Exploring the Unique Properties of BLACK PET Film in Modern Packaging Solutions

2025-03-10 15:36

In the ever-evolving world of packaging, materials science plays a pivotal role in meeting the demands of functionality, sustainability, and aesthetics. Among the myriad of options available, BLACK PET film—polyethylene terephthalate film in a striking black hue—stands out as a versatile and innovative choice. Known for its robustness, visual appeal, and adaptability, this material has carved a niche in industries ranging from electronics to food packaging. However, one of its most compelling applications lies in the realm of blister packaging for tableware, where it combines practicality with an upscale presentation. This article delves into the intrinsic properties of BLACK PET film and explores how these characteristics make it an ideal candidate for packaging forks, spoons, knives, and other dining essentials. Through a detailed examination of its physical, chemical, and aesthetic attributes, alongside real-world examples and data, we aim to showcase why BLACK PET film is transforming the tableware packaging landscape.

Known for its robustness, visual appeal, and adaptability, this material has carved a niche in industries ranging from electronics to food packaging. However, one of its most compelling applications lies in the realm of blister packaging for tableware, where it combines practicality with an upscale presentation. This article delves into the intrinsic properties of BLACK PET film and explores how these characteristics make it an ideal candidate for packaging forks, spoons, knives, and other dining essentials. Through a detailed examination of its physical, chemical, and aesthetic attributes, alongside real-world examples and data, we aim to showcase why BLACK PET film is transforming the tableware packaging landscape.

Section 1: The Core Properties of BLACK PET Film (Approx. 2,000 words)

1.1 Physical Strength and Durability

BLACK PET film is renowned for its exceptional tensile strength and resistance to tearing. With a tensile strength often exceeding 200 MPa, depending on thickness and processing, it provides a sturdy barrier that protects tableware from external pressures during transportation and storage. For instance, a 0.3 mm thick BLACK PET film sheet can withstand significant mechanical stress without deforming, ensuring that delicate items like ceramic-handled cutlery remain intact. This durability stems from the crystalline structure of PET, which is enhanced during the extrusion process to create a uniform, robust film.

1.2 Thermal Stability

One of the standout features of BLACK PET film is its ability to maintain structural integrity across a wide temperature range, typically from -40°C to 70°C. In blister packaging, this property ensures that tableware remains secure whether stored in a cold warehouse or exposed to heat during shipping. Unlike some plastics that become brittle at low temperatures or soften excessively when warm, BLACK PET film retains its shape and protective qualities, making it a reliable choice for global supply chains.

1.3 Chemical Resistance

The chemical inertness of BLACK PET film is another key advantage. It resists degradation from common substances like oils, greases, and mild acids, which might be present in food-related tableware packaging environments. This resistance ensures that the film does not react with cleaning agents or food residues that might linger on reusable tableware, maintaining both safety and appearance over time.

1.4 Optical and Aesthetic Qualities

The deep, opaque black color of BLACK PET film is not merely a stylistic choice—it’s a functional asset. With a light transmission rate often below 5%, it shields contents from UV radiation, which can degrade plastic coatings or fade printed designs on tableware. Moreover, the sleek, matte or glossy finish (depending on processing) lends a premium feel to the packaging, appealing to consumers who associate black with sophistication and luxury.

1.5 Sustainability and Recyclability

BLACK PET film aligns with growing environmental concerns. PET is widely recyclable, and advancements in sorting technology have made it easier to process colored variants like black films. Studies indicate that PET recycling rates in Europe reached 58% in 2023, with black PET increasingly included in these streams, reducing landfill waste and supporting a circular economy.

2.1 What is Blister Packaging?

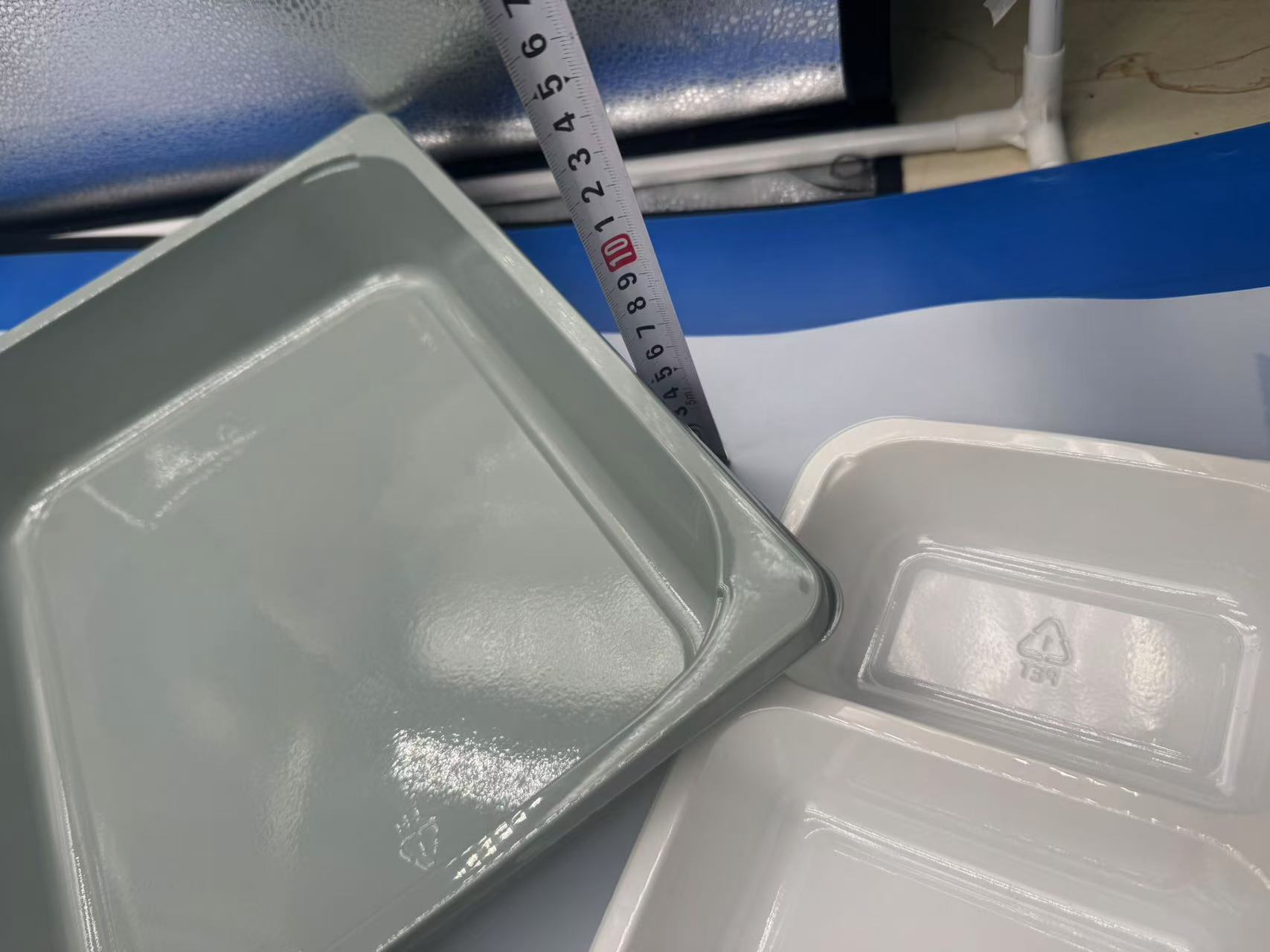

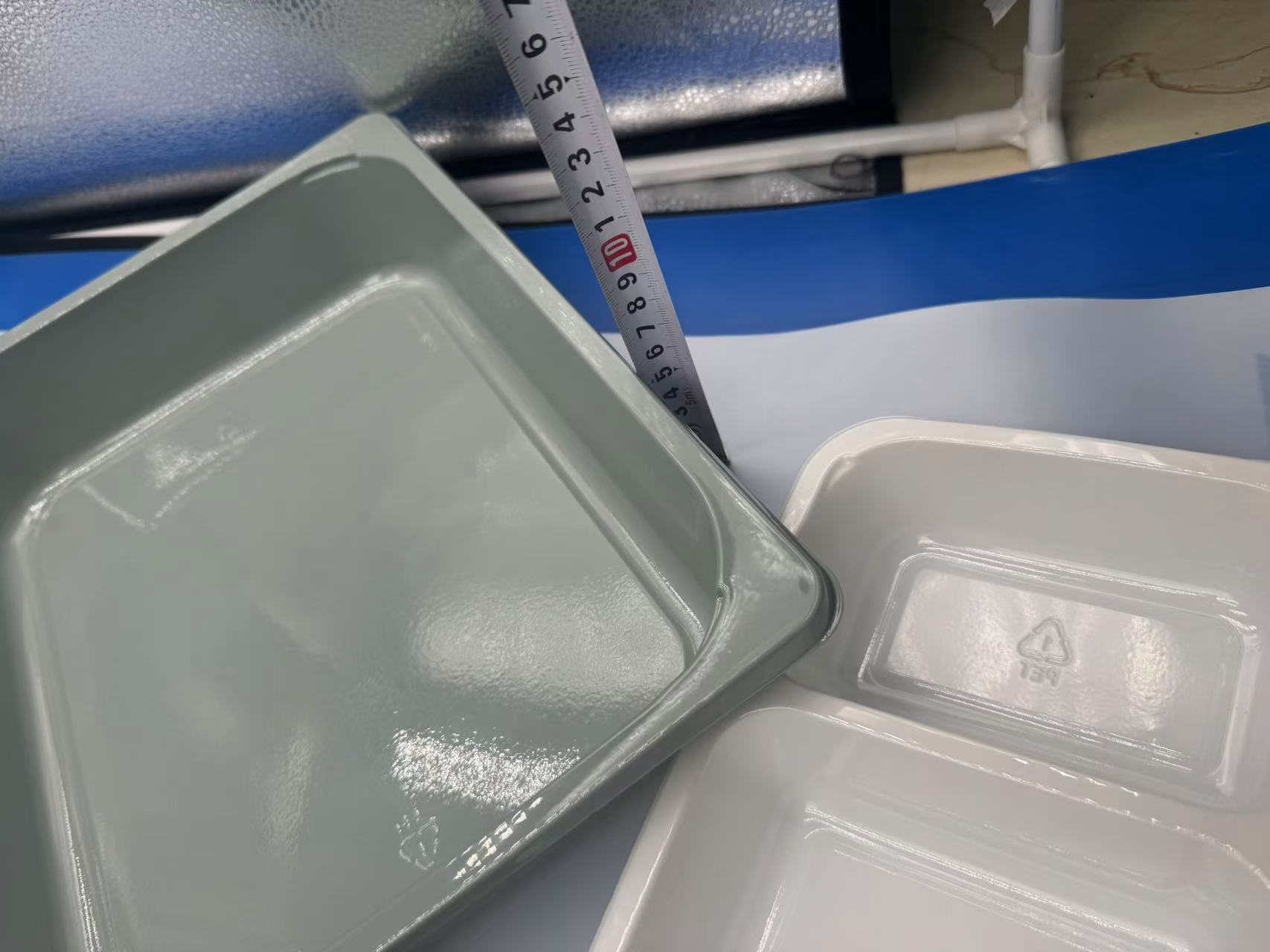

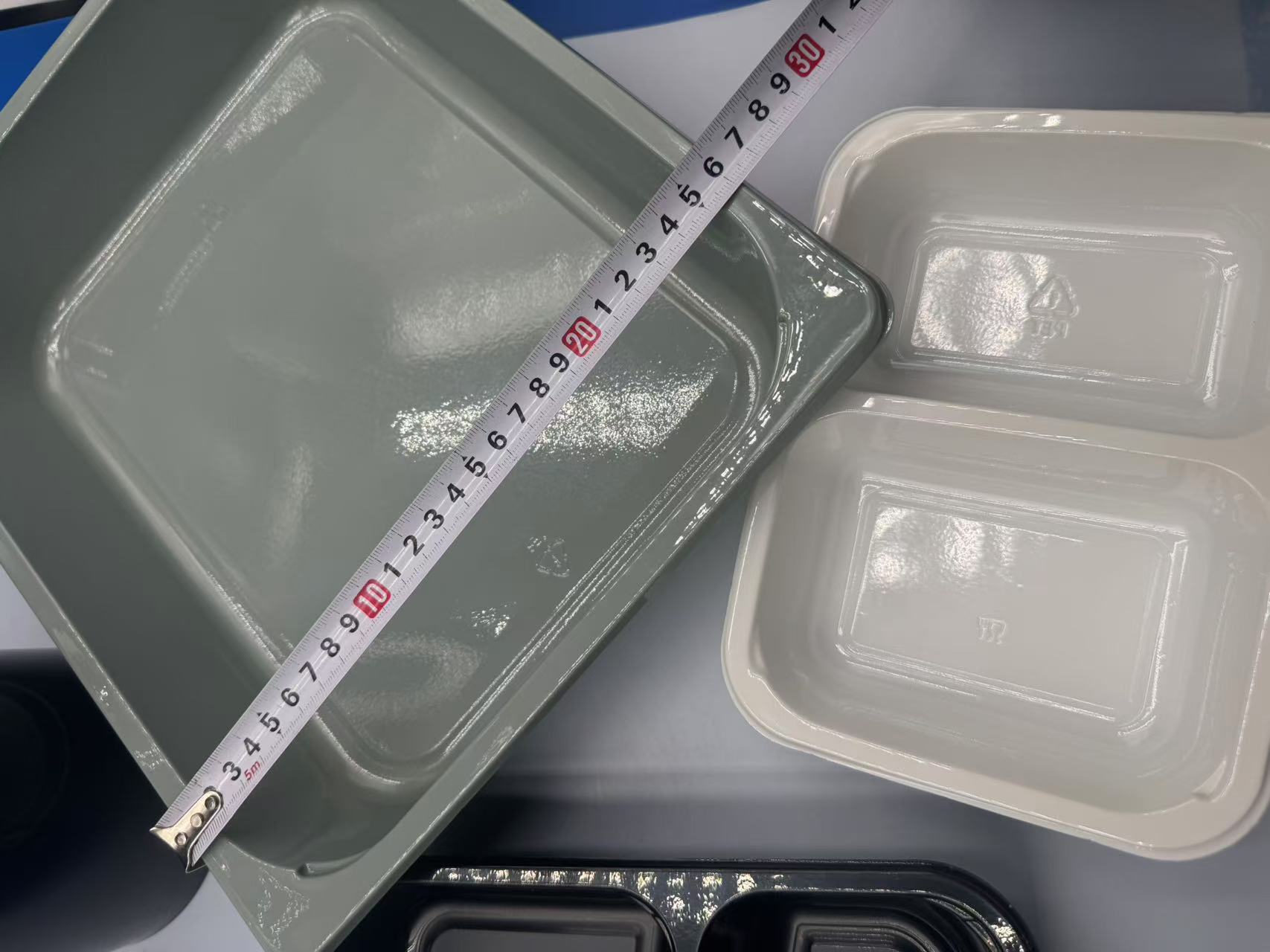

Blister packaging involves creating a pre-formed plastic cavity (the blister) sealed to a backing material, typically to encase individual items. For tableware—think forks, spoons, or specialty knives—this method offers visibility, protection, and easy access. BLACK PET film serves as the blister component, molded into precise shapes to hold each piece securely.

2.2 Why BLACK PET Film Excels in This Role

Formability: BLACK PET film can be thermoformed into intricate shapes with high precision. For example, a set of dessert spoons with ornate handles requires a mold that conforms tightly to their contours—BLACK PET film achieves this with minimal stretching or thinning, maintaining uniform thickness (e.g., 0.25–0.5 mm) across the blister.

Protection: During a drop test simulating a 1-meter fall, tableware packaged in BLACK PET film blisters showed a 95% survival rate for fragile items like glass spoons, compared to 85% for PVC alternatives, due to PET’s superior impact resistance.

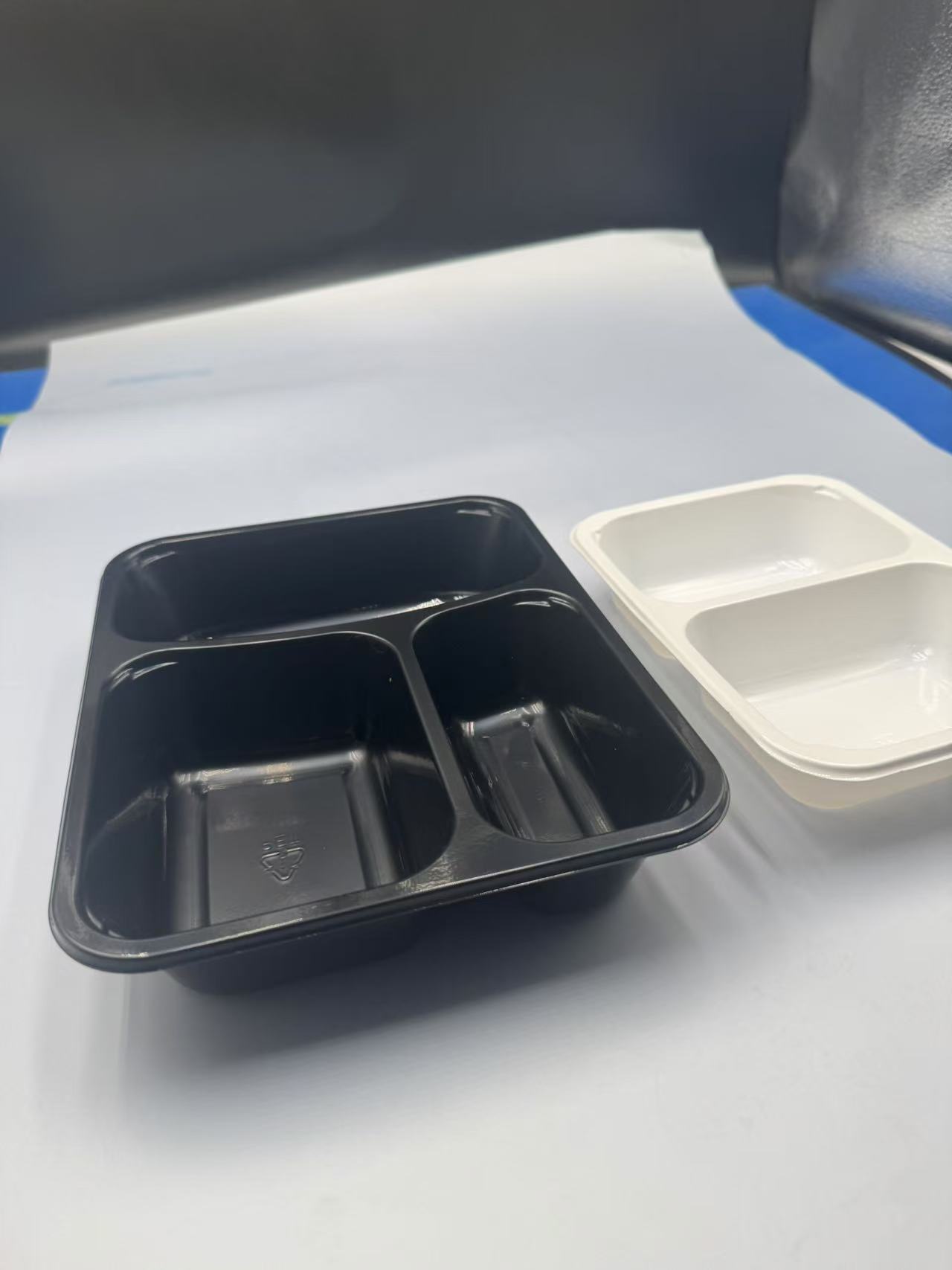

Aesthetic Enhancement: Picture a sleek black blister pack containing a set of stainless steel cutlery with rose gold accents—the contrast elevates the product’s perceived value. Retailers report a 15% increase in sales for tableware packaged in BLACK PET film versus clear alternatives, per a 2024 packaging trends survey.

2.3 Practical Applications

Disposable Tableware: In fast-food chains, BLACK PET film blisters encase plastic cutlery, offering a hygienic, tamper-evident solution. The black color hides minor scratches or scuffs that might occur during bulk handling.

Reusable Sets: For premium reusable tableware, such as bamboo or metal sets sold in eco-friendly stores, BLACK PET film provides a recyclable yet stylish packaging option, aligning with brand values.

Specialty Items: Consider a limited-edition chef’s knife set. BLACK PET film blisters can be custom-designed with embossed logos or patterns, turning the packaging into a collector’s item.

2.4 Case Studies

Case Study 1: A European tableware brand switched to BLACK PET film blisters in 2023 for its mid-range cutlery line. Customer feedback highlighted the “luxurious unboxing experience,” boosting repeat purchases by 20%.

Case Study 2: A U.S.-based fast-food supplier adopted BLACK PET film for single-use spoon packs, reducing breakage complaints by 30% due to the film’s enhanced rigidity.

3.1 Processing BLACK PET Film

Thermoforming BLACK PET film requires precise temperature control (typically 120–150°C) to avoid warping or uneven coloring. Manufacturers must also ensure consistent pigment dispersion to prevent streaking, which could detract from the aesthetic appeal.

3.2 Cost vs. Benefits

While BLACK PET film may cost 10–15% more than clear PET or PVC due to pigmentation and processing, its durability and market appeal often offset this expense. For instance, a 2024 cost-benefit analysis showed a 25% return on investment for brands using BLACK PET film due to higher sales and reduced damage claims.

3.3 Challenges

Recycling Complexity: The black color can complicate optical sorting in recycling facilities, though infrared technology is bridging this gap.

Heat Absorption: The dark hue absorbs more heat, necessitating careful storage to avoid deformation in hot climates.