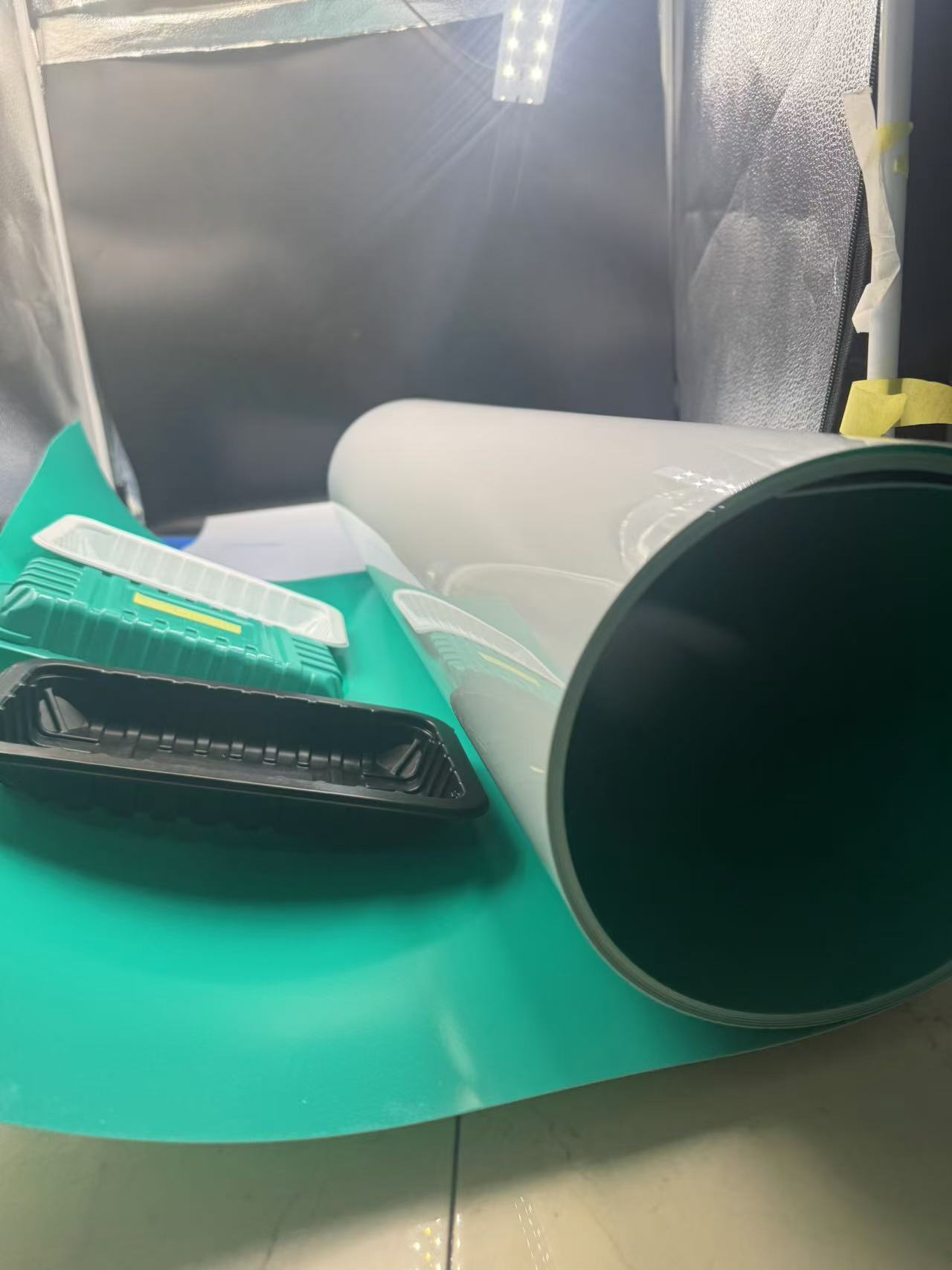

Unveiling the Properties of Dual-Color PP Film and Its Role in Food and Tableware Blister Packaging

2025-03-17 16:38Introduction: The Evolution of PP Film in Packaging

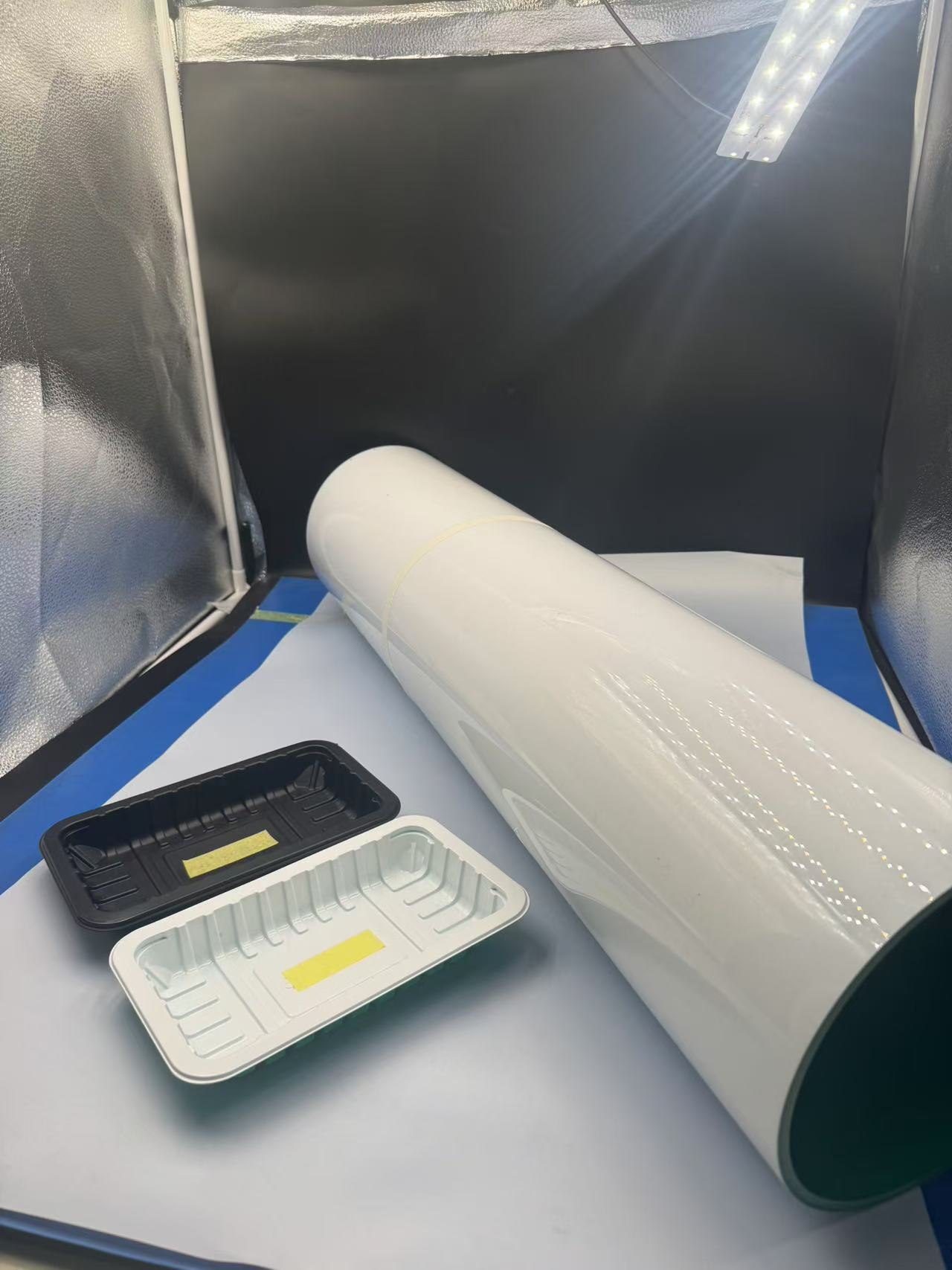

In the ever-evolving landscape of packaging materials, polypropylene (PP) film has long been a stalwart, valued for its versatility and resilience. Among its many iterations, dual-color PP film stands out as a specialized innovation, blending aesthetic appeal with functional excellence. This thermoplastic marvel has found a particularly compelling niche in the realm of food and tableware blister packaging, where it meets the demands of safety, durability, and visual allure. This article explores the distinctive characteristics of dual-color PP film and delves into how it transforms the packaging of food and disposable tableware, offering a detailed, evidence-based narrative enriched with vivid examples.

Section 1: Decoding the Core Properties of Dual-Color PP Film

To understand why dual-color PP film excels in blister packaging, we must first examine its inherent properties. Polypropylene, a polymer formed from propylene monomers, is renowned for its balance of strength and flexibility. The dual-color variant takes this a step further by incorporating two distinct color layers into a single film, achieved through co-extrusion or lamination processes. Let’s break down its key attributes:

Aesthetic Versatility

The defining feature of dual-color PP film is its two-tone design—think of a sleek black base paired with a vibrant red top layer, or a calming white offset by a translucent blue. This visual duality allows manufacturers to create packaging that stands out on shelves, signaling quality and brand identity without additional printing costs.Mechanical Resilience

PP film is inherently tough, with a high resistance to tearing and puncturing. The dual-color version retains this strength, ensuring that blister packs can protect fragile contents—like delicate pastries or plastic cutlery—against the rigors of transport and handling. It’s the kind of durability that withstands a bumpy delivery truck ride without compromise.

Thermal Resistance

With a melting point ranging from 130°C to 171°C, dual-color PP film can endure moderate heat, making it suitable for food packaging that might encounter warm environments, such as freshly baked goods or microwavable trays. This thermal stability ensures that the film maintains its shape and integrity under stress.Chemical Inertness

PP film resists reactions with oils, fats, and acids commonly found in food. This property is critical for blister packaging, where contact with greasy snacks or acidic sauces is routine. Dual-color PP film keeps its structure intact, preventing leaks or contamination that could spoil the product.Lightweight and Cost-Effective

Despite its robust qualities, PP film remains lightweight, reducing shipping costs and material use. The dual-color process adds visual value without significantly increasing expense, making it an economical choice for mass-produced food and tableware packaging.

These properties position dual-color PP film as a standout material, but its real impact comes to life in the context of blister packaging applications.

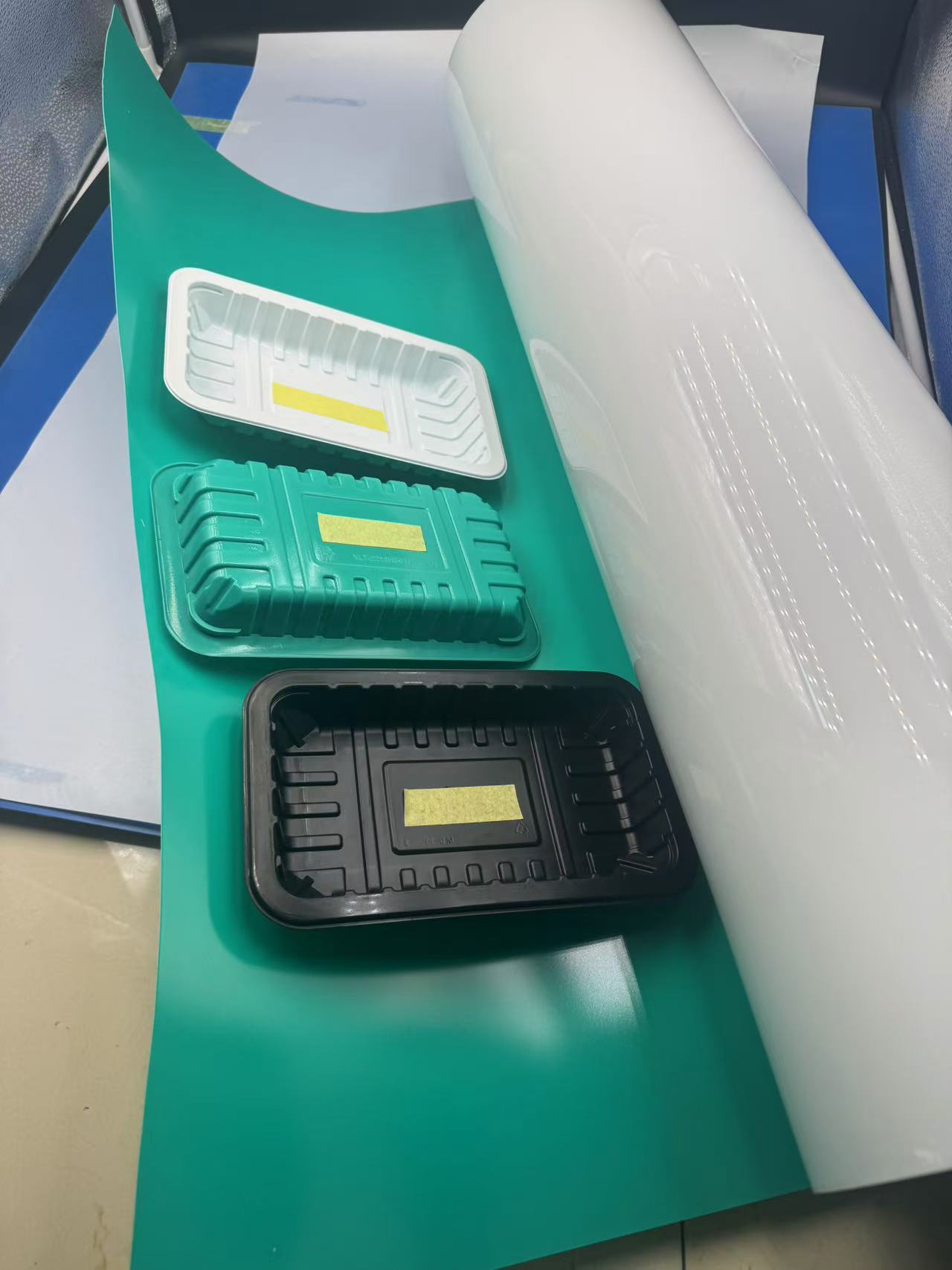

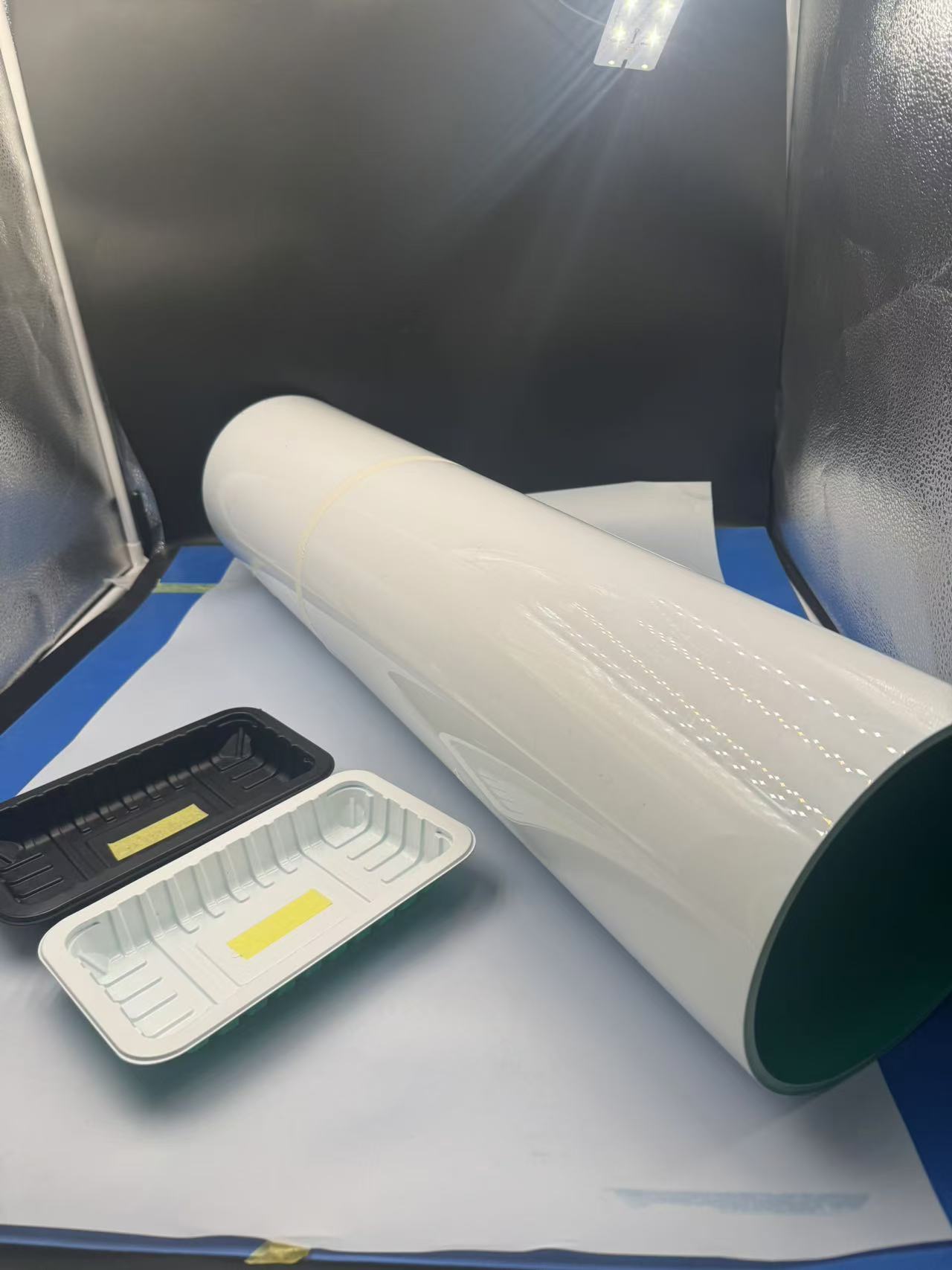

Section 2: The Anatomy of Food and Tableware Blister Packaging

Imagine a supermarket aisle: rows of neatly packaged sandwiches, fruit cups, and disposable spoons, each nestled in a molded plastic tray sealed with a protective film. This is the world of blister packaging—a method that encases products in a pre-formed cavity, often sealed with a lidding film or foil. For food, blister packs preserve freshness and portion control; for tableware, they ensure hygiene and convenience. Dual-color PP film plays a starring role here, offering both form and function in a single material.

Historically, materials like PVC or PET dominated blister packaging. However, dual-color PP film has surged in popularity, thanks to its unique blend of practicality and eye-catching design. The process of shaping it—typically through thermoforming—further showcases its strengths.

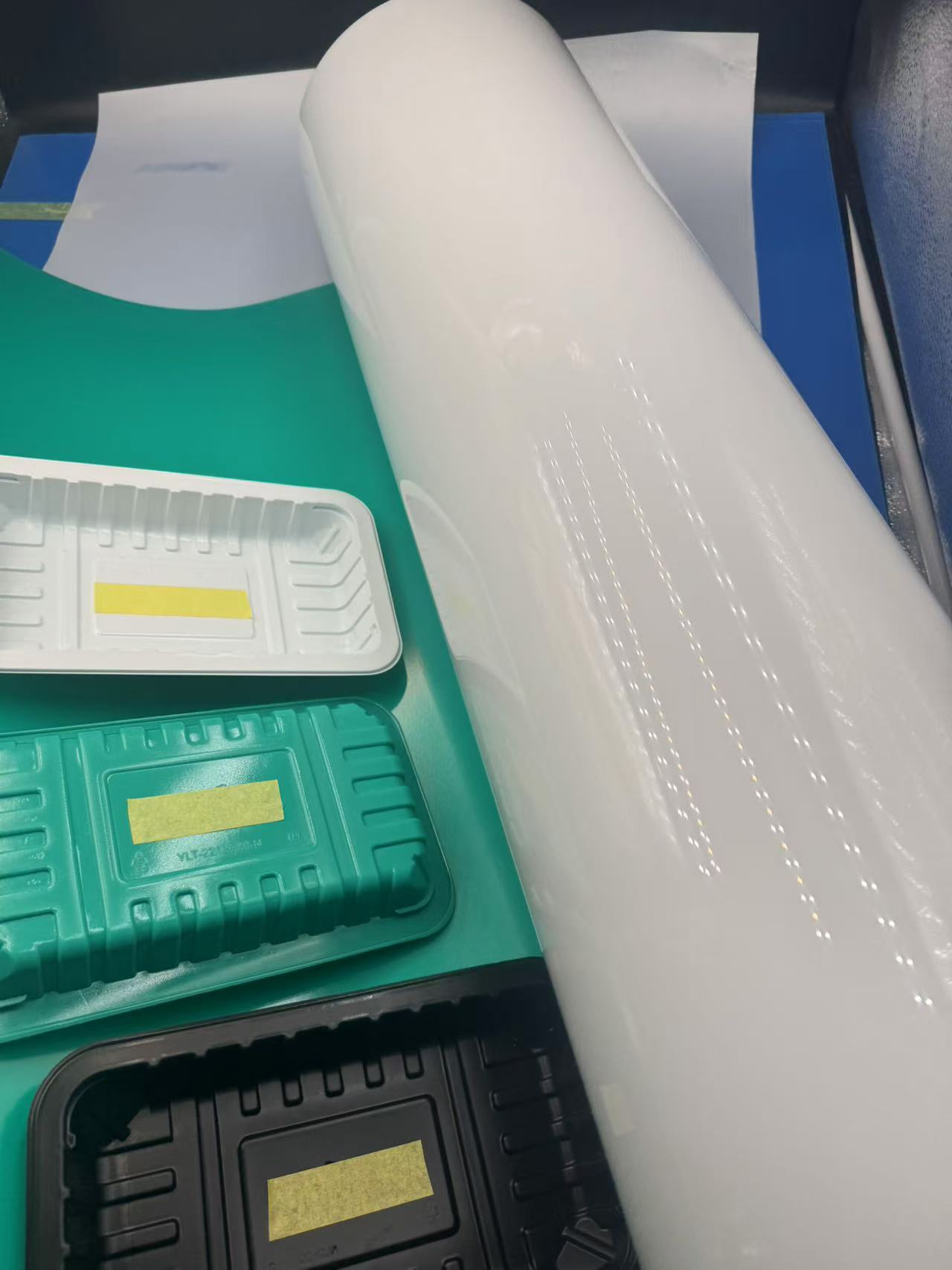

Section 3: Dual-Color PP Film in Thermoforming Blister Packs

Thermoforming involves heating a plastic sheet until it’s pliable, then molding it into a specific shape using vacuum or pressure. Dual-color PP film thrives in this process, and here’s how:

Precision Molding

When heated, PP film softens uniformly, allowing it to stretch into detailed molds—think of a tray with perfectly contoured slots for forks or a snug compartment for a sushi roll. The dual-color layering remains intact, ensuring the finished product retains its striking two-tone look.Shape Retention

Once cooled, dual-color PP film holds its form with minimal warping. This stability is vital for blister packs that must stack efficiently or fit into automated dispensing systems. Picture a stack of meal-prep trays; any distortion could disrupt the workflow, but PP film keeps everything aligned.

Smooth Finish

The surface of PP film is naturally glossy, reducing friction and making it easy to remove contents. For tableware, this means a spoon slides out cleanly; for food, it ensures a pastry lifts away without sticking. This smoothness also simplifies cleaning for reusable designs.

Through thermoforming, dual-color PP film evolves from a flat sheet into a tailored packaging solution, marrying practicality with visual flair.

Section 4: Practical Benefits of Dual-Color PP Film in Food and Tableware Packaging

The advantages of dual-color PP film go beyond the lab—they’re tangible in everyday use. Here’s how it enhances food and tableware blister packs:

Enhanced Product Appeal

The dual-color design elevates packaging from utilitarian to striking. A salad in a green-and-white PP film tray suggests freshness, while a black-and-gold pack for premium cutlery hints at sophistication. This visual boost draws consumers in, often without the need for extra labels.Protection and Hygiene

For food, PP film’s toughness shields against physical damage and contamination. Imagine a tray of cupcakes surviving a crowded grocery cart unscathed. For tableware, it ensures utensils remain sterile until use—crucial for on-the-go dining or medical settings.

Heat and Moisture Resistance

Dual-color PP film handles warm or oily foods without softening or degrading. A hot sandwich wrapped in a PP film blister stays secure, its oils contained. This reliability extends shelf life and maintains quality, a win for both producers and consumers.Lightweight Efficiency

The low weight of PP film reduces transport costs—a boon for bulk shipments of disposable forks or pre-packed meals. Workers handling trays also benefit from the ease of movement, especially in fast-paced kitchens or warehouses.Sustainability Potential

While not as recyclable as PET, PP film can be reused or repurposed in some systems. Forward-thinking companies are exploring ways to recycle dual-color PP film, aligning with the push for greener packaging solutions.

These benefits illustrate why dual-color PP film is more than a material—it’s a practical ally in the world of food and tableware.

Section 5: Comparing Dual-Color PP Film to Other Materials

To gauge its value, let’s pit dual-color PP film against alternatives like PVC and PET, common players in blister packaging:

PP Film vs. PVC

PVC is flexible and cheap, but it’s less eco-friendly and can release harmful chemicals when heated. Dual-color PP film offers safer food contact and a premium look, outshining PVC in both sustainability and aesthetics.

PP Film vs. PET

PET excels in clarity and recyclability, but it lacks the inherent flexibility of PP film. For tableware that needs to flex slightly—like a tray of bendable straws—PP film has the edge. Its dual-color feature also gives it a design advantage over PET’s typically single-tone appearance.

Dual-color PP film strikes a unique balance, offering durability, flexibility, and style that rivals can’t fully match.

Section 6: Real-World Applications and Scenarios

Let’s bring this to life with some vivid, realistic examples:

The Bakery Chain

A regional bakery uses dual-color PP film trays (brown and cream) to package muffins. The film’s heat resistance keeps the trays intact during cooling, while the two-tone design highlights the brand’s rustic charm. Customers notice—and sales rise.The Fast-Food Outlet

A chain opts for black-and-yellow PP film blisters to pack plastic cutlery sets. The durability ensures utensils stay pristine during delivery, and the bold colors reinforce the brand’s vibrant identity, making every meal kit pop.The Meal Prep Startup

A health-food company chooses green-and-clear PP film for pre-portioned salads. The film’s oil resistance prevents dressing leaks, and the dual colors signal freshness and transparency—key values for their eco-conscious clientele.

These cases show how dual-color PP film adapts to diverse needs, enhancing both utility and appeal.

Section 7: Challenges and Innovations Ahead

Dual-color PP film isn’t flawless. Its recycling lags behind PET, and the co-extrusion process can raise production costs slightly. Environmentalists also push for biodegradable options. Yet, the future looks promising—advances like recyclable PP blends or bio-based PP film could address these hurdles, keeping it competitive in a green-focused market.

Conclusion: Dual-Color PP Film as a Packaging Powerhouse

From its striking two-tone design to its robust performance, dual-color PP film redefines blister packaging for food and tableware. It protects, preserves, and persuades, all while offering a lightweight, cost-effective solution. As industries seek materials that blend form, function, and sustainability, dual-color PP film stands tall, proving that innovation can be both practical and beautiful—one blister pack at a time.