Unveiling the Crystal Shield: Transparent BOPET Film's Role in Modern Packaging InnovationTitle

2025-09-18 17:15Title 1: Unveiling the Crystal Shield: Transparent BOPET Film's Role in Modern Packaging InnovationTitle 2: From Clarity to Protection: The Versatile World of Transparent BOPET Film Applications

Keywords:

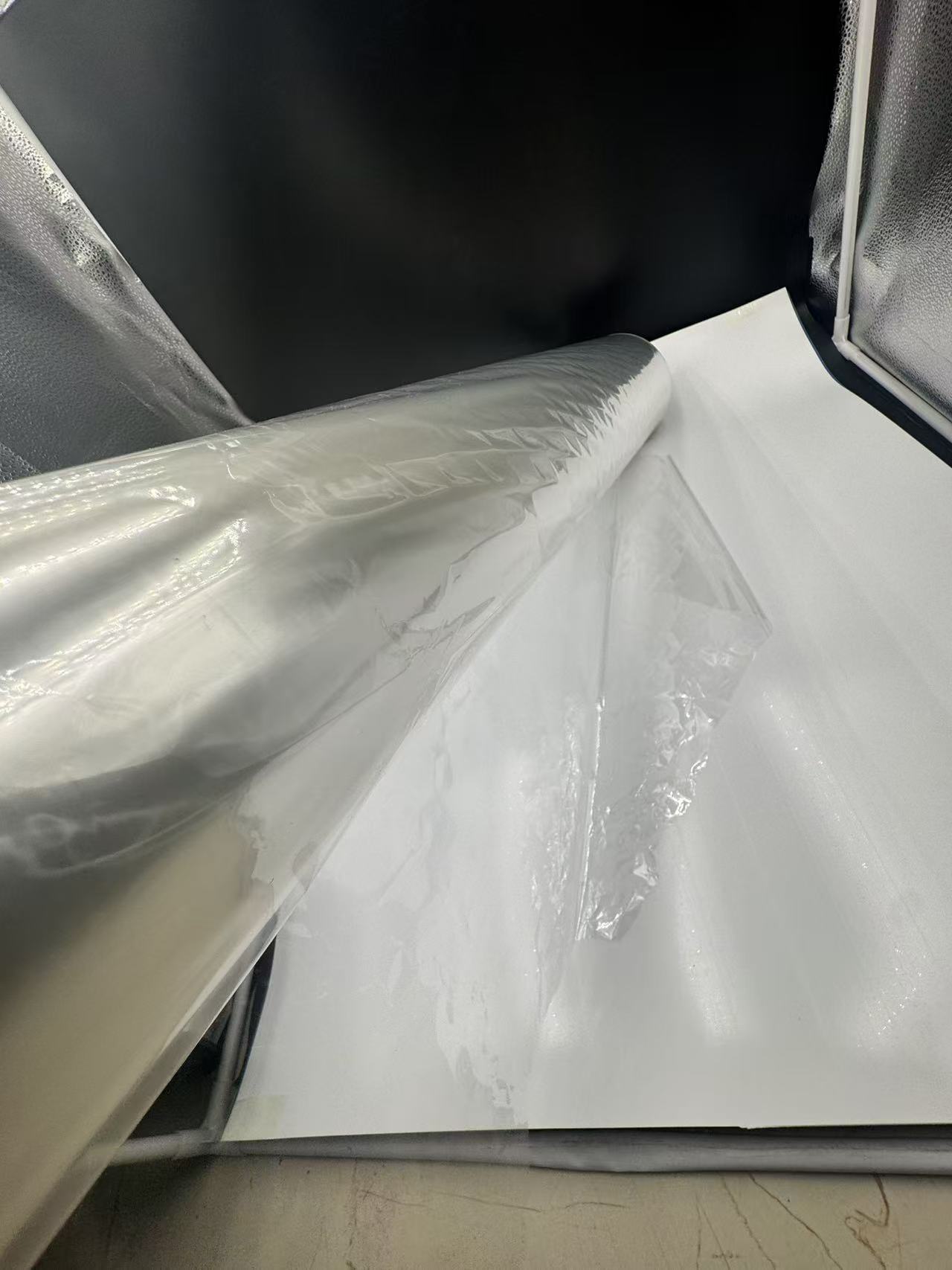

BOPET transparent film, printable packaging film, composite BOPET film, disposable tableware BOPET film, antistatic BOPET filmIn the bustling world of modern packaging, where every layer counts toward preserving freshness, enhancing appeal, and ensuring safety, one material stands out like a silent guardian: transparent BOPET film. Short for biaxially oriented polyethylene terephthalate, this versatile polyester film is engineered through a meticulous process of stretching PET resin in two directions—machine and transverse—creating a crystalline structure that delivers unparalleled performance. Imagine a film so clear it rivals glass,  yet flexible enough to wrap around delicate snacks or robust enough to shield sensitive electronics. This is the essence of transparent BOPET film, a material that has revolutionized industries by blending optical brilliance with mechanical might.At its core, transparent BOPET film's properties make it a powerhouse. Its high tensile strength, often exceeding 200 MPa for a mere 12-micron thickness, ensures it withstands the rigors of high-speed manufacturing lines without tearing or deforming.

yet flexible enough to wrap around delicate snacks or robust enough to shield sensitive electronics. This is the essence of transparent BOPET film, a material that has revolutionized industries by blending optical brilliance with mechanical might.At its core, transparent BOPET film's properties make it a powerhouse. Its high tensile strength, often exceeding 200 MPa for a mere 12-micron thickness, ensures it withstands the rigors of high-speed manufacturing lines without tearing or deforming.

This strength stems from the biaxial orientation, where polymer chains align parallel to the film's plane, boosting durability while maintaining a feather-light weight—typically around 1.4 g/cm³ density.

Chemical stability is another hallmark; it resists oils, greases, and most acids, making it ideal for food contact without leaching harmful substances.

Dimensional stability shines through minimal shrinkage—even at 120°C, it contracts by just 1.25% after 15 minutes—ensuring packages hold their shape from factory floor to consumer shelf.

But it's the film's optical clarity that truly captivates. With light transmission rates up to 90% and haze levels as low as possible, it offers a crystal-clear view of contents, turning packaging into a window of temptation.

Barrier properties further elevate its status: standalone, it blocks moisture with water vapor transmission rates (WVTR) around 0.3 g/m²/day in metallized variants, and oxygen transmission rates (OTR) of about 100 cc/m²/day at 12 microns, extendable through lamination.

Thermal resilience allows it to endure high-heat processes like pasteurization or microwave use without warping, while its electrical insulation and low water absorption (under 0.4%) make it a multitasker across sectors.

Recyclability adds a green edge—fully compatible with PET recycling streams, it supports circular economies by reducing waste and emissions in transport due to its lightweight nature.

These attributes aren't abstract; they're battle-tested in real-world scenarios, from safeguarding gourmet chocolates to protecting circuit boards.Delving into its applications, transparent BOPET film's journey begins in printable packaging, where it transforms mundane wrappers into vibrant marketing tools. Picture a bustling supermarket aisle: shelves lined with snack bags boasting eye-popping graphics of crispy chips or juicy fruits. This visual allure is powered by BOPET film's exceptional printability. Its smooth, corona-treated surface—often one side chemically coated for ink adhesion—ensures vibrant, high-resolution prints using solvent, UV, or water-based inks without smudging or fading.

For instance, in flexible printing for form-fill-seal (FFS) machines, low-haze variants like F-CLR-C1 allow for sharp logos and nutritional info, enhancing brand recall while the film's stiffness prevents wrinkling during high-speed runs.

Consider a real-world example: coffee pouches. Here, transparent BOPET film serves as the outer layer in multi-layer structures, printed with intricate designs that evoke the aroma of freshly ground beans. Its gloss finish—up to high sheen levels—makes colors pop, drawing consumers in, while the underlying barrier properties preserve flavor for months by blocking oxygen and light.

In one case, a European coffee brand switched to printable BOPET laminates, extending shelf life from 6 to 12 months and boosting sales by 20% due to the premium look.

Beyond food, it's used in pharmaceutical blister packs, where precise printing of dosage instructions on the clear film ensures legibility and compliance, all while the material's chemical resistance prevents interactions with medications. This isn't just packaging; it's storytelling on a flexible canvas, where every hue and detail influences purchasing decisions in a crowded market.Shifting gears to composite packaging, transparent BOPET film acts as the sturdy backbone in multi-layer laminates, combining forces with materials like polyethylene (PE), aluminum foil, or nylon to create hybrid shields against environmental foes. In these setups, BOPET's role is pivotal: its dimensional stability anchors the structure, preventing delamination under stress, while its adhesion prowess—enhanced by co-extruded functional layers—bonds seamlessly without primers.

For hot-fill applications, like pasteurizing sauces, the film withstands temperatures up to 100°C, maintaining integrity where lesser materials would bubble or shrink.

Envision a stand-up pouch for ready-to-eat meals: the outer transparent BOPET layer laminated with inner PE for sealability and a metallized middle for aroma lock-in. This composite not only displays the steaming contents enticingly but also extends freshness by slashing OTR to near-zero levels.

In the beverage sector, BOPET-PE composites form flexible bottles or pouches for juices, where the film's puncture resistance—far superior to polypropylene—survives rough handling in transit, reducing spoilage rates by up to 30%.

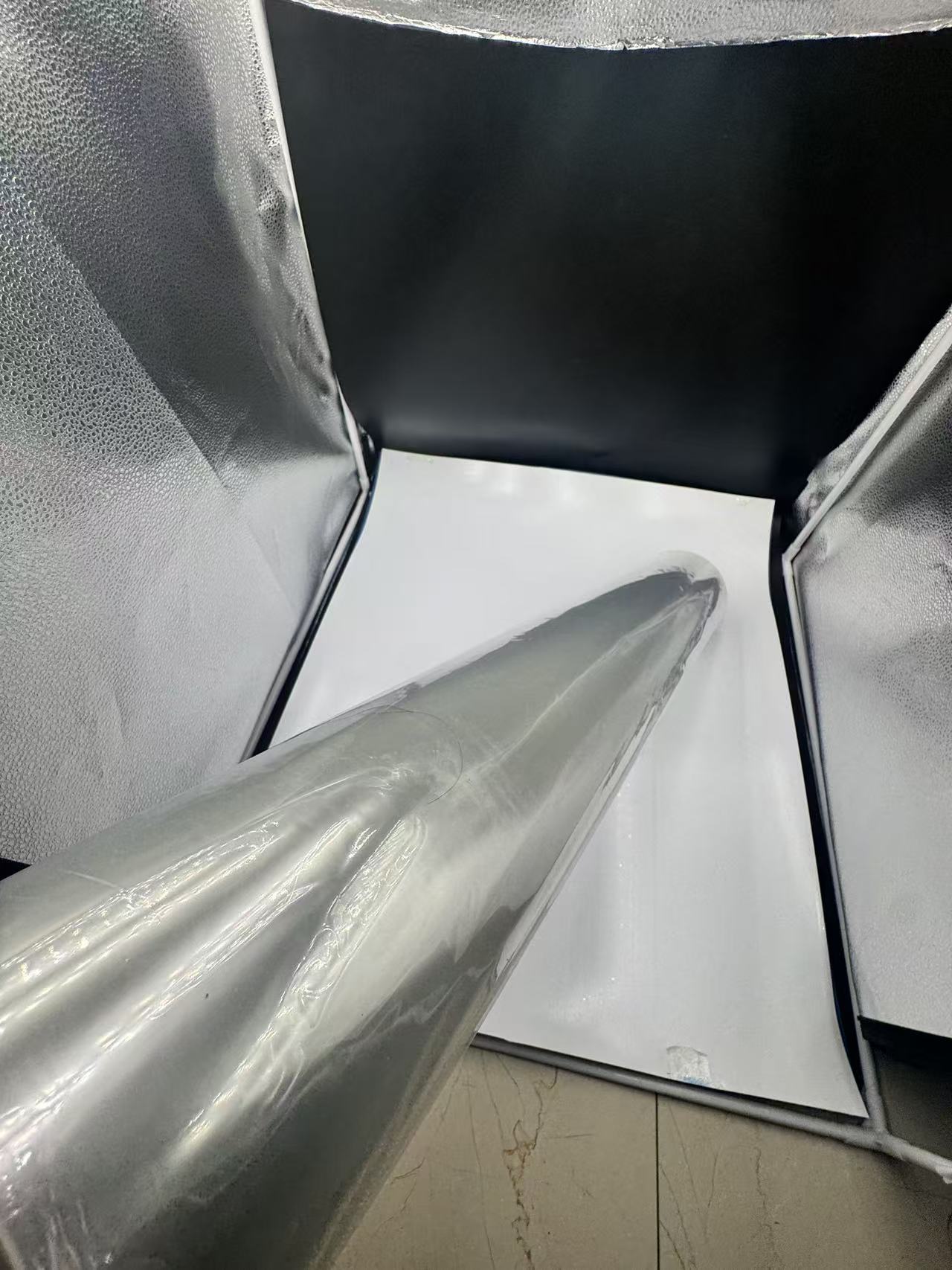

A vivid illustration comes from the snack industry: a major chip producer layered BOPET with EVOH for oxygen scavenging, resulting in bags that keep crisps crunchy for twice as long, all while the transparency teases the golden flakes inside. These composites aren't mere stacks; they're engineered symphonies, where BOPET conducts the harmony of protection, aesthetics, and functionality, slashing food waste and delighting eco-conscious consumers.Now, let's turn to a niche yet crucial arena: disposable tableware packaging. In the fast-paced world of takeout and events, where plastic cutlery and plates must travel safely from factory to fork, transparent BOPET film emerges as the unsung hero. Its thermoformability—enabled by excellent machinability and low haze—allows it to be vacuum-formed into blister packs that snugly encase forks, knives, and napkins, providing a tamper-evident seal without obscuring the contents.

With thicknesses from 19 to 100 microns, it balances rigidity for stacking with flexibility to avoid cracking during molding.

Picture a catering service prepping for a wedding: stacks of clear BOPET blister packs reveal pristine white utensils, printed with event branding for a touch of elegance. The film's heat resistance ensures it survives sterilization processes, while its barrier qualities keep contaminants at bay, maintaining hygiene standards that rival glass but at a fraction of the weight.

In one innovative application, a U.S. chain adopted BOPET for single-serve condiment packets alongside tableware, where the composite with PE lidding prevented leaks during shipping, cutting returns by 15% and enhancing user convenience.

This isn't a gimmick; the coating—often acrylic or co-polyester—maintains clarity while adding dust-repelling properties, crucial in cleanrooms.

Visualize a smartphone assembly line: trays of chips wrapped in antistatic BOPET sleeves, where the film's flatness and endurance prevent triboelectric buildup during sliding or stacking. In one documented case, an Asian electronics firm integrated 50-micron antistatic BOPET in reel-to-reel packaging, slashing ESD incidents by 40% and boosting yield rates.

For medical devices, like pacemakers in transit, the film's chemical inertness pairs with ESD protection to ensure sterility and functionality, often laminated with PE for added cushioning.

Beyond gadgets, it's used in pharmaceutical blister packs for static-prone powders, where transparency allows quick inspections without risking contamination. This application underscores BOPET's adaptability: a film that guards against sparks as deftly as it showcases products, proving its worth in precision-driven worlds.As we peel back the layers of transparent BOPET film's story, its impact is undeniable. From the glossy allure of printable packs that seduce shoppers, to the fortified composites that fortify supply chains, the hygienic blisters cradling our utensils, and the charge-neutral shields for tomorrow's tech—this film weaves through daily life with quiet efficiency. Its properties—strength, clarity, barriers, and now static-slaying prowess—aren't just specs; they're solutions born from innovation, backed by decades of refinement since its 1950s debut.

In an era of sustainability pressures, its recyclability positions it as a forward-thinker, reducing the 40% of plastic waste from packaging.

Yet challenges linger: scaling antistatic coatings for mass markets or enhancing bio-based variants. Still, with the global BOPET market eyeing $9.48 billion by 2028, its trajectory soars.

Transparent BOPET film isn't merely a material; it's a canvas of possibility, a barrier of brilliance, and a partner in progress. Whether whispering temptations through a snack wrapper or silently safeguarding a silicon heart, it embodies the fusion of science and sensibility. As industries evolve, so will this crystal shield—clear, strong, and ever-ready for the next wrap.