Unlocking the Potential of Polypropylene Film: Versatile Applications in Packaging

2025-08-18 17:20Polypropylene (PP) film, a versatile thermoplastic polymer, has become a cornerstone in the packaging industry due to its exceptional properties and adaptability. Renowned for its strength, clarity, and resistance to environmental factors, PP film is widely used in applications ranging from food vacuum packaging to disposable tableware and antistatic packaging.  This article explores the unique characteristics of PP film and its diverse applications, highlighting its significance in ensuring safety, functionality, and sustainability across various sectors. By delving into its properties and practical uses, we aim to provide a comprehensive understanding of why PP film is a preferred choice in modern packaging solutions.Key Characteristics of PP FilmPP film, derived from the polymerization of propylene monomers, exhibits a range of properties that make it ideal for packaging applications. These characteristics include:High Mechanical Strength and Durability: PP film is known for its robust molecular structure, particularly in its isotactic form, which provides excellent tensile strength and impact resistance. This durability ensures that PP film can withstand the stresses of handling, transportation, and storage without tearing or deforming. For instance, in food vacuum packaging, PP film's strength prevents punctures, maintaining an airtight seal critical for preserving product freshness.

This article explores the unique characteristics of PP film and its diverse applications, highlighting its significance in ensuring safety, functionality, and sustainability across various sectors. By delving into its properties and practical uses, we aim to provide a comprehensive understanding of why PP film is a preferred choice in modern packaging solutions.Key Characteristics of PP FilmPP film, derived from the polymerization of propylene monomers, exhibits a range of properties that make it ideal for packaging applications. These characteristics include:High Mechanical Strength and Durability: PP film is known for its robust molecular structure, particularly in its isotactic form, which provides excellent tensile strength and impact resistance. This durability ensures that PP film can withstand the stresses of handling, transportation, and storage without tearing or deforming. For instance, in food vacuum packaging, PP film's strength prevents punctures, maintaining an airtight seal critical for preserving product freshness.

Chemical and Moisture Resistance: PP film is chemically inert, meaning it does not react with food, chemicals, or other substances, ensuring product safety and integrity. Its low moisture absorption rate makes it an effective barrier against water vapor, which is essential for protecting perishable goods from spoilage. This property is particularly valuable in food packaging, where maintaining quality and extending shelf life are paramount.

Thermal Stability: With a high melting point (approximately 160–170°C) and the ability to withstand temperatures up to 100°C, PP film is suitable for applications involving heat, such as microwaveable containers and retort packaging. Its thermal resistance ensures that it remains stable during high-temperature processing, making it ideal for hot-fill and sterilization processes.

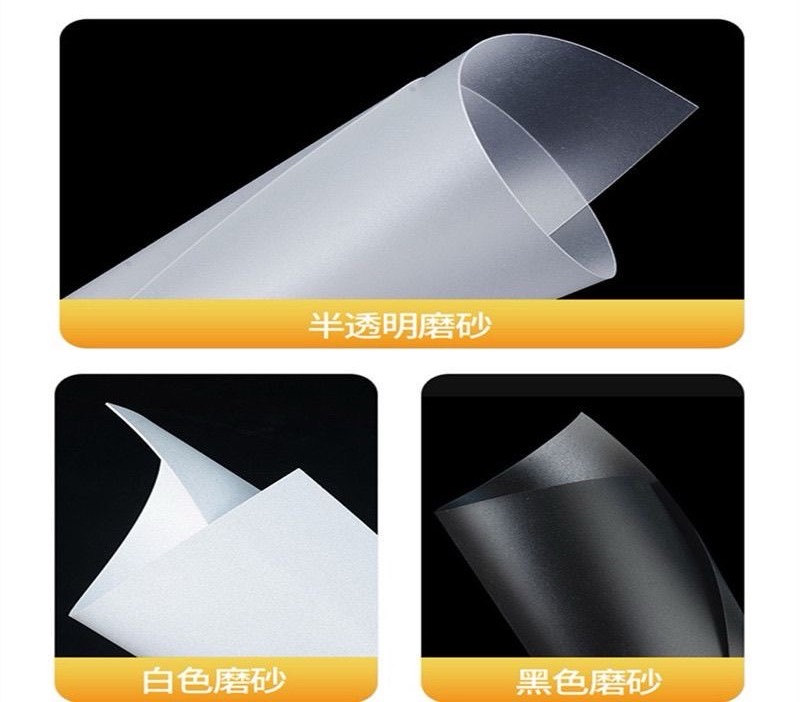

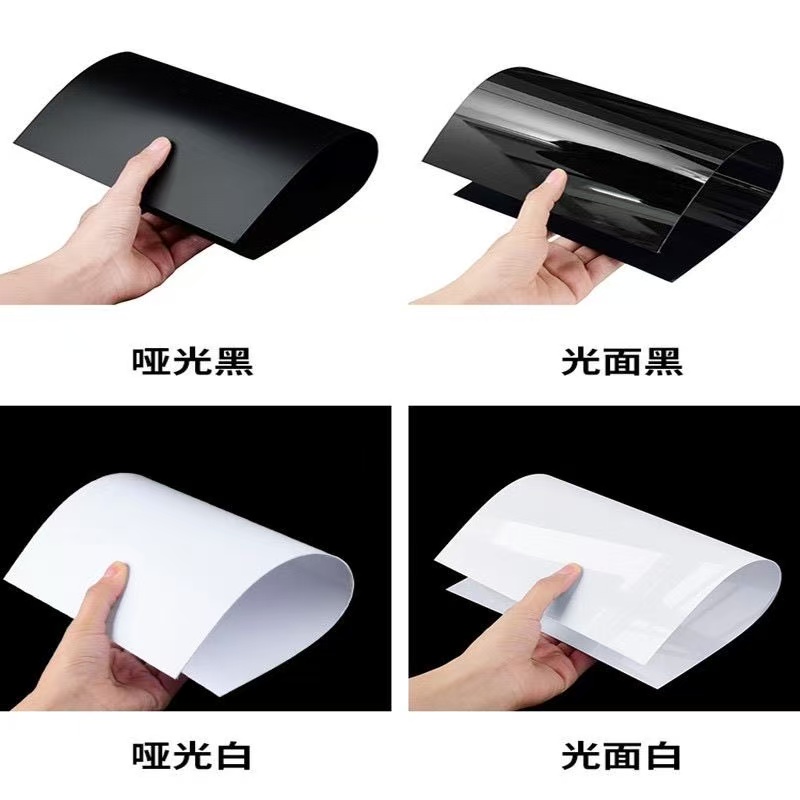

Clarity and Printability: Biaxially oriented polypropylene (BOPP) film, a common type of PP film, offers excellent transparency, allowing for clear product visibility, which is crucial for consumer appeal in food packaging. Additionally, PP film’s surface is highly receptive to printing, enabling vibrant graphics and branding, which enhances product marketability.

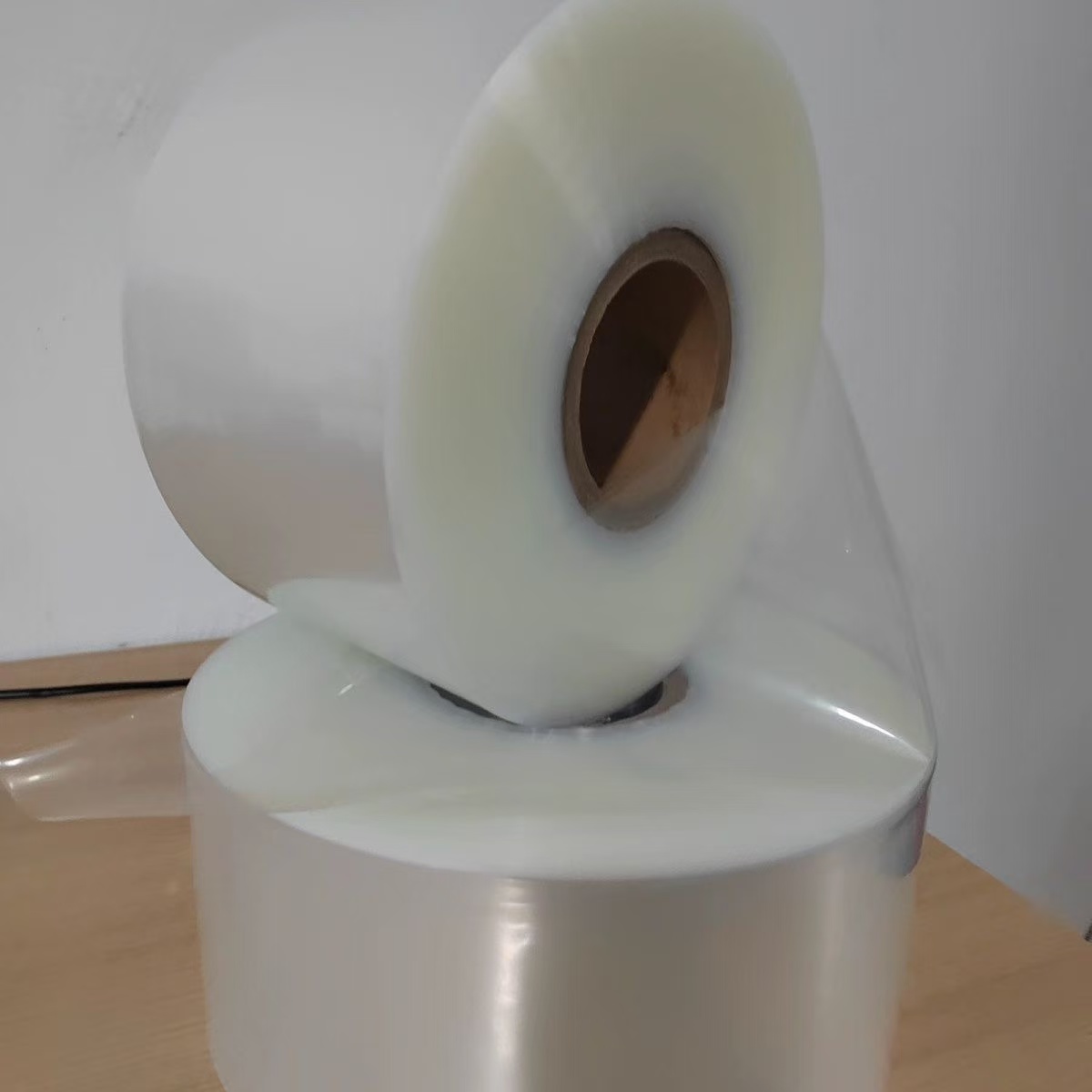

Lightweight and Recyclability: PP film has a low density (approximately 0.9 g/cm³), making it one of the lightest plastics used in packaging. This reduces material usage and transportation costs, contributing to cost-effectiveness and sustainability. Moreover, PP film is widely recyclable, aligning with growing environmental concerns and circular economy principles.

Applications of PP Film in Food Vacuum Packaging

Food vacuum packaging is a critical application where PP film excels due to its ability to create a protective barrier and extend shelf life. Vacuum packaging involves removing air from the package to inhibit the growth of bacteria and other microorganisms, thereby preserving perishable foods such as meat, cheese, and vegetables. PP film is particularly suited for this purpose due to its unique properties.Barrier Properties: PP film provides an excellent moisture barrier, preventing water loss or gain that could compromise food quality. While PP film is not inherently an oxygen barrier, it can be combined with other materials, such as ethylene vinyl alcohol (EVOH), in multilayer structures to enhance gas barrier properties. This is crucial for vacuum packaging, where low oxygen levels are necessary to prevent oxidation and spoilage. For example, vacuum-packed meats rely on PP film’s barrier capabilities to maintain freshness during transport and storage.

Durability and Sealability: The mechanical strength of PP film ensures that vacuum-sealed packages remain intact under pressure, preventing leaks or ruptures. Its heat-sealing properties allow for strong, airtight seals, which are essential for maintaining the vacuum environment. This is particularly important for products like seafood, where even minor leaks can lead to spoilage.

Regulatory Compliance: Food-grade PP film complies with stringent safety standards set by regulatory bodies such as the FDA and the European Food Safety Authority (EFSA). It is non-toxic and does not leach harmful chemicals into food, ensuring consumer safety. This makes PP film a trusted choice for vacuum packaging applications, where direct food contact is common.

A practical example of PP film in food vacuum packaging is its use in sous-vide cooking, where food is vacuum-sealed in PP-based pouches and cooked at precise temperatures. The film’s thermal stability and durability ensure that the package withstands prolonged exposure to heat and moisture, preserving the food’s flavor and texture.PP Film in Disposable Tableware PackagingDisposable tableware, such as plates, cups, and cutlery, is widely used in foodservice settings, including restaurants, catering, and takeaways. PP film plays a pivotal role in packaging these items, ensuring hygiene, convenience, and cost-effectiveness.Hygiene and Safety: PP film’s chemical inertness and non-porous surface prevent the growth of bacteria and mold, making it ideal for packaging disposable tableware. Its compliance with food safety regulations ensures that packaged items remain hygienic and safe for consumer use. For instance, PP film is used to wrap plastic cutlery sets, protecting them from dust and contaminants during storage and transport.

Lightweight and Cost-Effective: The low density of PP film reduces the weight of packaged tableware, lowering shipping costs and improving handling efficiency. Its affordability compared to other materials, such as PET or polystyrene, makes it a cost-effective choice for high-volume production. This is particularly beneficial for single-use tableware, where cost is a significant factor.

Customizability: PP film’s printability allows manufacturers to create visually appealing packaging with branding and product information. For example, PP film used to wrap disposable cups often features vibrant logos and designs, enhancing brand visibility in competitive markets.

A real-world application is the use of PP film in packaging disposable coffee cups for retail sale. The film’s clarity showcases the product, while its durability ensures that the cups remain undamaged during distribution. Additionally, PP film’s recyclability supports sustainable practices, addressing consumer demand for eco-friendly packaging solutions.PP Film in Antistatic PackagingAntistatic packaging is essential for protecting sensitive electronic components, such as circuit boards and microchips, from electrostatic discharge (ESD). PP film, when modified with antistatic additives, serves as an effective material for this purpose, combining its inherent properties with specialized functionality.Antistatic Properties: PP film can be treated with antistatic agents, such as conductive fillers or coatings, to dissipate static electricity and prevent