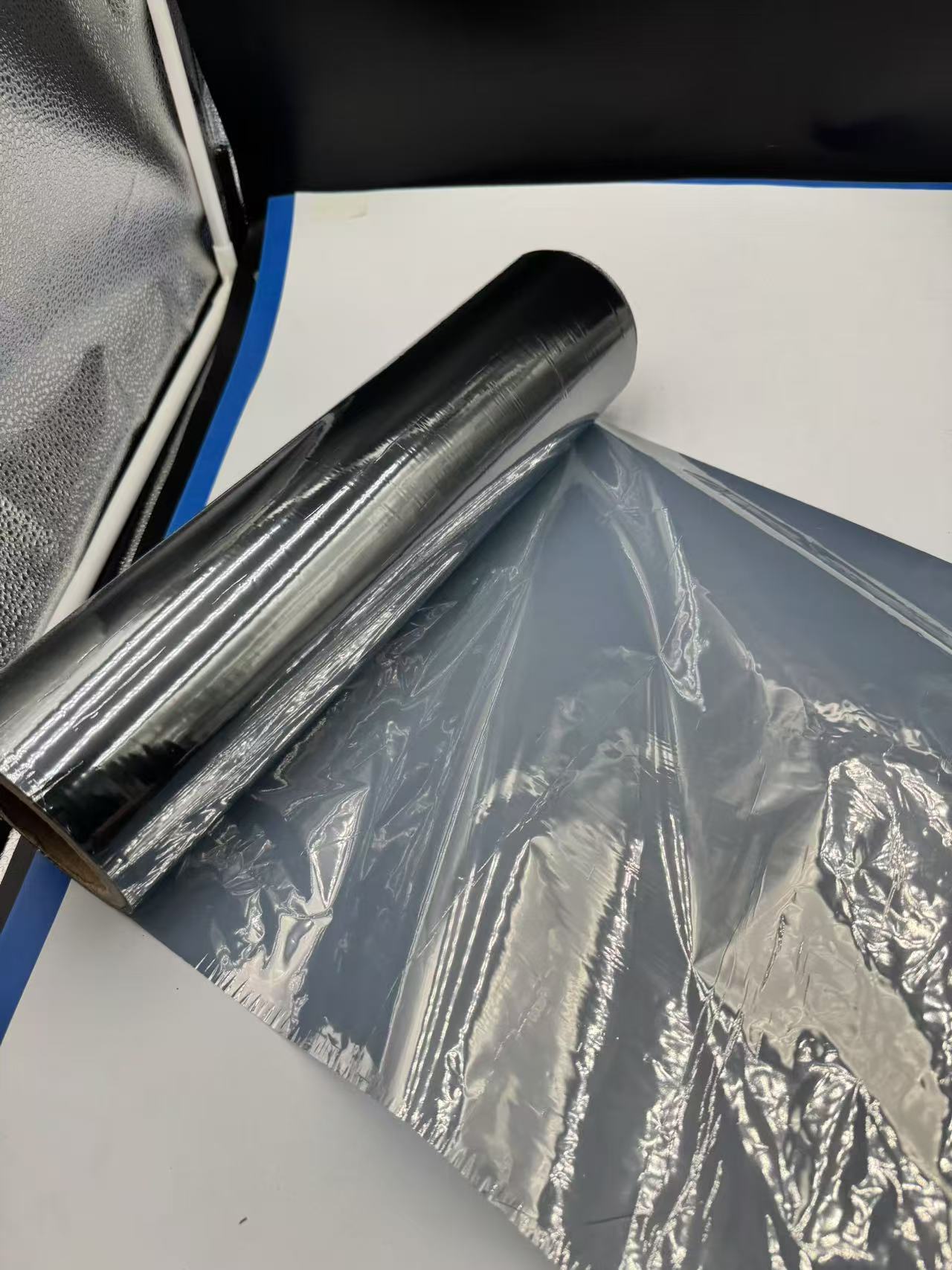

Grey PET Antistatic Film: Safeguarding Precision with Advanced Static Control

2025-07-21 16:51IntroductionIn industries where precision and reliability are non-negotiable, such as electronics, semiconductors, and medical device manufacturing, controlling electrostatic discharge (ESD) is critical to protecting sensitive components and ensuring product integrity.

Grey polyethylene terephthalate (PET) antistatic film has emerged as a high-performance material engineered to mitigate static buildup while offering the durability, clarity, and versatility of PET. Unlike standard PET, which is an excellent insulator and prone to static accumulation, grey PET antistatic film incorporates conductive additives or coatings to dissipate static charges effectively. Its distinctive grey color not only enhances its aesthetic appeal but also serves as a visual cue for its antistatic properties, making it ideal for controlled environments. This article delves into the unique characteristics of grey PET antistatic film and its diverse applications, supported by technical insights and real-world examples, highlighting its transformative role in modern industrial processes

.Characteristics of Grey PET Antistatic FilmGrey PET antistatic film combines the inherent strengths of PET—such as high tensile strength, tChallenges include higher production costs compared to PS-based films and the need for precise processing to preserve antistatic properties. Excessive heat during manufacturing can degrade conductive coatings, necessitating advanced equipment and quality control measures.Future Prospects The global market for antistatic films is projected to grow at a CAGR of 7.5% from 2025 to 2033, fueled by demand in electronics, automotive, and medical sectors. Innovations in eco-friendly PET formulations, such as bio-based conductive additives, are expected to enhance sustainability. Emerging technologies like graphene-based coatings could improve the film’s performance in applications like flexible electronics or wearable devices. The increasing adoption of automation and cleanroom manufacturing will further drive demand for high-performance, customizable antistatic films.

Conclusion

Grey PET antistatic film is a cornerstone of industries requiring stringent static control, offering a robust combination of strength, thermal stability, and static dissipation. Its ability to protect sensitive electronics, medical devices, and automotive components from ESD ensures product reliability and operational efficiency. From ESD-safe trays in semiconductor production to sterile packaging for medical devices, grey PET antistatic film is a critical enabler of precision and safety. As industries prioritize sustainability, automation, and advanced manufacturing, this film is well-positioned to meet evolving needs, with innovations paving the way for broader applications in cutting-edge technologies.