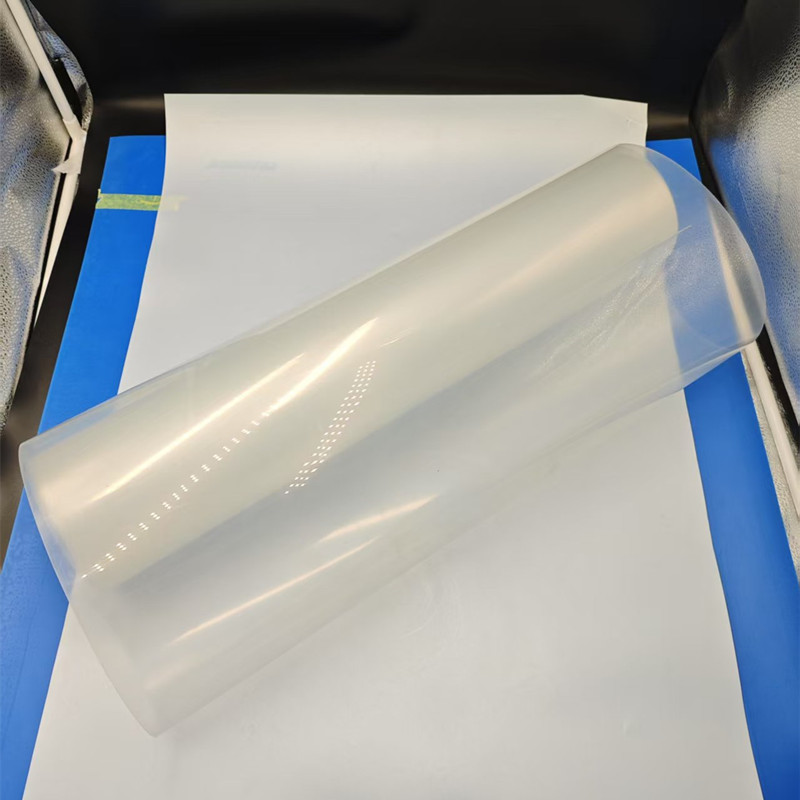

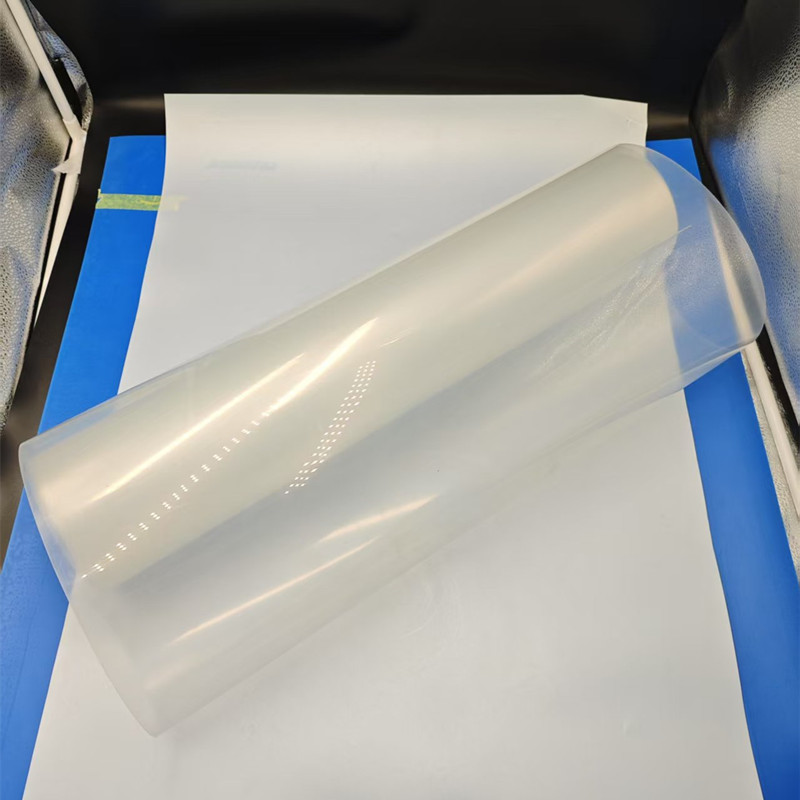

One of the key advantages of our Clear PP Thermoforming Sheet is its remarkable thermoformability. Unlike some traditional transparent PP sheets that rely on nucleating agents and have high melting temperatures, our sheet softens at a relatively lower temperature. This property provides a broad thermo - formable temperature range. Manufacturers can easily shape the sheet into various complex forms, from the simple trays for bakery items to the intricate clamshells for consumer goods. The ease of thermoforming not only reduces production time but also allows for greater design flexibility, enabling the creation of unique packaging shapes that can attract consumers on the shelves.

During the thermoforming process, our Clear PP Thermoforming Sheet maintains its fine structure while crystallization progresses. This results in a sheet that combines high transparency with a rigidity comparable to general PP materials. The rigid nature of the formed products ensures that they can withstand handling, stacking, and transportation without deformation. In food packaging, it can hold the weight of the food contents without sagging, and in industrial applications like electronic component trays, it provides reliable protection to the sensitive components from external pressure.