Unveiling the Versatility of BOPP Film: Properties and Applications Across Industries

2025-08-20 17:33

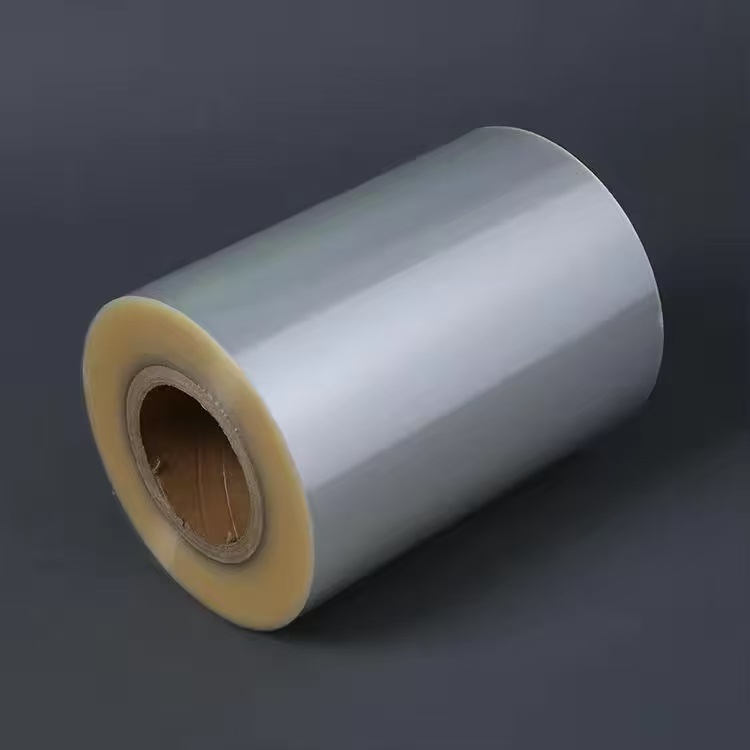

BOPP composite film The Characteristics and Applications of Transparent BOPP FilmBiaxially Oriented Polypropylene (BOPP) film is a cornerstone of modern material science, renowned for its exceptional clarity, strength, and adaptability. This transparent, lightweight, and durable plastic film, derived from polypropylene resin stretched in both machine and transverse directions, has become indispensable across industries such as packaging, labeling, printing, and apparel. Its unique properties—ranging from high tensile strength to excellent printability—make it a go-to material for applications requiring both functionality and aesthetic appeal. This article delves into the characteristics of BOPP transparent film and explores its diverse applications, supported by industry insights and practical examples.Characteristics of Transparent BOPP FilmClarity and Aesthetic Appeal

Transparent BOPP film is celebrated for its crystal-clear appearance, offering a glass-like finish that enhances product visibility. Its high gloss and low haze (typically less than 2%) make it ideal for showcasing contents in packaging or creating vibrant labels. For instance, in food packaging, the film’s transparency allows consumers to see the product inside, fostering trust and boosting visual appeal.

Mechanical Strength and Durability

The biaxial orientation process imparts remarkable tensile strength and toughness to BOPP film. With a tensile strength often exceeding 100 MPa, it resists punctures, tears, and abrasions, ensuring product protection during handling and transportation. This durability is critical in applications like composite packaging, where the film must withstand mechanical stress without compromising integrity.

Barrier Properties

While standard BOPP transparent film offers moderate moisture barrier properties, its oxygen and gas barrier capabilities can be enhanced through coatings or lamination. For example, metallized or PVDC-coated BOPP films are used in snack packaging to extend shelf life by preventing moisture ingress and oxidation. The film’s ability to be tailored for specific barrier needs makes it versatile for food and pharmaceutical applications.

Printability and Surface Versatility

BOPP film’s smooth surface is highly receptive to printing techniques such as flexography, gravure, and digital printing. Its ability to hold vibrant, high-resolution graphics without smudging or fading is a key reason for its dominance in label manufacturing. Additionally, the film can be treated to enhance adhesion for inks, adhesives, or coatings, making it customizable for diverse applications.

Chemical and Thermal Stability

Resistant to oils, greases, and most chemicals, BOPP transparent film maintains its integrity in harsh environments. It also performs well across a wide temperature range, typically from -20°C to 80°C, making it suitable for both refrigerated and ambient storage conditions. This stability is vital for applications like frozen food packaging or labels exposed to varying climates.

Lightweight and Cost-Effectiveness

BOPP film is lightweight, reducing transportation costs and environmental impact compared to alternatives like glass or rigid plastics. Its cost-effectiveness, coupled with high yield (due to its low density of approximately 0.91 g/cm³), makes it an economical choice for large-scale production in industries like packaging and apparel.

Recyclability and Sustainability

As a thermoplastic, BOPP film is recyclable, aligning with growing demands for sustainable materials. Advances in recycling technologies have enabled the reuse of BOPP in applications like injection molding or film reprocessing, reducing waste. Some manufacturers also produce bio-based BOPP films, further enhancing its eco