PET (Polyethylene terephthalate) Thermoformed Transparent PET Sheet

2024-10-10 15:52PET (Polyethylene terephthalate) Thermoformed Transparent PET Sheet

Thermoforming is a widely used manufacturing process that uses heat and pressure to shape various materials, including plastics, into the desired form. One popular thermoforming material is transparent PET (Polyethylene terephthalate) sheet.

In the packaging industry, thermoformed PET is a versatile and reliable process that can shape raw materials into excellent packaging solutions. At Wallis, we take pride in providing high-quality PET thermoformed products that exceed industry standards and meet our customers' ever-changing needs. 1. Introduction

1. Introduction

Transparent PET thermoformed sheet has many advantages in various industries due to its excellent transparency, strength, and versatility. We will explore the characteristics, advantages, applications, manufacturing process, and other aspects of high-quality thermoformed transparent PET sheet.

2. What is PET thermoforming?

Hot forming is a manufacturing process that involves heating plastic sheets until they become pliable, then shaping them into the desired form using a mold. The process can be divided into three main types: vacuum forming, pressure forming, and dual-sheet forming. Hot forming is an economical and efficient way to produce high-quality plastic products.

What makes PET different?

Polyethylene terephthalate (PET) is the core material in hot forming, known for its transparency, strength, and recyclability. These characteristics make PET an ideal choice for packaging solutions, which not only showcase the contents but also ensure durability and environmental friendliness.

Revealing the PET Thermoforming Sheet Process

Our advanced thermoforming process involves heating PET sheets until they become pliable, shaping them in a mold, and then cooling to form the desired shape. This method allows us to produce complex designs and custom packaging solutions according to your specifications.

3. How is Transparent PET Thermoforming Sheet Film Manufactured?

The manufacturing process of transparent PET sheet film involves several stages:

Material selection: Choosing high-quality PET resin ensures the desired characteristics, such as transparency, strength, and heat resistance.

Extrusion: The PET resin is melted and extruded into thin sheets. This process ensures the uniformity and consistency of the sheet thickness and quality.

Cooling: The extruded sheet is quickly cooled to solidify and improve its dimensional stability.

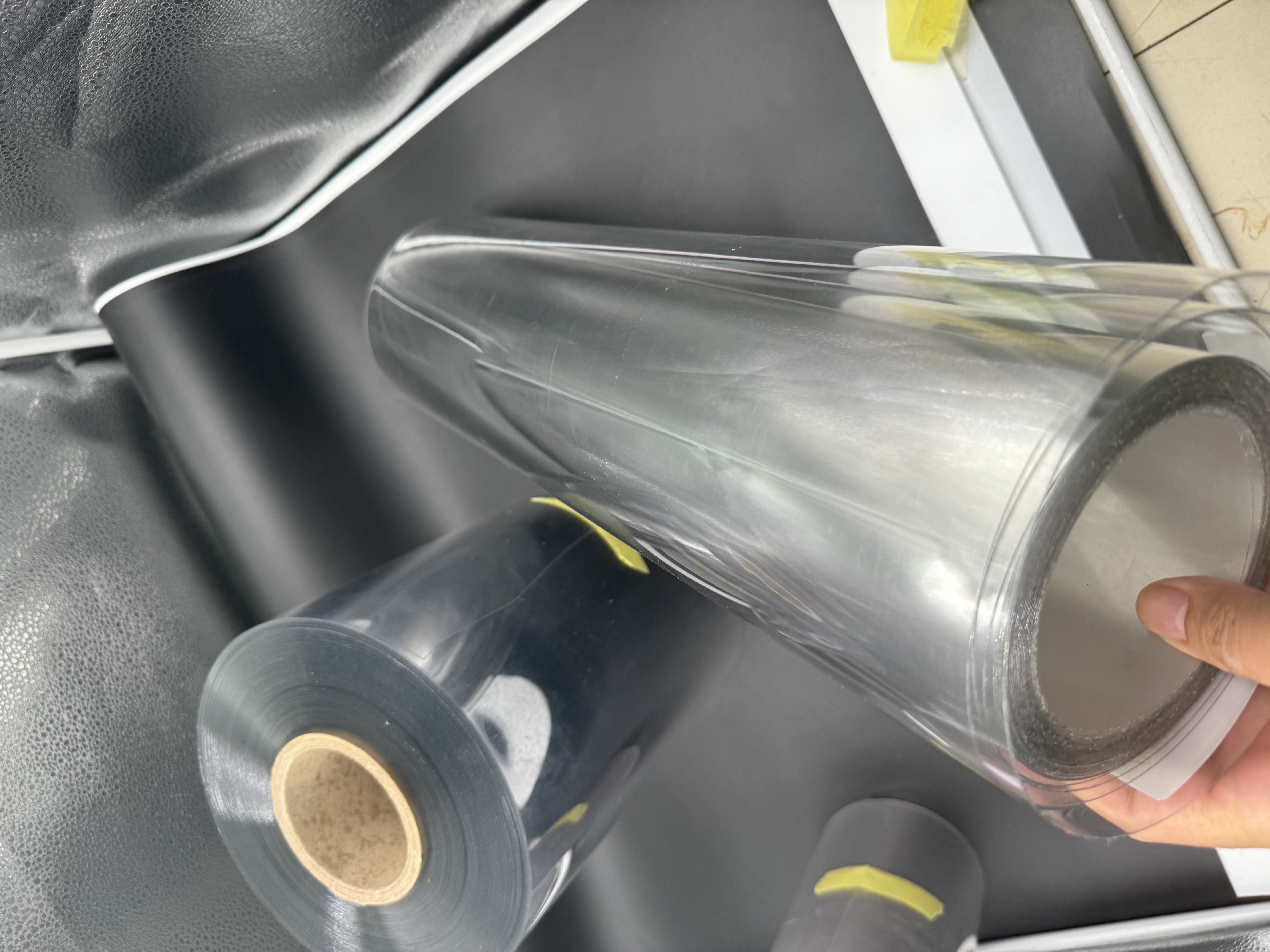

Winding: The cooled sheet is wound into rolls for convenient storage and transportation.

4. Future trends of transparent PET thermoformed sheet film

The transparent PET thermoformed sheet film industry is constantly evolving, and several trends can be expected in the future:

Enhanced sustainability: Manufacturers will focus on developing PET sheet film with higher recyclability and incorporating bio-based materials to reduce its impact on the environment.

Advanced barrier properties: Research and development efforts are aimed at enhancing the barrier properties of PET sheet film, making it suitable for applications requiring higher oxygen, moisture, and UV protection.

Customization and aesthetics: The industry will see advancements in printing technology and surface treatment, allowing for greater customization and visually appealing designs on thermoformed PET sheet film.

Integration of smart technology: Thermoformed PET sheet film may incorporate smart functions such as sensors, RFID tags, or antibacterial properties to meet the constantly changing needs of various industries.