Unveiling the Potential of Black PP Film in Disposable Cutlery Blister Packaging

2025-03-05 11:55Introduction: The Rise of Black PP Film in Packaging

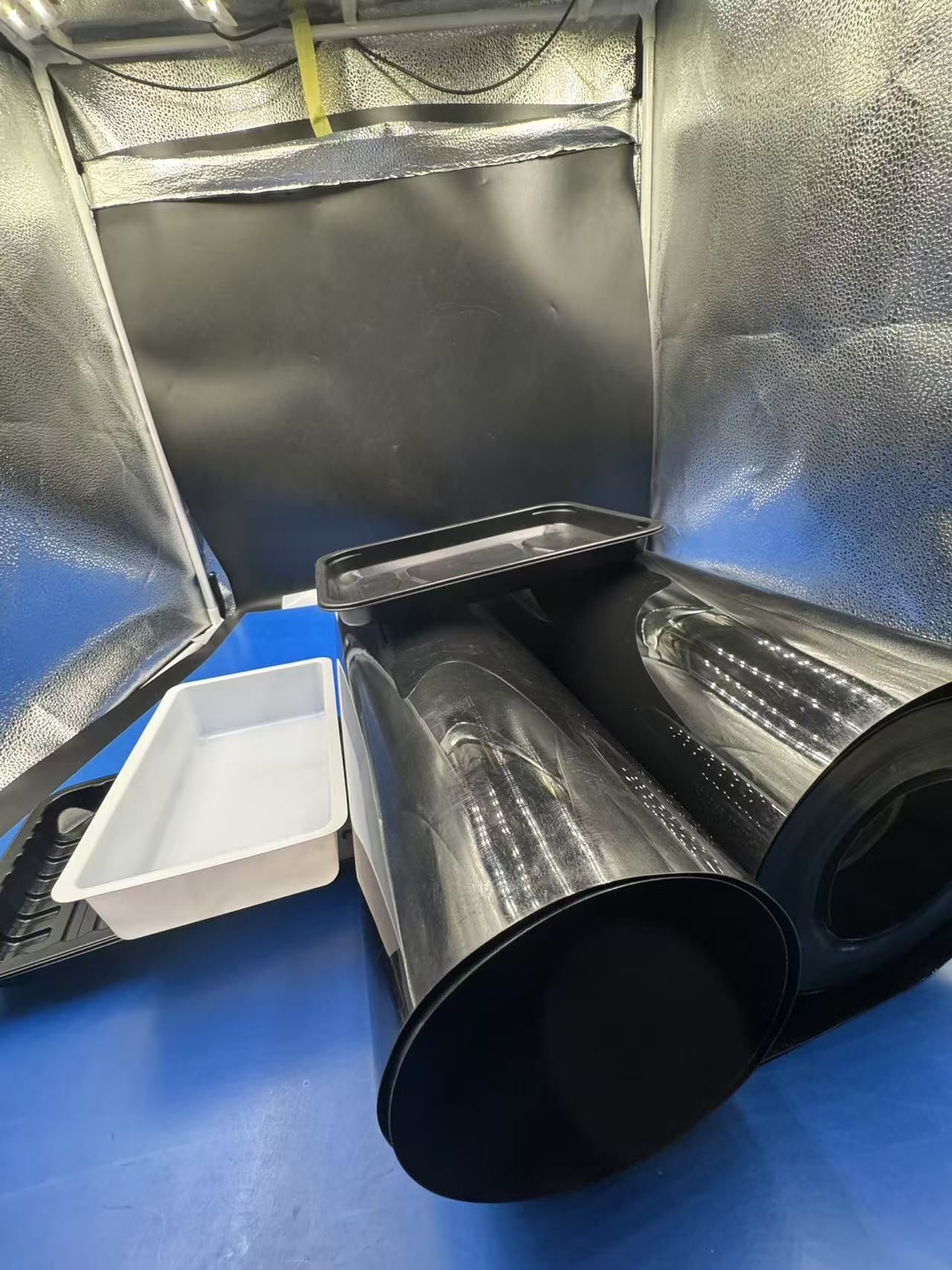

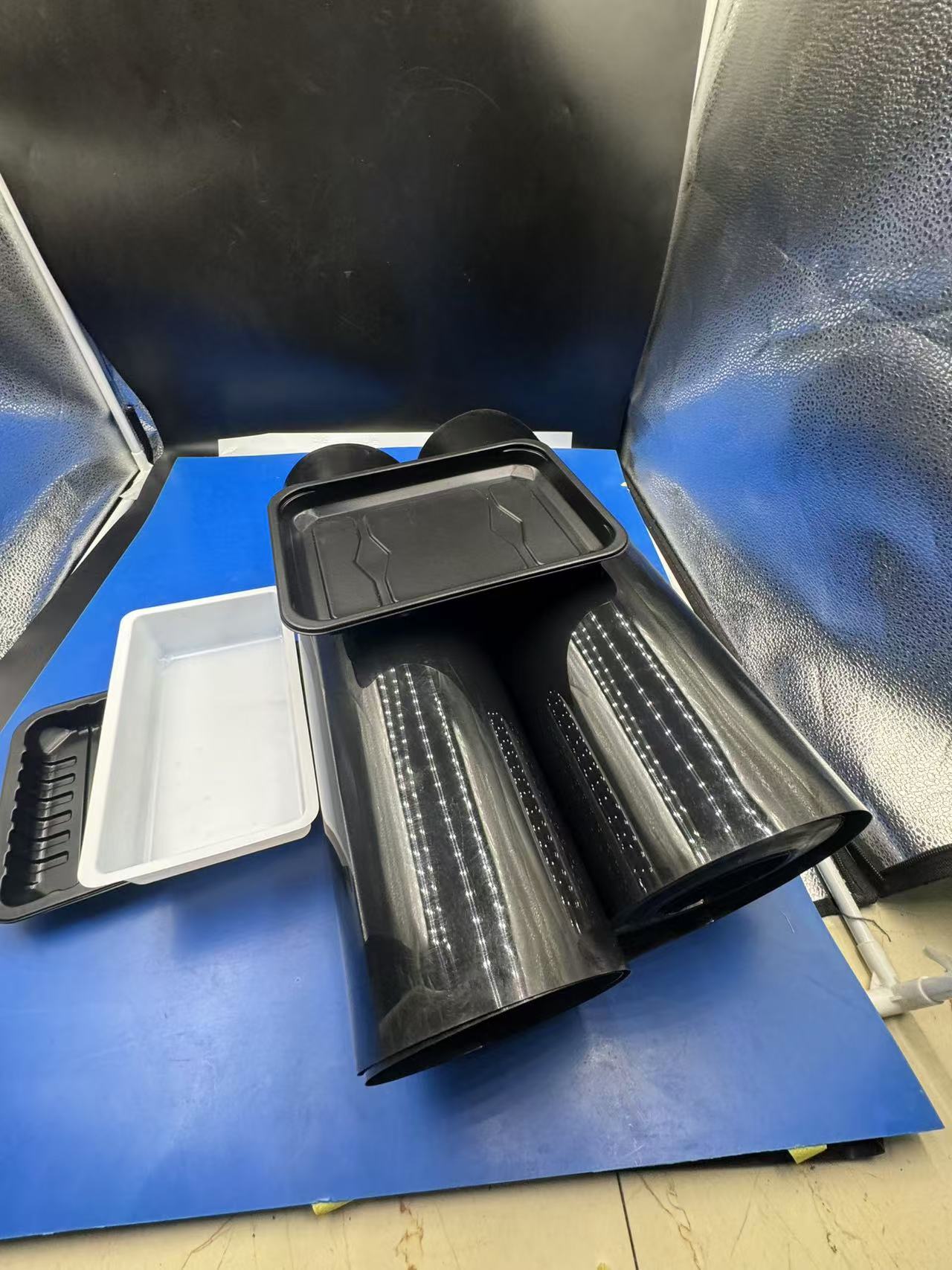

In the ever-evolving world of packaging, materials are constantly being refined to meet the demands of functionality, aesthetics, and sustainability. Among these, black polypropylene (PP) film has emerged as a compelling choice, particularly in the niche of disposable cutlery blister packaging. This versatile thermoplastic, known for its durability, flexibility, and cost-effectiveness, brings a unique blend of practicality and visual appeal to the table—quite literally. Whether it’s a sleek black fork nestled in a transparent tray or a set of utensils elegantly showcased in a retail display, blac k PP film is redefining how we package and perceive single-use cutlery.

k PP film is redefining how we package and perceive single-use cutlery.

This article delves into the characteristics of black PP film, exploring its physical, chemical, and aesthetic properties, and examines its practical applications in blister packaging for disposable cutlery. From its ability to withstand the rigors of thermoforming to its role in enhancing product visibility and protection, black PP film proves to be more than just a packaging material—it’s a solution tailored to modern needs. Over the next several thousand words, we’ll unpack the science behind this material, its manufacturing nuances, and why it’s become a go-to option for cutlery packaging, all while painting a vivid picture of its real-world impact.

Section 1: Understanding the Core Characteristics of Black PP Film

Polypropylene, or PP, is a thermoplastic polymer renowned for its versatility across industries, from automotive components to food containers. When pigmented black and extruded into a thin, flexible film—herein referred to as black PP film—it takes on a distinct set of characteristics that make it particularly suited for blister packaging. Let’s break these down into key categories: physical properties, chemical resistance, thermal behavior, and aesthetic appeal.

1.1 Physical Properties: Strength Meets Flexibility

Black PP film boasts an impressive balance of strength and flexibility, a duo that’s critical for blister packaging. With a tensile strength typically ranging from 20 to 40 MPa (depending on thickness and processing conditions), it can endure the mechanical stresses of forming and sealing without tearing or cracking. This robustness ensures that a blister pack made from black PP film can securely cradle a plastic spoon or knife, protecting it from damage during transport or handling. contoured to hold a fork’s tines or a knife’s blade. This adaptability is due to PP’s semi-crystalline structure, which provides a degree of elasticity while maintaining structural integrity. Compared to rigid materials like polystyrene (PS), black PP film offers a softer, more forgiving texture that resists brittleness, making it less prone to shattering under impact.

1.2 Chemical Resistance: A Shield Against the Elements

One of the standout features of black PP film is its resistance to a wide range of chemicals. Unlike some plastics that degrade when exposed to oils or solvents, PP remains largely inert. This property is particularly valuable in disposable cutlery packaging, where utensils might come into contact with greasy residues, cleaning agents, or even food-grade sanitizers during production or storage. For instance, a set of black PP film-packaged forks stored in a warehouse won’t suffer from discoloration or weakening if accidentally splashed with a mild detergent—unlike PVC, which might soften or leach plasticizers under similar conditions.

This chemical stability also extends to moisture resistance. Black PP film exhibits a low water vapor transmission rate (WVTR), typically around 0.20 g/m²/day for a 12-mil thickness, making it an effective barrier against humidity. In the context of cutlery, this means the packaging can prevent rust on metal-hybrid utensils or maintain the integrity of biodegradable plastic forks in damp environments, ensuring they reach the consumer in pristine condition.

1.3 Thermal Behavior: Precision in Thermoforming

Thermoforming is the heartbeat of blister packaging, and black PP film excels in this arena despite its narrow processing window. PP’s melting point hovers around 160–170°C (320–338°F), allowing it to soften just enough to be molded without degrading. However, its thermoforming temperature range is tighter than that of PVC, requiring precise control—typically between 130–150°C—to avoid warping or uneven stretching. This challenge is offset by the material’s ability to cool rapidly once formed, locking in the shape of the blister cavities with minimal shrinkage.

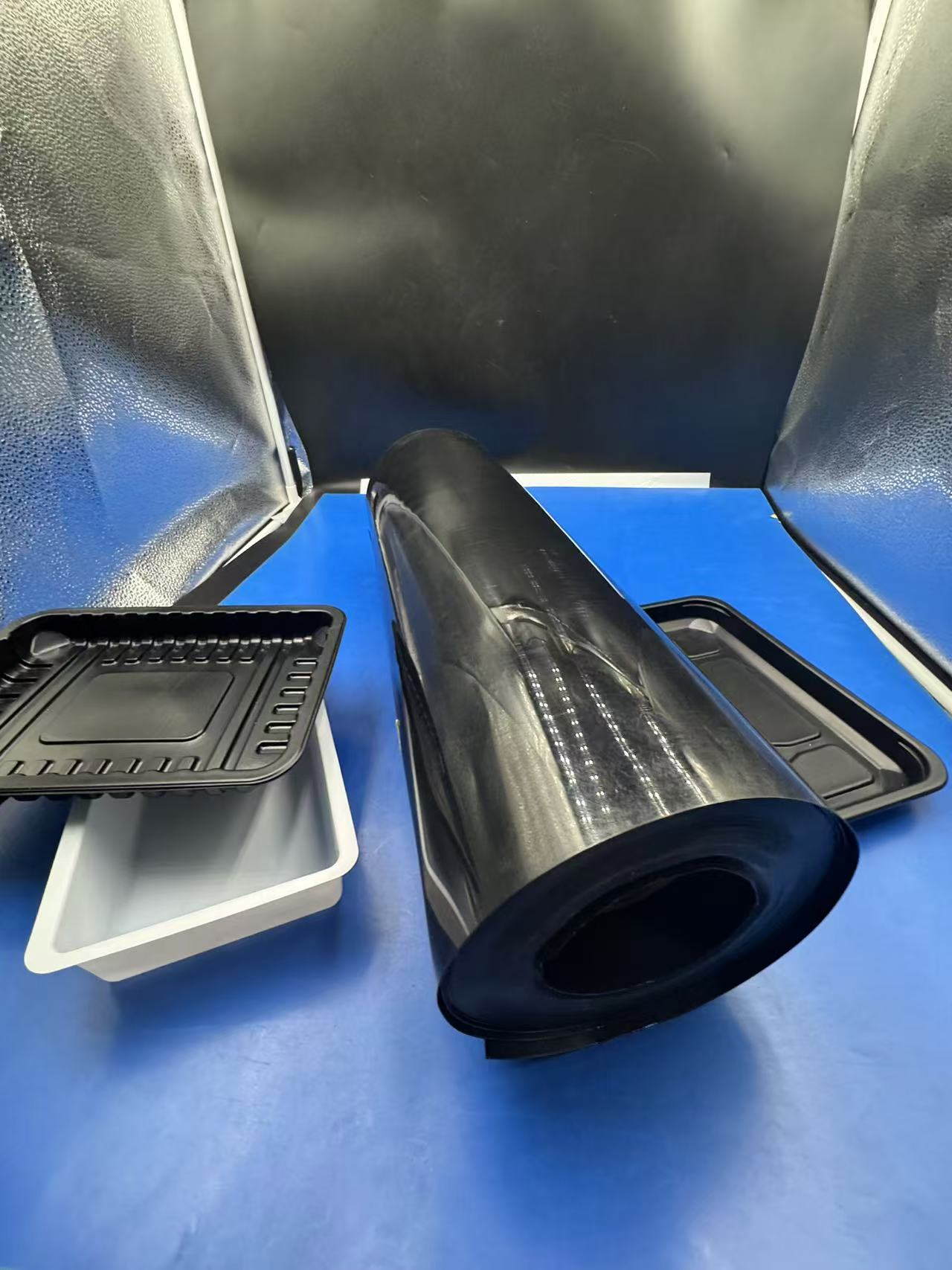

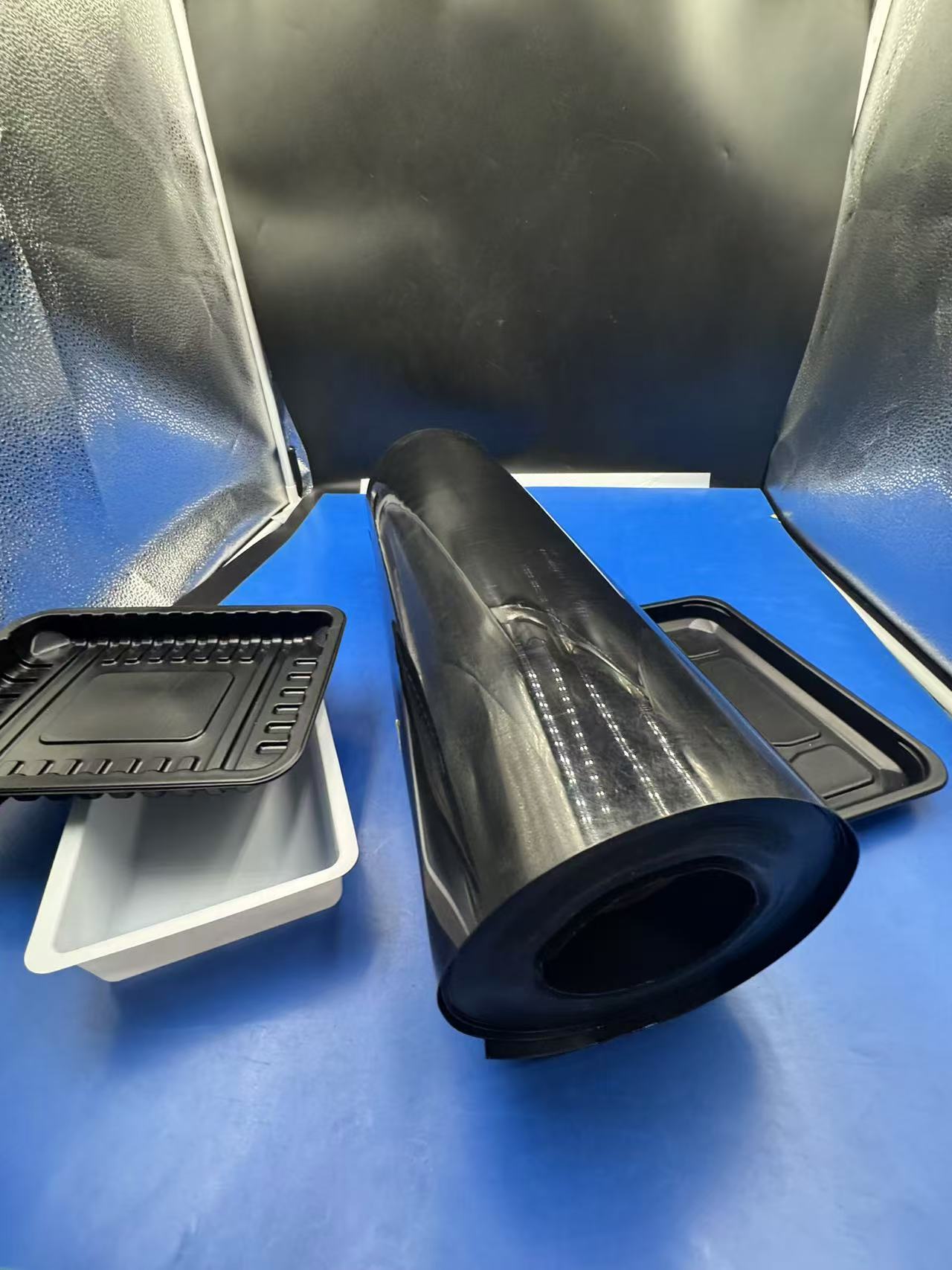

Picture a production line: a roll of black PP film feeds into a heating chamber, where infrared lamps bring it to a pliable state. It’s then sucked into a mold by vacuum pressure, forming pockets that snugly fit a disposable spoon. The black hue absorbs heat uniformly, reducing the risk of hot spots that could weaken the film. This thermal consistency is a boon for manufacturers, ensuring each blister pack maintains a uniform thickness—often reduced from 250 μm to 50–100 μm in deep-drawn areas—while retaining its protective qualities.

1.4 Aesthetic Appeal: The Allure of Black

The black pigmentation of PP film isn’t just a functional choice; it’s a statement. In a sea of transparent or white packaging, black PP film stands out, offering a sleek, modern aesthetic that elevates the perceived value of disposable cutlery. The deep, opaque color contrasts sharply with the often-light hues of plastic utensils, making them pop visually on store shelves. Imagine a pack of white plastic forks encased in a black PP film blister— the stark contrast draws the eye, suggesting sophistication and quality.

Moreover, the black color can mask minor imperfections or dust that might settle on the film during production, maintaining a clean, polished look. This opacity also provides a degree of UV protection, shielding light-sensitive additives in biodegradable cutlery from degradation. While not as impermeable to light as aluminum foil, black PP film strikes a balance between cost, aesthetics, and functionality, making it a practical choice for retail display.