Unveiling the Versatility of Transparent PA/CPP Film in Modern Packaging Solutions

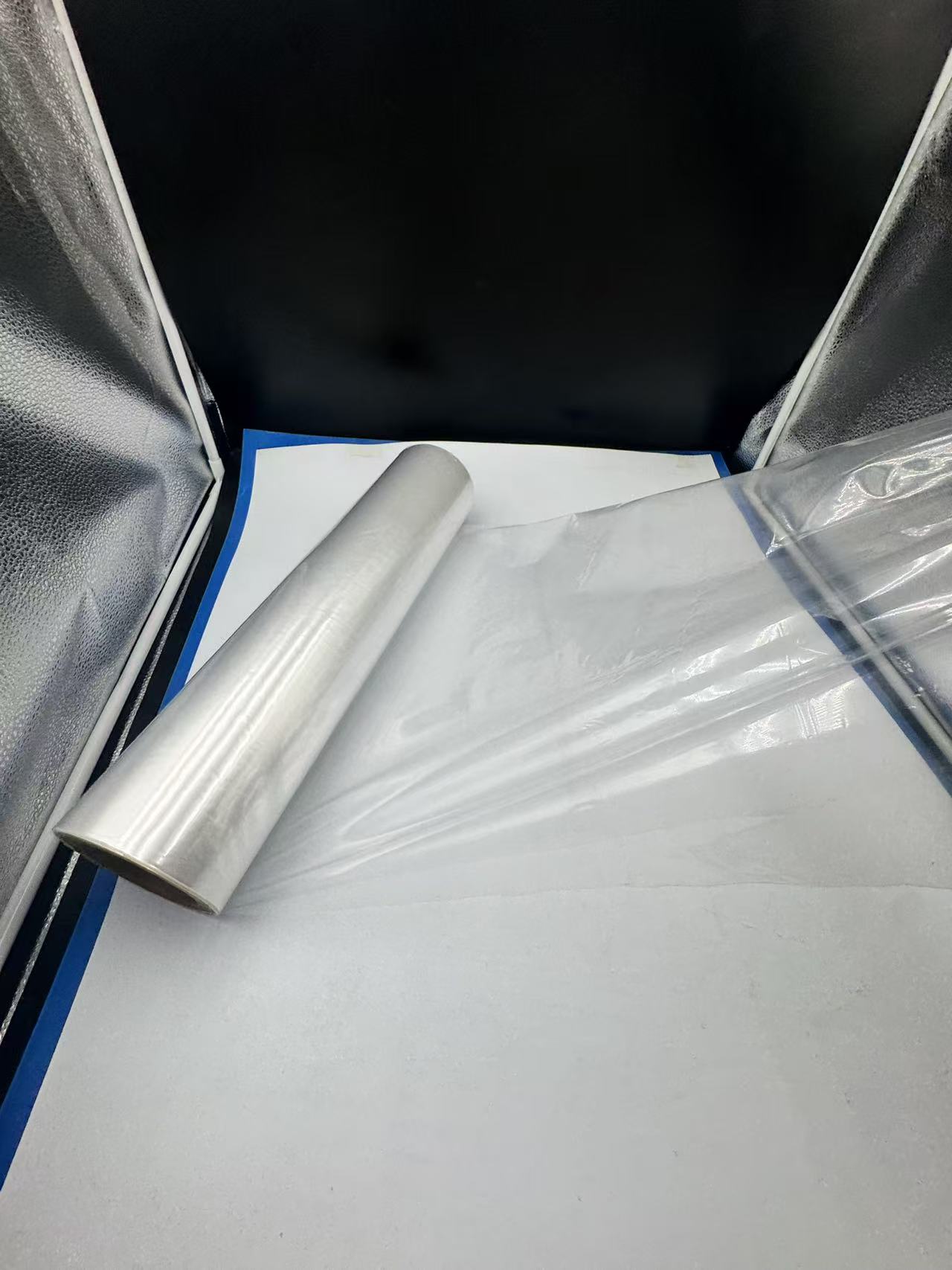

2025-08-21 16:57Transparent PA/CPP (Polyamide/Cast Polypropylene) film is a high-performance packaging material that combines the robust properties of polyamide (PA) and cast polypropylene (CPP) to meet the demanding needs of modern packaging industries. Renowned for its exceptional clarity, flexibility, and barrier properties, this composite film h as become a cornerstone in applications such as food vacuum packaging, composite packaging, and sealing packaging. This article explores the key characteristics of transparent PA/CPP film and its diverse applications, highlighting its critical role in ensuring product safety, extending shelf life, and enhancing consumer appeal.Characteristics of Transparent PA/CPP FilmSuperior Transparency and Aesthetics

as become a cornerstone in applications such as food vacuum packaging, composite packaging, and sealing packaging. This article explores the key characteristics of transparent PA/CPP film and its diverse applications, highlighting its critical role in ensuring product safety, extending shelf life, and enhancing consumer appeal.Characteristics of Transparent PA/CPP FilmSuperior Transparency and Aesthetics

Transparent PA/CPP film is celebrated for its outstanding clarity and gloss, making it an ideal choice for applications where product visibility is paramount. The high transmittance of the film allows consumers to view the packaged contents clearly, which is particularly valuable in retail settings where visual appeal drives purchasing decisions. For instance, in food packaging, the transparency of PA/CPP film showcases the freshness and quality of products like fresh produce, meats, and baked goods, fostering consumer trust. Studies indicate that transparent packaging can increase consumer preference by up to 20% in retail environments due to its ability to display product integrity.

Excellent Barrier Properties

The combination of PA and CPP creates a film with robust barrier properties against oxygen, moisture, and other environmental contaminants. Polyamide provides an excellent oxygen barrier, which is critical for preventing oxidative spoilage in perishable goods, while CPP contributes superior moisture resistance. This dual-barrier functionality makes PA/CPP film particularly suitable for vacuum packaging, where maintaining an airtight environment is essential to extend shelf life. For example, vacuum-packed meats and cheeses rely on the oxygen barrier of PA to prevent rancidity, while CPP’s moisture resistance protects against dehydration.

Excellent Heat-Sealability

One of the standout features of PA/CPP film is its superior heat-sealability, primarily due to the CPP layer. CPP’s low sealing initiation temperature (SIT) allows for secure seals at lower temperatures, reducing energy consumption and minimizing the risk of heat damage to sensitive products like frozen foods or pharmaceuticals. The film’s high hot tack strength ensures reliable seals even on high-speed packaging lines, making it a preferred choice for sealing packaging applications.

Temperature Resistance

PA/CPP film exhibits a wide temperature tolerance, making it suitable for both high- and low-temperature applications. The PA layer provides resistance to high temperatures, enabling the film to withstand processes like pasteurization or retort sterilization (up to 120–135°C for retort-grade CPP). Meanwhile, modified CPP formulations can maintain flexibility and impact resistance at low temperatures, such as -18°C, making the film ideal for frozen food packaging.

Applications of Transparent PA/CPP Film1. Food Vacuum PackagingTransparent PA/CPP film is a cornerstone in food vacuum packaging due to its ability to create an airtight seal that extends shelf life. The PA layer’s oxygen barrier prevents microbial growth and oxidative spoilage, while the CPP layer’s moisture resistance maintains product texture and quality. For example, vacuum-packed seafood, such as salmon or shrimp, benefits from PA/CPP film’s puncture resistance and low-temperature toughness, ensuring the package remains intact during freezing and transportation. The film’s clarity also allows consumers to inspect the product’s freshness, which is critical for premium items like meats and cheeses. According to industry data, vacuum packaging with PA/CPP film can extend the shelf life of perishable foods by up to 50% compared to traditional packaging.

In addition, PA/CPP film is used in modified atmosphere packaging (MAP), where the film’s barrier properties help maintain a controlled gas environment to preserve food freshness. For instance, fresh produce like salads or berries packaged in MAP with PA/CPP film retains its crispness and color for longer periods, reducing food waste.

2. Composite PackagingIn composite packaging, PA/CPP film is often used as a multi-layer structure, combining the strengths of both materials to create high-performance laminates. The PA layer serves as the outer or middle layer, providing mechanical strength and oxygen barrier properties, while the CPP layer acts as the inner sealing layer due to its excellent heat-sealability. This combination is widely used in stand-up pouches, flexible lids, and flow pack packaging for products like snacks, confectionery, and frozen foods. For example, a typical PA/CPP laminate for snack packaging might consist of a PA layer for durability, a metallized layer for light protection, and a CPP sealing layer for a secure closure.

The versatility of PA/CPP film in composite packaging allows it to be tailored for specific products. For instance, anti-fog PA/CPP films are used for refrigerated products like fresh produce or deli meats, preventing condensation from obscuring product visibility. These films enhance the consumer experience by ensuring clear product presentation even in humid conditions.

3. Sealing PackagingPA/CPP film’s heat-sealability makes it a preferred choice for sealing packaging applications, such as tray lidding and pouch sealing. The film’s ability to form strong, hermetic seals ensures product safety and prevents leaks, which is critical for liquid or semi-liquid products like sauces, soups, or ready-to-eat meals. For instance, retort-grade PA/CPP film is used in sealing pouches for ready-to-eat meals, where it withstands high-temperature sterilization processes (up to 135°C) without compromising seal integrity. The film’s high hot tack strength also supports high-speed packaging lines, improving production efficiency.

In flow pack packaging, PA/CPP film is used to wrap products like baked goods, cheeses, and cured meats. The film’s flexibility allows it to conform to irregular shapes, while its clarity and printability enhance product branding. For example, a bakery might use PA/CPP film to package artisanal bread, showcasing its texture and crust through the transparent film while ensuring a secure seal to maintain freshness.

4. Specialized ApplicationsBeyond traditional food packaging, PA/CPP film is used in specialized applications that require unique properties. For instance, in pharmaceutical packaging, the film’s chemical stability and barrier properties protect sensitive drugs from moisture and oxygen, ensuring their efficacy over extended periods. In the medical field, PA/CPP film is used for packaging sterile equipment, where its puncture resistance and clarity ensure product safety and visibility.

The film is also employed in non-food applications, such as packaging for textiles, cosmetics, and industrial goods. For example, PA/CPP film is used in protective wraps for clothing or electronics, where its durability and transparency provide both protection and aesthetic appeal. Additionally, advancements in anti-fog and antibacterial PA/CPP films have expanded their use in fresh produce and hygiene-sensitive applications, respectively.

5. Sustainability and Future TrendsAs sustainability becomes a priority in the packaging industry, PA/CPP film is evolving to meet environmental demands. Recyclable versions of CPP, combined with PA’s durability, are being developed to reduce plastic waste. For instance, some manufacturers are producing mono-material PA/CPP films that are 100% recyclable, aligning with EU packaging regulations and consumer preferences for eco-friendly solutions. Innovations like smart packaging, where PA/CPP films are embedded with sensors to monitor product freshness, are also emerging, positioning the film at the forefront of packaging technology.

Case Studies and Real-World ExamplesVacuum-Packed Seafood

A leading seafood supplier in Europe uses transparent PA/CPP film for vacuum packaging shrimp and salmon. The film’s oxygen barrier extends shelf life by up to 30 days, while its clarity allows retailers to display the product’s vibrant colors, boosting sales. The film’s low-temperature toughness ensures it remains intact during frozen storage at -18°C.

Stand-Up Pouches for Snacks

A global snack brand employs PA/CPP laminates for stand-up pouches. The PA layer provides structural integrity, while the CPP layer ensures a secure seal. The film’s printability allows for eye-catching designs, contributing to a 15% increase in market share due to enhanced shelf appeal.

Conclusion

Transparent PA/CPP film is a versatile and high-performance material that excels in food vacuum packaging, composite packaging, sealing packaging, and beyond. Its combination of clarity, barrier properties, mechanical strength, and heat-sealability makes it indispensable in preserving product quality, enhancing consumer appeal, and meeting industry demands. As sustainability and innovation drive the packaging industry forward, PA/CPP film continues to evolve, offering eco-friendly solutions and cutting-edge functionalities. Whether protecting fresh produce, sealing ready-to-eat meals, or enhancing brand visibility, transparent PA/CPP film remains a vital tool in the quest for efficient, safe, and attractive packaging solutions.