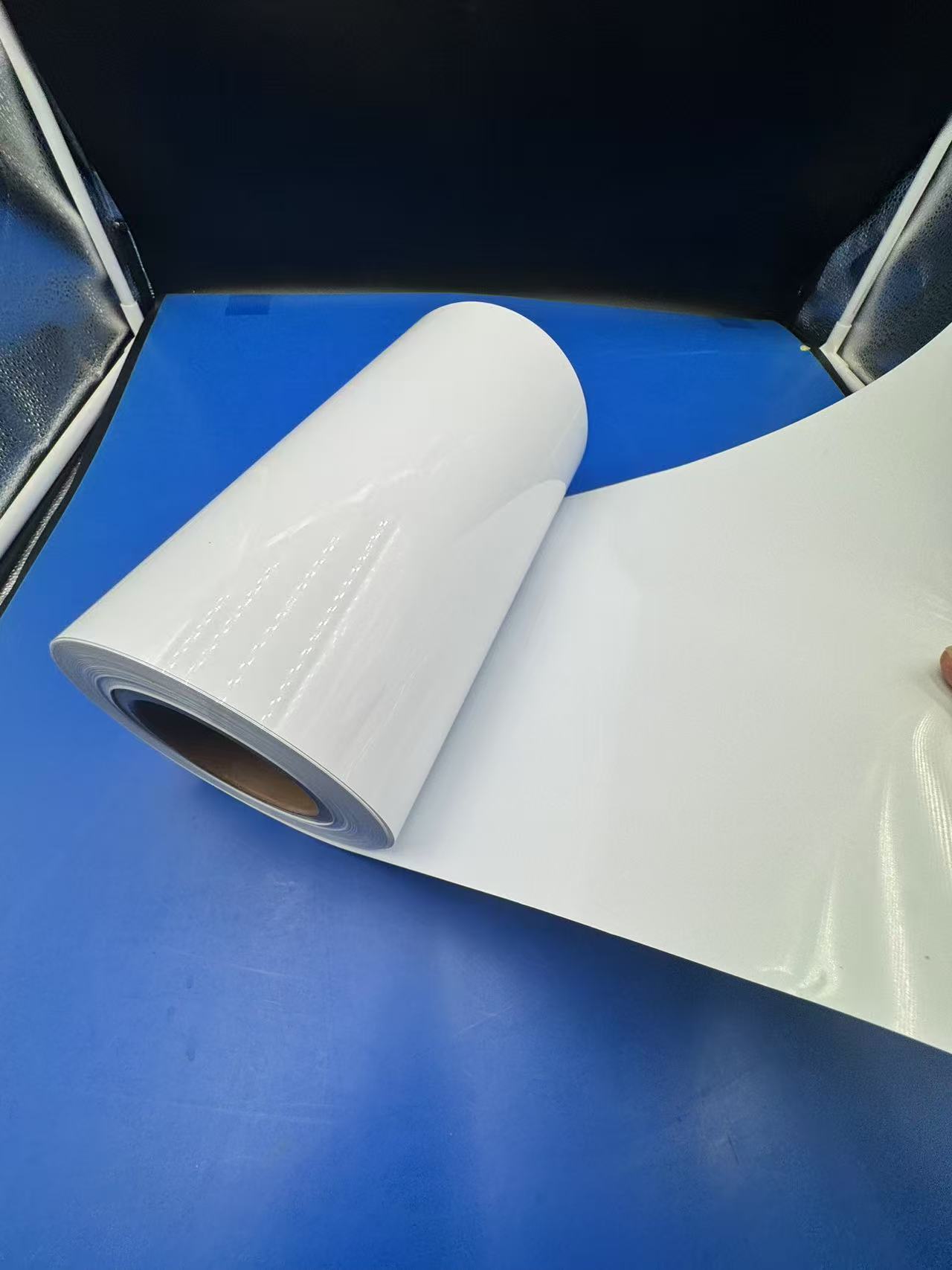

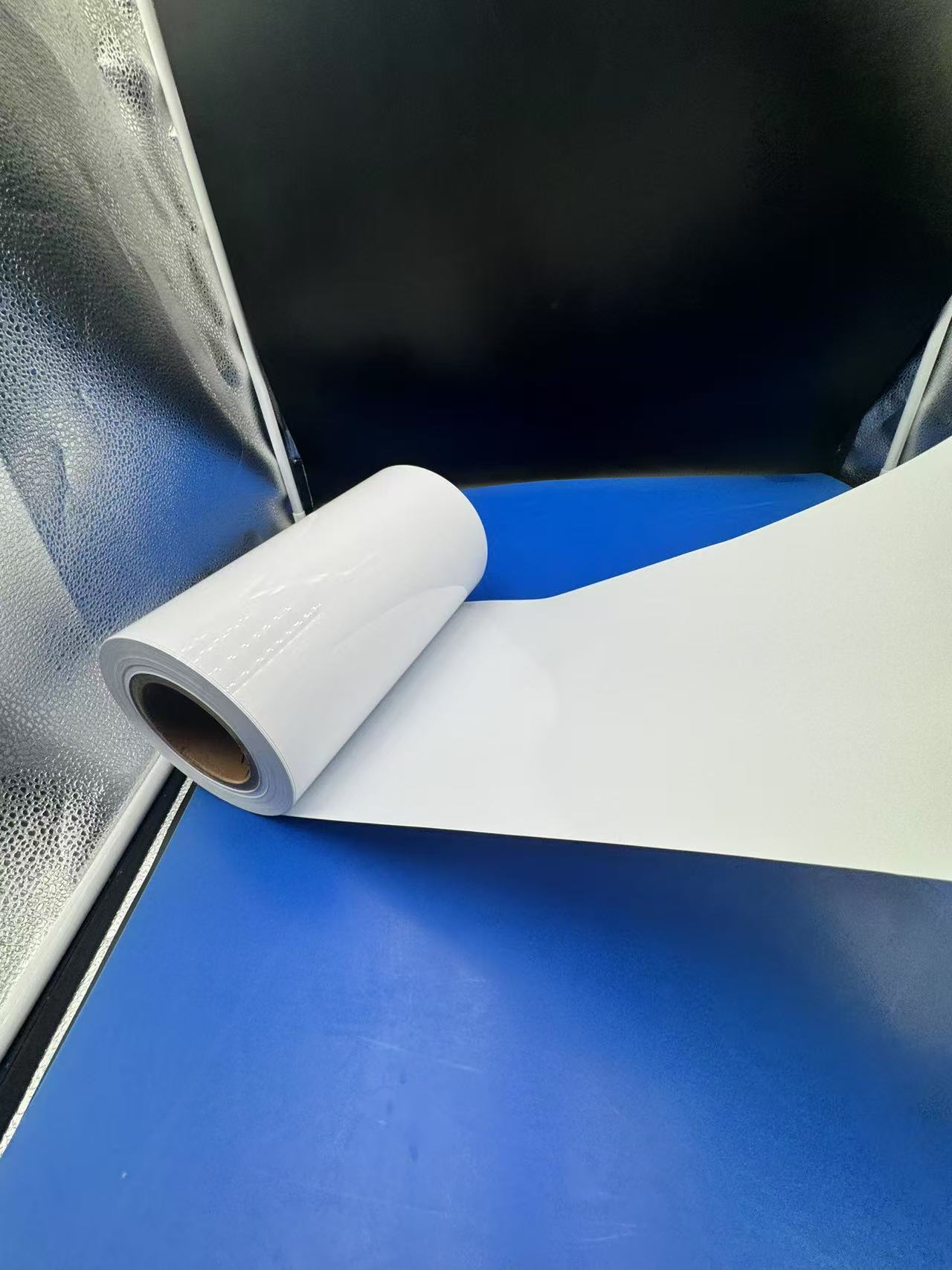

Exploring the Versatility of White PVC/PE Film in Modern Packaging and Beyond

2025-07-24 17:27White PVC/PE (Polyvinyl Chloride/Polyethylene) film is a laminated composite material widely recognized for its durability, flexibility, and excellent barrier properties. Combining the robustness of PVC with the sealing and softness of PE, this film is engineered to meet diverse packaging and industrial needs. Its opaque white appearance, achieved through pigmentation, offers both functional and aesthetic benefits, making it a preferred choice in industries ranging from food and medical packaging to industrial applications. This article explores the defining characteristics of white PVC/PE film and its practical uses, supported by technical insights and real-world examples, highlighting its role in modern packaging solutions.Characteristics of White PVC/PE Film

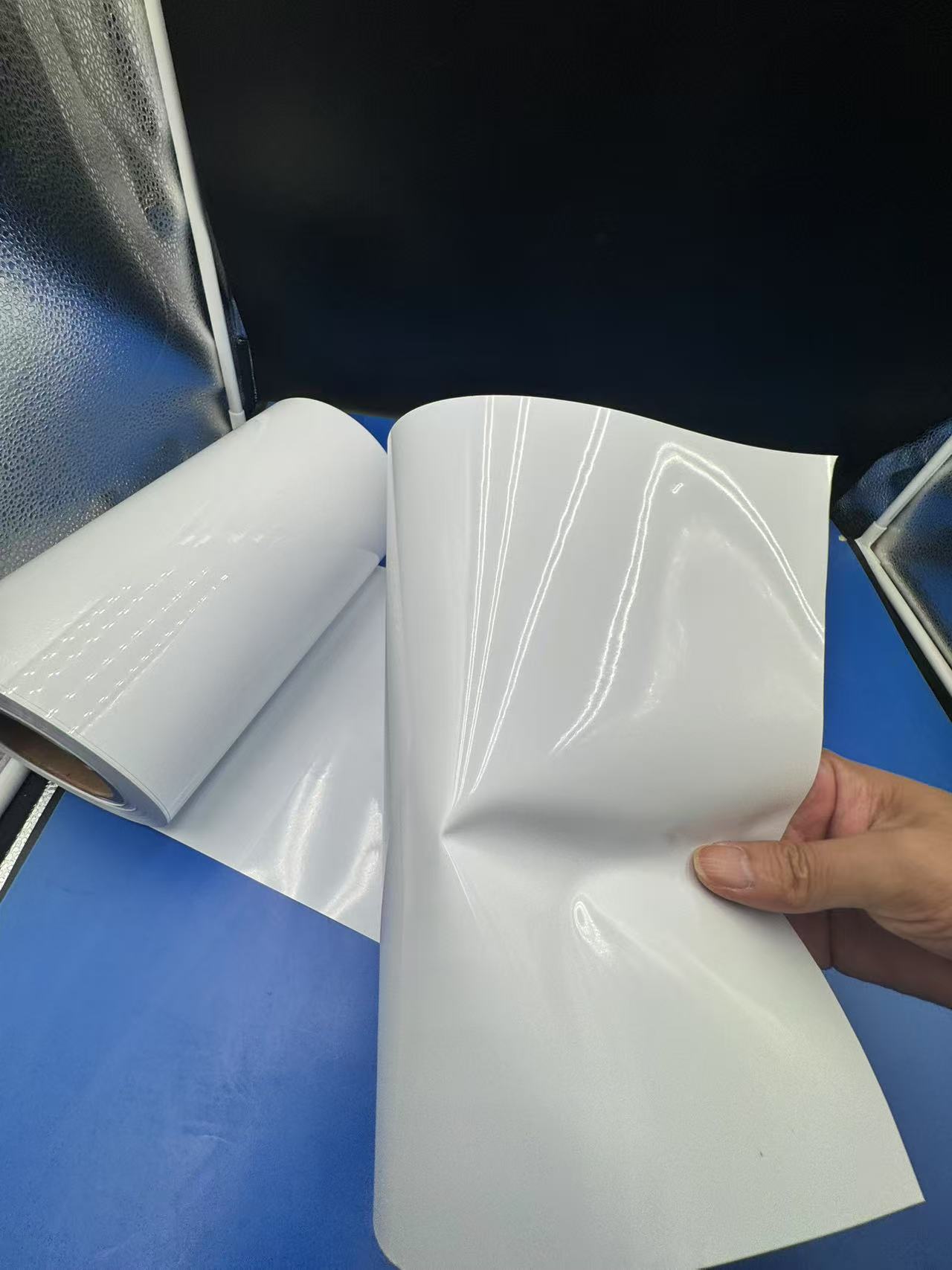

1. Opaque White AppearanceThe white coloration of PVC/PE film, achieved through titanium dioxide (TiO₂) or other pigments, provides excellent opacity, blocking light transmission. This is particularly valuable for protecting light-sensitive products, such as pharmaceuticals or certain foods, from UV degradation. The opaque finish also enhances branding opportunities, offering a clean, professional backdrop for printed logos and product information. Unlike transparent films, the white PVC/PE film conceals contents, adding a layer of privacy or security for sensitive items.

2. Superior Barrier PropertiesThe laminated structure of PVC/PE film combines PVC’s inherent resistance to gases and moisture with PE’s excellent sealing capabilities. PVC provides a low oxygen transmission rate (OTR) of approximately 20–40 cm³/m²/day at 23°C, while the PE layer enhances moisture resistance, with a water vapor transmission rate (WVTR) as low as 10 g/m²/day for a 50 µm film. This dual-barrier functionality protects products from environmental factors, extending shelf life and maintaining quality, especially for perishable goods or sterile medical supplies.3. Mechanical Strength and FlexibilityPVC/PE film is known for its robustness, with a tensile strength of around 50–70 MPa, depending on thickness and formulation.

The PVC layer provides rigidity and tear resistance, while the PE layer adds flexibility, allowing the film to conform to various shapes without cracking. This balance makes it suitable for both rigid blister packaging and flexible pouches. The film’s durability ensures it withstands handling, transportation, and storage stresses, reducing the risk of damage to packaged goods.4. Heat-Sealing CapabilitiesThe PE layer in PVC/PE film is designed for heat sealing, enabling strong, airtight seals at temperatures typically between 120°C and 180°C. This property ensures secure closure for packaging, preventing leaks and contamination. The film is compatible with high-speed sealing equipment, making it efficient for large-scale production. Its ability to form reliable seals even in the presence of minor contaminants, such as grease or moisture, enhances its utility in food and medical applications.5. Chemical ResistancePVC/PE film exhibits excellent resistance to oils, acids, and alkalis, making it suitable for packaging products exposed to harsh environments. The PVC layer is particularly resistant to chemical degradation, while the PE layer adds a protective barrier against moisture and grease. This makes the film ideal for packaging fatty foods, such as cheeses or meats, or industrial products like lubricants and chemicals.6. Printability and CustomizationThe white surface of PVC/PE film is highly receptive to printing, allowing for vibrant, high-resolution graphics. Corona treatment enhances ink adhesion, enabling manufacturers to add branding, barcodes, or regulatory information. The film can also be embossed or coated for additional functionality, such as anti-slip surfaces or enhanced barrier properties. This versatility supports customized packaging solutions tailored to specific market needs.7. Cost-EffectivenessCompared to alternatives like PET or aluminum-based laminates, PVC/PE film is relatively cost-effective, balancing performance with affordability. Its widespread availability and ease of processing further reduce production costs, making it a popular choice for manufacturers seeking high-quality packaging without premium pricing.Applications of White PVC/PE Film

1. Food PackagingWhite PVC/PE film is extensively used in food packaging due to its safety, barrier properties, and aesthetic appeal. Certified as food-grade under EU and FDA regulations, the film ensures no migration of harmful substances, making it suitable for direct food contact.Dairy Products: The film is commonly used for packaging cheeses, yogurts, and butter, where its moisture and oxygen barriers prevent spoilage. For example, white PVC/PE film is used as a lidding material for yogurt containers, providing a tamper-evident seal and protecting the product from light-induced flavor changes. The opaque white color enhances the premium look of the packaging, appealing to consumers.

Meat and Poultry: The film’s resistance to grease and moisture makes it ideal for vacuum-sealed meat and poultry packaging. Its flexibility allows it to conform tightly to the product, reducing air pockets that could lead to oxidation. The white appearance also masks any discoloration, maintaining an appealing presentation on supermarket shelves.

Bakery and Snacks: White PVC/PE film is used for wrapping baked goods like bread or pastries, where its barrier properties maintain freshness. For snacks, such as cookies or crackers, the film’s opacity protects against light-induced rancidity, while its printability allows for eye-catching designs that boost brand visibility.

2. Medical PackagingIn the medical and pharmaceutical industries, white PVC/PE film is valued for its sterility, chemical resistance, and light-blocking properties, ensuring the safety and efficacy of sensitive products.Blister Packaging for Pharmaceuticals: PVC/PE film is widely used for blister packs housing tablets, capsules, or medical devices. The PVC layer provides rigidity for forming cavities, while the PE layer ensures a secure, peelable seal. The white opacity protects light-sensitive medications, such as antibiotics or vitamins, from photodegradation. For example, a 250 µm PVC/PE film is commonly used for blister packs, offering a balance of strength and flexibility.

Sterile Medical Supplies: The film is used to package sterile items like syringes, bandages, or surgical tools. Its chemical resistance ensures compatibility with sterilization processes, such as ethylene oxide (EtO) or gamma radiation. The white color provides a clean, professional appearance, reinforcing consumer confidence in the product’s hygiene.

Diagnostic Kits: White PVC/PE film is used for packaging diagnostic test kits, where its barrier properties protect reagents from moisture and contamination. The film’s flexibility allows for easy opening, while its opacity safeguards light-sensitive components, ensuring accurate test results.

3. Industrial ApplicationsBeyond food and medical sectors, white PVC/PE film finds applications in industrial settings due to its durability, chemical resistance, and versatility.Chemical and Lubricant Packaging: The film is used to package industrial chemicals, lubricants, or cleaning agents, where its resistance to aggressive substances prevents degradation. For instance, white PVC/PE pouches are used for automotive lubricants, offering a robust, leak-proof solution that withstands rough handling.

Protective Wrapping: The film is employed as a protective wrap for industrial components, such as machine parts or tools, shielding them from moisture, dust, and corrosion. Its white color provides a clean appearance, while its flexibility allows it to conform to irregular shapes, ensuring comprehensive protection.

Labels and Tapes: White PVC/PE film is used for durable labels and adhesive tapes in industrial environments. Its printability supports clear, long-lasting text or barcodes, while its chemical resistance ensures legibility even in harsh conditions, such as exposure to oils or solvents.

Case Studies and Real-World ExamplesTo illustrate the practical applications of white PVC/PE film, consider the following examples:Supermarket Cheese Packaging: A dairy brand uses white PVC/PE film as a lidding material for cheese trays. The film’s moisture barrier extends shelf life by 20%, while its opacity prevents light-induced flavor changes. The white background also enhances the brand’s logo, increasing shelf appeal and boosting sales by 10% in trial markets.

Pharmaceutical Blister Packs: A pharmaceutical company employs 200 µm PVC/PE film for blister packaging of light-sensitive vitamins. The film’s opacity protects the vitamins from UV degradation, while its peelable seal improves patient accessibility. This packaging solution has reduced product returns due to spoilage by 15%.

Industrial Lubricant Pouches: An automotive supplier packages lubricants in white PVC/PE pouches. The film’s chemical resistance ensures no degradation, while its heat-sealing strength prevents leaks during transportation. The white color provides a professional appearance, aligning with the brand’s premium positioning.

Challenges and Future TrendsDespite its advantages, white PVC/PE film faces challenges. Environmental concerns surrounding PVC’s recyclability and potential chlorine emissions during incineration have prompted scrutiny. However, advancements in recycling technologies, such as chemical recycling, are improving PVC’s sustainability profile. Additionally, the film’s cost can be higher than single-layer PE films, though its superior performance often justifies the investment.Future trends include the development of eco-friendly PVC/PE formulations, such as bio-based PE layers or additives that enhance biodegradability. Innovations in barrier coatings, like EVOH or SiOx, are improving the film’s oxygen and moisture resistance, expanding its use in high-barrier applications. Smart packaging features, such as time-temperature indicators printed on PVC/PE films, are also emerging, enhancing functionality for food and medical applications.ConclusionWhite PVC/PE film is a versatile, high-performance material that excels in food packaging, medical packaging, and industrial applications. Its opaque appearance, excellent barrier properties, mechanical strength, and heat-sealing capabilities make it a go-to choice for protecting and presenting products. By balancing functionality with aesthetic appeal, the film meets the diverse needs of modern industries while offering opportunities for customization and branding. As sustainability and innovation drive the packaging sector, white PVC/PE film is poised to evolve, delivering solutions that combine performance, safety, and environmental responsibility.