TL-BOPP -342 bopp film for kinds of packing

2024-11-14 15:00The Widespread Application of FOG BOPP Film in Packaging

Introduction

In the realm of packaging, the FOG BOPP film has emerged as a remarkable innovation with far - reaching implications. This specialized film has opened up new possibilities and improved the quality of packaging across various industries. Its unique properties make it a highly sought - after material for protecting and presenting a diverse range of products.

Understanding FOG BOPP Film

Definition and Composition

FOG BOPP film, or biaxially oriented polypropylene film with anti - fog properties, is a complex material. It is primarily composed of polypropylene, which provides the base structure of the film. The polypropylene is carefully processed to achieve the desired orientation and mechanical properties. However, what sets it apart are the anti - fog additives incorporated into its formulation. These additives are designed to modify the surface characteristics of the film, enabling it to resist fogging under various conditions.

Anti - fogging Principle

The anti - fog mechanism of FOG BOPP film is fascinating. Under normal circumstances, when there is a temperature difference between the inside and outside of a package or when humidity levels change, moisture in the air can condense on the inner surface of traditional packaging films. This leads to the formation of water droplets that scatter light and cause fogging. In contrast, the anti - fog additives in FOG BOPP film work by reducing the surface tension of the film. When moisture comes into contact with the film, instead of forming droplets, it spreads out evenly as a thin, transparent layer. This allows for clear visibility of the contents within the package at all times.

Other Key Properties

Apart from its anti - fog capabilities, FOG BOPP film boasts several other important properties. It has excellent mechanical strength, with high tensile strength and good puncture resistance. This means that it can withstand the rigors of handling, transportation, and storage without easily tearing or getting damaged. The film also exhibits good barrier properties against moisture, gases such as oxygen and carbon dioxide, and other environmental factors. This helps in maintaining the quality and freshness of the packaged products. Additionally, it has good chemical stability, allowing it to be in contact with a wide range of substances without degradation.

Manufacturing Process of FOG BOPP Film

Raw Material Selection and Preparation

The journey of FOG BOPP film begins with the careful selection of polypropylene resin. The quality and type of resin play a crucial role in determining the final properties of the film. High - grade polypropylene with the appropriate molecular weight and distribution is chosen. Along with the resin, the anti - fog additives are selected based on their effectiveness and compatibility with the resin. These additives are often mixed with other auxiliaries such as stabilizers to prevent thermal degradation during processing. The raw materials are then thoroughly blended in precise proportions to ensure a homogeneous mixture.

Extrusion Process

Once the raw materials are prepared, they are fed into an extruder. The extruder heats the mixture to a molten state under carefully controlled temperature and pressure conditions. The molten polymer is then forced through a flat - die to form a continuous sheet of plastic. During this process, the temperature profile along the extruder barrel and the die is critical. It needs to be adjusted to ensure that the polymer is melted uniformly and flows smoothly through the die. The speed at which the polymer is extruded also affects the thickness and quality of the resulting sheet.

Orientation and Annealing

After extrusion, the plastic sheet undergoes biaxial orientation. This is a key step that significantly enhances the mechanical and physical properties of the film. The sheet is first stretched in the machine direction using a series of rollers with different speeds. This aligns the polymer chains in the direction of the stretch, increasing the tensile strength in that direction. Subsequently, the sheet is stretched in the transverse direction in a tenter frame. This biaxial orientation results in a film with improved strength, clarity, and barrier properties. After orientation, the film is annealed. Annealing involves heating the film to a specific temperature and holding it for a period to relieve internal stresses generated during the orientation process. This step helps to stabilize the film's structure and further improve its performance.

Coating and Finishing

In some cases, additional coatings may be applied to the FOG BOPP film to enhance its properties. For example, a coating may be added to improve the film's printability, allowing for clear and vibrant labeling of the packaged product. Coatings can also be used to further enhance the barrier properties or to provide other functional features such as anti - static properties. After coating, the film may undergo finishing operations such as trimming to remove any irregular edges and winding onto rolls for storage and subsequent packaging applications.

Applications of FOG BOPP Film in Food Packaging

Fresh Produce Packaging

Fruits

When it comes to packaging fruits, FOG BOPP film is a game - changer. Take strawberries, for instance. These delicate fruits need packaging that not only protects them but also showcases their freshness and quality. The anti - fog property of the film ensures that the strawberries remain clearly visible through the packaging, whether they are in a cold storage environment or on a warm supermarket shelf. Consumers can easily see the bright red color and plumpness of the strawberries, which is highly appealing. The film's moisture barrier also helps to maintain the right humidity level around the strawberries, preventing them from drying out or becoming moldy too quickly.

For citrus fruits like oranges and lemons, FOG BOPP film provides similar benefits. The clear packaging allows the natural shine and color of the fruits to be visible, enhancing their marketability. The film's ability to resist puncture and its mechanical strength protect the fruits from being damaged during handling and transportation. Moreover, the gas barrier properties of the film can help in maintaining the internal atmosphere of the package, which is beneficial for prolonging the shelf life of the fruits by reducing the rate of respiration.

Vegetables

In the case of vegetables, FOG BOPP film is equally valuable. Consider leafy greens such as lettuce and spinach. These are highly perishable and require packaging that can keep them fresh. The anti - fog film allows consumers to see the crispness and greenness of the leaves, making the product more attractive. The moisture - controlling properties of the film prevent the leaves from wilting by maintaining an appropriate humidity level inside the package. For root vegetables like carrots and potatoes, the film's mechanical strength protects them from being bruised during handling. The clear packaging also enables easy identification of the vegetables, which is convenient for both consumers and retailers.

Meat and Seafood Packaging

Meat

FOG BOPP film is widely used in packaging meat products. For red meats like beef and pork, the clear film allows consumers to assess the color, texture, and quality of the meat. The film's oxygen barrier properties are crucial in preventing the oxidation of the meat, which can cause discoloration and spoilage. The moisture barrier property helps to keep the meat juicy and tender by reducing moisture loss. In addition, the good puncture resistance of the film protects the meat from any sharp edges within the package, such as bones.

Seafood

In the seafood industry, FOG BOPP film is used for packaging fish, shrimp, and other products. For fish, the clear packaging showcases the freshness of the product, including the color of the flesh and the clarity of the eyes. The film's ability to control moisture and gases helps to maintain the quality of the fish during storage and transportation. For shrimp, the anti - fog property allows consumers to see the size and quality of the shrimp clearly. The film's mechanical strength protects the delicate seafood from being damaged, and its chemical stability ensures that it does not react with the natural oils and moisture present in seafood.

Dairy and Bakery Product Packaging

Dairy Products

Dairy products such as cheese, yogurt, and milk also benefit from FOG BOPP film packaging. For cheese, the film's transparency allows consumers to see the type and quality of the cheese, including its texture and any visible mold veins in the case of certain cheeses. The moisture and gas barrier properties of the film are essential for maintaining the flavor and texture of the cheese during storage. In the case of yogurt, the anti - fog property ensures that the product remains visible even in cold storage conditions. The film's chemical resistance is important as it can withstand contact with the acidic nature of yogurt without any adverse effects.

Bakery Products

Bakery products like bread, cakes, and pastries are often packaged using FOG BOPP film. The clear film showcases the delicious appearance of the products, making them more enticing to consumers. The film's moisture - controlling properties are crucial for maintaining the freshness of the bakery products. For example, in the case of bread, the film can prevent it from drying out too quickly, keeping the crust soft and the interior moist. The mechanical strength of the film protects the delicate pastries from being crushed during handling and transportation.

Applications of FOG BOPP Film in Non - food Packaging

Electronics Packaging

In the electronics industry, FOG BOPP film plays a vital role. Electronic components such as circuit boards, microchips, and mobile phone parts require packaging that can protect them from environmental factors and electrostatic discharge. The film's moisture barrier and chemical resistance properties protect these sensitive components from humidity and exposure to chemicals. In some cases, anti - static coatings can be applied to the FOG BOPP film to further enhance its protection against electrostatic damage. The clear packaging also allows for easy inspection of the components during the manufacturing process and quality control.

Cosmetics Packaging

Cosmetics products, including lipsticks, creams, and powders, are commonly packaged with FOG BOPP film. The clear film allows consumers to see the color and texture of the cosmetics, which is an important marketing factor. The film's chemical resistance ensures that it does not react with the various ingredients in the cosmetics, which can range from oils to pigments. The moisture barrier property helps to maintain the stability of the product by preventing water absorption or evaporation, which could affect the quality of the cosmetics. For example, in the case of creams, the film helps to keep the product's consistency intact.

Toys Packaging

Toys are often packaged in FOG BOPP film. The clear film allows children and parents to see the toy inside, which can increase the appeal of the product. The film's mechanical strength and puncture resistance protect the toy from being damaged during transportation and storage. Additionally, the film's resistance to chemicals ensures that it does not react with any painted or plastic parts of the toy. This is especially important for toys with intricate designs or those made from different materials.

Pharmaceutical Packaging

In the pharmaceutical industry, FOG BOPP film is used for packaging various products. For tablets and capsules, the clear film allows for easy identification of the medication. The film's moisture and gas barrier properties help to maintain the stability of the active pharmaceutical ingredients. In the case of liquid medications or medical devices, the film's chemical resistance and mechanical strength ensure that the products are protected during storage and transportation. The anti - fog property can also be beneficial in certain situations, such as when packaging products that need to be stored in cold environments or when quick visual inspection is required.

Advantages of FOG BOPP Film in Packaging

Enhanced Product Visibility

The anti - fog property of FOG BOPP film significantly enhances the visibility of the products within the package. This is a major advantage in both food and non - food packaging. In a supermarket aisle, products packaged with clear FOG BOPP film stand out, attracting consumers' attention. For example, in the case of fresh produce, consumers can easily assess the quality and freshness of the fruits and vegetables, which can lead to increased sales. In the electronics and cosmetics industries, the clear packaging allows consumers to see the product details, which is crucial for making a purchasing decision.

Improved Product Protection

FOG BOPP film provides excellent protection to the packaged products. Its mechanical strength, including high tensile strength and puncture resistance, safeguards the products from physical damage during handling, transportation, and storage. The moisture and gas barrier properties help to maintain the quality and freshness of perishable products in the food industry and protect sensitive products in other industries from environmental factors. The chemical stability of the film ensures that it does not react with the contents of the package, further enhancing the protection of the products.

Extended Shelf Life

For many products, especially perishable food items, the use of FOG BOPP film can lead to an extended shelf life. The film's ability to control moisture, gases, and temperature within the package helps to slow down the deterioration process. For example, in the case of fresh fruits and vegetables, the film can reduce the rate of respiration, delay the growth of spoilage - causing microorganisms, and prevent moisture loss. In the dairy and meat industries, the film's barrier properties prevent oxidation and spoilage, allowing the products to remain fresh for a longer period.

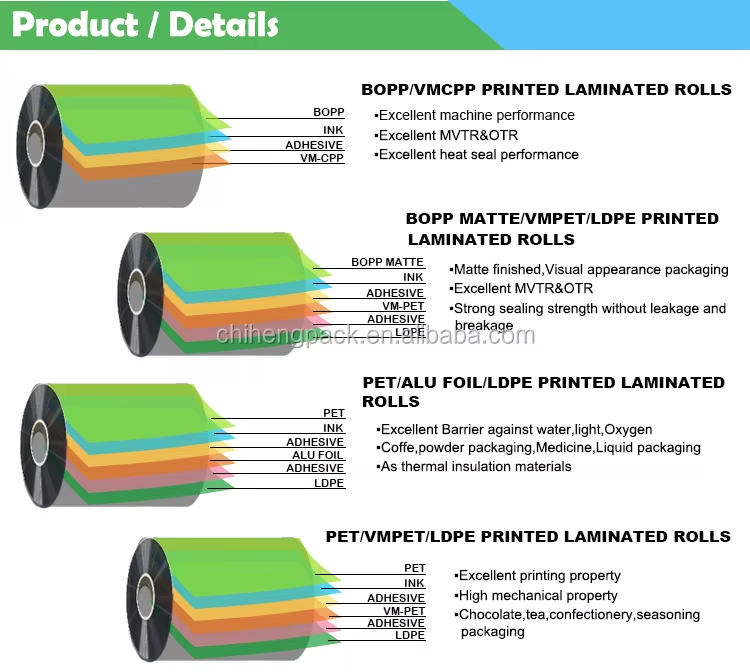

Versatility in Packaging Design

FOG BOPP film is highly versatile in terms of packaging design. It can be easily formed into different shapes and sizes to accommodate various products. The film can be used for single - layer or multi - layer packaging, depending on the specific requirements of the product. It also has good compatibility with other packaging materials, such as labels, adhesives, and seals. This allows for creative and functional packaging designs that can meet the unique needs of different industries.

Environmental Benefits

In an era of increasing environmental awareness, FOG BOPP film offers some environmental advantages. It is a lightweight material, which reduces the energy consumption during transportation compared to heavier packaging materials. Additionally, polypropylene is a recyclable material, and efforts can be made to recycle used FOG BOPP film. This helps to reduce the environmental impact of packaging waste and contributes to a more sustainable packaging solution.

Case Studies of FOG BOPP Film in Packaging Applications

Case Study 1: A Fresh Produce Supplier

A fresh produce supplier was facing challenges with the packaging of their strawberries. Traditional packaging materials often fogged up, reducing the visibility of the strawberries and making them less appealing to consumers. Additionally, the strawberries were spoiling relatively quickly due to poor moisture control. The supplier decided to switch to FOG BOPP film packaging. After the switch, they noticed a significant improvement in the appearance of the strawberries on the store shelves. The anti - fog property ensured that the strawberries remained clearly visible, and the moisture barrier property extended their shelf life by up to 50%. This led to increased sales and reduced waste for the supplier.

Case Study 2: An Electronics Manufacturer

An electronics manufacturer was looking for a better packaging solution for their circuit boards. The previous packaging material was not providing sufficient protection against moisture and electrostatic discharge. They adopted FOG BOPP film with an anti - static coating. The new packaging not only protected the circuit boards from environmental factors but also reduced the incidence of electrostatic - related damage during handling and transportation. The clear packaging also allowed for easier quality control inspections, improving the overall efficiency of the manufacturing process.

Case Study 3: A Cosmetics Brand

A cosmetics brand was having issues with the packaging of their lipsticks. The previous packaging material was reacting with the lipstick formula, causing changes in color and texture. They switched to FOG BOPP film due to its chemical resistance property. The new packaging maintained the quality of the lipsticks, and the clear film allowed consumers to see the true color of the product. This led to improved customer satisfaction and increased sales for the brand.

Challenges and Solutions in Using FOG BOPP Film in Packaging

Cost Considerations

One of the main challenges in using FOG BOPP film is the cost. The production process of this specialized film, including the incorporation of anti - fog additives and other quality - enhancing features, can be more expensive than traditional packaging films. To address this issue, manufacturers can work on optimizing the manufacturing process to reduce costs. They can also explore economies of scale by increasing production volumes. Additionally, companies can consider the long - term benefits of using FOG BOPP film, such as reduced product spoilage and increased sales, which can offset the higher initial cost.

Recycling and Disposal

Although polypropylene is recyclable, the presence of anti - fog additives and other coatings in FOG BOPP film can complicate the recycling process. To overcome this challenge, research and development efforts should be focused on developing recycling methods that can effectively handle these specialized films. Packaging manufacturers can also work with recycling facilities to educate them about the properties of FOG BOPP film and to develop proper sorting and recycling techniques. In addition, consumers can be educated about the importance of recycling packaging materials and provided with clear instructions on how to dispose of FOG BOPP film properly.

Compatibility with Products

In some cases, there may be compatibility issues between FOG BOPP film and certain products. For example, some highly acidic or alkaline substances may interact with the film over time. To address this, manufacturers should conduct thorough compatibility tests during the product development stage. If necessary, they can modify the film's formulation or use additional protective layers to ensure compatibility. They can also provide guidelines to users on the types of products that are best suited for packaging with FOG BOPP film.

Conclusion

FOG BOPP film has revolutionized the packaging industry with its unique anti - fog property and a host of other valuable characteristics. Its applications span across food and non - food industries, providing enhanced product visibility, improved protection, extended shelf life, and versatility in packaging design. Despite the challenges related to cost, recycling, and product compatibility, continuous efforts in research, development, and process improvement are helping to overcome these obstacles. As the demand for high - quality and sustainable packaging solutions continues to grow, FOG BOPP film is set to play an even more significant role in the future of packaging, ensuring that products are presented and protected in the best possible way.