Exploring the Sheer Brilliance: Properties and Applications of Transparent Polyethylene Film

2025-10-11 15:20 Polyethylene, the most widely produced plastic globally, owes its transparency in film form to careful extrusion processes that minimize crystallization, allowing light to pass through with minimal distortion. Unlike opaque alternatives, transparent PE film offers a window into the product it protects, fostering consumer trust and aesthetic appeal. Its global production exceeds millions of tons annually, driven by demand in sectors from retail to agriculture. This article delves into the intrinsic properties of transparent PE film and illuminates its diverse applications, from humble PE bags to sophisticated composite structures, demonstrating why it remains indispensable in an era of sustainable and efficient design.The Core Properties: Why Transparent PE Film ExcelsAt its heart, transparent PE film's appeal lies in a symphony of physical and chemical attributes that make it a multitasker par excellence. Foremost is its optical clarity, often exceeding 90% light transmission, which rivals glass but at a fraction of the weight—typically just 0.025 to 0.1 millimeters thick. This transparency isn't accidental; it's engineered through blown or cast extrusion methods, where molten PE is stretched into thin sheets, aligning polymer chains for a glossy, haze-free finish. In practical terms, this means a shopper can inspect the ripeness of fruits in a produce bag without opening it, reducing food waste and enhancing impulse buys.Durability is another pillar. With a tensile strength of 10-30 MPa, transparent PE film resists punctures and tears better than many paper alternatives, yet it remains supple with an elongation at break up to 600%. This flexibility shines in dynamic environments: consider a PE bag loaded with groceries bouncing in a car trunk, its film stretching without splitting. Chemically inert and non-toxic, it boasts low water vapor transmission rates (around 1-2 g/m²/day), preserving moisture-sensitive goods like cheeses or electronics components. Its density, hovering at 0.91-0.94 g/cm³, ensures buoyancy and ease of handling, while thermal stability up to 80-100°C allows for heat-sealing without degradation—perfect for forming airtight pouches.

Polyethylene, the most widely produced plastic globally, owes its transparency in film form to careful extrusion processes that minimize crystallization, allowing light to pass through with minimal distortion. Unlike opaque alternatives, transparent PE film offers a window into the product it protects, fostering consumer trust and aesthetic appeal. Its global production exceeds millions of tons annually, driven by demand in sectors from retail to agriculture. This article delves into the intrinsic properties of transparent PE film and illuminates its diverse applications, from humble PE bags to sophisticated composite structures, demonstrating why it remains indispensable in an era of sustainable and efficient design.The Core Properties: Why Transparent PE Film ExcelsAt its heart, transparent PE film's appeal lies in a symphony of physical and chemical attributes that make it a multitasker par excellence. Foremost is its optical clarity, often exceeding 90% light transmission, which rivals glass but at a fraction of the weight—typically just 0.025 to 0.1 millimeters thick. This transparency isn't accidental; it's engineered through blown or cast extrusion methods, where molten PE is stretched into thin sheets, aligning polymer chains for a glossy, haze-free finish. In practical terms, this means a shopper can inspect the ripeness of fruits in a produce bag without opening it, reducing food waste and enhancing impulse buys.Durability is another pillar. With a tensile strength of 10-30 MPa, transparent PE film resists punctures and tears better than many paper alternatives, yet it remains supple with an elongation at break up to 600%. This flexibility shines in dynamic environments: consider a PE bag loaded with groceries bouncing in a car trunk, its film stretching without splitting. Chemically inert and non-toxic, it boasts low water vapor transmission rates (around 1-2 g/m²/day), preserving moisture-sensitive goods like cheeses or electronics components. Its density, hovering at 0.91-0.94 g/cm³, ensures buoyancy and ease of handling, while thermal stability up to 80-100°C allows for heat-sealing without degradation—perfect for forming airtight pouches. PE Bags: The Everyday Workhorses of Retail and Waste ManagementNo discussion of transparent PE film would be complete without its starring role in PE bags, those unassuming carriers that ferry everything from market vegetables to household trash. Crafted via blown film extrusion, these bags leverage the film's clarity to showcase contents enticingly—a bouquet of colorful carrots or a stack of neatly folded linens peeking through, tempting the eye and streamlining inventory checks for store clerks.In retail, transparent PE bags exemplify efficiency and hygiene. Grocery T-shirt bags, typically 0.025 mm thick, hold up to 10-15 kg while allowing visual inspection to curb contamination fears. Their heat-sealable edges form robust closures, and the film's moisture barrier extends shelf life for perishables by 20-30%, as evidenced by food preservation trials. Beyond supermarkets, clear PE produce bags reduce plastic usage by 15% compared to opaque versions, promoting sustainability without sacrificing strength.Waste management benefits equally. Heavy-duty transparent PE trash bags, often LLDPE-based for tear resistance, enable quick content identification—vital for recycling sorters distinguishing plastics from organics. In medical settings, clear biohazard bags ensure safe disposal of sharps, their transparency aiding compliance with visibility regulations. Picture a busy hospital ward: nurses glance through the film to confirm secure containment, averting mishaps. With over 500 billion PE bags produced yearly worldwide, their impact is profound, blending practicality with a touch of transparency that fosters accountability.

PE Bags: The Everyday Workhorses of Retail and Waste ManagementNo discussion of transparent PE film would be complete without its starring role in PE bags, those unassuming carriers that ferry everything from market vegetables to household trash. Crafted via blown film extrusion, these bags leverage the film's clarity to showcase contents enticingly—a bouquet of colorful carrots or a stack of neatly folded linens peeking through, tempting the eye and streamlining inventory checks for store clerks.In retail, transparent PE bags exemplify efficiency and hygiene. Grocery T-shirt bags, typically 0.025 mm thick, hold up to 10-15 kg while allowing visual inspection to curb contamination fears. Their heat-sealable edges form robust closures, and the film's moisture barrier extends shelf life for perishables by 20-30%, as evidenced by food preservation trials. Beyond supermarkets, clear PE produce bags reduce plastic usage by 15% compared to opaque versions, promoting sustainability without sacrificing strength.Waste management benefits equally. Heavy-duty transparent PE trash bags, often LLDPE-based for tear resistance, enable quick content identification—vital for recycling sorters distinguishing plastics from organics. In medical settings, clear biohazard bags ensure safe disposal of sharps, their transparency aiding compliance with visibility regulations. Picture a busy hospital ward: nurses glance through the film to confirm secure containment, averting mishaps. With over 500 billion PE bags produced yearly worldwide, their impact is profound, blending practicality with a touch of transparency that fosters accountability.Customization elevates these bags further. Printed logos or perforations for easy tearing add branding flair, while biodegradable additives infused during extrusion promise eco-friendlier dissolution in landfills. In essence, PE bags transform transparent PE film from a mere wrapper into a silent partner in daily logistics, proving that sometimes, seeing is believing—and buying.

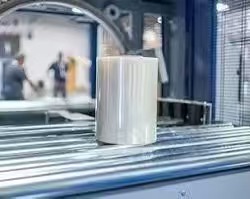

Shifting from the mundane to the meticulous, transparent PE head protection films emerge as unsung guardians for vulnerable product tops, particularly in bottling and construction. Often misinterpreted as niche, these films—typically 0.05-0.08 mm thick—encase bottle necks, cap threads, or even marble slab edges ("head" referring to the crown or top section), preventing dust ingress and scratches during transit.

Food packaging dominates, where transparent PE films extend freshness via oxygen barriers enhanced by EVOH co-extrusions, slashing spoilage by 25% in vacuum-sealed meats. In a bustling Tokyo fish market, clear overwrap films on sashimi trays allow color assessment—vibrant pink salmon signals peak quality—while the film's grease resistance handles oily residues effortlessly. Shrink films, heated to 120°C for contraction, hug irregular shapes like cheese wheels, their clarity aiding portion control labels.

Conclusion: A Transparent Legacy Forward

Conclusion: A Transparent Legacy ForwardTransparent PE film's journey from extrusion die to global guardian underscores its enduring allure: a material that reveals as much as it conceals, protects without imposing, and innovates ceaselessly. From the tactile rustle of a PE bag to the pristine arrival of a marble slab via head protection films, its applications permeate life, driven by properties that balance form and function. As sustainability imperatives intensify, advancements like recycled-content films promise a greener horizon, ensuring this sheer marvel remains central to packaging's evolution. In an opaque world, transparent PE film stands clear—a testament to human ingenuity wrapped in plastic perfection.