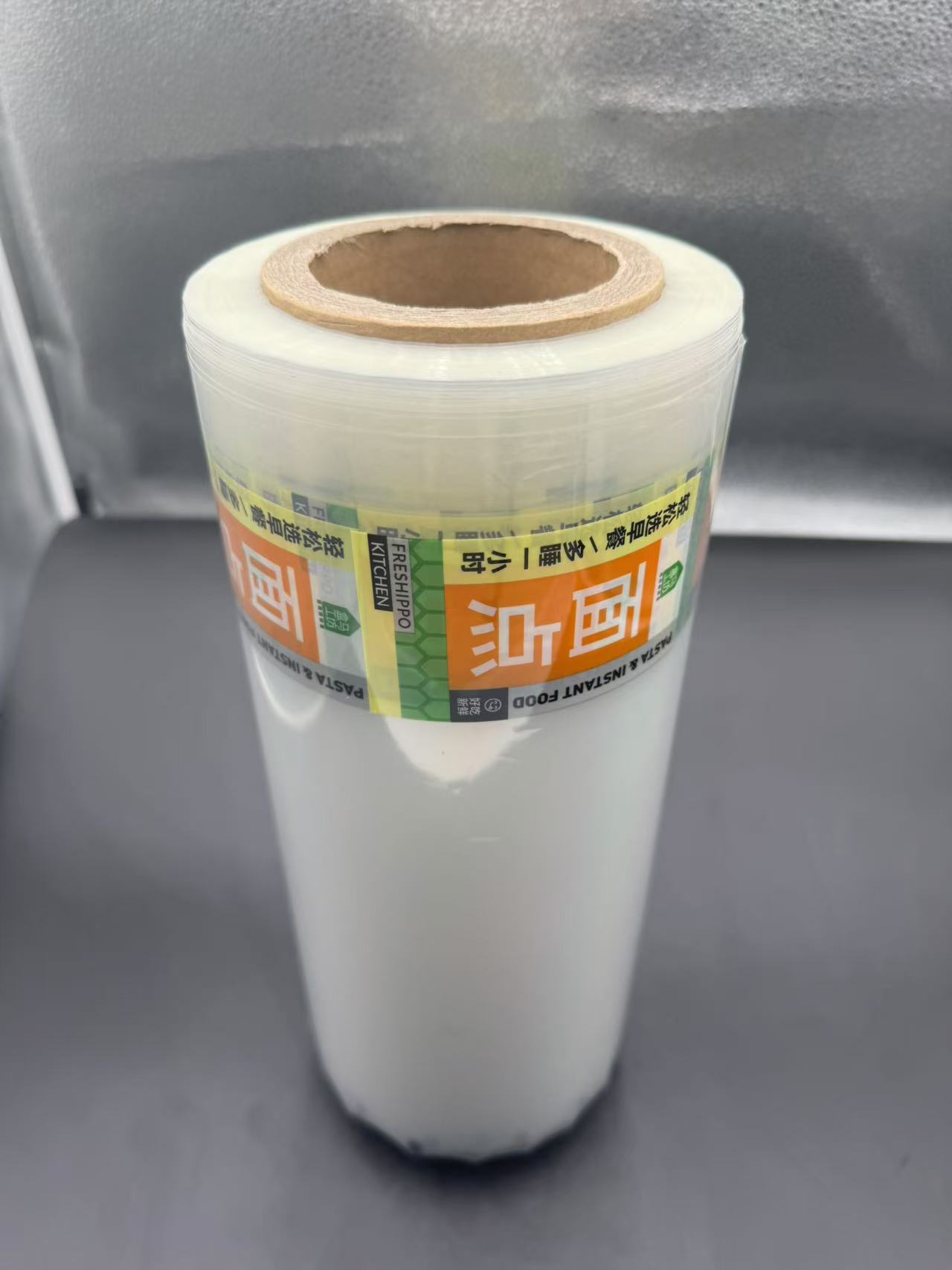

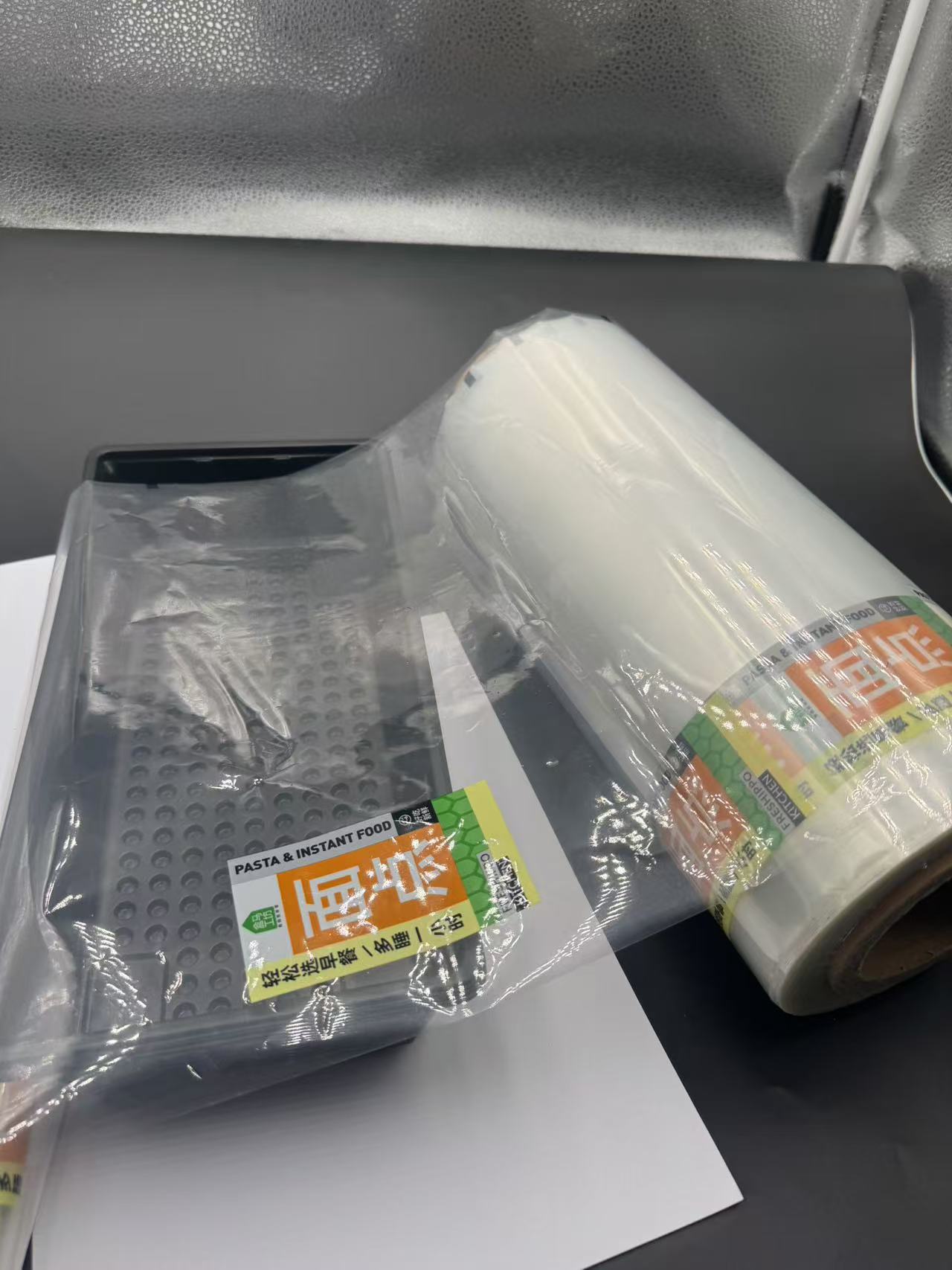

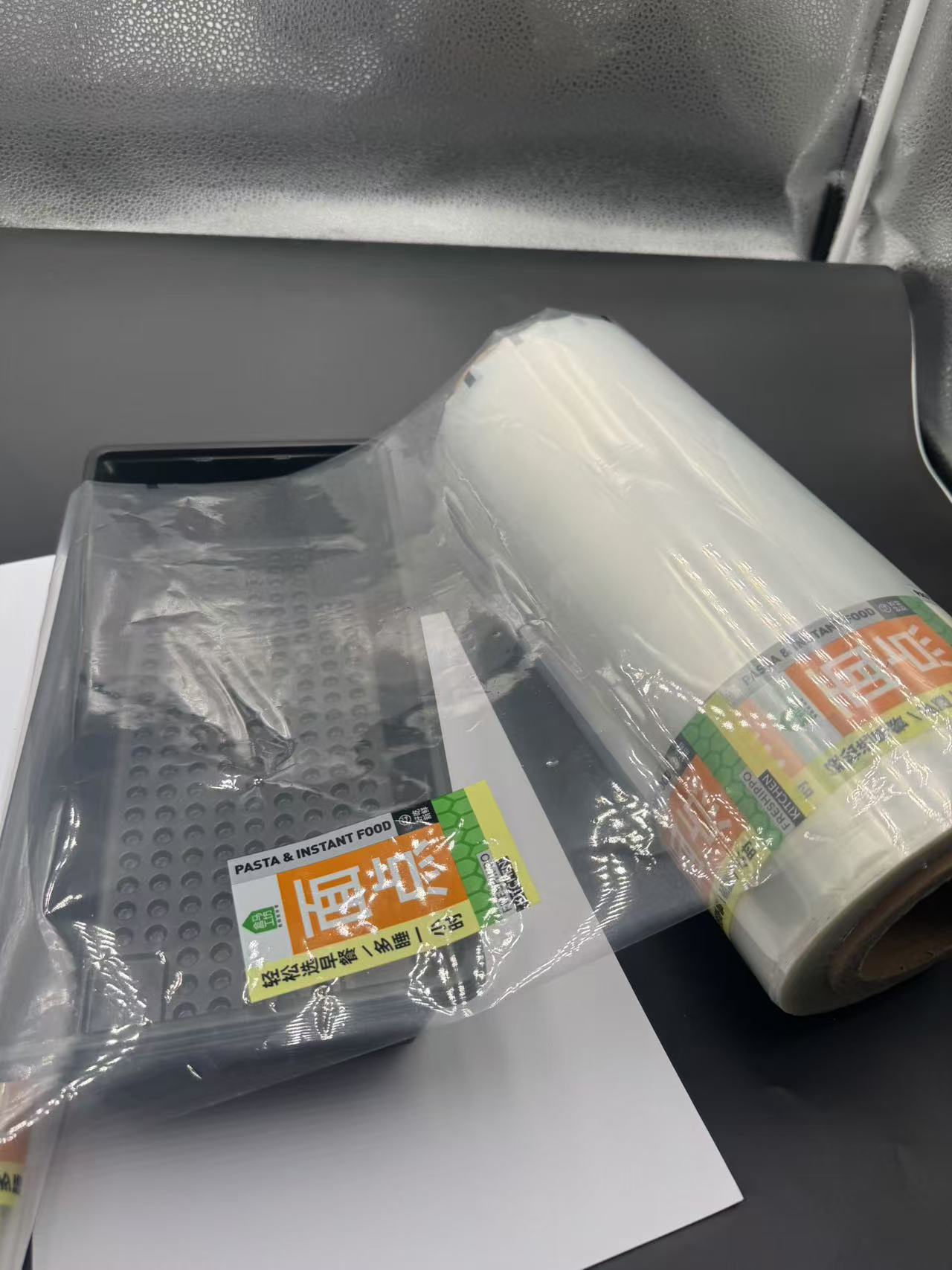

711PE/PA Film heat sealing for food, fruit tray , beverage cups

2024-12-10 16:19The Widespread Application of PA/PE Film in Thermosealing Packaging Abstract: This article comprehensively explores the extensive use of PA/PE film in various thermosealing packaging applications, including food blister boxes, fruit boxes, cutlery boxes, beverage cups, and pharmaceutical seals. It delves into the unique properties of PA/PE film that make it highly suitable for these applications, such as its excellent barrier properties, mechanical strength, and heat sealability.

In addition to an extensive description of the preparation routes, quality control measurements, and regulatory considerations for using such a film, the following advantages of using PA/PE films are discussed, as are the potential problems with these and future trends and developments that are foreseen in the application of such films. By thorough examination, it is obvious that PA/PE film plays a vital role in enhancing packaged product quality, safety, and shelf life, thus meeting the demands of modern consumers and industries for effective and reliable packaging solutions.

Keywords: PA/PE film; Thermosealing packaging; Food packaging; Pharmaceutical packaging; Barrier properties; Heat sealability

1. Introduction

The selection of the right material is one of the most important aspects in packaging that can make a difference regarding the integrity, safety, and quality of the packaged products. Among other materials, PA/PE film, a combination of polyamide and polyethylene, is one of the popular versatile options for thermosealing packaging. Its balanced blend of properties makes it suitable for use across many industries, ranging from food and beverages to pharmaceuticals. The following article will explain in detail how PA/PE film is used in different packaging applications and the importance it holds in modern packaging technology.

2. Properties of PA/PE Film

2. Properties of PA/PE Film

2.1 Barrier Properties

Among the most outstanding features of PA/PE film is its excellent barrier properties. The PA layer provides a strong barrier against oxygen, carbon dioxide, and other gases. This is very important in food packaging, as it prevents spoilage and maintains the freshness and flavor of the food. This is well explained in food packaging, such as the packaging of fresh meats: the oxygen barrier property of the film inhibits the proliferation of aerobic bacteria and, therefore,

slows down oxidation, which prolongs its shelf life. In the case of carbonated beverages, for example, the barrier against carbon dioxide loss maintains the drink's fizziness. The PE layer contributes to a good moisture barrier, thus preventing moisture ingress or loss within the contents. This is quite important for products sensitive to humidity-for instance, dry food items and pharmaceutical tablets.

2.2 Mechanical Strength

PA/PE film exhibits high mechanical strength, which makes it durable and resistant to punctures, tears, and abrasions. In food packaging, this property is vital for protecting the contents during handling, transportation, and storage. For instance, in the packaging of sharp-edged food items like cutlery or products with irregular shapes, the film's strength prevents it from being damaged and ensures the integrity of the package. In the pharmaceutical industry, this film helps in protecting tablets or capsules from any external force with its mechanical strength in the highest regard for their safety and integrity. 2.3 Heat Sealability The heat sealability is one of the major features characterizing this film and its applications related to thermosealing packaging. This kind of film can be sealed easily by heat to a strong and reliable bond. It also makes for efficient and effective packaging. The heat-sealing characteristics of PA/PE film allow the production of airtight and tamper-evident seals in the manufacture of food blister boxes, fruit boxes, and cutlery boxes. The sealant characteristics allow for an effective sealing process where the sealing is appropriately done to an airtight package to prevent leakages and other forms of contaminations. In the case of beverage cups, the film can be heat-sealed to form a secure lid, keeping the drink inside and maintaining its quality.

2.4 Transparency and Printability

2.4 Transparency and Printability

PA/PE film is quite transparent, which makes it easier for consumers to view the content of the package. This is quite beneficial in food packaging because it enhances the appearance of the product and helps consumers make better choices. For example, in fruit boxes, the transparency of the film showcases the freshness and quality of the fruits inside. The film's surface is also receptive to printing, enabling manufacturers to print attractive labels, nutritional information, branding elements, and product details directly onto the package. High-quality printing not only provides essential information to the consumers but also adds to the overall aesthetic value of the product, making it stand out on the shelves.

2.5 Chemical Resistance

The film is chemically resistant to a wide range of substances, which is important in both food and pharmaceutical packaging. It does not react with the food or drug products, ensuring the safety and integrity of the packaged items. In food packaging, it can withstand contact with various food acids, oils, and spices without degrading or leaching harmful substances. In pharmaceutical packaging, it is compatible with different drug formulations and does not affect the potency or stability of the medications.

3. Application in Food Packaging

3. Application in Food Packaging

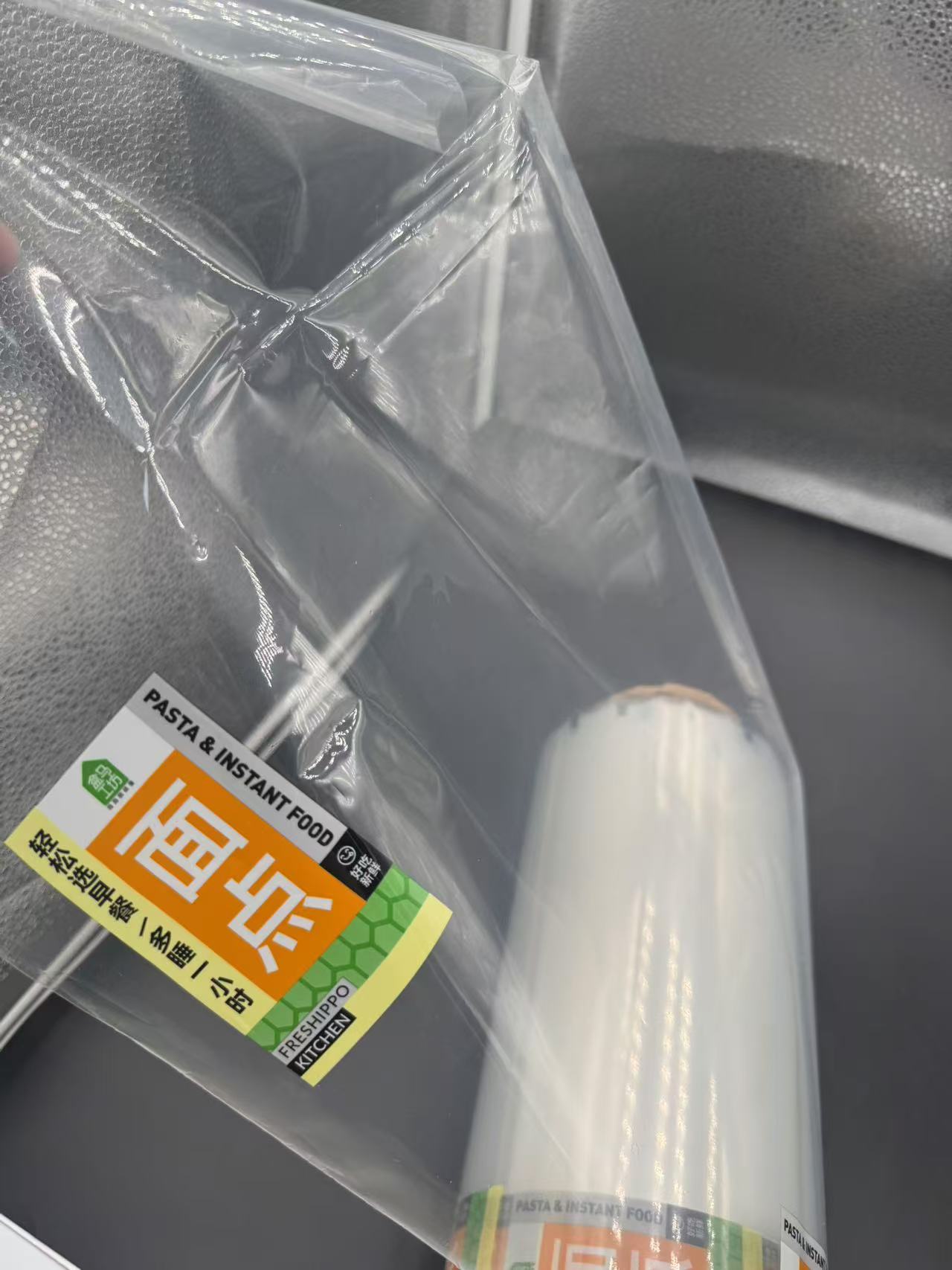

3.1 Food Blister Boxes

PA/PE film is widely used in the production of food blister boxes. The process begins with the thermoforming of the film. It is heated to the extent that it becomes pliable and molded into the shape of the blister cavity by vacuum or pressure-forming techniques. Excellent formability of PA/PE film allows complex and precise shapes according to different food products. Once the food item is placed in the blister, the film is heat-sealed with lidding material, usually a laminated film or foil. The heat seal gives the food protection by a hermetic seal against oxygen, moisture, and contaminants. The barrier properties of the film maintain the freshness and quality of the food, be it a processed snack, a piece of cheese, or a ready-to-eat meal. The transparency of the film allows consumers to easily view the product, which can be an important factor in their purchasing decision.

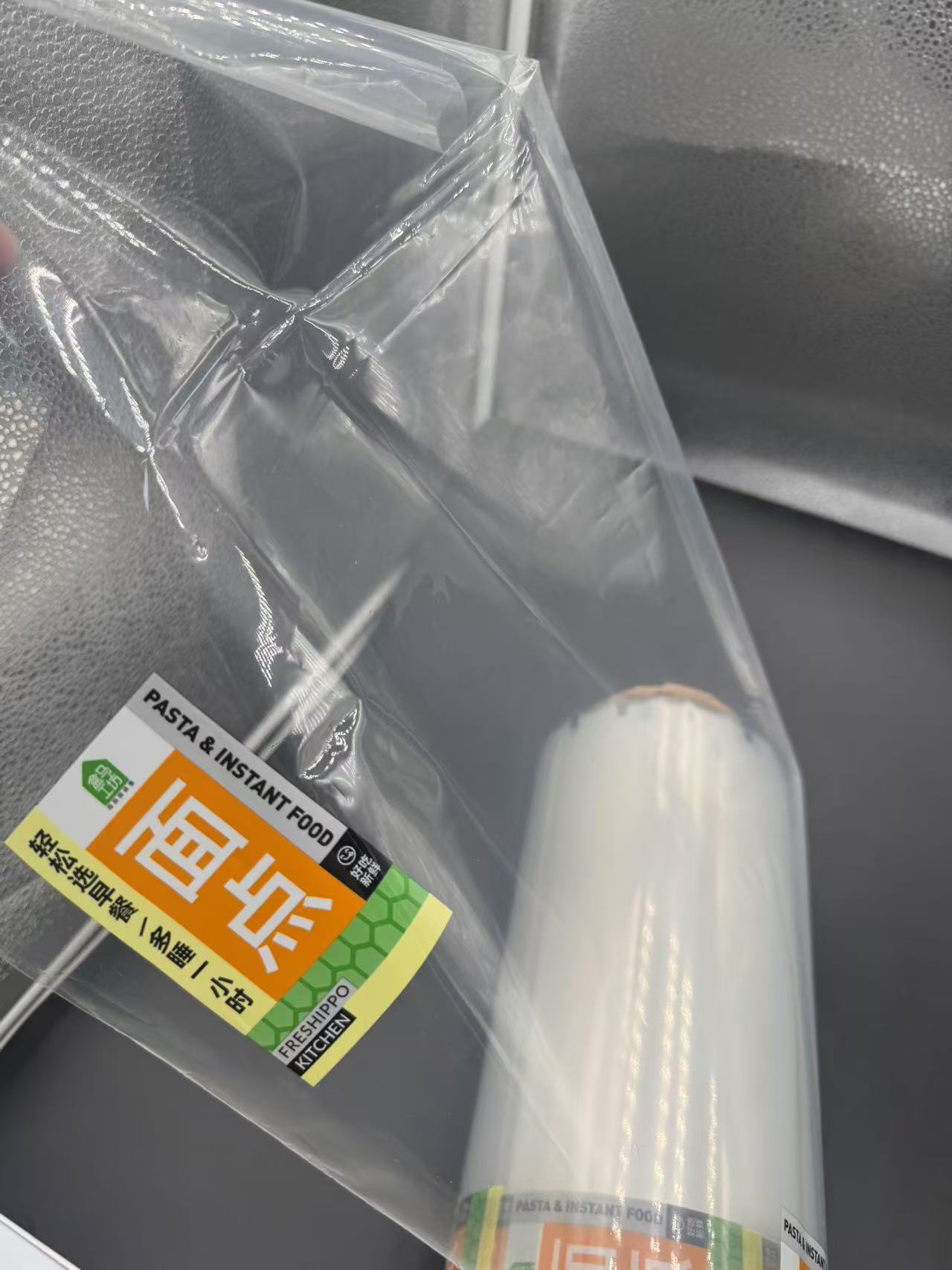

3.2 Fruit Boxes

3.2 Fruit Boxes

The usages of PA/PE film for fruit boxes provide certain advantages. The film's property of acting as a moisture barrier helps the fruits inside the box not to lose their moisture, hence keeping them fresh and retaining their texture. Its gas barrier properties act by moderating the internal atmosphere of the box, hence slowing the rate of ripening, that reduces spoilage. This film is transparent, allowing consumers to view the quality and variety of fruits inside the box. In fact, this transparency in films is especially appealing in the fresh produce market. The mechanical strength of the film allows the box to bear up under handling and transportation without any risks of the film tearing or puncturing and damaging the fruits. Besides, the film can be printed with information like the origin of the fruits, their nutritious value, and handling instructions which is of great importance to the consumers.

3.3 Cutlery Boxes

For the packaging of cutlery, PA/PE film is one of the best solutions. The high mechanical strength of the film prevents the sharp edges from the cutlery items from puncturing through the packing and creating hazards. The heat sealability of the film allows for the creation of a secure and tamper-evident seal, ensuring that the cutlery remains clean and sterile until it is used. The transparency of the film makes it easy for consumers and food service providers to quickly identify the contents of the package. Whether it is a single-use plastic cutlery set or a more durable stainless steel set, PA/PE film can effectively protect and present the cutlery in a hygienic and convenient manner.

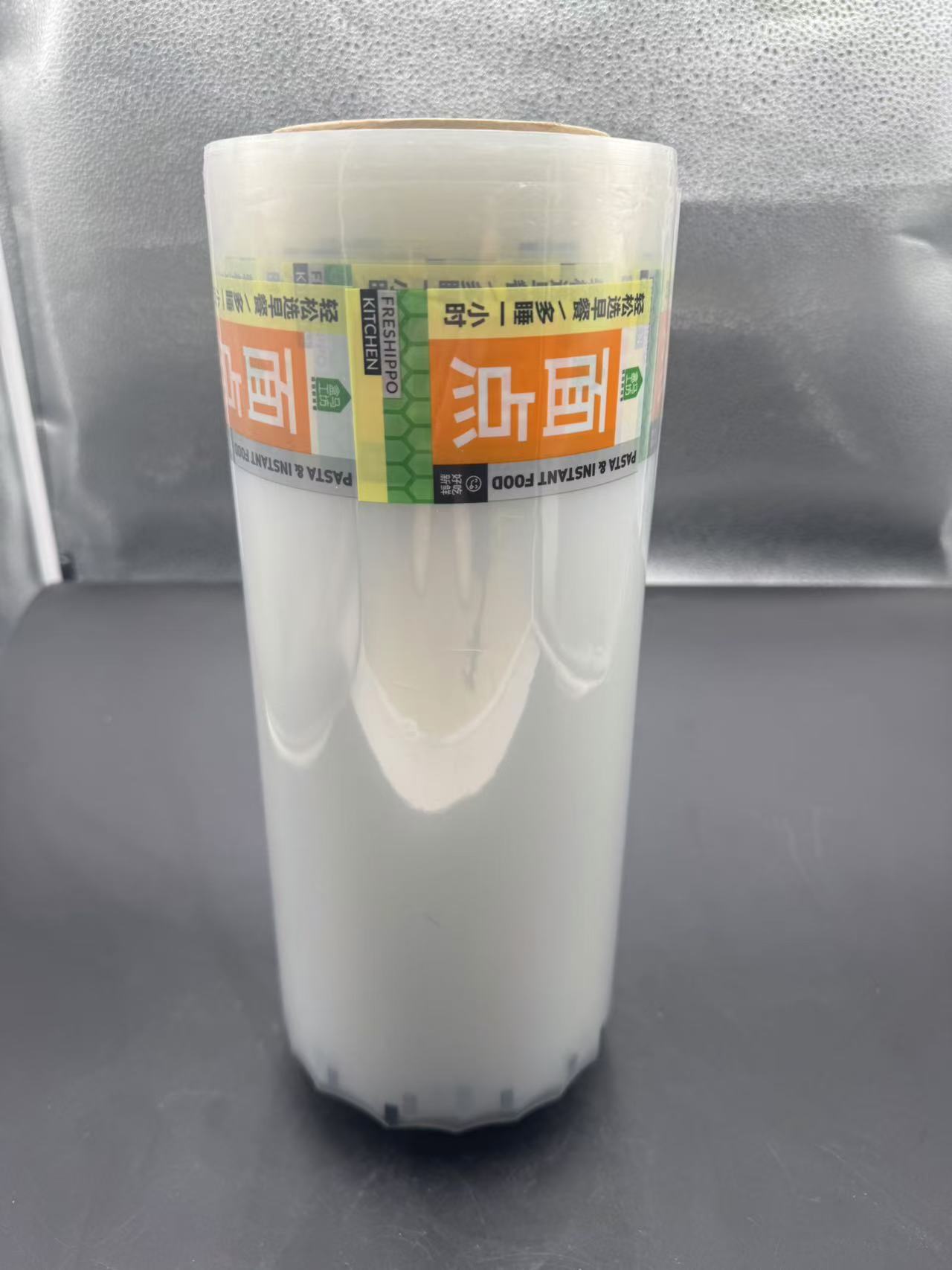

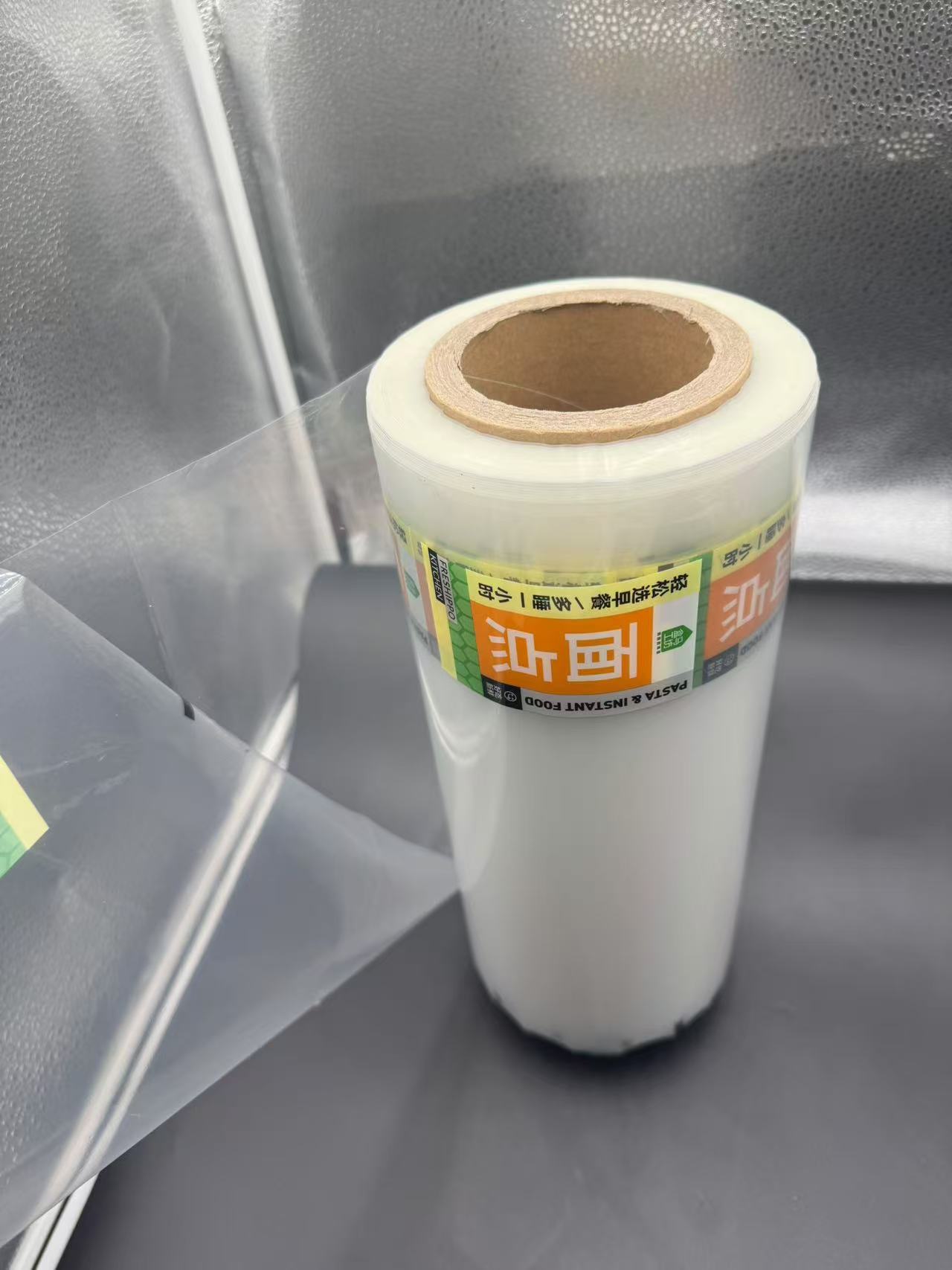

3.4 Beverage Cups

3.4 Beverage Cups

PA/PE film is used in the production of lids for beverage cups. The film is heat-sealed onto the cup rim, forming a tight seal that prevents any leakage of the beverage. The barrier properties of the film help to maintain the carbonation and flavor of carbonated drinks and prevent the absorption of odors from the surrounding environment for other beverages. The transparency of the film allows consumers to see the contents of the cup, which can be an important aspect for certain types of drinks, such as fruit juices or smoothies. The film can also be printed with branding and promotional information, further enhancing the appearance of the beverage cup and contributing to brand recognition.

4. Application in Pharmaceutical Packaging

4. Application in Pharmaceutical Packaging

4.1 Pharmaceutical Seals

In the pharmaceutical industry, PA/PE film is used for sealing various types of pharmaceutical packaging, such as blister packs and bottles. The excellent barrier properties of this film protect the drugs from moisture, oxygen, and those environmental conditions that can contribute to degradation of their quality and potency. Heat sealability secures a reliable, tamper-evident seal crucial for maintaining the integrity of the pharmaceutical product. The chemical resistance of the film makes it compatible with a wide range of drug formulations to ensure there is no interaction between the film and the drugs. For instance, in the packaging of tablets or capsules, the PA/PE film seal helps prevent moisture ingress that may lead to the dissolution or deterioration of drugs before time. This transparency of the film can also be advantageous in order to allow health professionals and patients to identify the contents easily.

5. Manufacturing Processes of PA/PE Film

5. Manufacturing Processes of PA/PE Film

5.1 Coextrusion Process

Manufacturing of PA/PE film involves a coextrusion process normally. In this process, the PA and PE resins are melted separately and then combined in a coextrusion die. The die is designed to form a multilayer structure whereby the PA layer and the PE layer are extruded together in one film. Depending on the specific requirements of the packaging application, different thicknesses and ratios of the PA and PE layers can be produced. The coextrusion process requires precise control of temperature, pressure, and flow rate to ensure the uniformity and quality of the film. The addition of additives, such as antioxidants, slip agents, and antiblocking agents into the resins before extrusion can improve the film's performance or processing characteristics.5.2 ORIENTATION AND ANNEALINGAfter the coextrusion of the film,

it can be subjected to an orientation that enhances the mechanical properties. This can be done in machine direction, transverse direction, or biaxial direction through the stretching operation which aligns the polymer chains, making the film strong with enhanced stiffness. Uniaxial orientation stretches the film in a single direction, while biaxial orientation stretches it in both the machine direction and the transverse direction. Biaxially oriented PA/PE film has better dimensional stability and is more suitable for applications where the film needs to maintain its shape. Following orientation, the film may be annealed to relieve internal stresses and improve its thermal stability. Annealing involves heating the film to a specific temperature and then slowly cooling it under controlled conditions.

5.3 Surface Treatment

5.3 Surface Treatment

To improve the printability and heat sealability of the film, surface treatment may be carried out. One common method is corona treatment, which uses a high-voltage electrical discharge to modify the surface energy of the film. This makes the surface of the film more receptive to inks and adhesives, thus giving improved printing and sealing results. Another method is plasma treatment, which can also enhance the surface properties of the film by creating reactive species on the surface. These surface treatments are of great importance for ensuring the proper adhesion of printed labels and the formation of strong heat seals in the packaging process.

6. Quality Control and Regulatory Compliance

6. Quality Control and Regulatory Compliance

6.1 Quality Control Measures

Quality control in PA/PE film includes the assurance of its use in packaging through strict quality control. These include tests on the film's physical and chemical properties, such as thickness, tensile strength, elongation at break, barrier properties, and chemical resistance. Another critical test is the heat sealability to ensure that the film would provide reliable seals. The transparency and printability of the film are checked to meet the aesthetic and informational requirements of the packaging. Regular inspections are carried out during the manufacturing process to detect any defects or inconsistencies in the film, such as pinholes, thickness variations, or surface irregularities. Samples of the film are also tested under simulated real-world conditions to ensure its performance in different packaging scenarios.

6.2 Regulatory Requirements

6.2 Regulatory Requirements

The use of PA/PE film in food and pharmaceutical packaging is subject to strict regulatory compliance. Regulatory bodies such as the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in Europe have established guidelines and standards for packaging materials. PA/PE film must meet requirements related to safety, toxicity, and drug or food compatibility. It should not migrate harmful substances into the packaged products, and it should maintain its integrity and performance for the lifetime of the product. The manufacturer must provide substantial testing and documentation that their PA/PE film meets these requirements. That includes testing for migration from the film into the food or drugs and stability of the film under various storage conditions.

7. Benefits of PA/PE Film Usage

7.1 Product Protection

The excellent barrier properties, mechanical strength, and heat sealability in PA/PE film provide ultimate protection to the packaged product. In addition, good quality maintenance, freshness, and potency of food or pharmaceuticals are preserved to minimize spoilage, degradation, or contamination during transportation or storage. That is important in assuring product safety, efficacy, consumer expectations, and those of regulating authorities.

7.2 Packaging Efficiency

The heat sealability and formability of PA/PE film allow for efficient packaging. Thermoforming can be done into various shapes and sizes, enabling the formation of packaging containers at a fast rate. Heat sealing reliably results in consistent, leak-free packaging with fewer defects or failures. It leads to a reduction in costs related to production and enhances productivity within the sector of packaging.

7.3 Aesthetic and Marketing Benefits

7.3 Aesthetic and Marketing Benefits

The transparency and printability of PA/PE film offer significant aesthetic and marketing advantages. The clear view of the product inside the package attracts consumers and provides them with valuable visual information. The ability to print high-quality graphics and information on the film helps to create attractive and informative packaging. This can enhance brand recognition, promote product features, and influence consumer purchasing decisions, especially in a competitive market.

7.4 Versatility

7.4 Versatility

The film is pretty versatile and can be used for a wide array of packaging applications. It can be tailored to different product types, shapes, and sizes-from the small pharmaceutical tablet to large food blister boxes and beverage cups. This is just one of the reasons it stands out in so many industries because it can answer diversified packaging requirements with a single solution.

8. Potential Challenges and Solutions

8.1 Cost Considerations

One of the potential drawbacks of using PA/PE film could be the associated cost. Coextruded multilayer films, and the addition of many different additives to these films in their production process, tend to make them more costly than some single-layer films. However, these long-term benefits, in the form of better product protection, extended shelf life, and reduced waste, might balance out the initial cost. Manufacturers can also work to maximize efficiency and minimize material waste in the production process in a way that would decrease overall costs associated with using PA/PE film.

8.2 Recycling and Environmental Impact

8.2 Recycling and Environmental Impact

Like many plastics, PA/PE film poses several difficulties regarding recycling and environmental impact: the multi-layer structure could make it harder to recycle as compared to single-layered plastic. However, research is in progress to develop better technologies and processes for recycling. A few recycling facilities have started separating the different layers of PA/PE film and recycling them. Besides, the development of biodegradable or compostable variants of PA/PE film is also in the realm of consideration, which could potentially reduce its environmental footprint in the future.

9. Future Trends and Developments

9.1 Advancements in Material Technology

PA/PE film might continue to show improvements through ongoing research and development of packaging materials. Improvements could be made concerning its barrier properties, mechanical strength, and biodegradability through the addition of different additives or new formulations. Active research is going on towards nanocomposite PA/PE films with improved properties achieved using nanotechnology. These various ways in which PA/PE films are continuously being made better could extend their scope and performance in packaging further.

9.2 Smart Packaging Applications: The concept of smart packaging is gaining momentum, and PA/PE film could play a role in this trend. Smart packaging features such as sensors that can monitor temperature, humidity, or the integrity of the package could be integrated into PA/PE film. This would provide real-time information about the quality and condition of the packaged products, enabling better supply chain management and ensuring product safety. This can, for example, be implemented in the pharmaceutical industry whereby smart packaging with PA/PE film can serve to indicate whether the drug has been exposed to unfavorable conditions during storage or transportation.

9.3 Sustainable Packaging Solutions

Considering the current trends, much emphasis is directed toward sustainability, and the future of PA/PE film is likely to incorporate sustainable packaging solutions. This may involve the development of completely recyclable or biodegradable PA/PE films, along with better recycling and waste management systems. The manufacturers will also look for alternative raw materials or methods of production that will have a lesser environmental impact on the production of PA/PE film. Besides, packaging design with PA/PE film will be optimized to minimize material use and waste, further contributing to sustainable packaging.

Considering the current trends, much emphasis is directed toward sustainability, and the future of PA/PE film is likely to incorporate sustainable packaging solutions. This may involve the development of completely recyclable or biodegradable PA/PE films, along with better recycling and waste management systems. The manufacturers will also look for alternative raw materials or methods of production that will have a lesser environmental impact on the production of PA/PE film. Besides, packaging design with PA/PE film will be optimized to minimize material use and waste, further contributing to sustainable packaging.

10. Conclusion

PA/PE film has proved to be one of the important web materials in thermosealing packaging, starting from food packaging up to pharmaceutical seals. Due to the excellent barrier properties, mechanical strength, heat sealability, transparency, and printability, it is highly suitable for protecting and presenting various products. The manufacturing processes of PA/PE film have been refined to ensure high quality and consistency. While there are some challenges associated with its use, such as cost and environmental impact, ongoing research and development efforts are expected to address these issues and lead to further improvements. In the future, when the packaging industry continues to evolve, PA/PE film will most probably remain a key player, adapting to new trends and requirements and contributing to efficient, safe, and sustainable packaging of products.