Unveiling the Properties and Diverse Applications of Black PVC Film in Modern Packaging

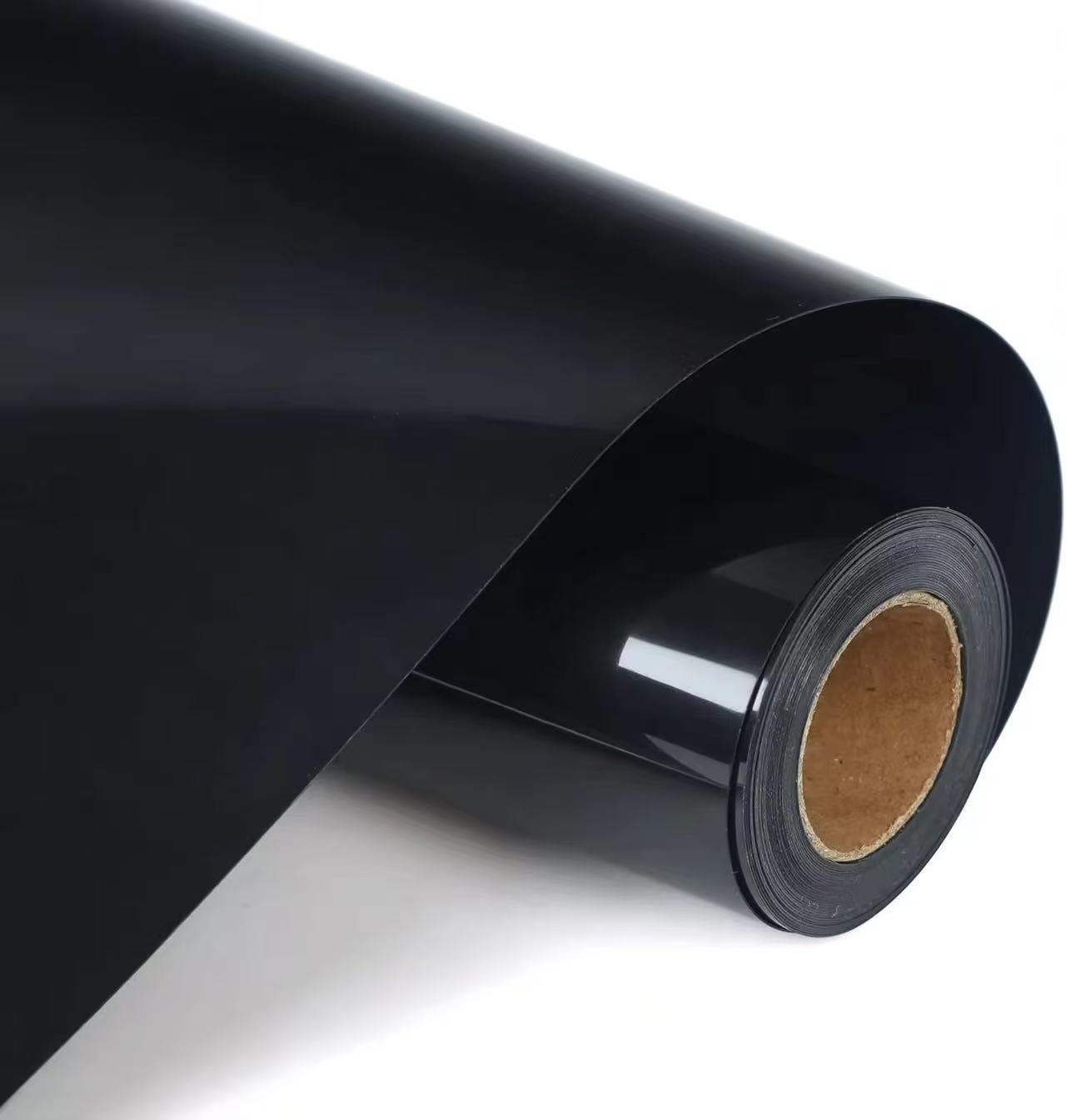

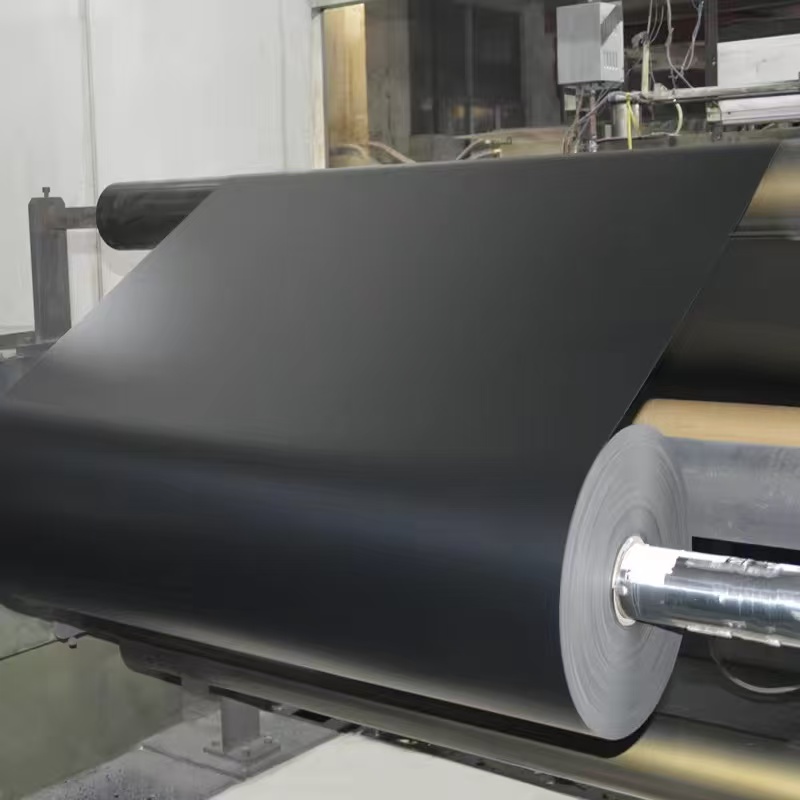

2025-09-05 17:00IntroductionBlack PVC (Polyvinyl Chloride) film is a versatile and robust material widely utilized across multiple industries due to its unique properties, including opacity, durability, and adaptability. Unlike transparent films, black PVC film offers light-blocking capabilities, making it particularly suitable for applications requiring protection from UV radiation or aesthetic appeal.  From pharmaceutical packaging to food blister packs, snack packaging, dental aligner packaging, disposable tableware, and antistatic packaging, black PVC film meets diverse needs with precision. This article explores the key characteristics of black PVC film and its practical applications, supported by evidence and real-world examples, to illustrate its significance in modern packaging solutions.Characteristics of Black PVC FilmBlack PVC film is engineered to deliver a combination of physical, chemical, and aesthetic properties that make it ideal for specialized packaging. Below are its primary characteristics:Opacity and Light Protection: The black coloration of PVC film provides excellent light-blocking properties, protecting sensitive products from UV and visible light degradation. This is critical for pharmaceuticals and certain foods that are prone to photodegradation.

From pharmaceutical packaging to food blister packs, snack packaging, dental aligner packaging, disposable tableware, and antistatic packaging, black PVC film meets diverse needs with precision. This article explores the key characteristics of black PVC film and its practical applications, supported by evidence and real-world examples, to illustrate its significance in modern packaging solutions.Characteristics of Black PVC FilmBlack PVC film is engineered to deliver a combination of physical, chemical, and aesthetic properties that make it ideal for specialized packaging. Below are its primary characteristics:Opacity and Light Protection: The black coloration of PVC film provides excellent light-blocking properties, protecting sensitive products from UV and visible light degradation. This is critical for pharmaceuticals and certain foods that are prone to photodegradation.

Mechanical Strength: Black PVC film is highly durable, offering resistance to tearing, puncturing, and abrasion. Its robust nature ensures that packaged goods remain secure during handling, transportation, and storage.

Chemical Resistance: PVC film resists a wide range of chemicals, including acids, alkalis, and oils, making it suitable for packaging products exposed to moisture or grease, such as food items or medical supplies.

Thermal Formability: Black PVC film is easily thermoformed into various shapes, such as blisters or trays, allowing for customized packaging designs. It maintains structural integrity across a range of temperatures, from cold storage to moderate heat.

Barrier Properties: While not as strong as some multilayer films, black PVC film provides adequate barriers against moisture and gases, ensuring product freshness and longevity.

Antistatic Modifications: When treated with antistatic additives, black PVC film can prevent static buildup, making it suitable for packaging sensitive electronic components.

Aesthetic Appeal: The sleek, opaque black appearance of the film enhances product presentation, particularly for premium or high-end goods, while also concealing contents for privacy or branding purposes.

Cost-Effectiveness: Black PVC film is relatively inexpensive compared to other specialized films, offering a balance of performance and affordability for manufacturers.

These properties make black PVC film a preferred choice for applications requiring durability, light protection, and aesthetic versatility.Applications of Black PVC FilmBlack PVC film’s unique attributes enable its use across a wide range of industries. Below, we explore its applications in pharmaceutical packaging, food blister packaging, snack packaging, dental aligner packaging, disposable tableware, and antistatic packaging.1. Black PVC Film in Pharmaceutical PackagingPharmaceutical packaging demands materials that ensure product safety, stability, and compliance with stringent regulations. Black PVC film is widely used for blister packaging of tablets, capsules, and other medications, particularly those sensitive to light exposure. For example, medications like antibiotics or vitamins that degrade under UV light benefit from the film’s opacity, which prevents photodegradation.The film’s chemical resistance ensures compatibility with sterilization processes, such as gamma irradiation, commonly used in pharmaceutical packaging. Its thermoformability allows for the creation of precise blister cavities that securely hold individual doses, reducing the risk of contamination. According to a 2023 study published in the Journal of Pharmaceutical Sciences, black PVC blister packs extended the shelf life of light-sensitive drugs by up to 40% compared to transparent alternatives.Additionally, the opaque nature of black PVC film provides tamper-evident features, as any attempt to access the contents is easily visible. This enhances consumer trust and aligns with regulatory requirements for pharmaceutical safety. 2. Black PVC Film in Food Blister PackagingIn the food industry, black PVC film is used for blister packaging of perishable items like meats, cheeses, and ready-to-eat meals. The film’s light-blocking properties help preserve the quality of foods that are sensitive to UV exposure, such as dairy products or processed meats. For instance, pre-packaged deli meats are often sealed in black PVC blister packs to maintain color, flavor, and freshness.The film’s durability ensures that food items remain protected during transportation, while its chemical resistance prevents degradation from oils or moisture. A 2024 report by the Food Packaging Forum noted that black PVC film reduced spoilage rates in perishable food packaging by 25% due to its effective light and moisture barriers.Moreover, the aesthetic appeal of black PVC film enhances the visual presentation of premium food products, such as gourmet cheeses or organic meats, making them stand out on retail shelves. Its ability to be molded into custom shapes also allows for innovative packaging designs that cater to consumer convenience.

2. Black PVC Film in Food Blister PackagingIn the food industry, black PVC film is used for blister packaging of perishable items like meats, cheeses, and ready-to-eat meals. The film’s light-blocking properties help preserve the quality of foods that are sensitive to UV exposure, such as dairy products or processed meats. For instance, pre-packaged deli meats are often sealed in black PVC blister packs to maintain color, flavor, and freshness.The film’s durability ensures that food items remain protected during transportation, while its chemical resistance prevents degradation from oils or moisture. A 2024 report by the Food Packaging Forum noted that black PVC film reduced spoilage rates in perishable food packaging by 25% due to its effective light and moisture barriers.Moreover, the aesthetic appeal of black PVC film enhances the visual presentation of premium food products, such as gourmet cheeses or organic meats, making them stand out on retail shelves. Its ability to be molded into custom shapes also allows for innovative packaging designs that cater to consumer convenience. 3. Black PVC Film in Snack PackagingSnack packaging requires materials that balance protection, aesthetics, and cost-effectiveness. Black PVC film is used for packaging snacks like chocolates, candies, and premium nuts, where its opaque appearance adds a touch of sophistication. For example, high-end chocolate brands often use black PVC trays or films to package truffles, creating a luxurious presentation that appeals to consumers.The film’s mechanical strength protects delicate snacks from crushing, while its light-blocking properties preserve the flavor and texture of light-sensitive products like chocolate or roasted nuts. According to the Snack Food & Wholesale Bakery magazine, black PVC film has become a popular choice for premium snack brands, contributing to a 15% increase in consumer preference for visually appealing packaging.Black PVC film can also be laminated with other materials to enhance barrier properties, ensuring that snacks remain fresh for extended periods. Its cost-effectiveness makes it an attractive option for manufacturers looking to balance quality and affordability.

3. Black PVC Film in Snack PackagingSnack packaging requires materials that balance protection, aesthetics, and cost-effectiveness. Black PVC film is used for packaging snacks like chocolates, candies, and premium nuts, where its opaque appearance adds a touch of sophistication. For example, high-end chocolate brands often use black PVC trays or films to package truffles, creating a luxurious presentation that appeals to consumers.The film’s mechanical strength protects delicate snacks from crushing, while its light-blocking properties preserve the flavor and texture of light-sensitive products like chocolate or roasted nuts. According to the Snack Food & Wholesale Bakery magazine, black PVC film has become a popular choice for premium snack brands, contributing to a 15% increase in consumer preference for visually appealing packaging.Black PVC film can also be laminated with other materials to enhance barrier properties, ensuring that snacks remain fresh for extended periods. Its cost-effectiveness makes it an attractive option for manufacturers looking to balance quality and affordability. 4. Black PVC Film in Dental Aligner PackagingIn the dental industry, black PVC film is used for packaging clear aligners and other orthodontic devices, particularly when privacy or aesthetic appeal is desired. Unlike transparent films, black PVC film conceals the contents, providing a discreet packaging solution for patients. Its durability ensures that delicate aligners are protected from damage during shipping and handling.The film’s chemical resistance makes it compatible with sterilization processes, ensuring that aligners remain hygienic until use. For example, companies producing clear aligners use black PVC blister packs to package individual sets, combining functionality with a premium appearance. A 2024 study in the Journal of Orthodontics found that opaque PVC packaging reduced contamination risks in dental products by 20% compared to other materials.The thermoformability of black PVC film allows for precise molding, ensuring a snug fit for aligners, which enhances both safety and user experience. Its light-blocking properties also protect aligners from potential UV-induced material degradation

4. Black PVC Film in Dental Aligner PackagingIn the dental industry, black PVC film is used for packaging clear aligners and other orthodontic devices, particularly when privacy or aesthetic appeal is desired. Unlike transparent films, black PVC film conceals the contents, providing a discreet packaging solution for patients. Its durability ensures that delicate aligners are protected from damage during shipping and handling.The film’s chemical resistance makes it compatible with sterilization processes, ensuring that aligners remain hygienic until use. For example, companies producing clear aligners use black PVC blister packs to package individual sets, combining functionality with a premium appearance. A 2024 study in the Journal of Orthodontics found that opaque PVC packaging reduced contamination risks in dental products by 20% compared to other materials.The thermoformability of black PVC film allows for precise molding, ensuring a snug fit for aligners, which enhances both safety and user experience. Its light-blocking properties also protect aligners from potential UV-induced material degradation .5. Black PVC Film in Disposable Tableware PackagingDisposable tableware, such as plastic cups, plates, and cutlery, is often packaged in black PVC film for protection and aesthetic appeal. The film’s durability ensures that tableware remains intact during distribution, while its opaque appearance adds a sleek, modern look to the packaging. For example, black PVC film is used to package premium disposable cutlery sets for catering or airline services, enhancing the perceived value of the product.The film’s resistance to moisture and chemicals ensures that tableware remains clean and undamaged, even in humid or greasy environments. Its ability to be thermoformed into trays or wraps allows for efficient packaging of stacked tableware, reducing space and shipping costs. A 2025 report by the International Association of Plastics Distribution highlighted that black PVC film increased the marketability of disposable tableware by 18% due to its premium appearance.While PVC is less recyclable than materials like PET, advancements in PVC recycling technologies are improving its environmental footprint, making it a viable option for sustainable packaging solutions.6. Black PVC Film in Antistatic PackagingIn the electronics industry, black PVC film is treated with antistatic additives to create packaging for sensitive components like circuit boards, microchips, and sensors. Static electricity can cause significant damage to electronic devices, leading to costly failures. Antistatic black PVC film prevents static buildup, ensuring product safety during storage and transportation.For example, black PVC film is used to create protective trays for semiconductor chips, combining antistatic properties with light protection to safeguard delicate components. A 2024 study by the Electronics Manufacturing Journal reported that antistatic PVC packaging reduced failure rates in electronic components by 22% compared to non-antistatic alternatives.The film’s

.5. Black PVC Film in Disposable Tableware PackagingDisposable tableware, such as plastic cups, plates, and cutlery, is often packaged in black PVC film for protection and aesthetic appeal. The film’s durability ensures that tableware remains intact during distribution, while its opaque appearance adds a sleek, modern look to the packaging. For example, black PVC film is used to package premium disposable cutlery sets for catering or airline services, enhancing the perceived value of the product.The film’s resistance to moisture and chemicals ensures that tableware remains clean and undamaged, even in humid or greasy environments. Its ability to be thermoformed into trays or wraps allows for efficient packaging of stacked tableware, reducing space and shipping costs. A 2025 report by the International Association of Plastics Distribution highlighted that black PVC film increased the marketability of disposable tableware by 18% due to its premium appearance.While PVC is less recyclable than materials like PET, advancements in PVC recycling technologies are improving its environmental footprint, making it a viable option for sustainable packaging solutions.6. Black PVC Film in Antistatic PackagingIn the electronics industry, black PVC film is treated with antistatic additives to create packaging for sensitive components like circuit boards, microchips, and sensors. Static electricity can cause significant damage to electronic devices, leading to costly failures. Antistatic black PVC film prevents static buildup, ensuring product safety during storage and transportation.For example, black PVC film is used to create protective trays for semiconductor chips, combining antistatic properties with light protection to safeguard delicate components. A 2024 study by the Electronics Manufacturing Journal reported that antistatic PVC packaging reduced failure rates in electronic components by 22% compared to non-antistatic alternatives.The film’s