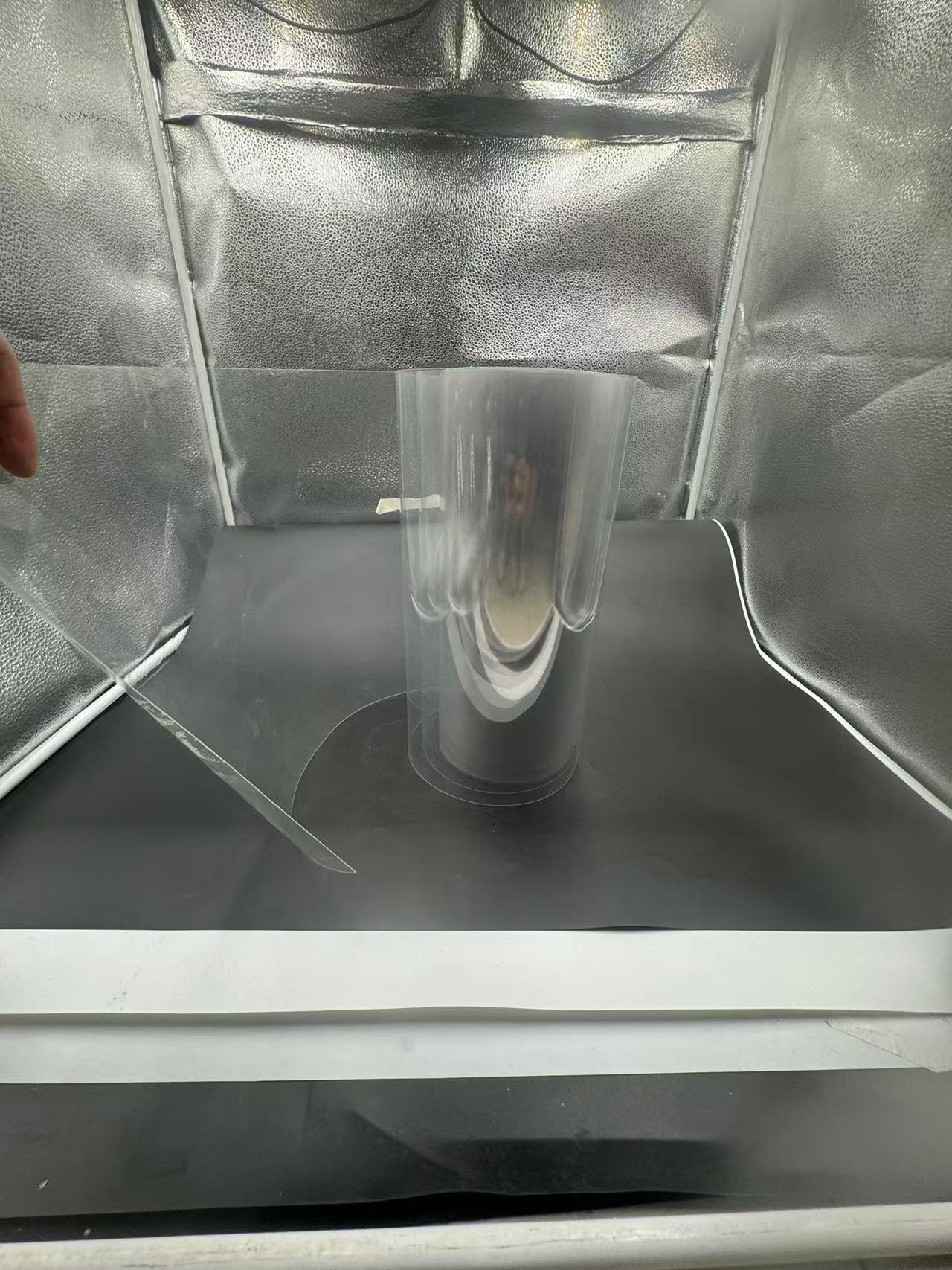

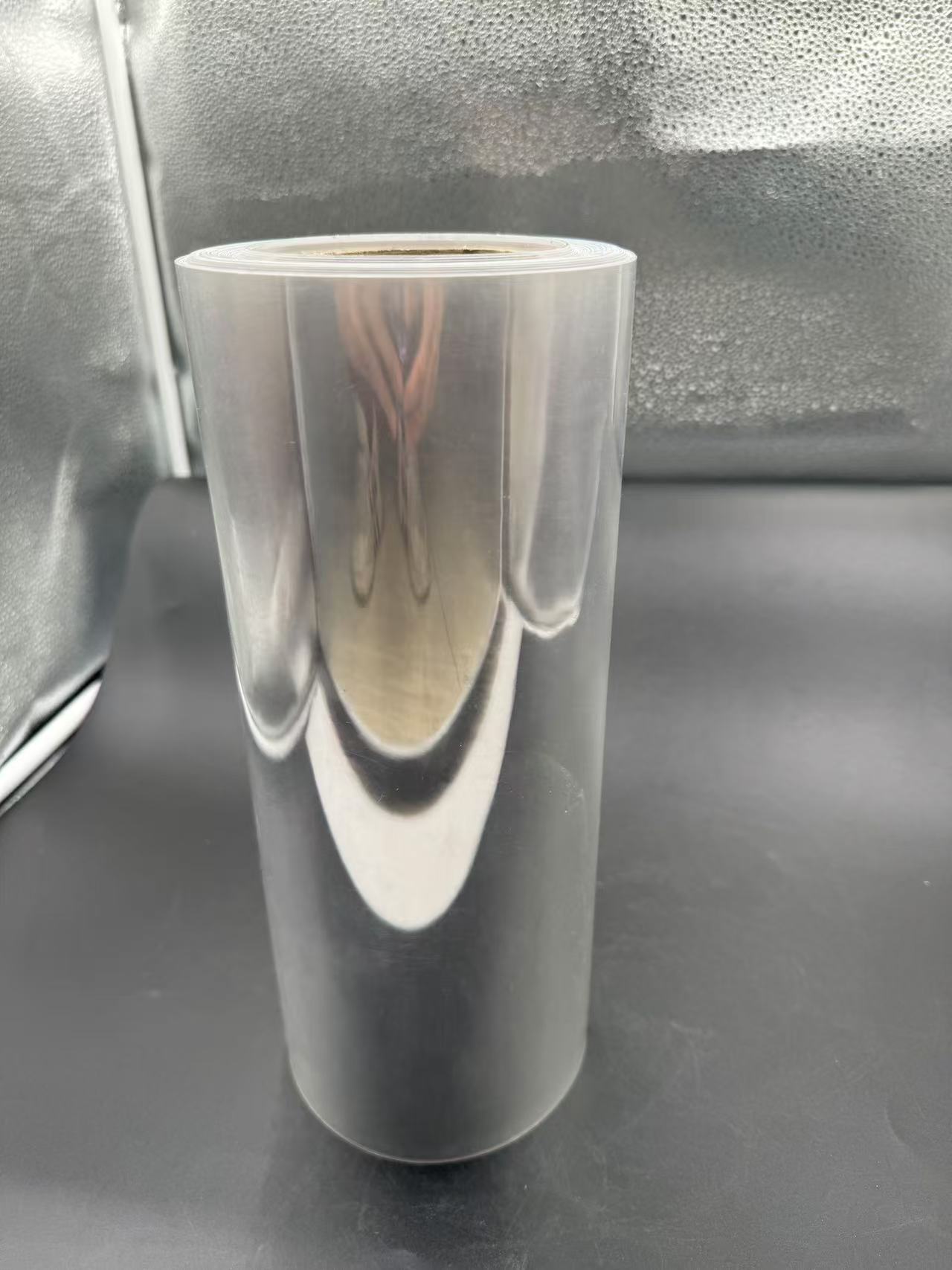

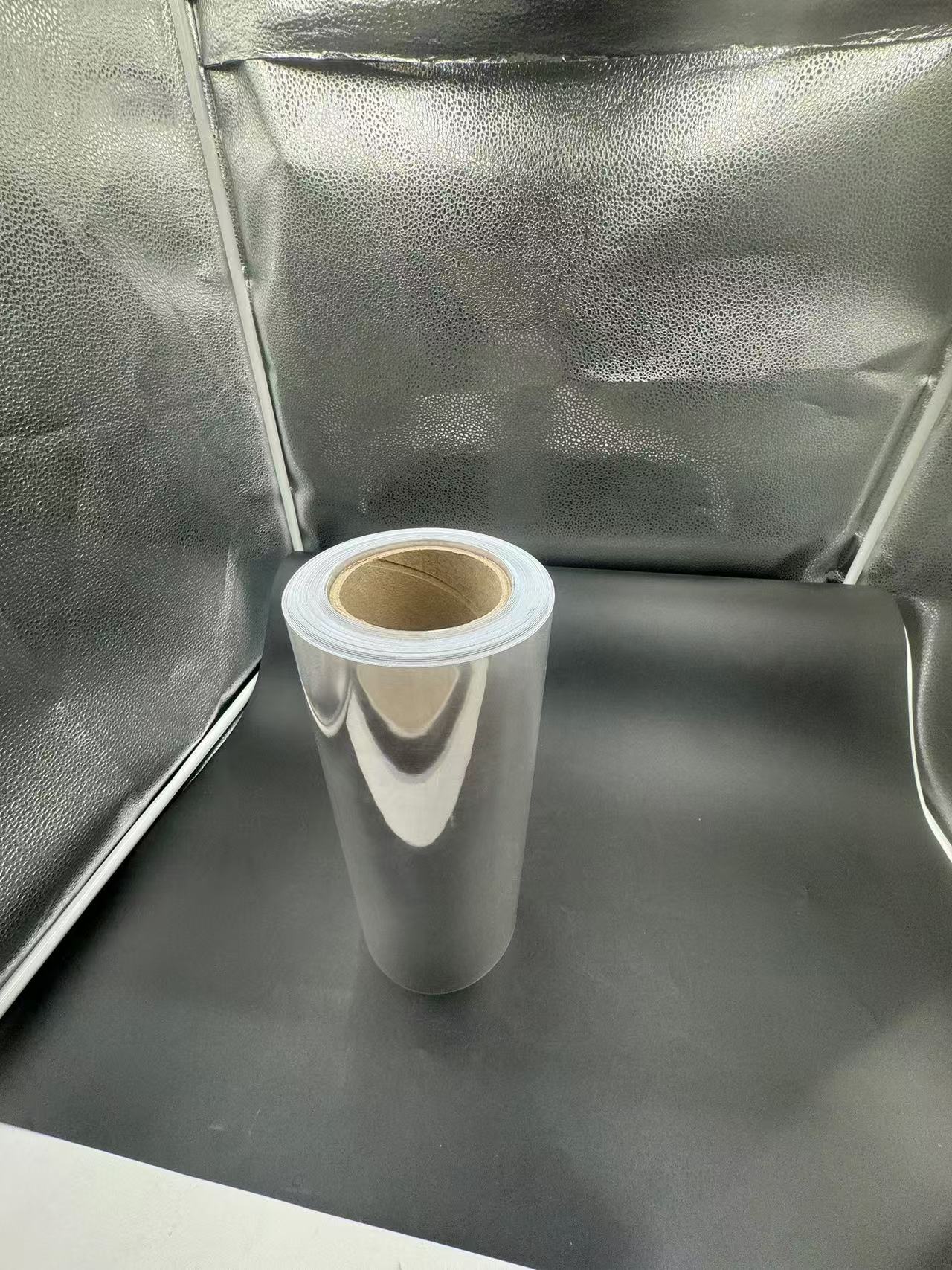

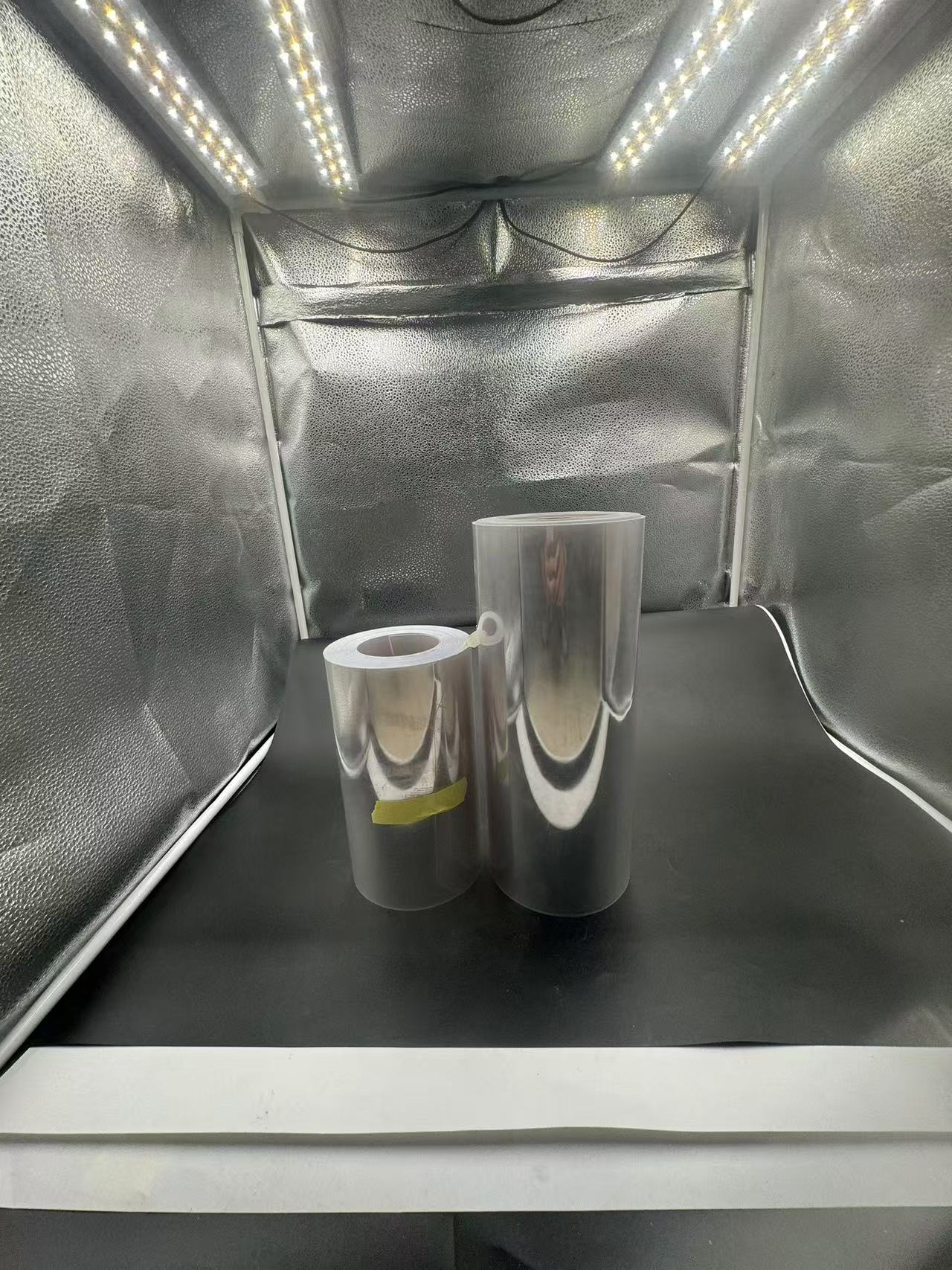

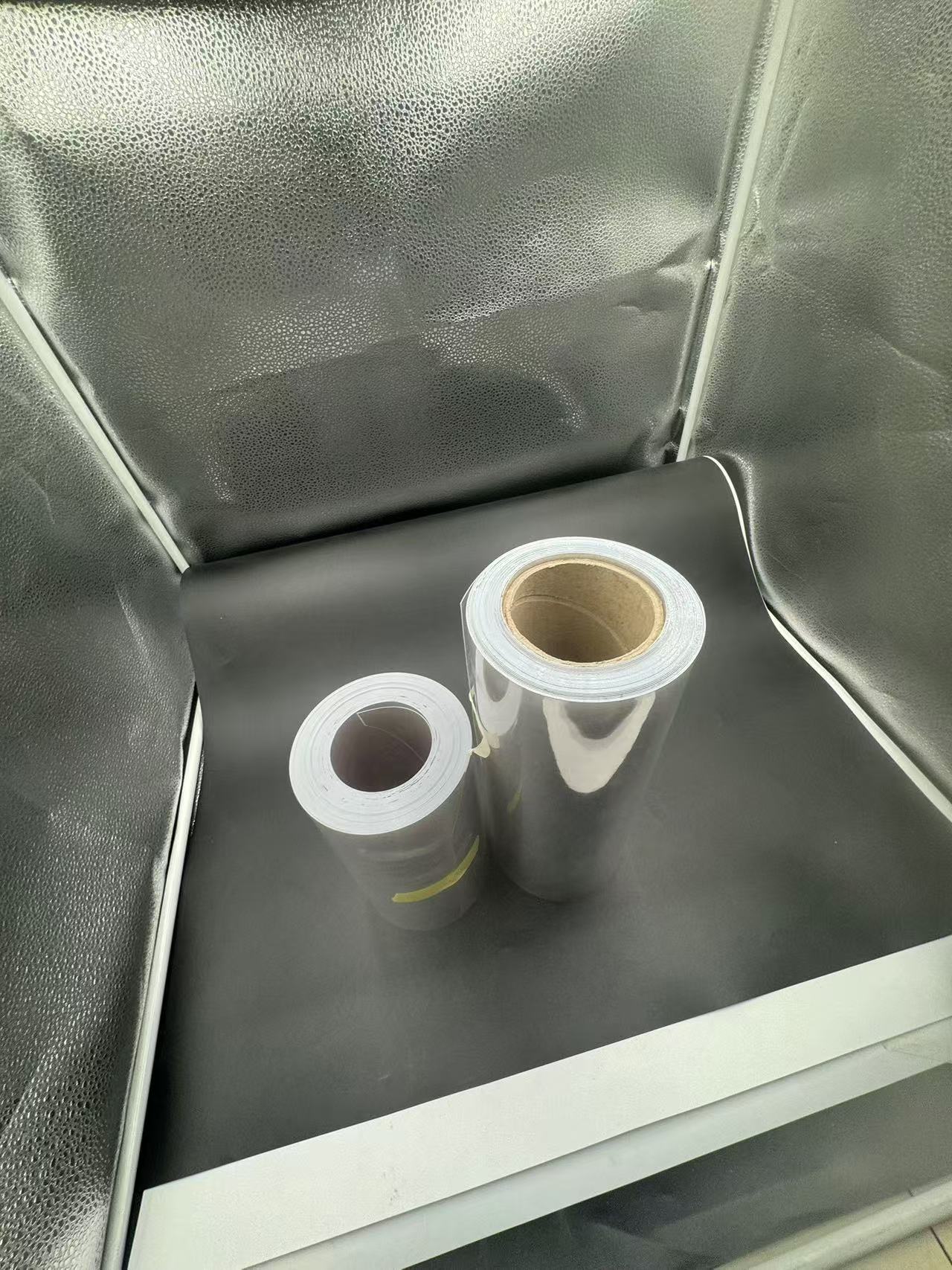

TL-PET-195 BLISTER PET FILM FOR PACKAGING

2024-10-09 16:49Title: The Versatile Use of Multi-Pet Films in Blister Packaging

Introduction

In the world of packaging, innovation is constantly driving the industry forward. One such innovation that has gained significant prominence in recent years is the use of multi-Pet films in blister packaging. These films offer a combination of durability, clarity, and functionality that makes them an ideal choice for a wide range of products. In this extensive article, we will explore the various aspects of multi-Pet films and their extensive use in blister packaging.

The Evolution of Blister Packaging

Blister packaging has come a long way since its inception. Originally used for packaging small items such as pills and buttons, it has now expanded to include a vast array of products, from electronics to cosmetics and everything in between. The evolution of blister packaging can be attributed to several factors, including advancements in materials technology, changing consumer preferences, and the need for more efficient and protective packaging solutions.

Multi-Pet Films: A Game Changer

Multi-Pet films have emerged as a game-changer in the field of blister packaging. These films are made from multiple layers of polyethylene terephthalate (Pet), which gives them unique properties that set them apart from traditional packaging materials. The multiple layers provide enhanced strength, puncture resistance, and barrier properties, ensuring that the packaged product remains safe and secure during transportation and storage.

One of the key advantages of multi-Pet films is their clarity. The transparent nature of these films allows the product to be clearly visible, enhancing its appeal on the store shelf. Consumers can easily see the product inside, which can help in making an informed purchasing decision. Additionally, the clarity of multi-Pet films makes it possible to showcase the product's features and details, adding to its overall marketability.

Durability and Strength

Multi-Pet films are known for their exceptional durability and strength. The multiple layers of Pet provide a high level of resistance to punctures, tears, and abrasions. This makes them ideal for packaging products that are likely to be subjected to rough handling during transportation and storage. Whether it's a delicate electronic component or a heavy-duty tool, multi-Pet films can provide the necessary protection to ensure that the product arrives in perfect condition.

The strength of multi-Pet films also allows for thinner gauges to be used, which can result in significant cost savings. Thinner films require less material, reducing packaging weight and shipping costs. At the same time, they still offer the same level of protection as thicker films, making them a highly efficient packaging solution.

Barrier Properties

Another important aspect of multi-Pet films is their barrier properties. These films can provide a barrier against moisture, oxygen, and other environmental factors that can degrade the quality of the packaged product. For example, in the case of food products, multi-Pet films can help to extend shelf life by preventing spoilage and maintaining freshness. In the case of electronics, the barrier properties can protect sensitive components from moisture and dust, ensuring proper functioning.

Customization Options

Multi-Pet films offer a wide range of customization options, allowing packaging designers to create unique and eye-catching blister packs. The films can be printed with high-quality graphics and logos, enhancing brand visibility and recognition. Different colors and finishes can be applied to create a distinct look and feel. Additionally, the films can be die-cut into various shapes and sizes to fit specific product requirements.

Environmental Considerations

In today's environmentally conscious world, packaging materials need to be sustainable and eco-friendly. Multi-Pet films offer several advantages in this regard. They are recyclable, which means that they can be processed and reused, reducing waste and environmental impact. Additionally, some multi-Pet films are made from recycled materials, further reducing the demand for virgin resources.

Applications of Multi-Pet Films in Blister Packaging

Multi-Pet films find extensive applications in various industries due to their versatility and performance. Let's take a look at some of the common applications:

1. Cosmetics and Personal Care Products

Cosmetics and personal care products often require attractive packaging that showcases the product while providing protection. Multi-Pet films are ideal for packaging items such as lipsticks, mascaras, creams, and lotions. The clarity of the films allows consumers to see the product's color and texture, while the strength and barrier properties ensure that the product remains fresh and protected.

2. Pharmaceuticals

In the pharmaceutical industry, blister packaging is widely used for packaging pills, tablets, and capsules. Multi-Pet films offer excellent barrier properties, protecting the medications from moisture and oxygen. The tamper-evident features of blister packs made with multi-Pet films also provide an added level of security.

3. Electronics

Electronics products such as mobile phones, headphones, and chargers require packaging that provides protection against shocks, vibrations, and moisture. Multi-Pet films with their durability and barrier properties are well-suited for packaging electronics. The clear films allow consumers to see the product inside, while the packaging provides a sleek and modern look.

4. Toys and Games

Toys and games often come in small parts that need to be protected during transportation and storage. Blister packaging made with multi-Pet films can keep the parts organized and prevent damage. The colorful printing options available for multi-Pet films can also make the packaging more appealing to children.

5. Hardware and Tools

Hardware and tools need packaging that can withstand rough handling and provide protection against scratches and damage. Multi-Pet films are strong enough to handle the weight and size of these products, while the clarity of the films allows consumers to see the product's features and quality.

The Future of Multi-Pet Films in Blister Packaging

As the demand for innovative and sustainable packaging solutions continues to grow, multi-Pet films are expected to play an even more significant role in blister packaging. With advancements in materials technology, we can expect to see even more enhanced properties and customization options for these films.

For example, new developments in nanotechnology may lead to the creation of multi-Pet films with improved barrier properties and strength. Smart packaging solutions that incorporate sensors and indicators may also become more common, providing consumers with valuable information about the product's condition and freshness.

In addition, as environmental concerns become more prominent, there will be a greater focus on developing more sustainable multi-Pet films. This may include the use of bio-based materials and increased recycling efforts.

Conclusion

Multi-Pet films have revolutionized the field of blister packaging with their unique combination of clarity, durability, strength, and barrier properties. Their versatility and customization options make them an ideal choice for a wide range of products across various industries. As the packaging industry continues to evolve, multi-Pet films are likely to remain a key player, offering innovative solutions that meet the changing needs of consumers and businesses. Whether it's protecting delicate electronics or showcasing the latest cosmetics, multi-Pet films are sure to make an impact in the world of packaging.