Properties and Applications of PEVA Film for food , protection, bags

2025-01-09 16:40Properties and Applications of PEVA Film

I. Composition and Properties of PEVA Film

PEVA film is composed of Polyethylene (PE) and Ethylene-Vinyl Acetate copolymer (EVA).

(I) Properties of Polyethylene (PE)

Polyethylene, with the English name Polyethylene, is the simplest high-molecular organic compound in structure. It is also a widely used polymer material in the world today, polymerized from ethylene. According to different densities, it can be divided into High-Density Polyethylene, Medium-Density Polyethylene, and Low-Density Polyethylene.

Low-Density Polyethylene: It is relatively soft and is usually polymerized under high pressure. It has a smooth feel like wax and is transparent when not dyed. It has extremely low water absorption. For chemical solvents such as toluene and acetic acid, it is only slightly soluble at temperatures above 70°C. Particulate low-density polyethylene can melt or solidify with temperature changes between 15°C - 40°C. It absorbs heat when melting as the temperature rises and releases heat when solidifying as the temperature drops.

High-Density Polyethylene: It has the characteristics of rigidity, hardness, and high mechanical strength, and is mostly polymerized under low pressure. It can be used to make containers, pipelines, and can also be used as a high-frequency electrical insulating material in applications such as radar and television. When not dyed, high-density polyethylene is opaque.

(II) Properties of EVA

Biodegradability: It will not cause harm to the environment when discarded or burned, which gives PEVA film outstanding advantages in the context of increasingly strict environmental requirements.

Price Advantage: The price of EVA is more expensive than toxic PVC, but it is cheaper than PVC without phthalates. This allows PEVA film to achieve a good balance between cost and safety.

Light Weight: The density of EVA ranges from 0.91 to 0.93. Compared with PVC's 1.32, PEVA film has more advantages in weight-sensitive application scenarios.

Odorless: It does not contain organic odors such as ammonia, making it suitable for product packaging and other fields with high requirements for odor.

Compliance with Safety Standards: It does not contain heavy metals and complies with relevant international toy regulations (EN - 71 Part 3 and ASTM - F963); it does not contain phthalates, making it suitable for children's toys and will not pose a risk of plasticizer release.

Superior Performance: It has high transparency, softness, and toughness, with a very wide range of applications; it has super low-temperature resistance (-70°C), suitable for icy environments; it is resistant to water, salts, and other substances and can remain stable in most application scenarios; it has high heat adhesion and can be firmly adhered to nylon, polyester, canvas, and other fabrics; it has a low lamination temperature, which can speed up the production speed.

Printing Adaptability: It can be screen-printed and offset-printed, and can be used for more fancy products (but EVA-based inks must be used), which provides possibilities for diversified product design.

II. Applications of PEVA Film in Various Aspects

(I) Foamed Shoe Materials

In the field of shoe materials, PEVA is widely used. In the EVA resin used in shoe materials, the vinyl acetate content is generally between 15% - 22%. Due to the softness, good elasticity, and chemical corrosion resistance of its blended foamed products, it is widely used in the soles and interior materials of mid-to-high-end tourist shoes, mountaineering shoes, slippers, and sandals. In addition, it is also used in sound insulation boards, gymnastics mats, and sealing materials. Major shoe production bases in China, such as Shunde and Zhongshan in Guangdong, Jinjiang and Quanzhou in Fujian, and Wenzhou in Zhejiang, consume a large amount of PEVA-containing products every year.

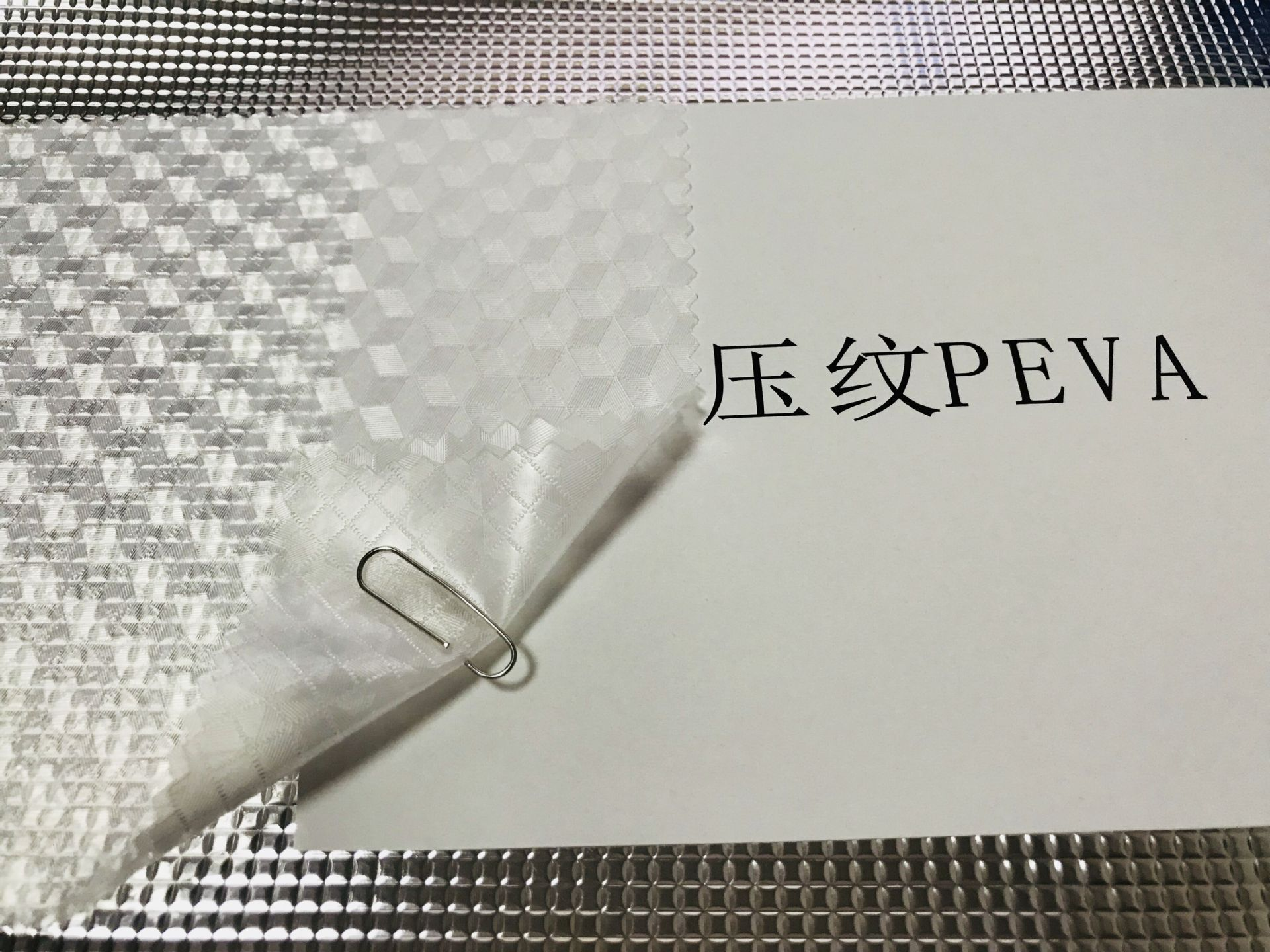

(II) Films

Functional Greenhouse Films: PEVA film can be used to produce functional greenhouse films. Since polyethylene is non-polar, even if a certain amount of anti-fogging agent is added,

its anti-fogging performance can only be maintained for about 2 months. However, the greenhouse film made by adding a certain amount of EVA resin not only has high light transmittance but also significantly improved anti-fogging performance, generally exceeding 4 months.

Other Films: It can also be used to produce packaging films, medical films, laminated films, casting films, etc. In the packaging field, its good flexibility and moisture resistance can effectively protect products; in the medical film aspect, its safety and stability meet medical requirements.

(III) Wire and Cable

With the development of computer and network engineering, considering the safety of computer rooms, the use of halogen-free flame-retardant cables and silane-crosslinked cables is increasing. Due to the good filler compatibility and crosslinkability of EVA resin,

it is widely used in halogen-free flame-retardant cables, semiconductor shielding cables, and two-step silane-crosslinked cables. In addition, it is also used to make the sheaths of some special cables. In the EVA resin used in wire and cable, the vinyl acetate content is generally between 12% - 24%.

(IV) Toys

PEVA is widely used in toys, such as children's bike wheels and seat cushions. In recent years, China's toy processing industry has developed rapidly, with production mainly concentrated in coastal areas, mainly for export and external processing. Some products, such as the Little Mushroom Bean Sound Mat, have raised the development of floor mats to a new level. These manufacturers consume a large amount of PEVA-containing materials every year.

(V) Hot Melt Adhesives

Hot melt adhesives with EVA resin as the main component do not contain solvents, do not pollute the environment, and have high safety, making them very suitable for automated assembly line production. Therefore, they are widely used in book perfect binding, furniture edge sealing, assembly of automobiles and household appliances, shoe-making, carpet coating, and anti-corrosion coating of metals. The hot melt adhesives mainly use varieties with a vinyl acetate content of 25% - 40%.

(VI) Other Fields

PEVA resin is also widely used in fields such as inks, luggage, and wine bottle gaskets. In inks, its properties help improve the performance of inks; in luggage making, it can be used for some parts to enhance the overall quality; in wine bottle gaskets, it can play a good role in sealing and protection.