The Versatile World of PP Film: Properties and Applications

2025-09-26 17:10The Versatile World of PP Film: Properties and Applications

Exploring the Characteristics and Diverse Uses of PP Film

Keywords: PP film, food blister packaging, disposable tableware packaging, antistatic packaging, polypropylene

Introduction to PP Film

Polypropylene (PP) film, a versatile thermoplastic polymer, has become a cornerstone in modern packaging and industrial applications due to its exceptional properties. Derived from propylene monomers, PP film is widely recognized for its durability, flexibility, and costeffectiveness. This article delves into the intrinsic characteristics of PP film and explores its extensive applications in food blister packaging, disposable tableware packaging, and antistatic packaging, providing a comprehensive understanding of why this material is indispensable in various industries.

Characteristics of PP Film

PP film boasts a unique combination of physical, chemical, and mechanical properties that make it a preferred choice across multiple sectors. Below are the key characteristics that define its utility:

1. High Tensile Strength and Durability: PP film exhibits excellent tensile strength, allowing it to withstand significant stress without tearing or deforming. This durability ensures that PP film maintains its integrity during transportation, storage, and handling, making it ideal for packaging applications where robustness is essential.

2. Chemical Resistance: PP film is highly resistant to a wide range of chemicals, including acids, alkalis, and organic solvents. This property ensures that the film remains stable when exposed to various substances, making it suitable for packaging food, pharmaceuticals, and other sensitive products.

3. Thermal Stability: With a melting point ranging from 130°C to 171°C, PP film can withstand high temperatures, making it suitable for applications involving heat sealing or sterilization processes. Its ability to maintain structural integrity under heat is particularly valuable in food packaging.

4. Transparency and Clarity: PP film can be manufactured with excellent optical clarity, allowing consumers to view the packaged product clearly. This is particularly advantageous in food blister packaging, where visual appeal drives consumer purchasing decisions.

5. Flexibility and Lightweight: PP film is lightweight yet flexible, enabling it to be molded into various shapes and sizes. This adaptability makes it an excellent choice for creating intricate packaging designs, such as blister packs or trays for disposable tableware.

6. Moisture Resistance: PP film is inherently resistant to moisture, preventing water ingress that could compromise the quality of packaged goods. This characteristic is critical for food packaging, where maintaining freshness and preventing spoilage are paramount.

7. AntiStatic Properties: Through specialized additives, PP film can be engineered to exhibit antistatic properties, reducing the accumulation of static electricity. This makes it ideal for packaging sensitive electronic components, where static discharge could cause damage.

8. Recyclability: PP film is recyclable, aligning with the growing demand for sustainable packaging solutions. Its ability to be repurposed reduces environmental impact, making it a preferred choice for ecoconscious industries.

Applications of PP Film

The remarkable properties of PP film enable its use in a wide array of applications. Below, we explore three key areas where PP film plays a pivotal role: food blister packaging, disposable tableware packaging, and antistatic packaging.

1. PP Film in Food Blister Packaging

Food blister packaging is a popular method for presenting and protecting food products, such as fresh produce, deli items, and readytoeat meals. PP film is a preferred material for this application due to its unique combination of clarity, strength, and barrier properties.

Enhanced Product Visibility: The transparency of PP film allows consumers to inspect the quality and freshness of food items, enhancing trust and appeal. For example, in supermarkets, PP film blister packs are used to display sliced meats, cheeses, or fruits, showcasing their vibrant colors and textures.

Barrier Protection: PP film provides an effective barrier against moisture, oxygen, and contaminants, extending the shelf life of perishable goods. For instance, in seafood packaging, PP film prevents moisture loss, ensuring the product remains fresh during transportation and storage.

HeatSealing Capabilities: The thermal stability of PP film makes it ideal for heatsealed blister packs. This ensures a tamperevident seal, which is crucial for maintaining food safety and consumer confidence. For example, prepackaged salads or meal kits often rely on PP film for secure sealing.

Case Study: Consider a manufacturer producing precut vegetable packs. By using PP film for blister packaging, the company ensures that the vegetables remain fresh, visually appealing, and protected from external contaminants. The film's lightweight nature also reduces transportation costs, while its recyclability aligns with sustainable packaging trends.

2. PP Film in Disposable Tableware Packaging

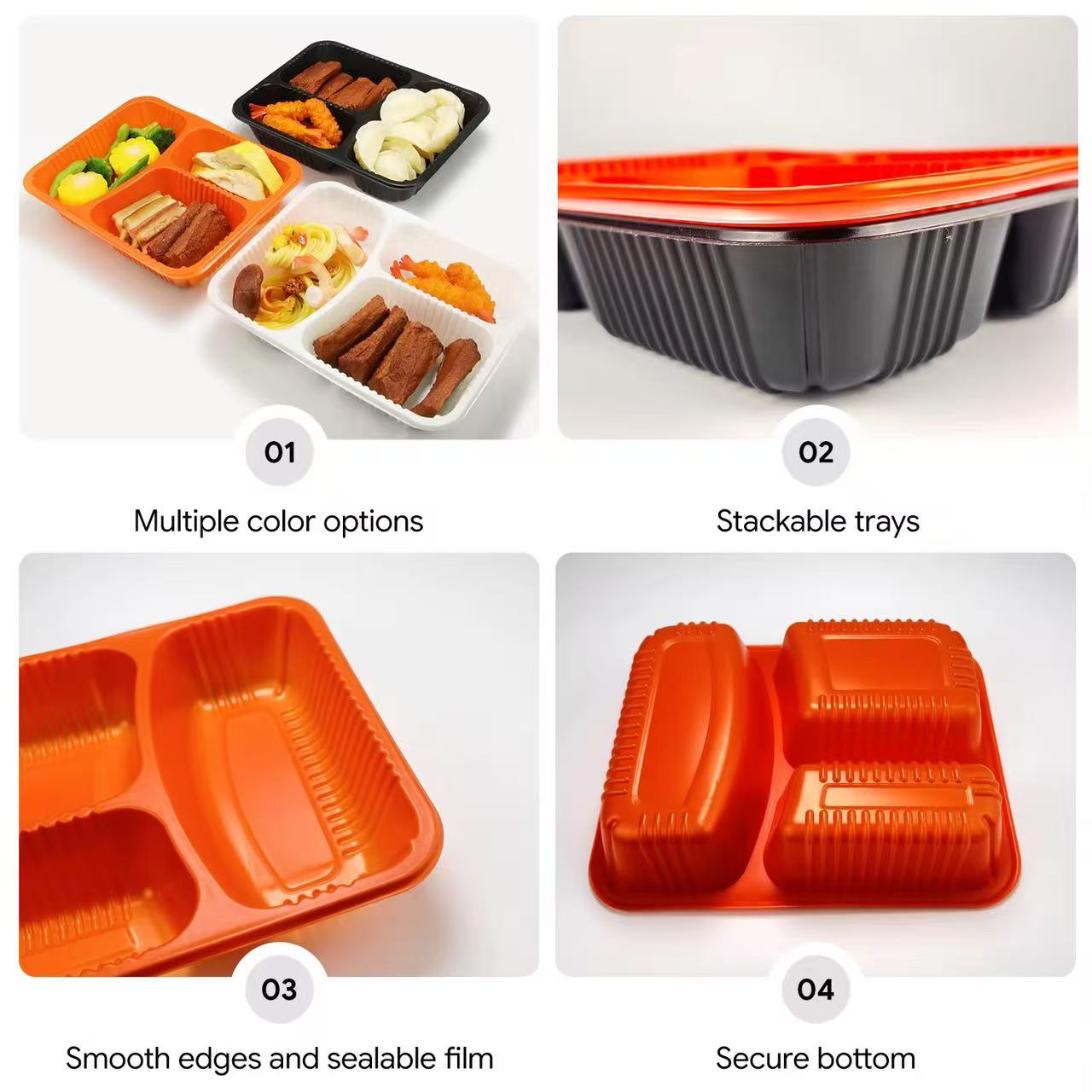

Disposable tableware, such as plates, cups, and cutlery, is widely used in fastfood restaurants, catering services, and household settings. PP film is extensively employed in packaging these items due to its flexibility, durability, and costeffectiveness.

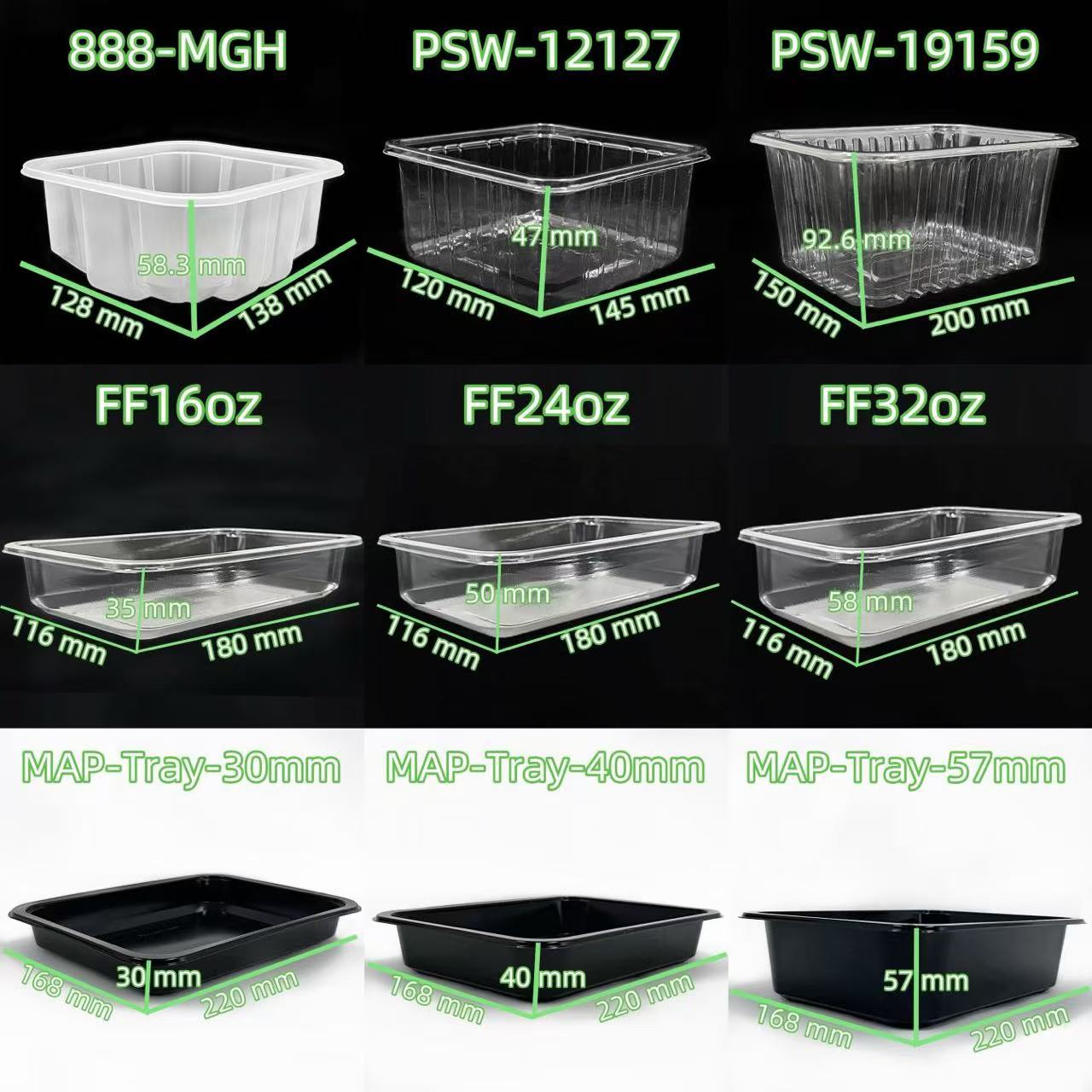

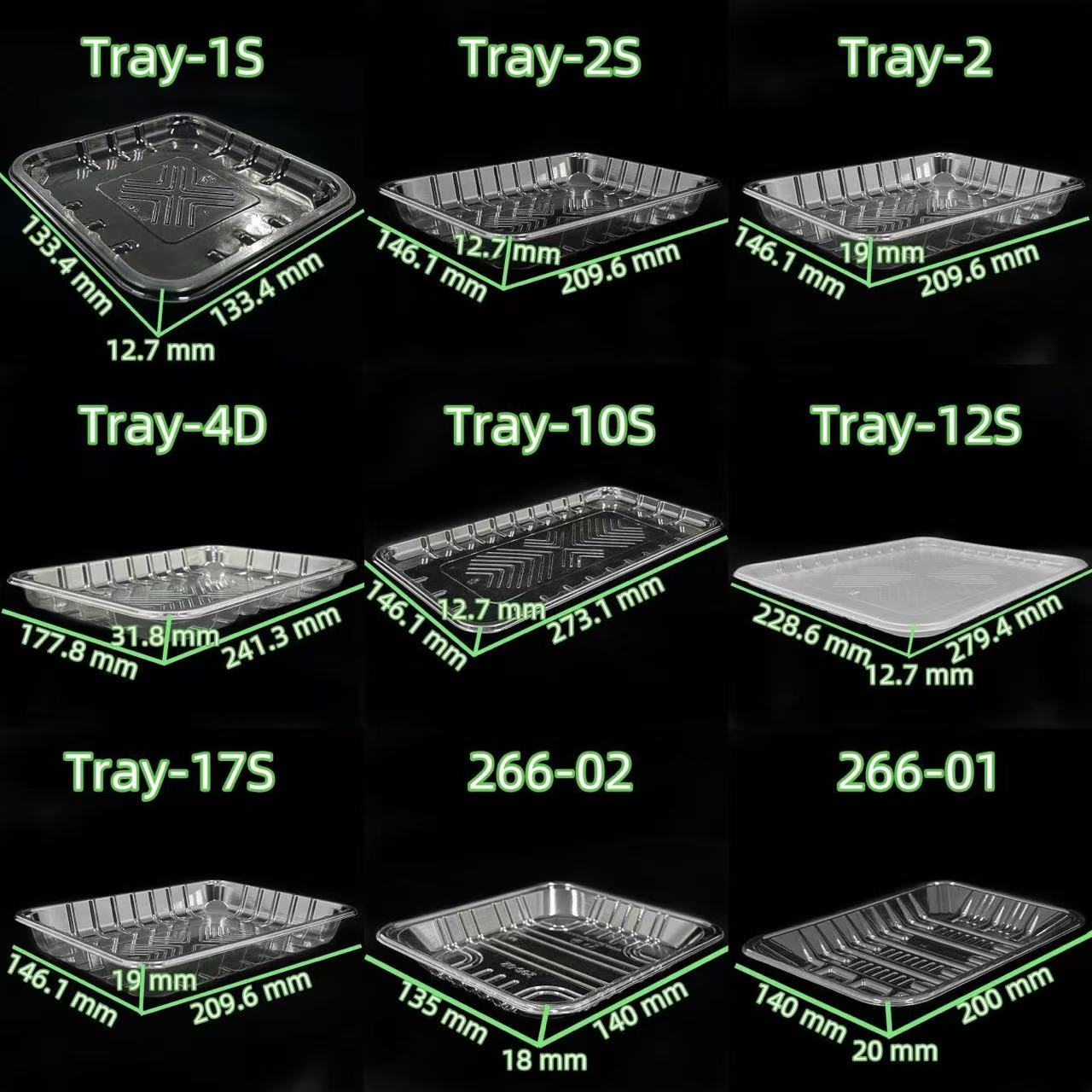

Customizable Packaging Solutions: PP film can be easily molded into trays, lids, or wraps, accommodating the diverse shapes and sizes of disposable tableware. For instance, PP film trays are used to package stacks of plastic cups, ensuring they remain intact during shipping and display.

Hygiene and Safety: The chemical resistance and moisture barrier properties of PP film ensure that disposable tableware remains hygienic and free from contamination. This is particularly important for singleuse items, where cleanliness is a top priority.

CostEffectiveness: PP film is an economical choice for packaging disposable tableware, allowing manufacturers to keep production costs low while maintaining highquality standards. This affordability benefits both producers and consumers in the competitive foodservice industry.

RealWorld Example: A fastfood chain supplying disposable cutlery sets uses PP film to create vacuumformed trays that securely hold forks, knives, and spoons. The film's durability prevents damage during transit, while its clarity allows customers to see the contents, enhancing the overall user experience.

3. PP Film in AntiStatic Packaging

In industries such as electronics and semiconductors, static electricity poses a significant risk to sensitive components. PP film, when treated with antistatic additives, becomes an ideal material for protecting these products.

Static Dissipation: Antistatic PP film is designed to dissipate static charges, preventing damage to delicate electronic components like circuit boards or microchips. This is achieved by incorporating conductive additives during the manufacturing process, ensuring consistent performance.

Durability and Protection: The tensile strength of PP film ensures that it can withstand the rigors of handling and transportation, protecting electronic components from physical damage. Its moisture resistance further safeguards against corrosion caused by humidity.

Versatility in Design: Antistatic PP film can be used to create bags, trays, or covers tailored to specific electronic components. For example, PP film bags are commonly used to store and transport hard drives, ensuring they remain free from static interference.

Industry Application: In the semiconductor industry, PP film is used to package integrated circuits in antistatic trays. These trays not only prevent static discharge but also provide a secure fit, reducing the risk of movementrelated damage during shipping.

Advantages of PP Film in Modern Industries

The widespread adoption of PP film across these applications highlights its numerous advantages:

Versatility: PP film's ability to be tailored for specific needs, such as transparency for food packaging or antistatic properties for electronics, makes it a versatile material across industries.

CostEffectiveness: Compared to alternatives like PVC or PET, PP film offers a costeffective solution without compromising on quality, making it accessible for both small and largescale manufacturers.

Sustainability: The recyclability of PP film aligns with global efforts to reduce plastic waste. Many companies are now incorporating recycled PP film into their packaging processes, contributing to a circular economy.

Consumer Appeal: The clarity and aesthetic qualities of PP film enhance product presentation, driving consumer interest and sales, particularly in the food and retail sectors.

Challenges and Future Trends

While PP film is highly versatile, it is not without challenges. For instance, its production relies on fossil fuels, raising concerns about environmental impact. However, advancements in biobased polypropylene and improved recycling technologies are addressing these issues. Additionally, the development of biodegradable PP film variants is gaining traction, offering a sustainable alternative for ecoconscious markets.

Looking ahead, the demand for PP film is expected to grow, driven by increasing needs in food packaging, ecommerce, and electronics. Innovations in additive technologies, such as enhanced antistatic properties or improved barrier coatings, will further expand its applications. Moreover, as sustainability becomes a priority, manufacturers are likely to invest in greener production methods and recyclable PP film solutions.