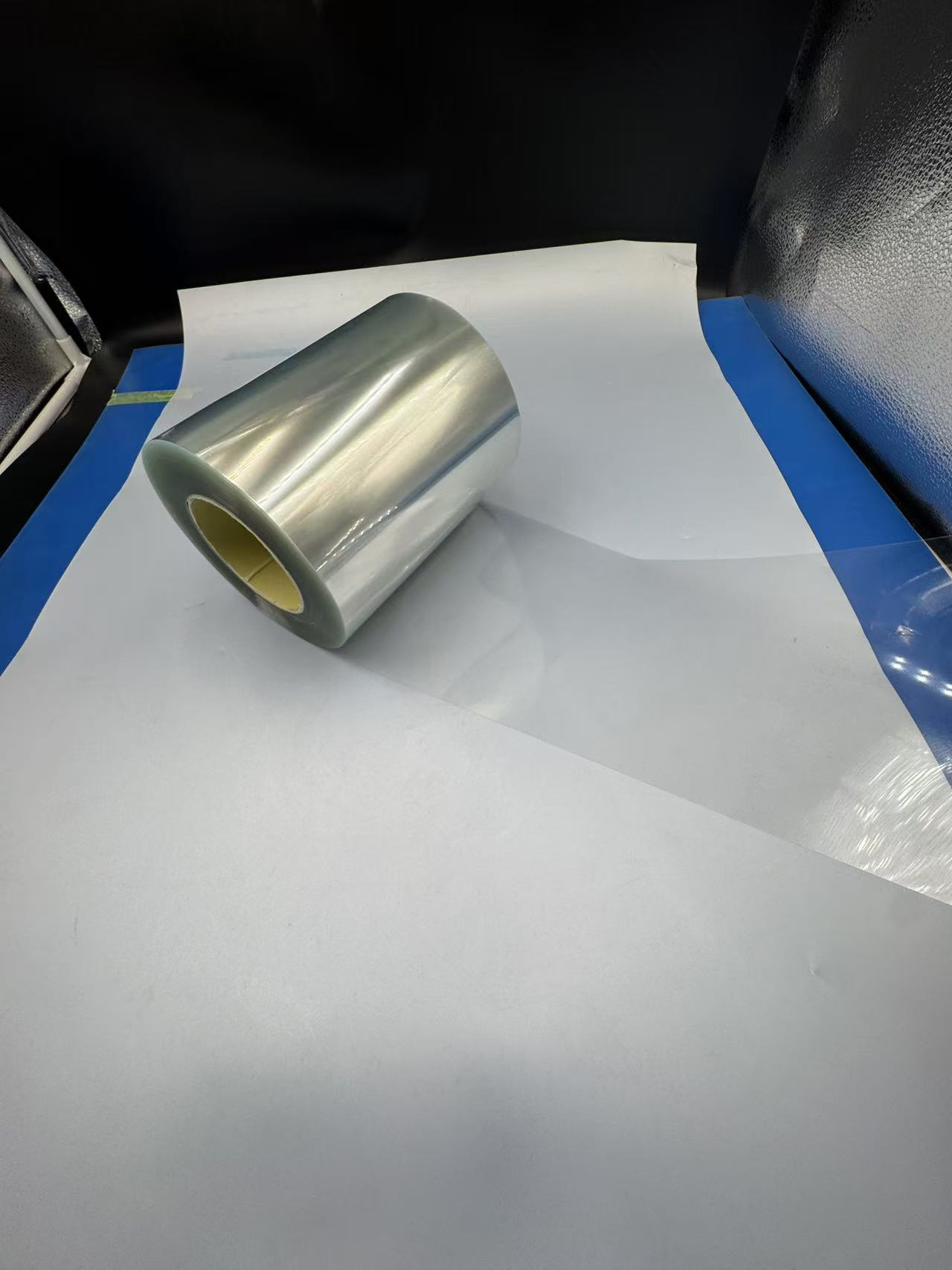

Standard PET has a melting point of around 250–260°C, but heat-resistant variants—often stabilized with additives or crystallization—can withstand continuous exposure up to 150–180°C without deforming. Its glass transition temperature (Tg) of 70–80°C ensures it remains rigid under moderate heat. Imagine a PET film layer in a circuit board enduring the warmth of a running laptop, holding its shape while others might warp.Transparency and Optical Clarity

With light transmission rates exceeding 90%, transparent PET film offers exceptional visibility. This clarity is crucial for applications where inspection or branding matters, maintaining a pristine finish even after processing. Picture a sleek smartphone screen protector made from PET, revealing every pixel in vivid detail while shielding the device beneath.

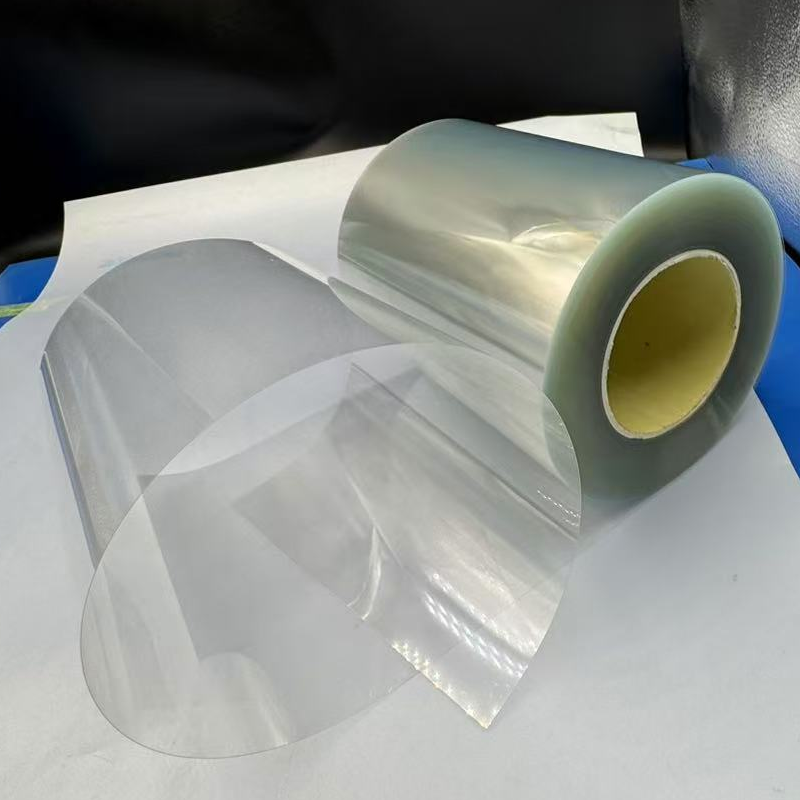

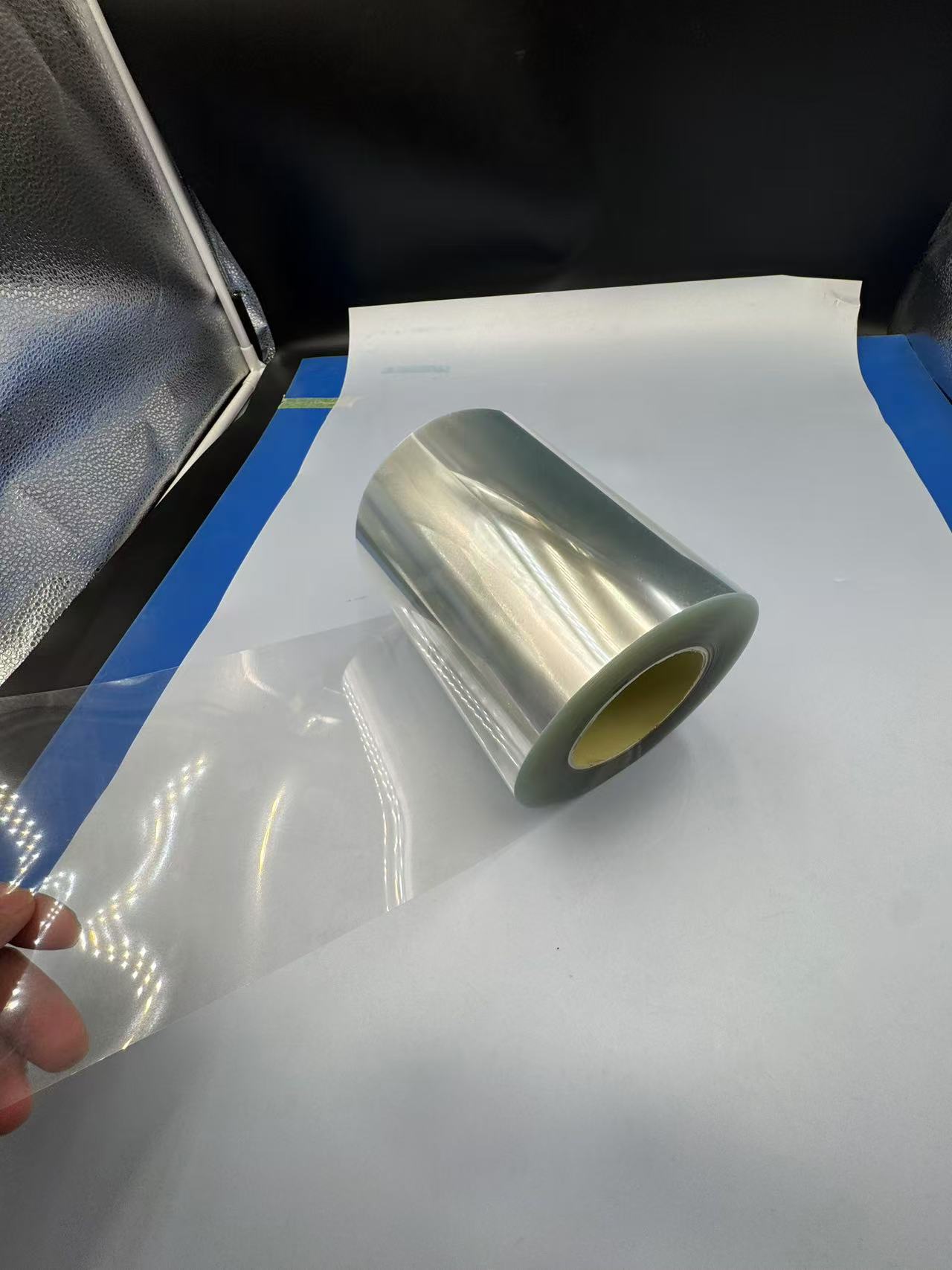

Mechanical Strength

PET film boasts a tensile strength of 50–200 MPa and an elongation at break of 50–150%, depending on thickness and treatment. This balance of toughness and flexibility allows it to resist tearing or puncturing under stress. Visualize a PET film wrap encasing a fragile microchip, bending slightly but never breaking during shipping.Electrical Insulation

With a dielectric strength of 60–170 kV/mm and a volume resistivity of 10¹⁶–10¹⁸ Ω·cm, PET film excels as an insulator. It prevents current leakage and withstands high voltages, making it a go-to for electronic components. Think of it as an invisible shield, keeping circuits safe from shorts or sparks.

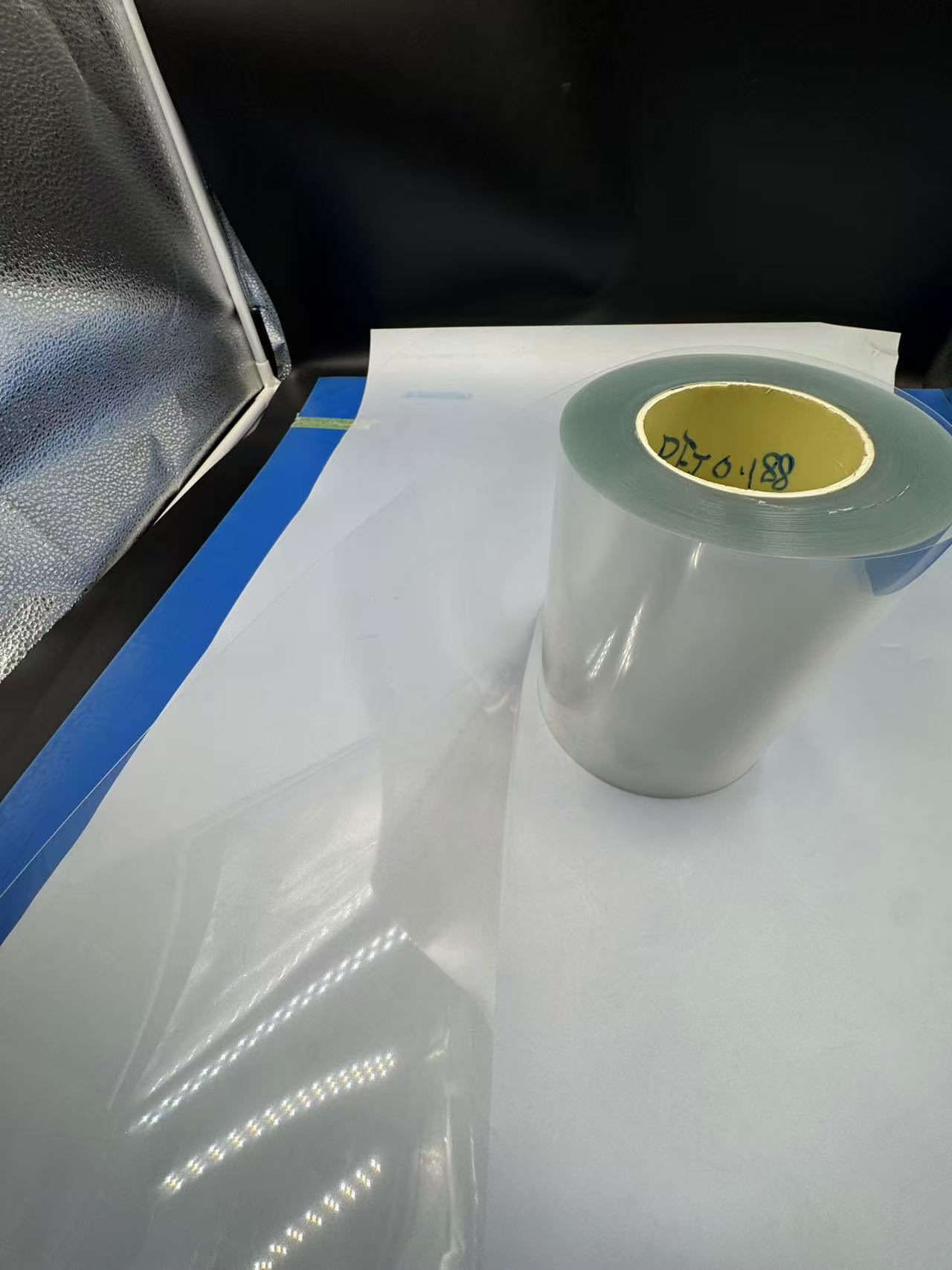

Surface Modifiability

PET film can be coated or treated to enhance properties like antistatic performance or adhesion. Corona treatment, for instance, increases surface energy, enabling better bonding with inks or antistatic agents. This adaptability transforms PET into a tailored solution for specific needs, whether it’s repelling dust or grounding static charges.

These properties position PET film as a dynamic material, ready to tackle the challenges of electronics with finesse.

PET Film in Antistatic Applications

Static electricity is a silent menace in electronics, capable of frying delicate components with a single discharge. Transparent PET heat-resistant film, when treated, steps in as an antistatic savior:

Static Dissipation

Antistatic PET film is coated with conductive layers—often quaternary ammonium compounds or carbon-based materials—reducing surface resistivity to 10⁶–10⁹ Ω/sq. This dissipates static charges before they can build up and harm sensitive parts. Imagine a PET film sleeve cradling a batch of microprocessors; as workers handle it, static from their fingers harmlessly disperses, leaving the chips unscathed.Dust and Contamination Control

By neutralizing static, PET film prevents dust attraction—a critical factor in cleanroom environments. A 2021 study showed that antistatic PET reduced particulate adhesion by 70% compared to untreated films. Picture a pristine semiconductor lab where PET film ensures every component stays spotless, ready for assembly.Heat-Resistant Performance

In processes like soldering or heat sealing, where temperatures spike, PET’s thermal stability shines. It maintains its antistatic properties without degrading, unlike some alternatives that lose efficacy under heat. Visualize a PET film liner in a hot manufacturing line, quietly protecting circuits as the machinery hums.Visibility and Safety

Its transparency allows technicians to monitor components without removing protective layers, reducing handling risks. A clear PET film cover on an antistatic tray reveals rows of LEDs, ensuring quality control without compromising static protection.

PET Film in Electronic Packaging

Electronic devices rely on packaging that’s tough, lightweight, and protective. Transparent PET heat-resistant film rises to the occasion, safeguarding components from factory to end user:

Physical Protection

PET film’s mechanical strength shields delicate electronics from scratches, impacts, and pressure. Thermoformed into trays or blisters, it cradles items like resistors or capacitors snugly. Think of a PET film clamshell encasing a new USB drive, absorbing the jostle of shipping while keeping it pristine.Thermal Endurance

During transit or storage, electronics may face temperature swings. PET film’s heat resistance ensures it won’t melt or deform, even in a sun-baked delivery truck. A 2019 test found PET trays maintained integrity at 150°C for hours—perfect for a batch of sensors en route to a warehouse.

Transparency for Branding

PET’s clarity doubles as a marketing tool, showcasing products through protective layers. A transparent PET film window on a retail package lets consumers peek at a gleaming circuit board, blending aesthetics with utility.Recyclability

Unlike some multilayer films, PET is widely recyclable, aligning with sustainability trends. After use, a PET film package can be reborn as a new product, reducing waste. Imagine a discarded PET tray from an old phone finding new life as part of a laptop casing.Challenges

PET’s rigidity can limit flexibility in some designs, and uncoated versions may lack moisture barriers. Manufacturers often pair it with coatings or laminates to address this, adding complexity but enhancing performance.

PET Film in Electronic Insulation

In the intricate dance of electrons within devices, insulation prevents chaos. Transparent PET heat-resistant film excels here, offering reliability and precision:

High Dielectric Strength

PET film’s ability to block voltage makes it ideal for insulating wires, capacitors, and circuit layers. A thin 25-micron PET film can withstand 4–5 kV, ensuring no current escapes where it shouldn’t. Picture it wrapped around a motor coil, silently maintaining order in a humming machine.Thermal Stability in Operation

Electronics generate heat—think of a CPU under load. PET film endures these conditions, preventing insulation failure. Its use in flexible printed circuits (FPCs) keeps signals flowing smoothly, even as temperatures climb to 120°C or more.

Thin yet Tough

PET’s strength-to-thickness ratio allows ultrathin films (down to 12 microns) to insulate effectively without bulking up designs. In a smartphone, layers of PET film separate components, keeping the device slim yet safe.Clarity for Inspection

Transparent PET lets engineers visually check insulated parts for alignment or damage during assembly. Imagine a technician peering through a PET film layer in a prototype, spotting a misaligned wire before it’s too late.Limitations

PET’s insulation weakens under extreme humidity unless treated, and it’s less flexible than some alternatives like polyimide. For ultra-high-voltage uses, it may cede ground to specialized materials, but for most consumer electronics, it’s a star performer.

Balancing Strengths and Realities

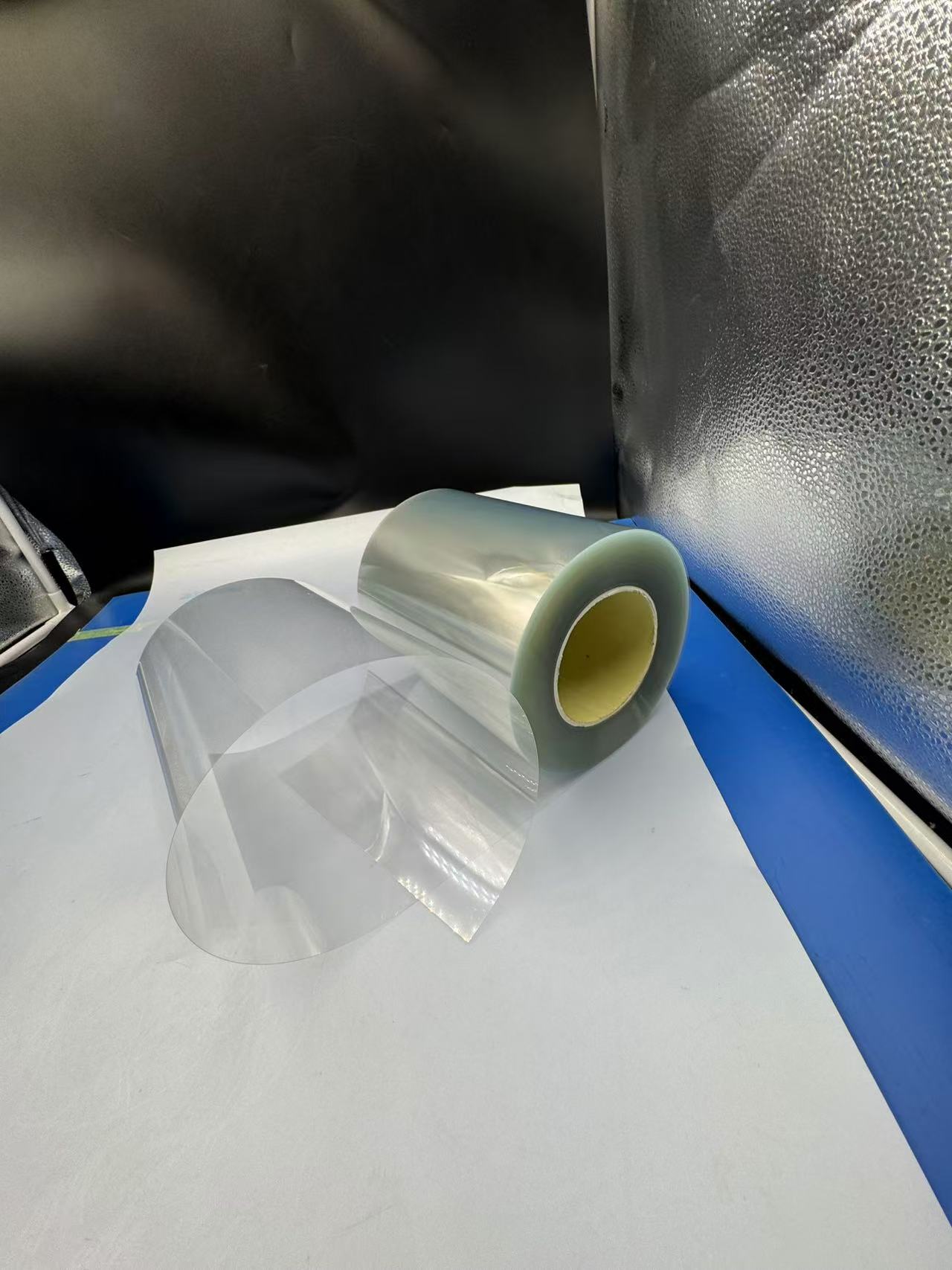

Transparent PET heat-resistant film is a workhorse, blending durability, clarity, and adaptability. In antistatic roles, it neutralizes threats to sensitive chips; in packaging, it guards products with style; in insulation, it maintains electrical harmony. Yet, its rigidity and moisture sensitivity remind us it’s not a one-size-fits-all solution—strategic enhancements like coatings often unlock its full potential.

Consider a bustling electronics factory: PET film trays ferry components past static-prone zones, then insulate them in finished devices, all while enduring heat and scrutiny. This seamless integration showcases its versatility, even as recycling efforts and cost pressures shape its future.

Conclusion

Transparent PET heat-resistant film is a quiet hero in the electronic realm, its properties—heat resistance, clarity, strength, and insulative power—making it indispensable. From dissipating static in cleanrooms to packaging gadgets and insulating circuits, it meets the demands of a tech-driven world. While not flawless, its strengths far outweigh its quirks, cementing its place in innovation. The next time you power up a device, consider the PET film within—unseen, unfaltering, and essential to the marvels of modern life.