Characteristics and Versatile Applications of Protective Film Coated Transparent PET Film

2025-09-01 17:23IntroductionPolyethylene Terephthalate (PET) film, particularly when coated with a protective layer, is a cornerstone material in modern packaging due to its exceptional physical, chemical, and mechanical properties. Known for its clarity, durability, and versatility, PET protective film has become a preferred choice across industries, from food packaging to electronics. The addition of a protective coating, often acrylic or silicone-based, enhances its functionality, making it ideal for applications such as PET fold boxes, food blister packaging, disposable cutlery packaging, and antistatic packaging. This article explores the characteristics of PET protective film and its diverse applications, highlighting its significance in meeting modern packaging demands with a focus on sustainability, safety, and performance.Characteristics of Protective Film Coated Transparent PET FilmPET protective film is a biaxially oriented polyethylene terephthalate (BoPET) film, typically coated with an adhesive layer (acrylic or silicone) and laminated with a release liner. Its unique properties make it a standout material for packaging applications. Below are its key characteristics:High Transparency and Gloss:

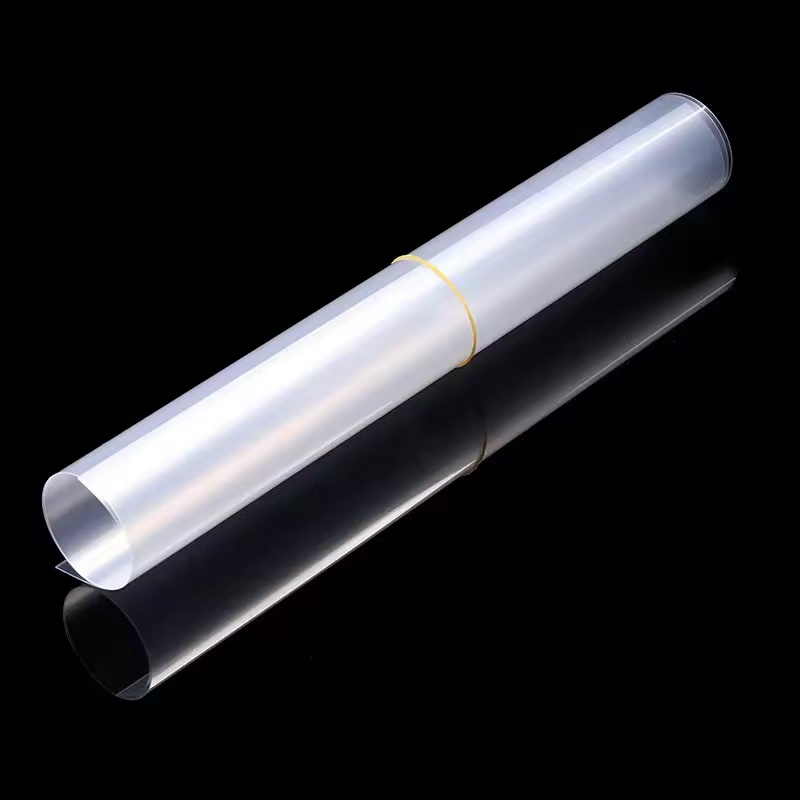

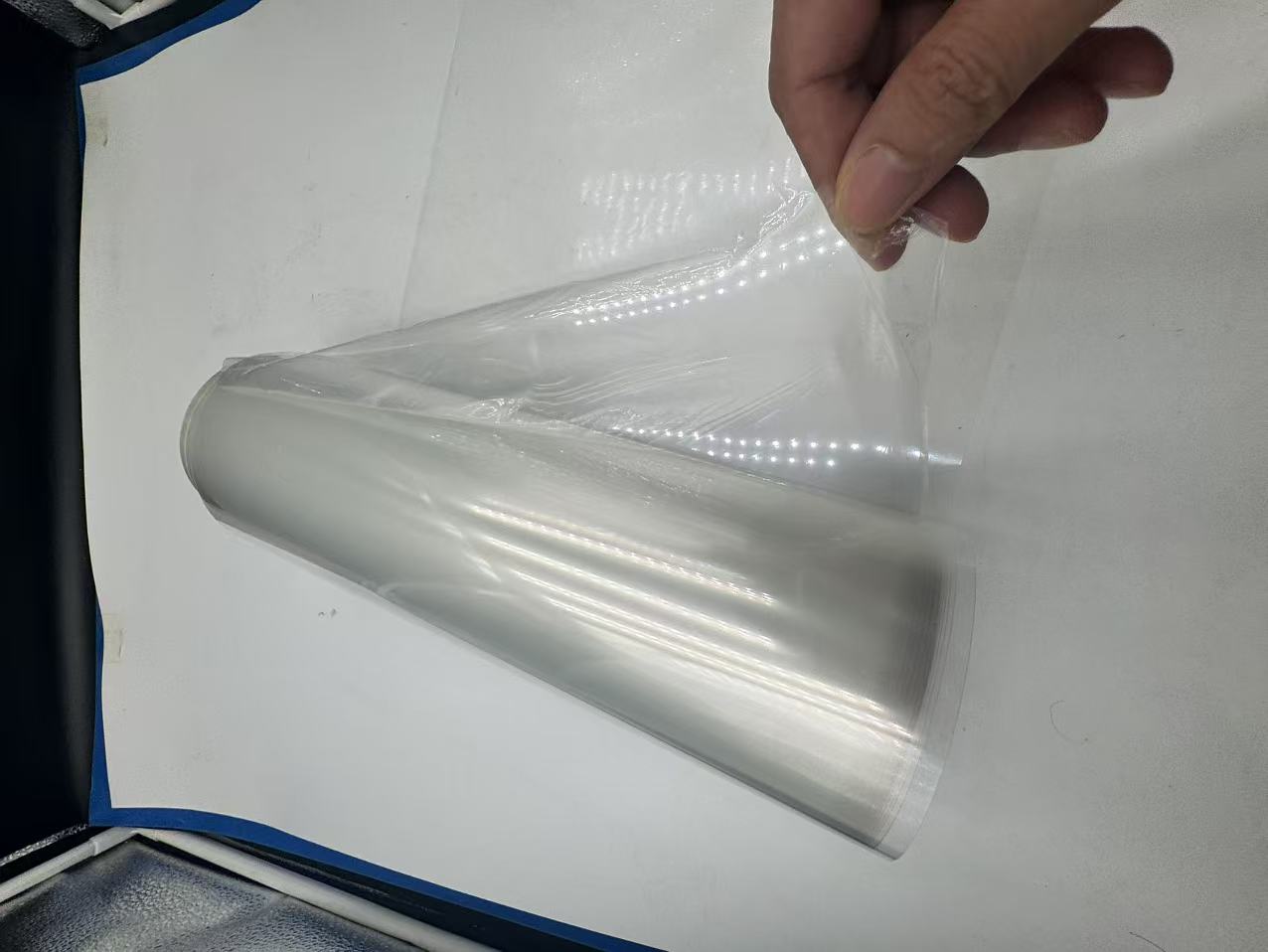

PET protective film is renowned for its crystal-clear transparency and high gloss, which enhance the visual appeal of packaged products. Its optical clarity allows consumers to view the contents clearly, making it ideal for retail packaging where product presentation is critical. The film's glossy surface also improves printability, ensuring vibrant and accurate colors for branding and labeling purposes.

Superior Mechanical Strength:

With a tensile strength 20% higher than polyvinyl chloride (PVC) film, PET protective film is robust and resistant to punctures, tears, and impacts. Its density, approximately 1.35–1.4 g/cm³, contributes to its lightweight yet sturdy nature, making it suitable for protecting products during transportation and storage.

Excellent Barrier Properties:

PET protective film offers good resistance to moisture, oxygen, and other environmental factors, extending the shelf life of perishable goods. When metallized or coated with additional barrier layers, such as low-density polyethylene (LDPE) or polyvinylidene chloride (PVdC), its gas and aroma barrier properties are further enhanced, making it suitable for sensitive food packaging applications.

Chemical and Thermal Stability:

The film exhibits excellent chemical resistance, remaining stable when exposed to alcohols, solvents, and other chemicals. It can withstand a wide temperature range, from -40°C to 220°C, without becoming brittle or deforming, which makes it suitable for both frozen and ovenable packaging.

Fold Resistance and Dimensional Stability:

Unlike PVC, PET protective film does not develop crack creases or stress-whitening when folded, making it ideal for applications requiring repeated flexing, such as fold boxes. Its biaxial orientation ensures dimensional stability, allowing it to maintain its shape under tension during processing, such as printing or thermoforming.

Antistatic and Protective Coatings:

The protective coating, typically acrylic or silicone, enhances the film’s functionality by providing antistatic properties, reducing dust attraction, and protecting surfaces from scratches during handling and transportation. These coatings can be customized to meet specific viscosity requirements, ensuring stable adhesion without residue upon removal.

Recyclability and Environmental Friendliness:

PET protective film is highly recyclable, with a recycling rate of 31% in the U.S. and 52% in Europe. Its inert nature ensures it does not react with packaged contents or degrade biologically, reducing environmental impact. Advances in recycling technologies, such as chemical and mechanical recycling, allow PET to be repurposed into new products, supporting sustainability efforts.

Applications of Protective Film Coated Transparent PET FilmThe versatility of PET protective film enables its use in a wide range of packaging applications. Below, we explore its specific uses in PET fold boxes, food blister packaging, disposable cutlery packaging, and antistatic packaging, with vivid examples to illustrate its practical benefits.1. PET Fold BoxesPET protective film is widely used in the production of PET fold boxes, which are transparent, rigid containers commonly used for retail packaging of cosmetics, electronics, and luxury goods. The film’s high transparency and gloss make it an excellent choice for showcasing products, such as perfumes or high-end confectionery, where visual appeal is paramount. For instance, a luxury chocolate brand might use a PET fold box to display its pralines, with the film’s clarity highlighting the intricate designs of each piece, enticing customers at the point of sale.The film’s fold resistance is critical in this application. Unlike PVC, which may crack when folded, PET protective film maintains its integrity, ensuring that fold boxes retain their shape and clarity even after repeated handling. Its mechanical strength also protects the contents from external impacts, such as during shipping or in-store display. Additionally, the protective coating prevents scratches on the box’s surface, maintaining its pristine appearance throughout the supply chain.

Moreover, PET protective film can be printed with high-quality graphics, allowing brands to incorporate logos, product information, or decorative patterns directly onto the fold box. This enhances brand visibility and consumer engagement. For example, a smartphone accessory packaged in a PET fold box might feature a vibrant, UV-printed design that highlights the product’s features, making it stand out on crowded retail shelves.2. Food Blister PackagingIn food blister packaging, PET protective film is used to create thermoformed trays and blisters for products like fruits, vegetables, meats, and baked goods. Its FDA and USDA-compliant grades ensure safety for direct food contact, while its barrier properties protect against moisture and oxygen, preserving freshness and extending shelf life.

For example, a supermarket might use PET protective film to create blister packs for fresh strawberries. The film’s transparency allows consumers to inspect the fruit’s quality, while its barrier properties prevent moisture loss, keeping the strawberries fresh for longer. The protective coating also ensures that the packaging remains free of scratches, maintaining a clean and professional appearance.The film’s ability to withstand low temperatures makes it suitable for frozen food packaging, such as ready-to-eat meals. Crystallizable PET (CPET), often used in blister packaging, can endure both freezing and oven baking temperatures, allowing consumers to heat their meals directly in the packaging without the need for additional containers. This convenience is exemplified in microwaveable meal trays, where PET protective film ensures safety and functionality.

3. Disposable Cutlery PackagingPET protective film is an ideal material for packaging disposable cutlery, such as plastic forks, knives, and spoons, due to its durability, clarity, and environmental benefits. The film’s high tensile strength protects cutlery from damage during transportation, while its transparency allows consumers to see the product clearly, ensuring trust in its quality.For instance, a fast-food chain might use PET protective film to package sets of disposable cutlery for takeout orders. The film’s protective coating prevents scratches on the cutlery’s surface, maintaining a hygienic and polished appearance. Its lightweight nature reduces shipping costs, and its recyclability aligns with growing consumer demand for sustainable packaging solutions.

The film’s chemical stability ensures it does not react with the cutlery, even under varying environmental conditions, such as high humidity or temperature fluctuations during transport. This makes PET protective film a reliable choice for ensuring that disposable cutlery remains safe and presentable from production to end use.4. Antistatic PackagingIn the electronics industry, PET protective film with antistatic coatings is widely used to package sensitive components, such as circuit boards, microchips, and displays. The antistatic properties prevent the buildup of static electricity, which could damage electronic components. The protective coating also shields surfaces from scratches and dust, ensuring that components remain functional and visually appealing.