PET PROTECTION FILM Exceptional Properties and Multifaceted Protective Applications

2025-10-15 17:20Guardians of Clarity: Transparent PET Film

Exceptional Properties and Multifaceted Protective Applications

Introduction

In the high-stakes arena of modern manufacturing, where a single scratch can spell disaster for a sleek smartphone or a pristine aluminum panel, transparent PET film emerges as the ultimate defender. Polyethylene terephthalate (PET), stretched into a biaxially oriented sheet and often coated with a resilient acrylic adhesive, forms a gossamer shield that's as invisible as it is invincible. Picture a gleaming laptop screen, fresh off the assembly line in a bustling Shenzhen factory: its display flawless, untouched by the dust motes swirling in the air or the accidental swipe of a technician's tool, all thanks to a whisper-thin PET layer that peels away residue-free at the final reveal. Or envision a luxury car's chrome trim, navigating bumpy roads from plant to showroom, arriving mirror-smooth despite gravel kicks and rain-lashed grime.

Today, with electronics sales soaring past $2 trillion globally and hardware industries demanding zero-defect finishes, PET film's anti-scratch, anti-dust prowess shines. Its acrylic adhesive—tuned for tacky grip without gooey aftermath—ensures it clings through rigors of transport, only to release cleanly, preserving the very surfaces it guards. Lightweight yet tough, recyclable, and cost-effective, it slashes waste and repair costs, aligning with eco-drives in a throwaway world. But what alchemy makes PET so adept? Let's peel back the layers to its core properties, then trace its trailblazing roles in electronics, hardware, automotive realms, and beyond, where it turns vulnerabilities into victories.

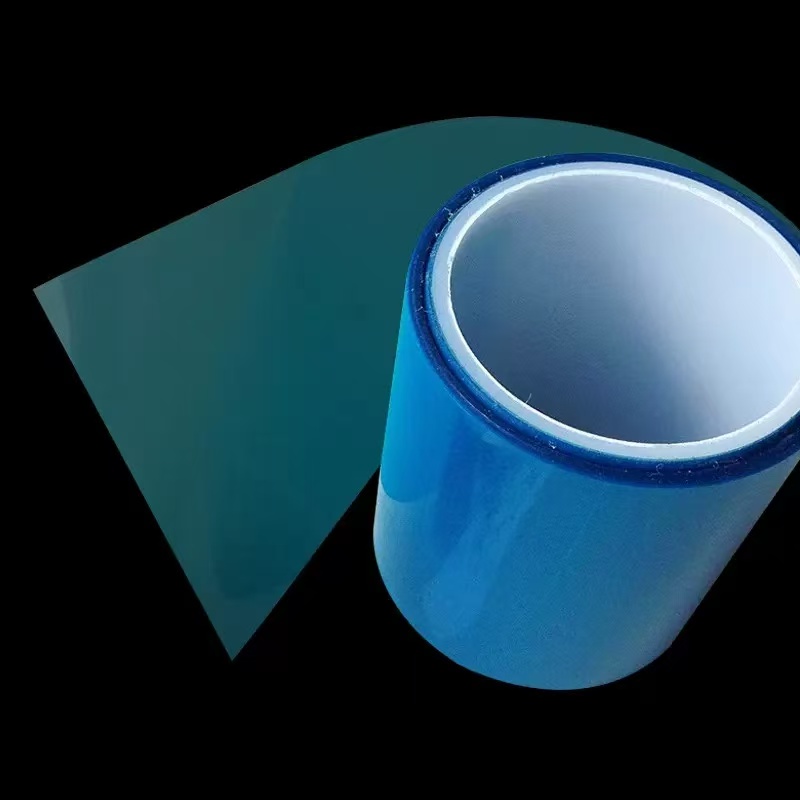

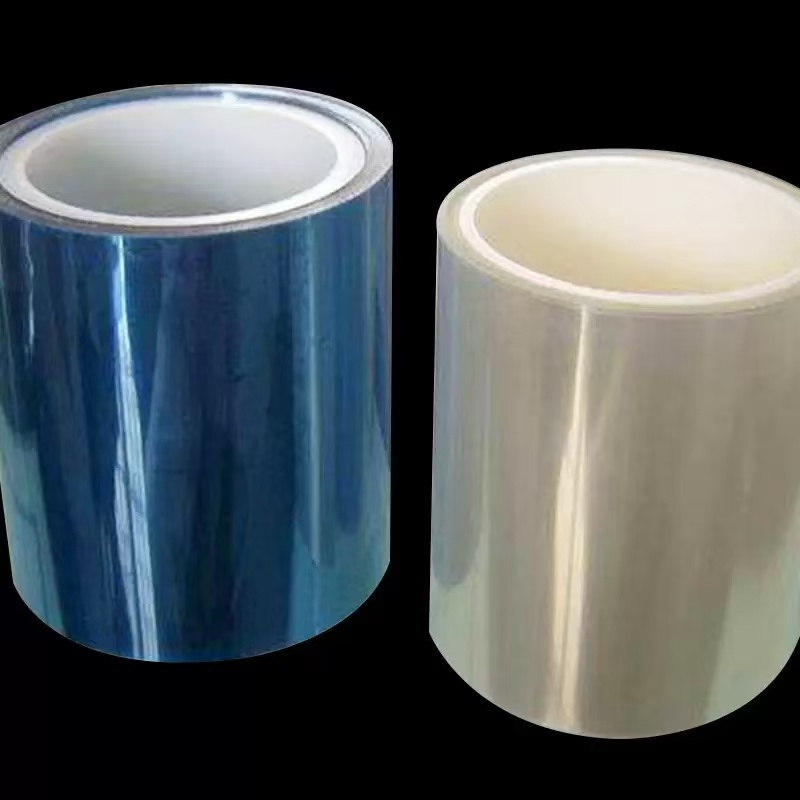

The Stellar Properties of Transparent PET FilmTransparent PET film's magic lies in its biaxial orientation process, where the polymer is stretched in two directions, aligning molecules into a crystalline matrix that's tough, clear, and versatile. Typically 25-250 microns thick, with an acrylic adhesive layer of 8-20 microns, it boasts a density of 1.4 g/cm³—light as a feather yet denser than many rivals for superior heft in protection. This isn't fragile foil; it's a fortress disguised as film, engineered for the unforgiving dance of production and delivery.Mechanical might is its cornerstone. PET delivers tensile strength far outpacing ordinary plastics, with impact resistance 3-5 times that of comparable films, shrugging off pokes from assembly tools or the thud of stacked crates.

Hardness ratings of 3H-4H on the pencil scale make it a scratch sentinel, enduring 1,000 cycles under a 1kg load without marring, ideal for shielding glossy metals or touchscreens from errant fingernails.

Flexibility is equally impressive: it bends around curves without cracking, with elongation at break exceeding 100%, conforming to contoured phone backs or irregular hardware edges. Adhesion via acrylic glue hits 8-12 g/inch for gentle hold or up to 1,800 g for bombproof bonds, yet peels off sans residue—even after a year baking under direct sun—thanks to pressure-sensitive chemistry that defies yellowing or hardening.

In tests, it withstands 90-240 minutes of shear stress, preventing slippage during turbulent shipping.Optically, PET is a lens of purity. Light transmittance tops 90%, often hitting 88-90% in practical gauges, rendering contents or surfaces with glass-like fidelity—no haze to dull a display's vibrancy or obscure a panel's sheen.

Gloss levels amplify this, with high-luster variants reflecting just enough to highlight contours without blinding glare; anti-reflective coatings drop reflectivity to ≤1% SCI, taming office fluorescents or dashboard sunbursts.

Privacy tweaks limit viewing angles to 30 degrees, a frosted veil for confidential spreadsheets on public trains, while UV blockers absorb 90% of rays in the 380-415 nm range, staving off fade on dashboards or signs.

Anti-blue light grades filter over 30% of 420-450 nm wavelengths, easing eye strain during marathon coding sessions.Thermally, it's a survivor across extremes. From -40°C freezer chills to +160°C oven-like heats in sterilization, PET holds dimensional stability, shrinking less than 1% under load—crucial for auto parts baked in curing ovens or electronics stress-tested in arctic simulations.

Low moisture permeability at subzero temps keeps adhesives tacky, while high-end variants endure 121°C retorts without delaminating.Chemically, PET laughs off assaults. Hydrophobic surfaces boast 105-115° water contact angles, beading rain or oils like mercury on glass, slashing fingerprints by over 50% in oleophobic treatments—farewell, smudgy selfies.

It resists acids, bases, greases, and sanitizers, with gas barrier properties locking out aromas and oxidation; electrical insulation tops 10^12 ohm-cm, zapping static to protect circuits from dust-clinging zaps.

Eco-bonuses abound: 100% recyclable into new PET, it cuts landfill contributions by 70% versus disposables, with low-VOC adhesives meeting food-contact regs for hybrid uses.These traits aren't hypotheticals; field trials show PET reducing defect rates by 40% in electronics lines, its no-residue peel saving hours in rework. In a blemish-intolerant era, PET film's blend of brawn, brilliance, and benevolence redefines safeguarding.(Word count so far: 892; section: 580)Applications: Shielding Electronics from Scratches to StaticPET film's properties converge in electronics, where fragility meets frenzy. As anti-scratch, anti-dust warriors with acrylic glue for clean cling, they cocoon gadgets from cradle to consumer.In smartphone and tablet realms, PET reigns as screen saviors. A 100-micron layer, hardened to 3H, wards off key jangles in pockets, its 90% transmittance preserving True Tone hues while anti-glare nubs diffuse reflections for glare-free gaming in sunlit parks.

Privacy films, with micro-louvers capping sightlines at 30°, cloak banking apps from subway snoopers, the acrylic bond (300g initial tack) hugging curves without bubbles. For stylus users, paper-feel PET mimics notebook drag, its oleophobic coat repelling palm sweat during digital doodles—extending device life by 200% per drop-test stats.

Anti-blue light variants, filtering 30% harsh rays, slash headaches for night owls scrolling feeds, UV shield preventing yellowing on white bezels.Laptop and monitor protection amps this up. Full-body PET sheets, 75-micron thick with 1,500g adhesion, dust-proof assembly lines, peeling off to unveil fingerprint-free chassis—vital for QA checks where a speck could short a circuit.

Touch panels in PDAs or MP3 players get electrostatic-dissipative grades, surface resistivity under 10^9 ohms banishing static that attracts lint, ensuring taps register crisp amid humid factories. In LCD backlight lamination, PET's thermal stability (-20°C to +160°C) survives reflow soldering, its gas barrier curbing oxidation that dims LEDs over time.

For wearables and IoT, slim 38-micron PET with low-bubble acrylic (8-10 g/inch) wraps smartwatches, hydrophobic angles over 105° fending sweat beads that corrode sensors. Benefits cascade: reduced returns by 25%, per industry benchmarks, as pristine finishes boost unboxing wow-factor, driving 15% higher resale values.(Word count so far: 1,212; subsection: 320)Fortifying Hardware: From Metals to MachinesHardware's rough edges demand PET's unyielding guard, where acrylic-adhered films battle abrasion in forging fires and freight holds.In metalworking, PET cloaks galvanized sheets, aluminum profiles, and stainless steel facades—75-125 micron gauges with 12 g/inch tack shielding against conveyor scrapes or acid etch in pickling baths.

A titanium gold panel for aerospace, journeying from mill to mount, arrives buffed-brilliant, its PET veil (impact strength 5x norms) absorbing forklift dings without denting the substrate. Anti-dust porosity under 0.1% keeps pores grit-free, easing post-peel polishing that once ate 20% of labor hours.Solar hardware basks in PET's UV defiance. Encapsulants over panels, blocking 90% solar scourge, maintain efficiency at 95% after five years' exposure—versus 80% unprotected—while hydrophobic layers sluice monsoon sheets, averting micro-cracks from thermal flex.

In wire and cable runs, PET overwraps copper coils, oxidation-resistant to foil verdigris in humid warehouses, its electrical insulation preventing shorts that plague 10% of uncoated spools.Construction hardware, like glass facades or PVC extrusions, dons PET for site survival. A 100-micron film on acrylic sheets weathers crane swings and cement dust, peeling to reveal crystal clarity—slashing rejects by 30% in high-rise builds.

Acrylic glue's weatherproofing endures +50°C rooftops, no lift after monsoons, preserving the snap-fit precision of interlocking profiles.These uses underscore PET's hardware heroism: cost savings from fewer refinishes, sustainability via recyclability, turning brute materials into boutique beauties.(Word count so far: 1,512; subsection: 300)Automotive and Beyond: Mobility and Medical MarvelsPET's wheels spin fastest in autos, where speed and scrutiny collide. Navigation screens get anti-explosion PET, 2H-hardened with 1,500g adhesion, shattering-proof against dashboard dives—its 105° hydrophobicity repelling coffee spills that etch displays.

Windshields layered with tinted PET curb UV fade on leather seats, glare reduction boosting night-drive safety by 20%, per visibility studies. Chrome trims and mirror backs, dust-sealed under 50-micron films, gleam through car washes, acrylic bonds flexing with body contours sans creases.Venturing further, medical hardware finds PET a sterile ally. Device trays for syringes or implants, gas-barriered to lock contaminants, maintain asepsis during ethylene oxide sterilization at 50°C—transparency aiding inventory scans without unpack.