Characteristics and Versatile Applications of White PS Film in Modern Packaging

2025-09-03 17:19Polystyrene (PS) film, particularly white PS film, is a versatile and widely utilized material in the packaging industry due to its unique properties, cost-effectiveness, and adaptability to various applications. Derived from the polymerization of styrene monomers, PS film is a thermoplastic material available in forms such as general-purpose polystyrene (GPPS),  high-impact polystyrene (HIPS), and expanded polystyrene (EPS). White PS film, often enhanced with additives like titanium dioxide for opacity and aesthetic appeal, is prized for its lightweight nature, rigidity, and ability to be molded into precise shapes. This article explores the key characteristics of white PS film and its applications in food vacuum packaging, disposable tableware packaging, antistatic packaging, and electronic packaging, highlighting its practical benefits and addressing environmental considerations.Characteristics of White PS Film White PS film exhibits a combination of physical, chemical, and aesthetic properties that make it a preferred choice for packaging solutions across industries. Below are its primary characteristics:Lightweight and Rigid Structure

high-impact polystyrene (HIPS), and expanded polystyrene (EPS). White PS film, often enhanced with additives like titanium dioxide for opacity and aesthetic appeal, is prized for its lightweight nature, rigidity, and ability to be molded into precise shapes. This article explores the key characteristics of white PS film and its applications in food vacuum packaging, disposable tableware packaging, antistatic packaging, and electronic packaging, highlighting its practical benefits and addressing environmental considerations.Characteristics of White PS Film White PS film exhibits a combination of physical, chemical, and aesthetic properties that make it a preferred choice for packaging solutions across industries. Below are its primary characteristics:Lightweight and Rigid Structure

White PS film is notably lightweight, which reduces transportation costs and enhances handling efficiency. Its inherent rigidity, particularly in HIPS and GPPS forms, provides structural integrity, making it ideal for applications requiring durability and shape retention. For instance, the rigidity of PS film ensures that it can withstand mechanical stress during packaging processes like thermoforming or vacuum forming.

Transparency and Aesthetic Appeal with White Opacity

While general-purpose PS film is naturally transparent, white PS film is achieved through the addition of pigments like titanium dioxide, which imparts opacity and a clean, professional appearance. This aesthetic quality is particularly valuable in retail settings, where visual appeal influences consumer perception. The white color enhances branding opportunities by providing a neutral backdrop for printing logos and designs.

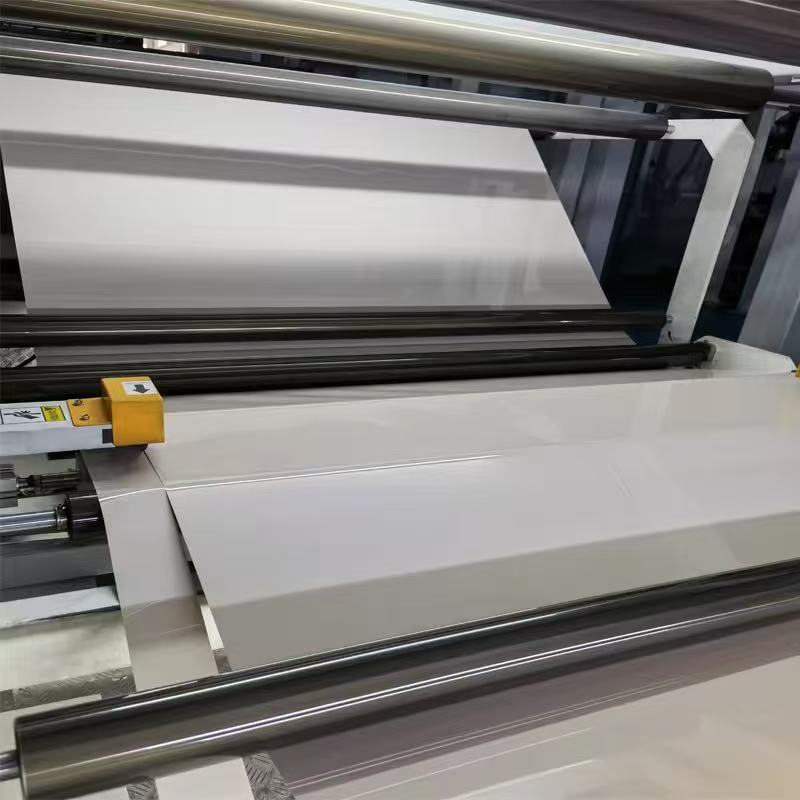

Ease of Processing

PS film is highly processable through methods such as thermoforming, injection molding, and vacuum forming. Its low melting point (around 100°C) allows it to be easily shaped into trays, containers, and clamshells, making it suitable for high-speed manufacturing. The material’s uniform shrinkage and resistance to warping during processing further enhance its appeal for precision packaging.

Chemical Resistance

White PS film demonstrates good resistance to many chemicals, including acids and bases, making it suitable for packaging products that may come into contact with various substances. This property is particularly important for food packaging, where the film must protect contents from external contaminants without reacting with the food itself.

Insulation Properties

Expanded polystyrene (EPS) variants of white PS film offer excellent thermal insulation, which is critical for maintaining the temperature of perishable goods. While EPS is more commonly associated with foam, thin EPS films can also be used in specific packaging applications to provide cushioning and insulation.

Cost-Effectiveness

Compared to other plastics like polyethylene terephthalate (PET) or polypropylene (PP), PS film is relatively inexpensive to produce. This cost-effectiveness makes it a go-to material for disposable and single-use packaging applications, particularly in price-sensitive markets.

Limited Barrier Properties

One notable drawback of PS film is its poor barrier properties against water vapor and oxygen. This limitation makes it less suitable for long-term storage of highly perishable goods unless combined with barrier coatings or multilayer films. For short-shelf-life products, however, this is less of a concern.

Environmental Considerations

While PS film is technically recyclable, its low density and challenges in collection make large-scale recycling difficult. Organizations like How2Recycle classify PS as “Not Yet Recyclable” due to limited infrastructure, prompting scrutiny over its environmental impact. However, advancements in biodegradable additives and recycling technologies are addressing these concerns.

Applications of White PS FilmWhite PS film’s versatility allows it to serve a wide range of industries. Below, we explore its applications in food vacuum packaging, disposable tableware packaging, antistatic packaging, and electronic packaging, providing detailed insights into its practical uses.

1. Food Vacuum PackagingWhite PS film is extensively used in food vacuum packaging, particularly for perishable items like meat, poultry, and dairy products. Vacuum packaging involves removing air from the package to extend shelf life and preserve freshness. White PS film, often in the form of high-impact polystyrene (HIPS), is ideal for this application due to its ability to be thermoformed into rigid trays or clamshells that maintain an airtight seal.Practical Benefits: The rigidity of HIPS ensures that vacuum-sealed trays maintain their shape under pressure, preventing deformation during transport or storage. The white color enhances product visibility and appeal, making it ideal for retail displays of meats or deli products. For example, white PS film trays are commonly used for vacuum-packed chicken breasts or sliced cheeses, where the film’s clarity and strength protect the product while showcasing its quality.

Case Study: A ravioli manufacturer switched to a white PS film-based tray with a specialized shrink film to address fogging issues in freezer storage. The white PS film retained clarity and gloss, improving shelf appeal and consumer satisfaction.

Limitations: PS film’s poor barrier properties against water vapor require additional coatings or laminations for products with extended shelf lives. For short-shelf-life items like fresh meats, however, this is less critical.

2. Disposable Tableware PackagingWhite PS film is a staple in the production of disposable tableware, including cups, plates, trays, and cutlery. Its lightweight nature, cost-effectiveness, and ease of molding make it ideal for single-use foodservice items used in fast-food restaurants, cafeterias, and catering services.Practical Benefits: The rigidity of white PS film ensures that disposable tableware can withstand the weight of food without collapsing. Its smooth surface supports high-quality printing, allowing for customized branding on items like coffee cups or takeout containers. For example, white PS film is used to create iconic red Solo cups, which are both functional and visually recognizable.