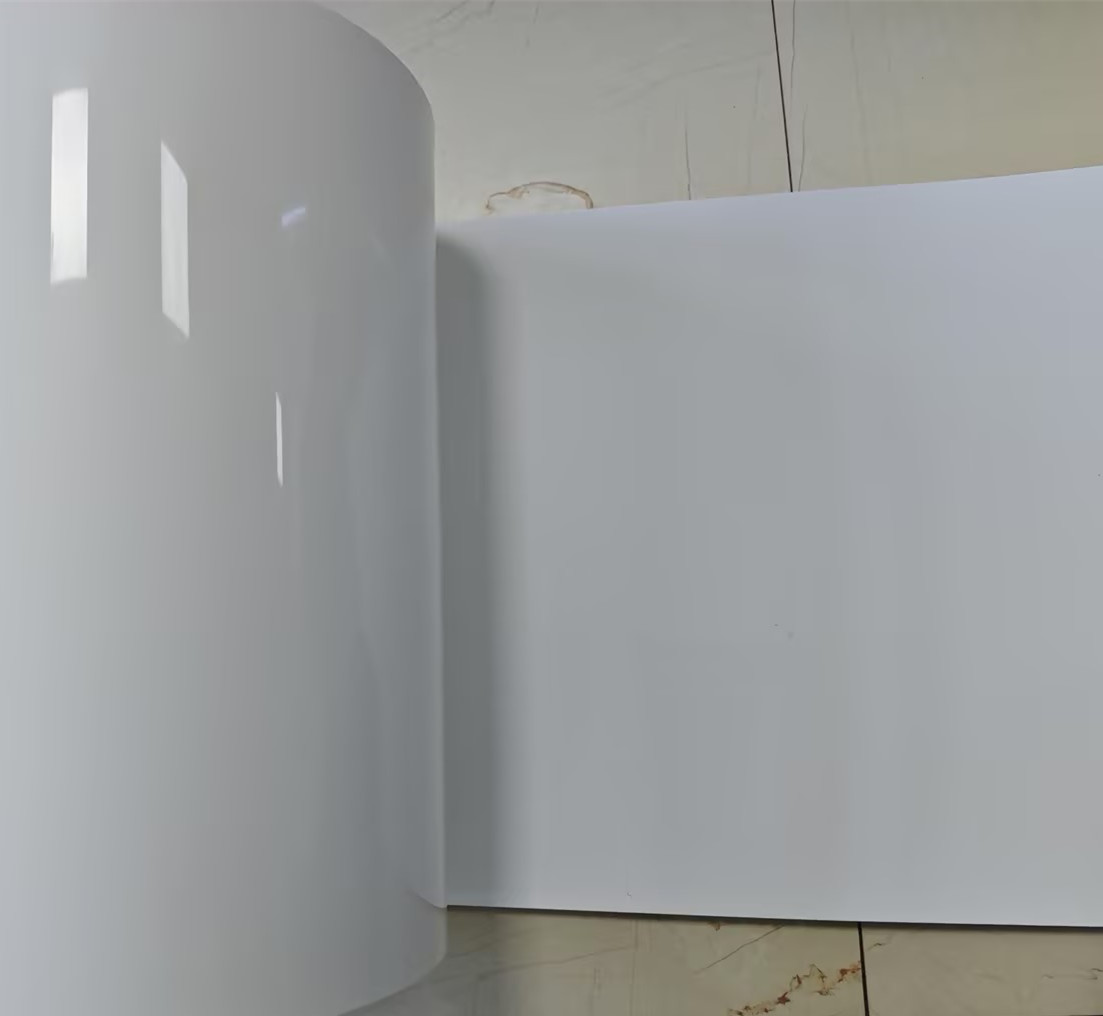

High-performance plastic PP sheet

2025-09-08 16:36Exceptional Thermoformability: PP sheets soften uniformly at moderate temperatures (160–190℃) and maintain stable shape during cooling, enabling easy formation into complex 3D structures—such as deep-drawn containers, trays, or custom-shaped parts. They exhibit minimal shrinkage after thermoforming, ensuring high dimensional accuracy for batch production.

Superior Mechanical Strength: With good impact resistance and tensile strength, thermoformed PP products retain structural integrity even under frequent handling or light load-bearing. Unlike brittle materials, PP sheets resist cracking or deformation, making them ideal for reusable packaging (e.g., food storage containers) or industrial component housings.

Chemical & Temperature Resistance: PP thermoforming sheets are resistant to most acids, alkalis, and organic solvents, as well as a wide temperature range (-20℃ to 120℃). This makes them suitable for packaging acidic/alkaline food (e.g., pickles, sauces) or products requiring sterilization (e.g., medical device trays).

Eco-Friendliness & Cost-Efficiency: As a recyclable material (marked with resin code 5), PP aligns with global sustainability goals. Compared to thermoforming sheets like PET or ABS, PP offers lower raw material costs and faster processing speeds, reducing overall production expenses for large-scale orders.