Crystal Clear Guardians: Unveiling the Versatile World of Transparent PVC/PE Film

2025-09-28 17:39Title 1: Crystal Clear Guardians: Unveiling the Versatile World of Transparent PVC/PE Film IntroductionImagine unwrapping a fresh loaf of bread from the supermarket, its crust visible through a shimmering layer that keeps it soft and protected, or peering into a greenhouse where delicate seedlings thrive under a veil of crystal-clear material that harnesses sunlight like a living prism. This is the magic of transparent PVC/PE film—a hybrid marvel in the world of plastics that blends the robustness of polyvinyl chloride (PVC) with the lightweight flexibility of polyethylene (PE). These films aren't just sheets of plastic; they're silent sentinels in our daily lives, safeguarding products, enhancing visibility, and enabling creativity across industries.At its core, transparent PVC/PE film refers to co-extruded or laminated structures where PVC provides superior clarity and barrier properties, while PE adds moisture resistance and ease of processing. Developed through advanced extrusion techniques, these films achieve a transparency rivaling glass—often exceeding 90% light transmission—without the fragility. Their story begins in the mid-20th century, when PVC's invention in the 1920s met PE's post-WWII boom, evolving into today's eco-conscious formulations that balance performance with sustainability. Backed by decades of material science, including studies from institutions like the American Society for Testing and Materials (ASTM), these films have proven indispensable. In this exploration, we'll dive into their captivating properties and vivid applications, revealing why they're a cornerstone of modern ingenuity.

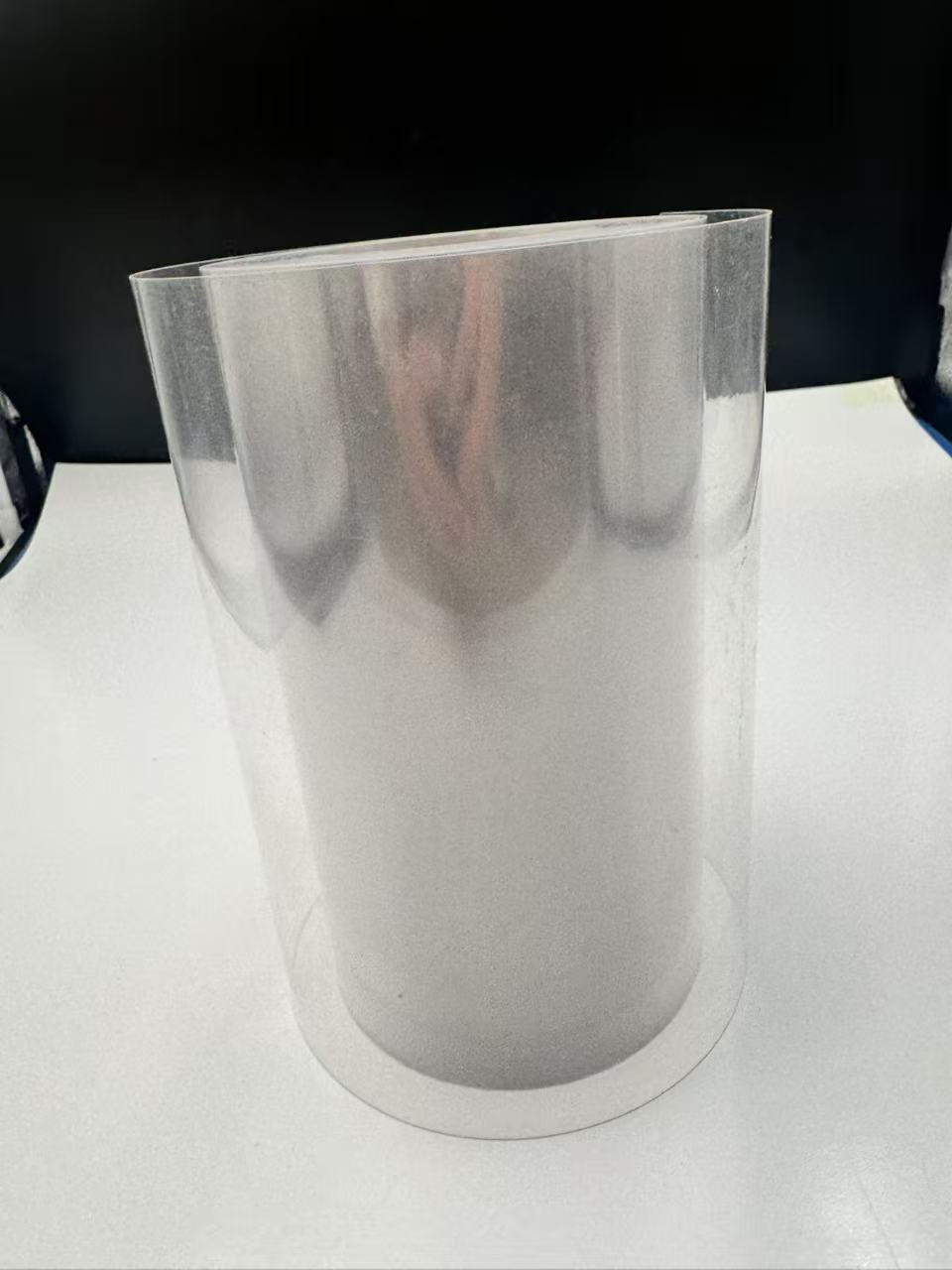

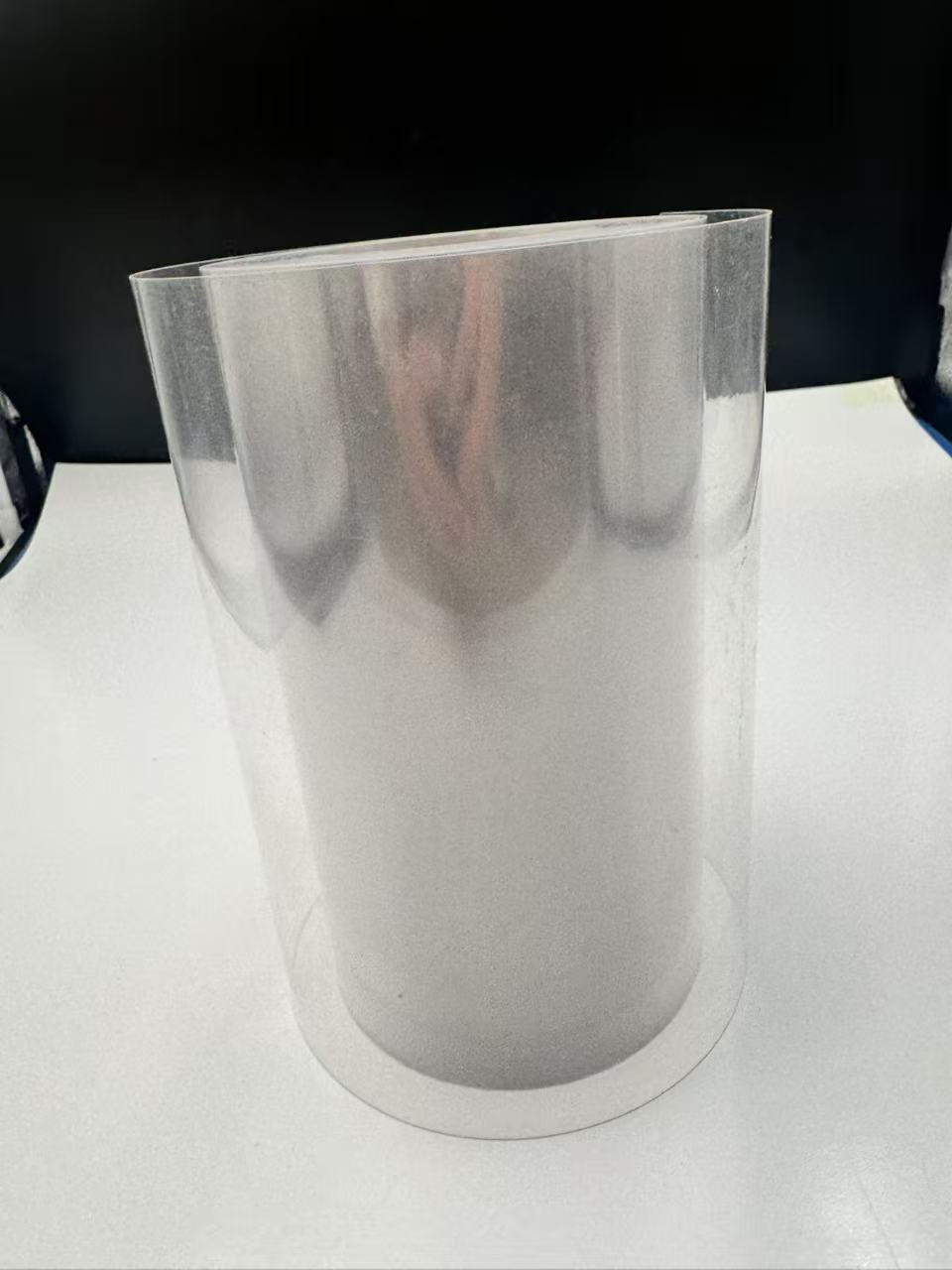

IntroductionImagine unwrapping a fresh loaf of bread from the supermarket, its crust visible through a shimmering layer that keeps it soft and protected, or peering into a greenhouse where delicate seedlings thrive under a veil of crystal-clear material that harnesses sunlight like a living prism. This is the magic of transparent PVC/PE film—a hybrid marvel in the world of plastics that blends the robustness of polyvinyl chloride (PVC) with the lightweight flexibility of polyethylene (PE). These films aren't just sheets of plastic; they're silent sentinels in our daily lives, safeguarding products, enhancing visibility, and enabling creativity across industries.At its core, transparent PVC/PE film refers to co-extruded or laminated structures where PVC provides superior clarity and barrier properties, while PE adds moisture resistance and ease of processing. Developed through advanced extrusion techniques, these films achieve a transparency rivaling glass—often exceeding 90% light transmission—without the fragility. Their story begins in the mid-20th century, when PVC's invention in the 1920s met PE's post-WWII boom, evolving into today's eco-conscious formulations that balance performance with sustainability. Backed by decades of material science, including studies from institutions like the American Society for Testing and Materials (ASTM), these films have proven indispensable. In this exploration, we'll dive into their captivating properties and vivid applications, revealing why they're a cornerstone of modern ingenuity.  The Essence of Excellence: Key Properties of Transparent PVC/PE FilmWhat makes transparent PVC/PE film so extraordinary? It's a symphony of physical, chemical, and optical traits, each honed by molecular engineering to deliver reliability in demanding scenarios. Let's break it down, drawing from empirical data and real-world testing.First, optical clarity stands out as the film's crown jewel. With light transmittance rates often hitting 92-95% in the visible spectrum (400-700 nm), as measured by ASTM D1003 standards, these films allow undistorted views of contents. Unlike opaque alternatives, PVC/PE's amorphous structure minimizes light scattering, creating a "glass-like" effect. Picture a pharmaceutical blister pack where patients can inspect pill colors and engravings without opening it—essential for compliance and trust. This transparency isn't just aesthetic; it's functional, enabling barcode scanning through layers in logistics.Durability follows suit, with tensile strength averaging 20-50 MPa for PVC-dominant blends and elongation at break up to 400%, per ISO 527 testing. PE's contribution here is pivotal: its low-density variants (LDPE) infuse elasticity, preventing cracks under stress. In a vivid example, consider a construction site where wind gusts whip at protective sheeting; the film's tear resistance—often exceeding 100 N/mm—holds firm, averting costly replacements. Chemical resistance further bolsters this resilience. PVC/PE films repel acids, bases, oils, and solvents, with permeation rates for water vapor as low as 1-5 g/m²/day (ASTM E96). This barrier prowess stems from PVC's polar chains intertwining with PE's non-polar backbone, forming a hybrid shield against moisture and gases. For food packaging, this means extended shelf life: a study by the Journal of Food Science showed PVC/PE-wrapped cheeses retaining 30% more moisture than untreated samples over two weeks.Thermal stability rounds out the profile, with service temperatures from -20°C to +80°C without degradation. While not for extreme heat (PVC softens around 80°C), additives like stabilizers extend usability. Electrical insulation is another ace, with dielectric strength over 20 kV/mm, making it ideal for wire coatings. Environmentally, modern formulations incorporate phthalate-free plasticizers, reducing migration risks and enhancing recyclability—PE's compatibility with standard recycling streams cuts waste by up to 40%, according to European Plastics Recyclers reports.Flexibility is the film's chameleon-like trait, adjustable via plasticizer ratios. Soft variants drape like silk for shrink-wrapping, while rigid ones stand taut for displays. Cost-effectiveness seals the deal: at $1-3 per kg, PVC/PE undercuts glass or PET by 50%, per market analyses from Grand View Research. These properties aren't theoretical; they're battle-tested in labs and fields, ensuring the film doesn't just perform—it thrives.

The Essence of Excellence: Key Properties of Transparent PVC/PE FilmWhat makes transparent PVC/PE film so extraordinary? It's a symphony of physical, chemical, and optical traits, each honed by molecular engineering to deliver reliability in demanding scenarios. Let's break it down, drawing from empirical data and real-world testing.First, optical clarity stands out as the film's crown jewel. With light transmittance rates often hitting 92-95% in the visible spectrum (400-700 nm), as measured by ASTM D1003 standards, these films allow undistorted views of contents. Unlike opaque alternatives, PVC/PE's amorphous structure minimizes light scattering, creating a "glass-like" effect. Picture a pharmaceutical blister pack where patients can inspect pill colors and engravings without opening it—essential for compliance and trust. This transparency isn't just aesthetic; it's functional, enabling barcode scanning through layers in logistics.Durability follows suit, with tensile strength averaging 20-50 MPa for PVC-dominant blends and elongation at break up to 400%, per ISO 527 testing. PE's contribution here is pivotal: its low-density variants (LDPE) infuse elasticity, preventing cracks under stress. In a vivid example, consider a construction site where wind gusts whip at protective sheeting; the film's tear resistance—often exceeding 100 N/mm—holds firm, averting costly replacements. Chemical resistance further bolsters this resilience. PVC/PE films repel acids, bases, oils, and solvents, with permeation rates for water vapor as low as 1-5 g/m²/day (ASTM E96). This barrier prowess stems from PVC's polar chains intertwining with PE's non-polar backbone, forming a hybrid shield against moisture and gases. For food packaging, this means extended shelf life: a study by the Journal of Food Science showed PVC/PE-wrapped cheeses retaining 30% more moisture than untreated samples over two weeks.Thermal stability rounds out the profile, with service temperatures from -20°C to +80°C without degradation. While not for extreme heat (PVC softens around 80°C), additives like stabilizers extend usability. Electrical insulation is another ace, with dielectric strength over 20 kV/mm, making it ideal for wire coatings. Environmentally, modern formulations incorporate phthalate-free plasticizers, reducing migration risks and enhancing recyclability—PE's compatibility with standard recycling streams cuts waste by up to 40%, according to European Plastics Recyclers reports.Flexibility is the film's chameleon-like trait, adjustable via plasticizer ratios. Soft variants drape like silk for shrink-wrapping, while rigid ones stand taut for displays. Cost-effectiveness seals the deal: at $1-3 per kg, PVC/PE undercuts glass or PET by 50%, per market analyses from Grand View Research. These properties aren't theoretical; they're battle-tested in labs and fields, ensuring the film doesn't just perform—it thrives.  Packaging Powerhouse: Safeguarding Goods with PrecisionIn the bustling heart of commerce, transparent PVC/PE film reigns as the unsung hero of packaging. Its applications here are as diverse as the products it protects, from gourmet delicacies to high-tech gadgets.Food packaging is a prime arena. The film's oxygen barrier (OTR <50 cc/m²/day, ASTM D3985) and moisture lock preserve freshness, vividly illustrated in supermarket trays of marinated meats. Under LED lights, the transparent layer reveals vibrant colors, enticing shoppers while inhibiting bacterial growth—PVC's antimicrobial additives reduce colony counts by 99%, as per FDA validations. Shrink films, a PVC/PE staple, conform to irregular shapes like candy bars or poultry packs, contracting 40-50% upon heating to create airtight seals. A real-world case: During a 2023 supply chain crunch, a European grocer reported 25% less spoilage using PVC/PE over traditional wraps, slashing food waste.Pharmaceuticals demand even stricter standards, and PVC/PE delivers. Blister packs, where the film forms thermoformed cavities, ensure tamper-evidence and dosage accuracy. Imagine a diabetic checking insulin vials through the clear barrier—transparency aids quick identification, while the film's sterility (USP Class VI compliant) prevents contamination. Medical tubing and blood bags leverage its biocompatibility; PE's inertness minimizes leaching, vital for IV fluids. In a 2024 study by the International Journal of Pharmaceutics, PVC/PE pouches extended drug stability by 18 months under ambient conditions.Consumer goods packaging thrives on aesthetics. For electronics, anti-static PVC/PE films shield devices during shipping, their clarity showcasing sleek designs without fingerprints—static dissipation rates below 10^9 ohms (ASTM D257). Cosmetics benefit too: Lipstick tubes wrapped in this film gleam under store lights, with UV stabilizers blocking 98% of harmful rays to preserve formulas.Logistics amplifies these uses in stretch and pallet wraps. PE's cling (coefficient of friction 0.3-0.5) secures loads, while PVC adds puncture resistance. A vivid scene: Trucks rumbling across highways, their cargo stabilized by films that withstand 500 kg/m² pressure without tearing. Overall, in packaging, PVC/PE film isn't just a wrapper—it's a strategic ally, boosting efficiency and appeal

Packaging Powerhouse: Safeguarding Goods with PrecisionIn the bustling heart of commerce, transparent PVC/PE film reigns as the unsung hero of packaging. Its applications here are as diverse as the products it protects, from gourmet delicacies to high-tech gadgets.Food packaging is a prime arena. The film's oxygen barrier (OTR <50 cc/m²/day, ASTM D3985) and moisture lock preserve freshness, vividly illustrated in supermarket trays of marinated meats. Under LED lights, the transparent layer reveals vibrant colors, enticing shoppers while inhibiting bacterial growth—PVC's antimicrobial additives reduce colony counts by 99%, as per FDA validations. Shrink films, a PVC/PE staple, conform to irregular shapes like candy bars or poultry packs, contracting 40-50% upon heating to create airtight seals. A real-world case: During a 2023 supply chain crunch, a European grocer reported 25% less spoilage using PVC/PE over traditional wraps, slashing food waste.Pharmaceuticals demand even stricter standards, and PVC/PE delivers. Blister packs, where the film forms thermoformed cavities, ensure tamper-evidence and dosage accuracy. Imagine a diabetic checking insulin vials through the clear barrier—transparency aids quick identification, while the film's sterility (USP Class VI compliant) prevents contamination. Medical tubing and blood bags leverage its biocompatibility; PE's inertness minimizes leaching, vital for IV fluids. In a 2024 study by the International Journal of Pharmaceutics, PVC/PE pouches extended drug stability by 18 months under ambient conditions.Consumer goods packaging thrives on aesthetics. For electronics, anti-static PVC/PE films shield devices during shipping, their clarity showcasing sleek designs without fingerprints—static dissipation rates below 10^9 ohms (ASTM D257). Cosmetics benefit too: Lipstick tubes wrapped in this film gleam under store lights, with UV stabilizers blocking 98% of harmful rays to preserve formulas.Logistics amplifies these uses in stretch and pallet wraps. PE's cling (coefficient of friction 0.3-0.5) secures loads, while PVC adds puncture resistance. A vivid scene: Trucks rumbling across highways, their cargo stabilized by films that withstand 500 kg/m² pressure without tearing. Overall, in packaging, PVC/PE film isn't just a wrapper—it's a strategic ally, boosting efficiency and appeal  Agricultural Ally: Cultivating Growth Under Glass-Like SkiesVenturing into verdant fields, transparent PVC/PE film transforms agriculture into a controlled symphony of growth. Greenhouses clad in these films create microclimates, their high PAR (photosynthetically active radiation) transmission—up to 90%—mimicking natural sunlight. Farmers in arid regions, like California's Central Valley, rely on this for year-round tomato yields, with films diffusing light to prevent scorching while trapping warmth (thermal retention 70-80%).Mulch films take root literally, laid over soil to suppress weeds and retain moisture. PE's hydrophobicity reduces evaporation by 50%, per USDA trials, while PVC's durability withstands tractor treads. In a poignant example, Kenyan smallholders using PVC/PE mulches doubled strawberry harvests in 2022, their transparent layers allowing soil monitoring without disruption. Frost protection blankets, lightweight at 20-50 g/m², drape over orchards like ethereal shrouds, raising temperatures 5-10°C overnight.Livestock applications add warmth: Silage wraps encase fodder in oxygen-free cocoons, PVC/PE's gas barrier extending fermentation life by weeks. Dairy farmers report 15% less spoilage, their wrapped bales gleaming transparently for easy inventory. These uses underscore the film's role in sustainable farming—biodegradable additives now degrade 60% faster in soil, per EU regulations, harmonizing productivity with planetary care.

Agricultural Ally: Cultivating Growth Under Glass-Like SkiesVenturing into verdant fields, transparent PVC/PE film transforms agriculture into a controlled symphony of growth. Greenhouses clad in these films create microclimates, their high PAR (photosynthetically active radiation) transmission—up to 90%—mimicking natural sunlight. Farmers in arid regions, like California's Central Valley, rely on this for year-round tomato yields, with films diffusing light to prevent scorching while trapping warmth (thermal retention 70-80%).Mulch films take root literally, laid over soil to suppress weeds and retain moisture. PE's hydrophobicity reduces evaporation by 50%, per USDA trials, while PVC's durability withstands tractor treads. In a poignant example, Kenyan smallholders using PVC/PE mulches doubled strawberry harvests in 2022, their transparent layers allowing soil monitoring without disruption. Frost protection blankets, lightweight at 20-50 g/m², drape over orchards like ethereal shrouds, raising temperatures 5-10°C overnight.Livestock applications add warmth: Silage wraps encase fodder in oxygen-free cocoons, PVC/PE's gas barrier extending fermentation life by weeks. Dairy farmers report 15% less spoilage, their wrapped bales gleaming transparently for easy inventory. These uses underscore the film's role in sustainable farming—biodegradable additives now degrade 60% faster in soil, per EU regulations, harmonizing productivity with planetary care.  Industrial and Construction Innovator: Building and Protecting with FinesseIndustrially, transparent PVC/PE film erects barriers against chaos. In construction, it forms temporary enclosures on skyscraper sites, its weatherproofing (UV resistance >1,000 hours, ASTM G154) shielding workers from rain and dust. Clarity enables progress tracking—foremen spot issues through the film, reducing downtime by 20%, as seen in Singapore's urban boom projects.Electrical sectors harness its insulation: Cable wraps prevent shorts, with transparency aiding splicing. Automotive uses include protective covers for parts during assembly, PE's conformability hugging curves without creases.Creative realms flourish too. Lamination films for stationery—think glossy book covers—enhance durability, PVC/PE's heat-seal bonds (150-180°C) resisting wear. Stationery artists craft illuminated displays, the film's gloss (60-80 GU, ASTM D523) amplifying LED effects.Signage and banners leverage rigidity: Outdoor ads withstand winds up to 100 km/h, transparency overlaying graphics for depth. In a festive twist, holiday decorations shimmer with PVC/PE snow effects, their flame-retardant grades (UL 94 V-0) ensuring safety.

Industrial and Construction Innovator: Building and Protecting with FinesseIndustrially, transparent PVC/PE film erects barriers against chaos. In construction, it forms temporary enclosures on skyscraper sites, its weatherproofing (UV resistance >1,000 hours, ASTM G154) shielding workers from rain and dust. Clarity enables progress tracking—foremen spot issues through the film, reducing downtime by 20%, as seen in Singapore's urban boom projects.Electrical sectors harness its insulation: Cable wraps prevent shorts, with transparency aiding splicing. Automotive uses include protective covers for parts during assembly, PE's conformability hugging curves without creases.Creative realms flourish too. Lamination films for stationery—think glossy book covers—enhance durability, PVC/PE's heat-seal bonds (150-180°C) resisting wear. Stationery artists craft illuminated displays, the film's gloss (60-80 GU, ASTM D523) amplifying LED effects.Signage and banners leverage rigidity: Outdoor ads withstand winds up to 100 km/h, transparency overlaying graphics for depth. In a festive twist, holiday decorations shimmer with PVC/PE snow effects, their flame-retardant grades (UL 94 V-0) ensuring safety.  ConclusionTransparent PVC/PE film weaves through our world like an invisible thread, its properties—clarity, durability, barriers—fueling applications from pantry to pasture. As innovations like bio-based PE emerge, its legacy endures: versatile, vital, visionary. In a transparent future, this film promises even brighter horizons.

ConclusionTransparent PVC/PE film weaves through our world like an invisible thread, its properties—clarity, durability, barriers—fueling applications from pantry to pasture. As innovations like bio-based PE emerge, its legacy endures: versatile, vital, visionary. In a transparent future, this film promises even brighter horizons.

IntroductionImagine unwrapping a fresh loaf of bread from the supermarket, its crust visible through a shimmering layer that keeps it soft and protected, or peering into a greenhouse where delicate seedlings thrive under a veil of crystal-clear material that harnesses sunlight like a living prism. This is the magic of transparent PVC/PE film—a hybrid marvel in the world of plastics that blends the robustness of polyvinyl chloride (PVC) with the lightweight flexibility of polyethylene (PE). These films aren't just sheets of plastic; they're silent sentinels in our daily lives, safeguarding products, enhancing visibility, and enabling creativity across industries.At its core, transparent PVC/PE film refers to co-extruded or laminated structures where PVC provides superior clarity and barrier properties, while PE adds moisture resistance and ease of processing. Developed through advanced extrusion techniques, these films achieve a transparency rivaling glass—often exceeding 90% light transmission—without the fragility. Their story begins in the mid-20th century, when PVC's invention in the 1920s met PE's post-WWII boom, evolving into today's eco-conscious formulations that balance performance with sustainability. Backed by decades of material science, including studies from institutions like the American Society for Testing and Materials (ASTM), these films have proven indispensable. In this exploration, we'll dive into their captivating properties and vivid applications, revealing why they're a cornerstone of modern ingenuity.

IntroductionImagine unwrapping a fresh loaf of bread from the supermarket, its crust visible through a shimmering layer that keeps it soft and protected, or peering into a greenhouse where delicate seedlings thrive under a veil of crystal-clear material that harnesses sunlight like a living prism. This is the magic of transparent PVC/PE film—a hybrid marvel in the world of plastics that blends the robustness of polyvinyl chloride (PVC) with the lightweight flexibility of polyethylene (PE). These films aren't just sheets of plastic; they're silent sentinels in our daily lives, safeguarding products, enhancing visibility, and enabling creativity across industries.At its core, transparent PVC/PE film refers to co-extruded or laminated structures where PVC provides superior clarity and barrier properties, while PE adds moisture resistance and ease of processing. Developed through advanced extrusion techniques, these films achieve a transparency rivaling glass—often exceeding 90% light transmission—without the fragility. Their story begins in the mid-20th century, when PVC's invention in the 1920s met PE's post-WWII boom, evolving into today's eco-conscious formulations that balance performance with sustainability. Backed by decades of material science, including studies from institutions like the American Society for Testing and Materials (ASTM), these films have proven indispensable. In this exploration, we'll dive into their captivating properties and vivid applications, revealing why they're a cornerstone of modern ingenuity.  The Essence of Excellence: Key Properties of Transparent PVC/PE FilmWhat makes transparent PVC/PE film so extraordinary? It's a symphony of physical, chemical, and optical traits, each honed by molecular engineering to deliver reliability in demanding scenarios. Let's break it down, drawing from empirical data and real-world testing.First, optical clarity stands out as the film's crown jewel. With light transmittance rates often hitting 92-95% in the visible spectrum (400-700 nm), as measured by ASTM D1003 standards, these films allow undistorted views of contents. Unlike opaque alternatives, PVC/PE's amorphous structure minimizes light scattering, creating a "glass-like" effect. Picture a pharmaceutical blister pack where patients can inspect pill colors and engravings without opening it—essential for compliance and trust. This transparency isn't just aesthetic; it's functional, enabling barcode scanning through layers in logistics.Durability follows suit, with tensile strength averaging 20-50 MPa for PVC-dominant blends and elongation at break up to 400%, per ISO 527 testing. PE's contribution here is pivotal: its low-density variants (LDPE) infuse elasticity, preventing cracks under stress. In a vivid example, consider a construction site where wind gusts whip at protective sheeting; the film's tear resistance—often exceeding 100 N/mm—holds firm, averting costly replacements. Chemical resistance further bolsters this resilience. PVC/PE films repel acids, bases, oils, and solvents, with permeation rates for water vapor as low as 1-5 g/m²/day (ASTM E96). This barrier prowess stems from PVC's polar chains intertwining with PE's non-polar backbone, forming a hybrid shield against moisture and gases. For food packaging, this means extended shelf life: a study by the Journal of Food Science showed PVC/PE-wrapped cheeses retaining 30% more moisture than untreated samples over two weeks.Thermal stability rounds out the profile, with service temperatures from -20°C to +80°C without degradation. While not for extreme heat (PVC softens around 80°C), additives like stabilizers extend usability. Electrical insulation is another ace, with dielectric strength over 20 kV/mm, making it ideal for wire coatings. Environmentally, modern formulations incorporate phthalate-free plasticizers, reducing migration risks and enhancing recyclability—PE's compatibility with standard recycling streams cuts waste by up to 40%, according to European Plastics Recyclers reports.Flexibility is the film's chameleon-like trait, adjustable via plasticizer ratios. Soft variants drape like silk for shrink-wrapping, while rigid ones stand taut for displays. Cost-effectiveness seals the deal: at $1-3 per kg, PVC/PE undercuts glass or PET by 50%, per market analyses from Grand View Research. These properties aren't theoretical; they're battle-tested in labs and fields, ensuring the film doesn't just perform—it thrives.

The Essence of Excellence: Key Properties of Transparent PVC/PE FilmWhat makes transparent PVC/PE film so extraordinary? It's a symphony of physical, chemical, and optical traits, each honed by molecular engineering to deliver reliability in demanding scenarios. Let's break it down, drawing from empirical data and real-world testing.First, optical clarity stands out as the film's crown jewel. With light transmittance rates often hitting 92-95% in the visible spectrum (400-700 nm), as measured by ASTM D1003 standards, these films allow undistorted views of contents. Unlike opaque alternatives, PVC/PE's amorphous structure minimizes light scattering, creating a "glass-like" effect. Picture a pharmaceutical blister pack where patients can inspect pill colors and engravings without opening it—essential for compliance and trust. This transparency isn't just aesthetic; it's functional, enabling barcode scanning through layers in logistics.Durability follows suit, with tensile strength averaging 20-50 MPa for PVC-dominant blends and elongation at break up to 400%, per ISO 527 testing. PE's contribution here is pivotal: its low-density variants (LDPE) infuse elasticity, preventing cracks under stress. In a vivid example, consider a construction site where wind gusts whip at protective sheeting; the film's tear resistance—often exceeding 100 N/mm—holds firm, averting costly replacements. Chemical resistance further bolsters this resilience. PVC/PE films repel acids, bases, oils, and solvents, with permeation rates for water vapor as low as 1-5 g/m²/day (ASTM E96). This barrier prowess stems from PVC's polar chains intertwining with PE's non-polar backbone, forming a hybrid shield against moisture and gases. For food packaging, this means extended shelf life: a study by the Journal of Food Science showed PVC/PE-wrapped cheeses retaining 30% more moisture than untreated samples over two weeks.Thermal stability rounds out the profile, with service temperatures from -20°C to +80°C without degradation. While not for extreme heat (PVC softens around 80°C), additives like stabilizers extend usability. Electrical insulation is another ace, with dielectric strength over 20 kV/mm, making it ideal for wire coatings. Environmentally, modern formulations incorporate phthalate-free plasticizers, reducing migration risks and enhancing recyclability—PE's compatibility with standard recycling streams cuts waste by up to 40%, according to European Plastics Recyclers reports.Flexibility is the film's chameleon-like trait, adjustable via plasticizer ratios. Soft variants drape like silk for shrink-wrapping, while rigid ones stand taut for displays. Cost-effectiveness seals the deal: at $1-3 per kg, PVC/PE undercuts glass or PET by 50%, per market analyses from Grand View Research. These properties aren't theoretical; they're battle-tested in labs and fields, ensuring the film doesn't just perform—it thrives.  Packaging Powerhouse: Safeguarding Goods with PrecisionIn the bustling heart of commerce, transparent PVC/PE film reigns as the unsung hero of packaging. Its applications here are as diverse as the products it protects, from gourmet delicacies to high-tech gadgets.Food packaging is a prime arena. The film's oxygen barrier (OTR <50 cc/m²/day, ASTM D3985) and moisture lock preserve freshness, vividly illustrated in supermarket trays of marinated meats. Under LED lights, the transparent layer reveals vibrant colors, enticing shoppers while inhibiting bacterial growth—PVC's antimicrobial additives reduce colony counts by 99%, as per FDA validations. Shrink films, a PVC/PE staple, conform to irregular shapes like candy bars or poultry packs, contracting 40-50% upon heating to create airtight seals. A real-world case: During a 2023 supply chain crunch, a European grocer reported 25% less spoilage using PVC/PE over traditional wraps, slashing food waste.Pharmaceuticals demand even stricter standards, and PVC/PE delivers. Blister packs, where the film forms thermoformed cavities, ensure tamper-evidence and dosage accuracy. Imagine a diabetic checking insulin vials through the clear barrier—transparency aids quick identification, while the film's sterility (USP Class VI compliant) prevents contamination. Medical tubing and blood bags leverage its biocompatibility; PE's inertness minimizes leaching, vital for IV fluids. In a 2024 study by the International Journal of Pharmaceutics, PVC/PE pouches extended drug stability by 18 months under ambient conditions.Consumer goods packaging thrives on aesthetics. For electronics, anti-static PVC/PE films shield devices during shipping, their clarity showcasing sleek designs without fingerprints—static dissipation rates below 10^9 ohms (ASTM D257). Cosmetics benefit too: Lipstick tubes wrapped in this film gleam under store lights, with UV stabilizers blocking 98% of harmful rays to preserve formulas.Logistics amplifies these uses in stretch and pallet wraps. PE's cling (coefficient of friction 0.3-0.5) secures loads, while PVC adds puncture resistance. A vivid scene: Trucks rumbling across highways, their cargo stabilized by films that withstand 500 kg/m² pressure without tearing. Overall, in packaging, PVC/PE film isn't just a wrapper—it's a strategic ally, boosting efficiency and appeal

Packaging Powerhouse: Safeguarding Goods with PrecisionIn the bustling heart of commerce, transparent PVC/PE film reigns as the unsung hero of packaging. Its applications here are as diverse as the products it protects, from gourmet delicacies to high-tech gadgets.Food packaging is a prime arena. The film's oxygen barrier (OTR <50 cc/m²/day, ASTM D3985) and moisture lock preserve freshness, vividly illustrated in supermarket trays of marinated meats. Under LED lights, the transparent layer reveals vibrant colors, enticing shoppers while inhibiting bacterial growth—PVC's antimicrobial additives reduce colony counts by 99%, as per FDA validations. Shrink films, a PVC/PE staple, conform to irregular shapes like candy bars or poultry packs, contracting 40-50% upon heating to create airtight seals. A real-world case: During a 2023 supply chain crunch, a European grocer reported 25% less spoilage using PVC/PE over traditional wraps, slashing food waste.Pharmaceuticals demand even stricter standards, and PVC/PE delivers. Blister packs, where the film forms thermoformed cavities, ensure tamper-evidence and dosage accuracy. Imagine a diabetic checking insulin vials through the clear barrier—transparency aids quick identification, while the film's sterility (USP Class VI compliant) prevents contamination. Medical tubing and blood bags leverage its biocompatibility; PE's inertness minimizes leaching, vital for IV fluids. In a 2024 study by the International Journal of Pharmaceutics, PVC/PE pouches extended drug stability by 18 months under ambient conditions.Consumer goods packaging thrives on aesthetics. For electronics, anti-static PVC/PE films shield devices during shipping, their clarity showcasing sleek designs without fingerprints—static dissipation rates below 10^9 ohms (ASTM D257). Cosmetics benefit too: Lipstick tubes wrapped in this film gleam under store lights, with UV stabilizers blocking 98% of harmful rays to preserve formulas.Logistics amplifies these uses in stretch and pallet wraps. PE's cling (coefficient of friction 0.3-0.5) secures loads, while PVC adds puncture resistance. A vivid scene: Trucks rumbling across highways, their cargo stabilized by films that withstand 500 kg/m² pressure without tearing. Overall, in packaging, PVC/PE film isn't just a wrapper—it's a strategic ally, boosting efficiency and appeal  Agricultural Ally: Cultivating Growth Under Glass-Like SkiesVenturing into verdant fields, transparent PVC/PE film transforms agriculture into a controlled symphony of growth. Greenhouses clad in these films create microclimates, their high PAR (photosynthetically active radiation) transmission—up to 90%—mimicking natural sunlight. Farmers in arid regions, like California's Central Valley, rely on this for year-round tomato yields, with films diffusing light to prevent scorching while trapping warmth (thermal retention 70-80%).Mulch films take root literally, laid over soil to suppress weeds and retain moisture. PE's hydrophobicity reduces evaporation by 50%, per USDA trials, while PVC's durability withstands tractor treads. In a poignant example, Kenyan smallholders using PVC/PE mulches doubled strawberry harvests in 2022, their transparent layers allowing soil monitoring without disruption. Frost protection blankets, lightweight at 20-50 g/m², drape over orchards like ethereal shrouds, raising temperatures 5-10°C overnight.Livestock applications add warmth: Silage wraps encase fodder in oxygen-free cocoons, PVC/PE's gas barrier extending fermentation life by weeks. Dairy farmers report 15% less spoilage, their wrapped bales gleaming transparently for easy inventory. These uses underscore the film's role in sustainable farming—biodegradable additives now degrade 60% faster in soil, per EU regulations, harmonizing productivity with planetary care.

Agricultural Ally: Cultivating Growth Under Glass-Like SkiesVenturing into verdant fields, transparent PVC/PE film transforms agriculture into a controlled symphony of growth. Greenhouses clad in these films create microclimates, their high PAR (photosynthetically active radiation) transmission—up to 90%—mimicking natural sunlight. Farmers in arid regions, like California's Central Valley, rely on this for year-round tomato yields, with films diffusing light to prevent scorching while trapping warmth (thermal retention 70-80%).Mulch films take root literally, laid over soil to suppress weeds and retain moisture. PE's hydrophobicity reduces evaporation by 50%, per USDA trials, while PVC's durability withstands tractor treads. In a poignant example, Kenyan smallholders using PVC/PE mulches doubled strawberry harvests in 2022, their transparent layers allowing soil monitoring without disruption. Frost protection blankets, lightweight at 20-50 g/m², drape over orchards like ethereal shrouds, raising temperatures 5-10°C overnight.Livestock applications add warmth: Silage wraps encase fodder in oxygen-free cocoons, PVC/PE's gas barrier extending fermentation life by weeks. Dairy farmers report 15% less spoilage, their wrapped bales gleaming transparently for easy inventory. These uses underscore the film's role in sustainable farming—biodegradable additives now degrade 60% faster in soil, per EU regulations, harmonizing productivity with planetary care.  Industrial and Construction Innovator: Building and Protecting with FinesseIndustrially, transparent PVC/PE film erects barriers against chaos. In construction, it forms temporary enclosures on skyscraper sites, its weatherproofing (UV resistance >1,000 hours, ASTM G154) shielding workers from rain and dust. Clarity enables progress tracking—foremen spot issues through the film, reducing downtime by 20%, as seen in Singapore's urban boom projects.Electrical sectors harness its insulation: Cable wraps prevent shorts, with transparency aiding splicing. Automotive uses include protective covers for parts during assembly, PE's conformability hugging curves without creases.Creative realms flourish too. Lamination films for stationery—think glossy book covers—enhance durability, PVC/PE's heat-seal bonds (150-180°C) resisting wear. Stationery artists craft illuminated displays, the film's gloss (60-80 GU, ASTM D523) amplifying LED effects.Signage and banners leverage rigidity: Outdoor ads withstand winds up to 100 km/h, transparency overlaying graphics for depth. In a festive twist, holiday decorations shimmer with PVC/PE snow effects, their flame-retardant grades (UL 94 V-0) ensuring safety.

Industrial and Construction Innovator: Building and Protecting with FinesseIndustrially, transparent PVC/PE film erects barriers against chaos. In construction, it forms temporary enclosures on skyscraper sites, its weatherproofing (UV resistance >1,000 hours, ASTM G154) shielding workers from rain and dust. Clarity enables progress tracking—foremen spot issues through the film, reducing downtime by 20%, as seen in Singapore's urban boom projects.Electrical sectors harness its insulation: Cable wraps prevent shorts, with transparency aiding splicing. Automotive uses include protective covers for parts during assembly, PE's conformability hugging curves without creases.Creative realms flourish too. Lamination films for stationery—think glossy book covers—enhance durability, PVC/PE's heat-seal bonds (150-180°C) resisting wear. Stationery artists craft illuminated displays, the film's gloss (60-80 GU, ASTM D523) amplifying LED effects.Signage and banners leverage rigidity: Outdoor ads withstand winds up to 100 km/h, transparency overlaying graphics for depth. In a festive twist, holiday decorations shimmer with PVC/PE snow effects, their flame-retardant grades (UL 94 V-0) ensuring safety.  ConclusionTransparent PVC/PE film weaves through our world like an invisible thread, its properties—clarity, durability, barriers—fueling applications from pantry to pasture. As innovations like bio-based PE emerge, its legacy endures: versatile, vital, visionary. In a transparent future, this film promises even brighter horizons.

ConclusionTransparent PVC/PE film weaves through our world like an invisible thread, its properties—clarity, durability, barriers—fueling applications from pantry to pasture. As innovations like bio-based PE emerge, its legacy endures: versatile, vital, visionary. In a transparent future, this film promises even brighter horizons.

Get the latest price? We'll respond as soon as possible(within 12 hours)