Exploring the Unique Properties and Applications of BOPS Film in Disposable Cutlery Blister Packaging

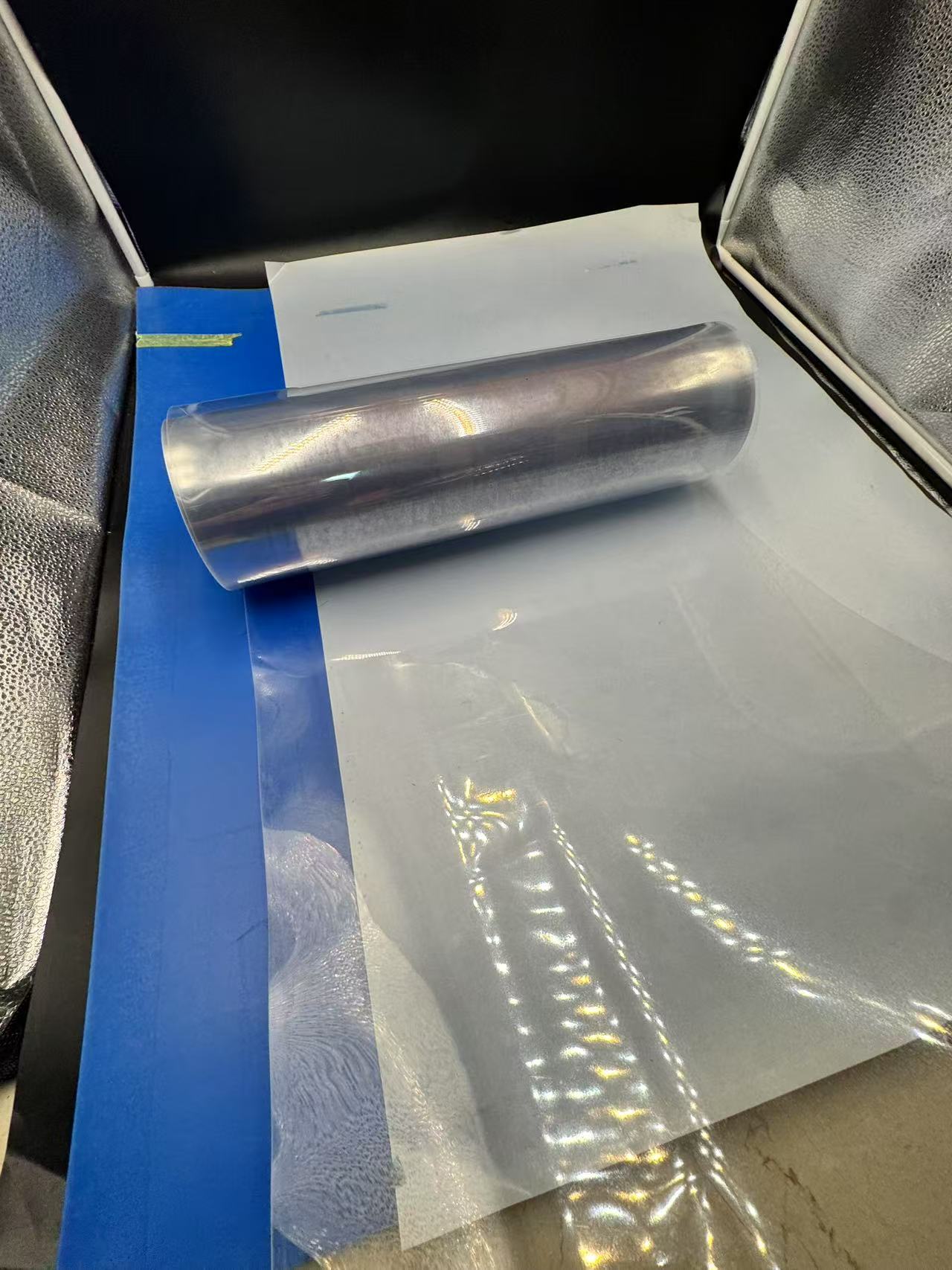

2025-04-15 16:30In the fast-evolving world of packaging, where functionality meets environmental responsibility, BOPS film (Biaxially Oriented Polystyrene film) has emerged as a standout material. Known for its remarkable clarity, strength, and versatility, BOPS film is reshaping how industries approach packaging solutions, particularly for disposable cutlery blister packaging. From supermarkets to fast-food chains, blister packs made from BOPS film securely encase forks, spoons, and knives, ensuring hygiene, visibility, and convenience. This article delves into the characteristics of BOPS film and explores its pivotal role in the packaging of disposable cutlery, offering a detailed, evidence-based analysis of why it’s a preferred choice in this niche.

Characteristics of BOPS Film

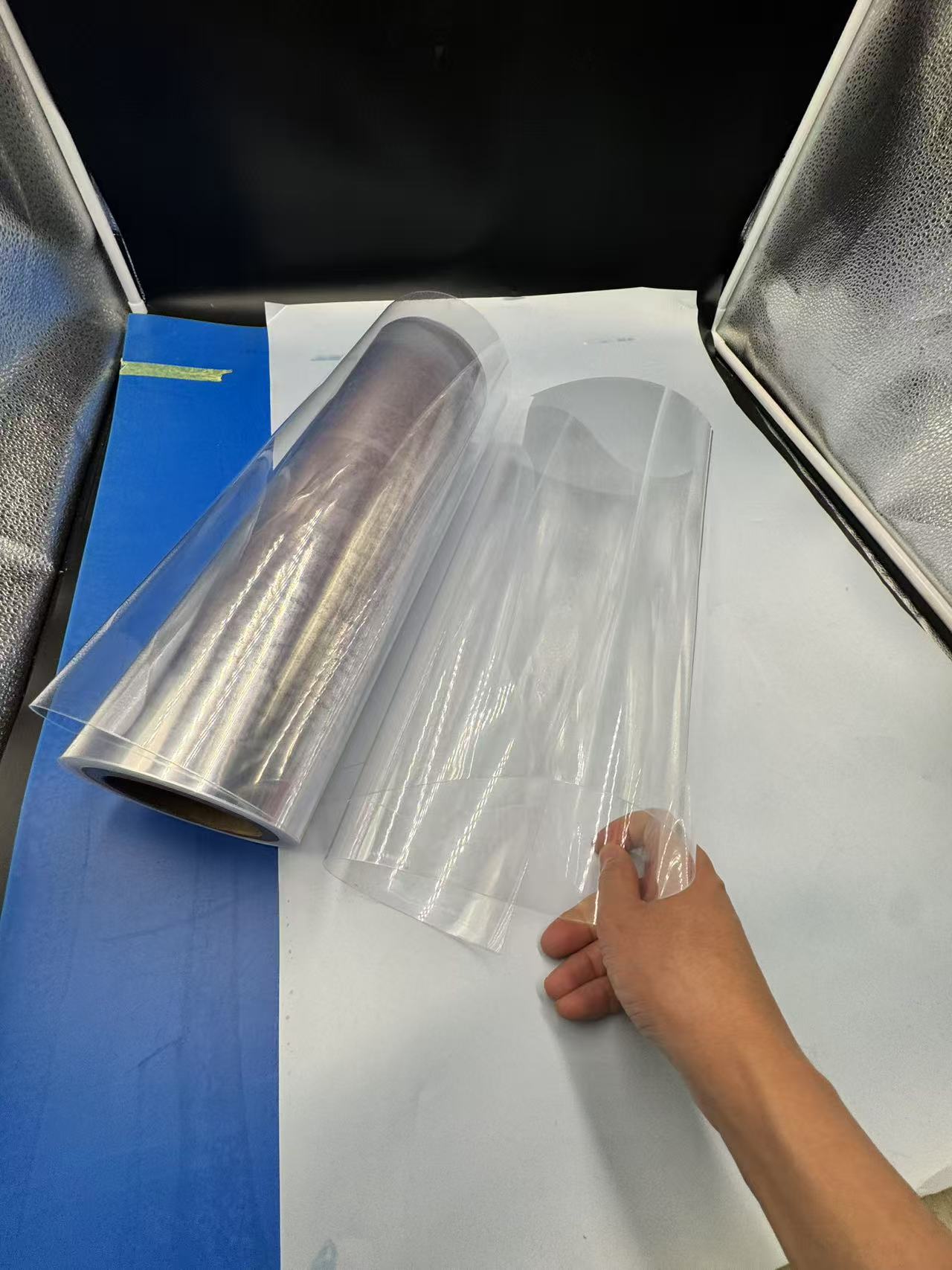

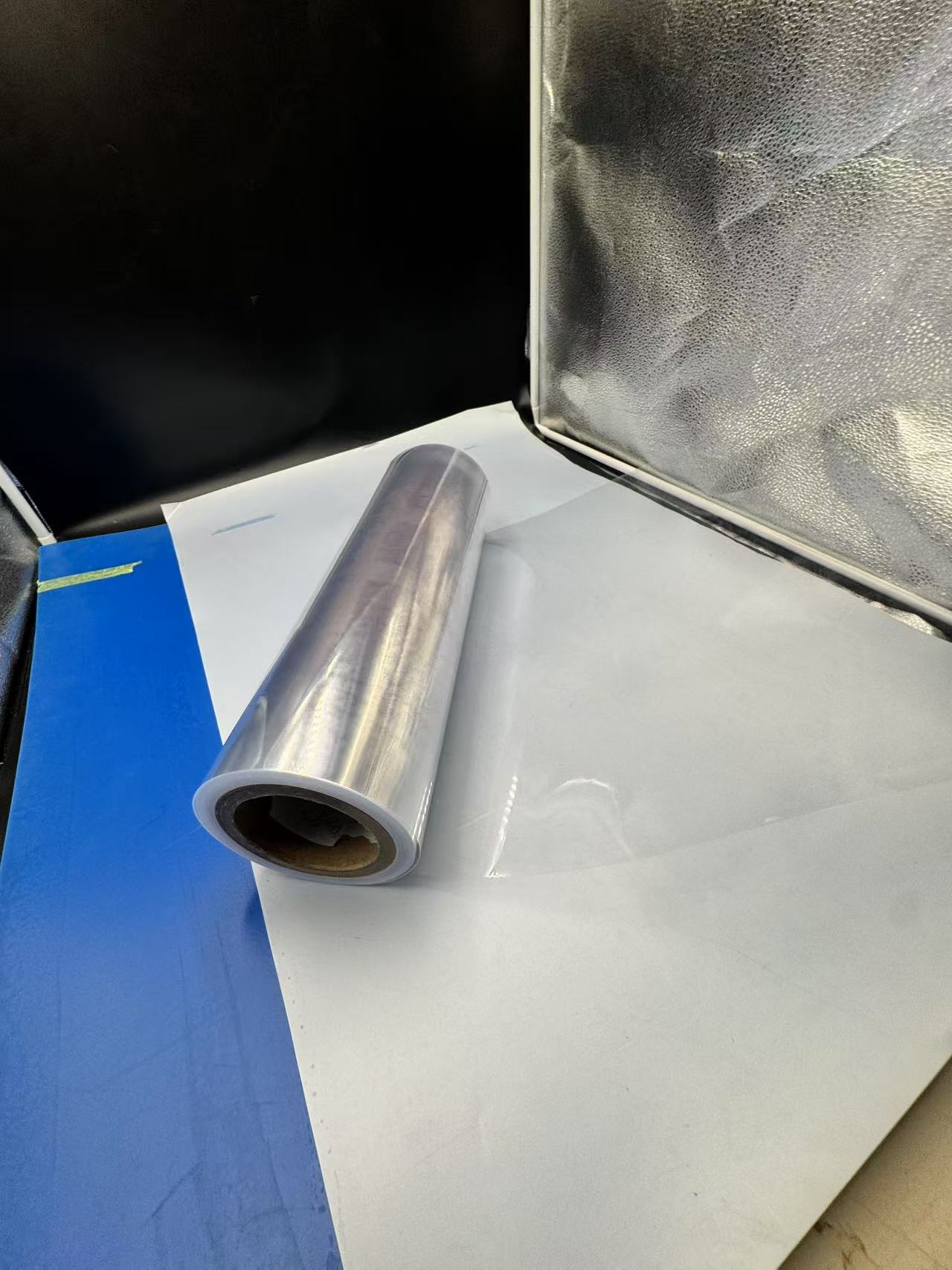

BOPS film is a high-performance material produced by stretching polystyrene in both machine and transverse directions, a process that enhances its mechanical and optical properties. Below are the key characteristics that make BOPS film exceptional for packaging applications:

Superior Clarity and Gloss

One of the hallmark features of BOPS film is its crystal-clear transparency and high gloss. Unlike other materials like PVC or PET, BOPS film offers exceptional optical clarity, allowing consumers to inspect the packaged cutlery without obstruction. This transparency is critical in retail settings, where visual appeal drives purchasing decisions. For instance, a shopper can easily assess the design and quality of a spoon through a BOPS film blister pack, fostering trust in the product.

High Strength and Tear Resistance

Despite its lightweight nature, BOPS film boasts impressive tensile strength and resistance to tearing. This durability ensures that blister packs maintain their integrity during transportation, handling, and display. For disposable cutlery, which often faces rough handling in bulk shipments, BOPS film provides a robust barrier that prevents cracks or punctures, safeguarding the contents.

Excellent Thermoforming Capabilities

BOPS film is highly amenable to thermoforming, a process where the film is heated and molded into precise shapes. Its ability to form deep cavities with uniform thickness makes it ideal for creating snug, custom-fit blister packs for cutlery. This characteristic reduces material waste and ensures that each piece of cutlery is securely held, minimizing movement that could lead to damage.

Chemical Stability and Safety

Non-toxic and chemically inert, BOPS film complies with international food and medical hygiene standards. It does not react with acids, alkalis, or salts, ensuring that the packaged cutlery remains uncontaminated. This safety profile is crucial for disposable cutlery, which comes into direct contact with food, guaranteeing consumer safety and product quality.

Temperature Adaptability

BOPS film maintains dimensional stability across a wide temperature range, from -35°C to 95°C. This versatility allows blister packs to withstand cold storage or hot display conditions without deforming. For example, cutlery packaged in BOPS film can be stored in refrigerated supermarket shelves or displayed near warm food counters without compromising the packaging’s shape or clarity.

Sustainability and Recyclability

In an era where environmental concerns dominate, BOPS film offers a compelling advantage: it is 100% recyclable. Unlike multilayered plastics that pose recycling challenges, BOPS film can be reprocessed into new products, reducing waste. Additionally, its incineration produces no toxic byproducts, making it an eco-friendly choice for manufacturers aiming to align with sustainability goals.

Applications of BOPS Film in Disposable Cutlery Blister Packaging

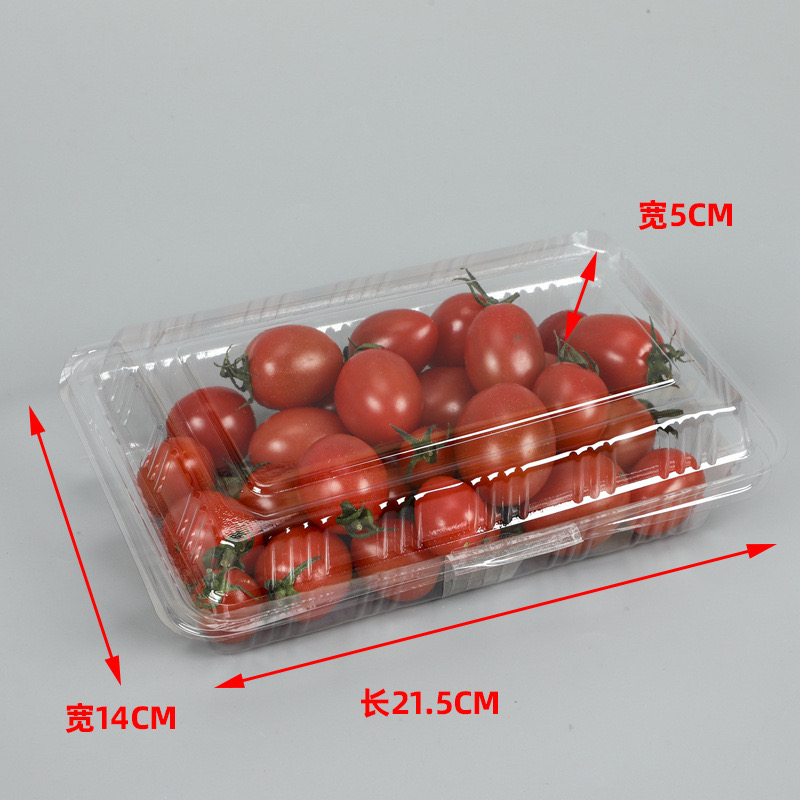

The unique properties of BOPS film make it an ideal candidate for blister packaging, particularly for disposable cutlery. Blister packaging involves a thermoformed plastic cavity (the blister) sealed with a backing material, such as paperboard or foil, to encase the product. Here’s how BOPS film excels in this application:

1. Enhanced Product Visibility

Disposable cutlery, such as plastic forks or biodegradable knives, relies on packaging to attract consumers. BOPS film’s transparency ensures that the cutlery is fully visible, allowing customers to evaluate its color, texture, and design. For instance, a set of eco-friendly bamboo spoons packaged in BOPS film showcases their natural grain, appealing to environmentally conscious buyers. This visibility not only enhances aesthetic appeal but also builds consumer confidence in the product’s quality.

2. Secure and Tamper-Evident Packaging

Blister packs made from BOPS film provide a secure enclosure for cutlery, preventing contamination and tampering. The film’s strength ensures that the blister remains intact, while its clarity allows retailers to detect any signs of tampering instantly. For example, a cracked or cloudy BOPS film blister would immediately signal mishandling, protecting consumers from compromised products. This tamper-evident feature is particularly valuable in high-traffic retail environments like convenience stores.

3. Customization and Design Flexibility

The thermoforming prowess of BOPS film allows manufacturers to create blister packs tailored to specific cutlery shapes and sizes. Whether it’s a single fork or a multi-piece set, BOPS film can be molded to fit snugly, reducing excess space and material use. This customization enhances efficiency and aesthetics, as seen in compact blister packs for travel-sized cutlery sets, where BOPS film ensures a sleek, professional look.

4. Protection Against Environmental Factors

Disposable cutlery must remain hygienic until use, and BOPS film excels at providing a barrier against moisture, dust, and microbes. Its low water vapor transmission rate ensures that cutlery stays dry, preventing corrosion in metal-coated or biodegradable options. For instance, a set of cornstarch-based spoons packaged in BOPS film remains unaffected by humid store conditions, preserving its usability and appearance.

5. Cost-Effectiveness and Production Efficiency

BOPS film is produced using fully automated positive air pressure thermoforming machines, which integrate heating, forming, and die-cutting in one seamless process. While mold development costs can be high, the unit price of BOPS film blister packs is low, making it economical for large-scale production. This cost-effectiveness is a boon for manufacturers of disposable cutlery, where margins are often tight, allowing them to deliver high-quality packaging without inflating prices.

6. Supporting Sustainability in Single-Use Products

The environmental impact of single-use plastics is a pressing concern, and BOPS film addresses this through its recyclability. Blister packs made from BOPS film can be collected, processed, and reused, reducing landfill waste. Moreover, its lightweight nature minimizes material consumption, lowering the carbon footprint of packaging production. For example, a restaurant chain using BOPS film for takeout cutlery can promote its eco-friendly packaging, appealing to green-minded customers.

Real-World Examples and Impact

To illustrate the impact of BOPS film, consider its use in supermarket chains across developed markets. In countries like Japan and Germany, where BOPS film has been a staple for decades, blister-packed cutlery dominates retail shelves. A typical example is a pack of plastic forks displayed in a BOPS film blister, hanging neatly on a pegboard. The film’s gloss catches the light, drawing attention, while its strength ensures the forks remain undamaged despite frequent handling by shoppers.

Another case is the fast-food industry, where BOPS film blister packs encase cutlery for takeout orders. A popular chain might use BOPS film to package a knife and fork set, sealed with a paperboard backing printed with branding. The film’s clarity highlights the cutlery’s sleek design, while its durability withstands the rigors of delivery, ensuring customers receive hygienic, intact utensils.

Challenges and Future Directions

While BOPS film offers numerous advantages, it’s not without challenges. Its reliance on polystyrene raises concerns in regions pushing for polystyrene bans due to recycling infrastructure limitations. However, advancements in recycling technology are mitigating these issues, with new facilities capable of processing BOPS film efficiently. Additionally, the high initial cost of thermoforming molds can deter small-scale manufacturers, though this is offset by the film’s low unit cost in mass production.

Looking ahead, innovations in BOPS film production could further enhance its appeal. For instance, incorporating bio-based additives could improve its biodegradability, aligning with global sustainability trends. Research into thinner yet stronger BOPS film variants could also reduce material use, making it even more cost-effective and eco-friendly for cutlery packaging.

Conclusion

BOPS film stands as a cornerstone of modern blister packaging, particularly for disposable cutlery. Its blend of clarity, strength, thermoforming ease, and recyclability makes it an unmatched choice for manufacturers seeking to balance functionality, aesthetics, and sustainability. From protecting cutlery against environmental hazards to enhancing retail appeal, BOPS film delivers on multiple fronts, proving its worth in a competitive market. As consumer demand for hygienic, visually appealing, and eco-conscious packaging grows, BOPS film is poised to lead the way, shaping the future of disposable cutlery packaging with innovation and reliability.